The Working Principle of Motor Armature in Motor

The working principle of a motor armature is about changing electrical energy into mechanical power. The armature is a key part of the motor. It carries electric current through its windings. This current moves inside a magnetic field. The magnetic field creates a force that turns the motor. This force also makes torque. The way the armature windings are made affects how much torque the motor gives. When the armature makes its own magnetic field, it mixes with the main field. This changes the speed and power. The electric motor needs these actions to work well all the time.

Key Takeaways

The motor armature turns electrical energy into mechanical power. It does this by letting current flow through windings in a magnetic field. This makes torque that spins the motor shaft.

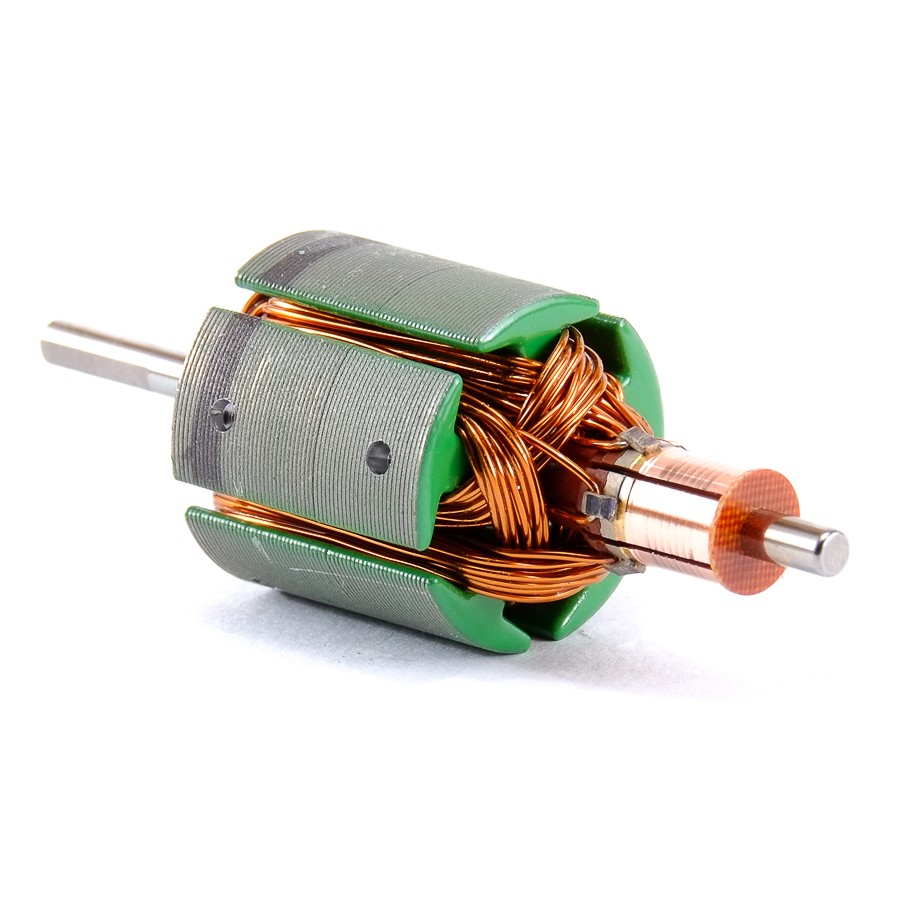

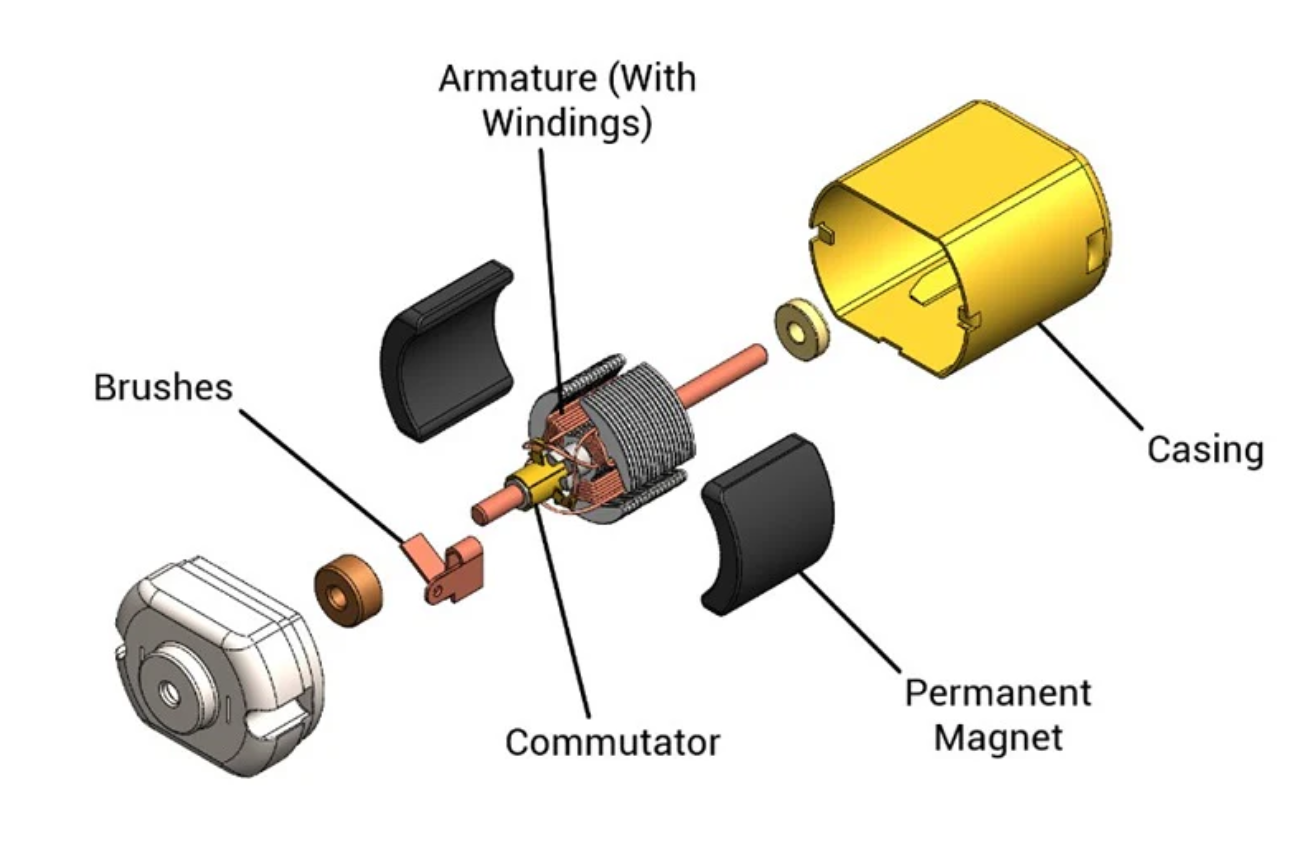

The armature has important parts like the laminated steel core, copper windings, commutator, and shaft. These parts work together to help the motor run smoothly and give good power.

Electromagnetic induction in the armature makes voltage (EMF) and current. These work with the magnetic field to make the force that spins the motor.

Armature reaction happens when the armature’s magnetic field changes the main field. This can lower how well the motor works and cause sparking. Good design and care help stop these problems.

A well-designed armature, good materials, and regular care make the motor work better and last longer. This helps the motor give steady power and not break down.

Motor Armature in Motors

Definition

The motor armature is a main part inside an electric motor. It sits in the middle and holds wire coils called windings. The armature works with the magnetic field to help the motor spin. In a dc motor, the armature connects to a commutator and brushes. These parts help the current move the right way. The armature core is made from thin layers of iron. This helps stop energy loss and keeps the motor working well. Different motors use different armature designs. For example, a dc motor might use lap winding for more current or wave winding for more voltage. The armature is always important for making the motor work.

Function

The motor armature does many important things in a motor. It carries electric current and helps turn electrical energy into movement. The table below lists the main jobs of the armature in motors:

Armature Function | Description |

|---|---|

Carrying Electric Current | The armature moves electric current in a magnetic field. This makes torque and changes electrical energy into power that spins the motor. |

Generating Electromotive Force (EMF) | The armature windings make EMF by electromagnetic induction. This EMF works with the magnetic field to make the motor move. |

Commutator Operation | The commutator changes the direction of current in the armature windings. This keeps the motor spinning smoothly and gives steady torque. |

Mechanical Support and Power Transmission | The armature shaft holds the spinning parts and sends out the power made by the motor. |

Speed and Torque Regulation | The EMF made in the armature pushes against the input current. This helps control the motor’s speed and torque so it runs steady. |

Resistance Adjustment | Changing resistance in the armature circuit helps control how fast and strong the motor is. |

Different motors use the armature in special ways. In a dc motor, the armature windings connect to the commutator and brushes. This setup helps the motor spin without stopping. Lap winding is good for high current, and wave winding is better for high voltage. Some motors use closed slots in the armature core to make them work better. Others use open slots to help cool the motor. Bigger wires in the armature lower resistance and heat, which is good for motors that need a lot of current. The way the motor armature is made changes how much power, speed, and torque the motor can give.

Note: Picking the right armature design helps the motor do its job well. This choice also affects how well the motor works and how long it lasts.

Key Components

Armature Core

The armature core is the main support for the motor armature. It sits in the middle of the motor and holds the armature windings. Laminated silicon steel is used to make the core. This helps stop eddy current losses and keeps the motor cool. The shape and material of the core help it work with the magnetic field. In a dc motor, the slots in the core keep the windings in place. How the core is made changes how much energy the motor can change and how much heat it makes. A strong core helps the motor work better and last longer.

Armature Windings

Armature windings are wire coils wrapped around the core. These windings carry current and make the magnetic field for the motor. Most windings use copper because it is a good conductor. How the windings are set up changes how the motor works. Lap winding is best for high current. Wave winding is better for high voltage. The way armature windings are made affects how well the motor works in many ways:

Copper windings in lap or wave shapes help spread current, lower resistance, and make the motor work better.

The laminated silicon steel core cuts down on eddy current losses, so the motor uses energy better and stays cooler.

Good materials and careful building help the motor make more torque and speed, lose less energy, and last longer in different jobs.

Back EMF from the armature helps control speed and stops too much current, so the motor stays safe and does not get too hot.

Tests like life and fatigue tests check if the windings will last. In a dc motor, the winding design changes how much torque and speed the motor can give.

Commutator and Shaft

The commutator and shaft are very important for the motor armature. The commutator sends current through the windings and switches the direction at the right time to keep torque steady. The shaft holds the spinning parts and sends out the power the motor makes. The table below shows what they do:

Component | Role in Motor Armature Operation | Key Functions and Details |

|---|---|---|

Commutator | Sends current through windings and switches direction to keep torque steady | Made of copper pieces with insulation; works with carbon brushes to keep contact; helps stop sparks and wear |

Helps the motor spin smoothly and keeps torque steady | Needs good design, care, and cleaning to stop problems and damage | |

Shaft | Holds the spinning parts and sends out power | Holds the core and commutator; must be lined up right to stop losses and wear |

Uses good bearings for smooth spinning and less friction | Strong steel makes it tough and long-lasting |

Good commutation needs the commutator and brushes to touch all the time. A smooth commutator helps stop sparks and wear. The right brush shape and pressure, a balanced armature, and good bearings help the motor run well. Cleaning and taking care of the commutator and shaft help them last longer in a dc motor.

Working Principle

Electromagnetic Induction

The motor armature works because of electromagnetic induction. When the armature spins in a magnetic field, the magnetic flux changes. This change makes a voltage, called EMF, in the armature winding. Faraday's Law explains how this happens. The law says that when the magnetic flux in a coil changes, it makes an EMF. If the armature spins faster, the flux changes more, and the EMF gets bigger.

Michael Faraday showed this in his early tests. He wrapped wire around an iron ring. When he changed the magnetic field, a current appeared. Later, he spun a copper disk near a magnet. This made a steady electric current. These tests proved that moving a wire in a magnetic field can make electricity.

The steps of electromagnetic induction in the armature are:

The armature winding moves through the magnetic field.

The movement changes the magnetic flux in the winding.

This change makes an EMF in the winding.

The EMF makes current flow if the circuit is closed.

The EMF always tries to stop the change in flux, as Lenz's Law says.

The current and magnetic field work together to make force and torque.

Concept | Explanation |

|---|---|

Faraday's Law | A changing magnetic flux in a coil makes an EMF. The EMF equals the negative rate of change of flux times the coil turns. |

Magnetic Flux | It is the magnetic field strength times the coil area. |

Lenz's Law | The EMF makes a current that fights the change in flux. |

Lorentz Force | This is the force on moving charges in the wire in the magnetic field. It helps make torque. |

Application in Armature | As the armature coil spins, the changing flux makes EMF and current. These work with the magnetic field to make torque and run the motor. |

Factors Affecting EMF | The number of coil turns, speed, and magnetic field strength decide the EMF size. |

EMF and Current Flow

The armature winding makes EMF as it cuts the magnetic field. This EMF comes from electromagnetic induction. When the armature spins, the wires move across magnetic lines. This movement makes voltage in the winding. The EMF amount depends on speed, magnetic field strength, and the number of wires.

You can find the EMF in the armature winding with this formula:

Eg = (P × φ × N × Z) / (60 × A)

Where:

Eg = Generated EMF

P = Number of poles

φ = Magnetic flux per pole

N = Armature speed in RPM

Z = Total armature wires

A = Number of parallel paths (depends on winding type)

When the armature winding makes EMF, it lets current flow in the circuit. In a dc motor, the commutator and brushes help guide this current. The current works with the magnetic field, which is needed for the motor to run. The current in the armature winding also makes its own magnetic field. This field mixes with the main field and changes how the motor works.

If you spin a small dc motor by hand and connect it to a galvanometer, you see a current. Spinning faster gives a higher reading. This shows the armature can make EMF and current by moving in a magnetic field.

Torque Production

Torque is the force that turns the motor shaft. The armature makes torque when the current in its wires meets the magnetic field. When current flows in the armature wires, the magnetic field pushes on them. This push happens away from the shaft center, making the shaft turn. This turning force is called shaft torque.

The link between current and torque is shown in this table:

Concept | Expression | Description |

|---|---|---|

Torque (T_m) | T_m = k_b * I_a - T_f | Torque is armature current minus friction torque |

Mechanical Power (P_m) | P_m = ω * T_m | Power is angular speed times torque |

Back EMF (U_b) | U_b = k_e * ω | Back EMF is angular speed times a constant |

Many things change how much torque the armature makes:

The winding type, like lap or wave, changes how the flux spreads and the torque amount.

Armature reaction, which is the armature's own field, can change the main field's strength and shape.

Changing the armature current, like by changing resistance, changes torque and speed.

Losses like copper loss and eddy current loss lower the power and torque.

New studies show that more armature current makes a stronger armature field. This can cause magnetic saturation in the core. It makes the force between the stator and rotor stronger. The motor then makes more torque and can give more power to the load.

Making shaft torque in a dc motor comes from electromagnetic induction, EMF, and current in the armature winding. The armature's design and use make sure electrical energy turns into mechanical power. This makes the motor important in many electric machines.

Armature Reaction

Effect on Magnetic Field

Armature reaction happens when the armature current makes its own magnetic field. This new field mixes with the main magnetic field from the stator. The mix changes how strong and where the main field is. The table below explains what armature reaction does to the magnetic field in a motor:

Aspect | Explanation |

|---|---|

Definition | Armature reaction is when the armature magnetomotive force (m.m.f.) changes the main magnetic field in electric motors, especially DC motors. |

Cause | The armature current’s magnetic field bends the main magnetic field in the air gap. |

Effect on Neutral Plane | It moves the neutral plane, so brushes may not touch coils with zero e.m.f., which can cause sparking. |

Flux Distribution | It makes the flux stronger under one pole tip and weaker under the other, which can cause magnetic saturation at the front pole tip. |

Impact on Main Flux | It usually makes the main flux weaker because of magnetic saturation and the way the motor is built, so the total flux goes down. |

Consequences | This can cause voltage to drop, sparking at the brushes, changes in speed and how the motor works, and less e.m.f. when the motor is working hard. |

Compensation | Big motors might use special windings to fight armature reaction by making an opposite m.m.f. |

Armature m.m.f. Orientation | The armature m.m.f. goes along the brush axis, which is sideways to the main flux axis along the stator poles. |

Magnetic Saturation Role | If there was no saturation, the armature reaction flux would not lower the main flux; but with saturation, the main flux gets weaker. |

Operational Impact | When the load goes up, the armature current goes up too, which makes the armature m.m.f. stronger, bends the main field more, and changes how the motor works. |

When the armature current gets bigger, the main magnetic field gets bent even more. This can move the neutral plane, which is where the brushes should be for best work. If the neutral plane moves, the brushes might spark and wear out faster. The main magnetic field can also get weaker, so the total flux in the motor drops.

Impact on Performance

Armature reaction changes how a motor works in many ways. The extra magnetic field from the armature current can make the motor less efficient and less steady. Some main effects are:

Armature reaction bends the main magnetic field and lowers the total flux, which makes the motor less efficient.

The bent field makes the motor less efficient and gives uneven torque.

The neutral plane moves, which makes commutation harder and causes sparking at the brushes, which can hurt the commutator and make the motor less steady.

Weaker flux means less total magnetic flux, so the motor gives less torque and is less efficient.

If not controlled, these things make the motor less efficient, give uneven torque, and make it work less smoothly.

When the total magnetic flux goes down, the motor may not make as much power as you want. If the neutral plane moves, the brushes can spark, which can hurt the commutator and make the motor not last as long. In big motors, engineers sometimes add special windings or interpoles to help balance the magnetic fields and keep the motor running well. Controlling armature reaction is important to keep the motor working well and lasting longer.

Note: Armature reaction can lower voltage, give less torque, and wear out brushes faster. Good design and regular care help stop these problems and keep the motor working well.

Motor Performance

Efficiency

A motor’s efficiency shows how well it changes electrical energy into movement. The armature design is very important for this. Using soft magnetic materials with high saturation flux density and good conductivity helps the armature make more force. Radially laminated sheets in the armature core help stop eddy currents and unwanted forces. This design lets more input current turn into useful power. Solid armatures with slits can lower eddy currents a bit, but they lose some magnetized volume, so the magnetic force drops. Picking good materials and the right structure helps the motor work better.

A good armature design also keeps the motor cool and saves energy. Laminated silicon steel sheets in the core, covered with varnish, help cut down on heat. Copper windings in lap or wave shapes spread the current out. This setup lowers resistance losses and makes the motor more efficient. Doing regular maintenance, like rewinding the armature, can make the motor work up to 5% better. These steps help the motor give steady power and use less energy.

Reliability

Reliability means the motor can run for a long time without breaking. How the armature is built affects this a lot. Manufacturers use laminated steel sheets and copper windings to handle heat and stress. The commutator must stay smooth and round to stop sparking and wear. Good materials help the armature last through tough jobs and keep the motor running.

Laminated cores help lower heat and keep efficiency high.

Copper windings lower resistance and handle big currents.

A strong commutator stops damage and helps the motor last longer.

Hard tests, like life and fatigue testing, check if the armature can last under stress.

Early fault tools, like insulation testers and thermal cameras, find problems before they cause failures.

When picking a motor, people should think about how long it will last, how much torque and speed it gives, and what kind of armature it has. Good care, like cleaning, checking brushes, and oiling bearings, keeps the motor reliable. Regular checks and quick fixes help stop breakdowns and keep the motor working well.

The armature is very important for turning electricity into movement in a motor. When people know how the armature works and how its parts connect, they can make motors work better and last longer. Using thicker wires and better materials helps stop energy loss and gives more power. Taking care of the motor, like cleaning the brushes and keeping it cool, helps it work well. New machines for winding and smart designs make motors stronger and help them last a long time. Doing these things helps everyone get the best use from their motor.

FAQ

What is the main job of a motor armature?

The armature’s main job is to change electrical energy into movement. It does this by letting current flow through its windings. The current meets the magnetic field and makes torque. This torque turns the motor shaft.

What happens if the armature windings get damaged?

If the windings are damaged, the motor can lose power or stop. The motor might get too hot or make odd sounds. Fixing or changing the windings can solve these issues.

What materials do manufacturers use for armature cores?

Manufacturers use laminated silicon steel for the armature core. This steel helps stop energy loss from eddy currents. It also keeps the motor cool and helps it work better.

What is armature reaction in a motor?

Armature reaction happens when the armature’s field mixes with the main field. This can change how strong or which way the main field goes. It might cause sparks or make the motor work less well.

What should people check during armature maintenance?

People should look for worn brushes, loose windings, and dirt on the commutator. They should also check for signs of too much heat. Cleaning and checking the motor often helps it work well.

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry