Why Use a Gearbox with a Motor for Maximum Efficiency

Pairing a motor with gear, such as a gearbox, with an electric motor helps it work better. It makes torque, speed, and energy use more efficient. You get more power from your motor with gear when you use a gearbox. The gearbox provides the right torque for your needs. For example, a motor with gear allows you to choose a smaller motor that can still perform well. The table below shows how a permanent magnet synchronous motor with a gearbox saves energy. It uses 40% less energy than an asynchronous motor. You get real benefits from using a motor with gear, including better efficiency and steady performance.

Motor Type | Energy Consumption (kW/hr) | Efficiency (%) | Energy Savings Compared to ASM |

|---|---|---|---|

Asynchronous Motor (ASM) | 0.26 | 61.5 | N/A |

Permanent Magnet Synchronous Motor (PMSM) | 0.16 | 87.7 | 40% reduction |

Key Takeaways

A gearbox with a motor gives more torque. It helps control speed better. Machines work well and lift heavy things.

Pick the best gear ratio and gearbox type. This matches your motor to the job. It saves energy and makes things work better.

Gearboxes that work well use less energy. They lower costs and keep your motor safe. They stop damage and overload.

Take care of your gearbox often. Check the oil and alignment. This keeps your system working and helps it last longer.

Electric motor gear drive systems work in many places. They fit lots of jobs. Choose the best one for your torque, speed, and space.

Torque Output

Motor with Gear

A motor with gear gives your system much more torque. The gearbox connects to the electric motor and changes how speed and torque work together. When the gearbox lowers speed, it makes torque go up by about the same amount as the gear ratio. For example, a 10:1 gear ratio means the output shaft turns ten times slower, but you get almost ten times more torque. This extra torque is very important for machines that move heavy things or work hard.

Tip: Pick the right gear ratio to match your motor with gear to what your job needs. This helps you get the best performance and save energy.

Here’s a table that shows how gear ratios change speed and torque:

Gearbox Ratio | Motor Speed (rpm) | Torque Output (in-lbs) |

|---|---|---|

No gearbox | 934 | 4.75 |

10:1 | 93.4 | 40.45 |

15:1 | 62.3 | 59.81 |

You can see that a motor with gear and a 10:1 gearbox gives almost ten times more torque than no gearbox. This makes electric motor gearbox systems great for jobs that need a lot of torque.

High Torque Applications

You will find motor with gear and gearbox sets in many places that need high torque. These include:

Industrial machines like cranes, lifts, jacks, and conveyor machines

Home appliances such as washing machines, mixers, clocks, hand tools, and dryers

Machines that need to work hard use electric motor gearbox systems for steady power and torque. Gearboxes change how speed and torque work, so you can swap speed for torque or the other way around. This lets you get the best results for your needs.

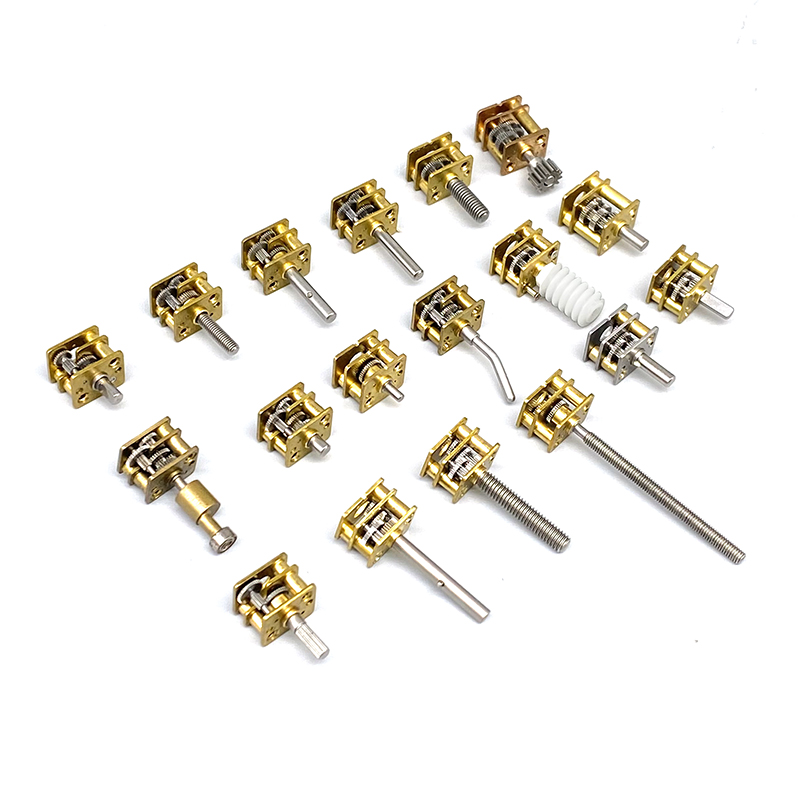

Some common gearbox types for more torque are worm, planetary, helical, bevel, and spur gear designs. Each type has special benefits for moving power and boosting torque in tough machines. For example, worm gearboxes give high reduction ratios and stop backdrive. Planetary gearboxes give a lot of torque in a small size.

Picking the right motor with gear and gearbox makes sure your electric motor gives enough torque for heavy loads and hard jobs. You get better performance, longer equipment life, and good power use in your work.

Speed Control

Use a Gearbox

A gearbox with your electric motor gives you better speed control. The gearbox changes how fast the motor turns by a set amount. This helps you make your machine go faster or slower. You can match the motor speed to what your job needs. For example, in material handling, you may need different speeds. The gearbox lets you do this without changing the motor.

Here is how a gearbox helps you control speed in electric motor systems:

The gearbox slows down the motor by a certain amount. This gives you many speed choices.

When the speed is lower, you get more torque. This keeps your motor safe from working too hard.

The gearbox makes it easier to start, stop, and change speeds.

You can use the gearbox with other speed controllers for even better control.

In hard jobs, the gearbox takes extra torque and protects your motor.

Gearboxes are easier and cheaper to fix than motors. This saves you money on repairs.

Using a gear motor makes less heat and needs less insulation. This helps save energy.

The table below shows common speed ratios for different gearboxes:

Gearbox Application | Typical Speed Ratio Range |

|---|---|

Steel Manufacturing Gearboxes | 1:1 to 75:1 |

Resin Gearboxes | 2:1 to 55:1 |

Paper Machine Gearboxes | 1.5:1 to 20:1 |

High-Speed Gearboxes | 1.15:1 to 31.99:1 |

Turbo Compressor Gearboxes | 1.36:1 to 21.43:1 |

Pumps Gearboxes | 1:1 to 16:1 |

Mill Gearboxes | 20:1 to 68:1 |

Precision Movement

Many modern machines need very exact movement. Robotics and automated systems use gearboxes for this. The gearbox helps you control where and how fast things move. In robotics, gearboxes help you move parts to the right spot every time. They cut down on mistakes caused by backlash and runout. Special gearboxes, like harmonic or planetary, have almost no backlash. This is important for robot arms, grippers, and wheels.

Gearboxes give strong torque and smooth moves for robot joints.

They turn motor power into careful motion for each part.

Precision gearboxes help robots work safely and well.

Tip: Use a gearbox when you need both speed control and exact movement. This helps your machines work smoothly and do hard jobs the right way.

Gearbox Efficiency

Energy Savings

You can get high efficiency by picking the right gearbox. New gearbox technology uses special gear teeth, light materials, and smart sensors. These things help save energy. Most good gearboxes, like helical and bevel, work at 92% to 98% efficiency. This means less power is lost as heat or friction. More energy goes to doing useful work.

Gearbox Category | Efficiency Range |

|---|---|

Typical Range | 92% - 95% |

Premium Range | 96% - 98% |

Switching to high efficiency gearboxes can cut energy use by 30%. If you use these gearboxes with IE5 motors, you save even more energy. Smart gearboxes with digital monitoring help your system work its best. You also help the planet by wasting less energy and making fewer greenhouse gases. Using efficient gearboxes helps with green goals in factories.

Note: Keep your gearbox in good shape with regular care. This keeps it working well and helps your electric motor gear drive systems last longer.

Cost Reduction

You spend less money when you use high efficiency gearboxes. One good gearbox lasts longer and breaks less than many cheap ones. Smaller gearboxes that are strong save money on bases, oil, and parts. Smart gearboxes and predictive care mean less downtime and fewer spare parts.

Lower total cost to own

Fewer fixes and swaps

Less waste and fewer resources used

New gearbox designs and better materials make your system work better. These things help your electric motor gear drive systems save money and work well. You get high efficiency, better results, and save money over time by choosing good gearboxes and taking care of them.

Protection and Reliability

Overload Prevention

A gearbox helps protect your motor from getting overloaded. It takes in shock loads and sudden force changes. This keeps the motor from getting hurt. The gearbox acts like a shield and takes the stress. This stops damage that could happen to the motor. Using the right gearbox parts and good habits helps you avoid problems.

If you use too much or too little oil, gears and bearings can get too hot and break.

If the gearbox is not lined up right or goes too fast, it can get too hot.

If things are not balanced or lined up, the gearbox can shake and get damaged inside.

If you put too much weight on the system or forget to oil it, gears can break.

Bearings can break if there is too much weight or not enough oil.

If oil seals break, oil can leak out and cause more problems.

If air cannot move around the gearbox, it can get too hot and not work well.

You can stop these problems by picking the right gearbox and putting it in the right way. Make sure to check the oil often. Adding things like temperature and vibration switches helps you find problems early. This makes the system more reliable and keeps your motor working well.

Durability

Taking care of your gearbox helps your motor last longer. You should do regular checks on all gearbox parts. This means looking at oil levels, checking seals, and listening for strange sounds. If your machine runs all the time, you should:

Check the gearbox soon after you start it and after cleaning to look for leaks or worn parts.

Test the oil to see if it is thick enough, too sour, or dirty.

Change out old bearings, seals, and gaskets before they break.

Use sensors to watch temperature and shaking for quick health checks.

If you take care of your gearbox and watch for problems, you can stop surprise breakdowns and make it last longer.

Most people who make choices at work want things to be reliable. If you follow a plan for taking care of your gearbox, you make it work better and stop it from breaking down. This can make your equipment work up to 15% better and save energy. Always change your care plan to fit your job and how much you use your machine. This helps your gearbox and motor work well for many years.

Application Versatility

Electric Motor Gear Drive Systems

Electric motor gear drive systems work in many industries. They give you lots of torque and speed choices. Gearboxes are made for both light and heavy jobs. For example, IE Drives has fixed ratio gearboxes. These can handle up to 3,000 Nm of torque. Their speed reduction ratios go from 2.5:1 to 10:1. Dana Brevini’s planetary gearboxes cover 200 Nm to millions of Nm. Their gear ratios start at 3.5 and go over 3,000. Wittenstein alpha servo gearboxes give 1,100 Nm to 10,450 Nm of torque. Their gear ratios range from 48 to 5,500. This means you can pick what fits your needs best.

Product Series | Torque Range (Nm) | Max Torque (Nm) | Gear Ratio Range |

|---|---|---|---|

Industrial Series | 200 - 29,400 | 1,000 - 35,000 | 3.5 - 3,000+ |

S Series Planetary | 16,000 - 2,170,000 | 54,000 - 5,400,000 | 4 - 3,000+ |

These systems help you get more torque and control speed. They also help move power better. You see them in conveyors, robots, assembly lines, and electric cars. Their small size saves space and makes them easy to put in. They help save energy and move power well. This is important for electric cars and robots. They work steady and stay reliable, even if loads change fast.

Tip: Pick electric motor gear drive systems for high performance, reliability, and saving energy in small spaces.

Selection Tips

To pick the right electric motor gearbox, look at some key things. First, know what torque, speed, and control you need. Make sure the motor and gearbox work together. Check charts for speed, torque, and efficiency. Decide if you want to buy parts alone or a gearmotor. Look at maker data for heat limits, torque, and how long it runs.

Think about these when picking a gearbox:

What you need: torque, speed, and shock loads

How it runs: all the time or sometimes, and overloads

Control: position, torque, speed, brakes, and feedback

Where it fits: space, and which way the shaft points

Environment: temperature, dust, water, and rust

Gear type: helical, worm, bevel, or planetary and how well they work

Motor: size, voltage, frequency, and if it matches

Also check the service factor, where it works, and how it connects. Make sure the output shaft fits your job. Where you put the gears and the case style change how well it works and how hot it gets. Harmonic gearboxes are good for small, precise jobs like robot arms. Planetary gearboxes are strong for big loads and tough places. Helical gearboxes are best for fast, heavy jobs. Each type gives special benefits when you use a reducer.

Note: Adding gearboxes to new electric motors can make things harder and cost more. Good design helps lower noise and shaking.

If you follow these tips, your electric motor gear drive systems work their best. You get better torque, speed control, and performance.

When you use a gearbox with a motor, you get many good things. You get more torque, better speed control, and higher efficiency. Gearmotors can move heavy things and work well when jobs change. They last longer and need less fixing.

You get more torque and can control speed exactly.

The design is small and works well every time.

You can use them in robots, conveyors, and other machines.

To do your best, think about how much torque, speed, and what kind of place you need. Ask experts to help you pick the right gearbox for your motor. This helps your system work well for a long time.

FAQ

What is the main benefit of using a gearbox with a motor?

You get more torque and better speed control. A gearbox lets your motor work at its best efficiency point.

Tip: Use a gearbox to handle heavy loads without needing a bigger motor.

How do you choose the right gearbox for your application?

Start by checking your torque and speed needs. Match the gearbox ratio to your job.

Review the environment and space.

Check compatibility with your motor.

How often should you maintain your gearbox?

You should check oil levels and inspect seals every month. Listen for unusual noises.

Note: Regular maintenance helps prevent breakdowns and extends the life of your system.

What mistakes should you avoid when pairing a motor and gearbox?

Do not ignore alignment or overload limits.

Always follow the manufacturer's guidelines.

Avoid using the wrong lubricant.

Never skip regular inspections.

See Also

Selecting The Best Planetary Gear Motor For Accurate Screwdrivers

Choosing Battery Operated Electric Motors For Peak Performance

Maximizing Efficiency By Tuning Resonance Frequency In LRA Motors

Best Methods To Optimize Frequency Vibrations In Small Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry