What Is an Electric Motor and How Does It Work

An electric motor is a device that uses electrical energy to make things move, often referred to as a power motor due to its ability to deliver strong mechanical force. You use power motors every day, often without noticing them. For example, when you press a button to start a blender, a power motor spins the blades. This demonstrates how power motors convert electricity into useful work. Power motors are found everywhere, from fans at home to machines in factories. They consume about half of the world’s electricity each year. When you see a motor running a pump or a fan, you are witnessing this essential power motor process in action.

Key Takeaways

Electric motors turn electrical energy into movement. They power things like fans, blenders, and cars.

The rotor, stator, windings, and magnets are the main parts. Each part helps the motor spin.

Magnetic fields and electric current work together in the motor. They make a force that turns the rotor. This force creates motion.

There are different kinds of electric motors. AC motors are used in homes and factories. DC motors are found in toys and electric bikes.

Electric motors save energy and cut down pollution. They help machines work faster and better in homes and industries.

Electric Motor Basics

What Is an Electric Motor

If you open an electric motor, you see a smart machine. It changes electricity into movement. Electric motors are in many things, like toys and washing machines. Science explains how a motor works.

Electric motors work because a wire with current in a magnetic field feels a push. This push moves the wire, so the motor spins. Electrical energy turns into mechanical energy.

These are the main science ideas that help electric motors work:

A wire with current in a magnetic field gets pushed (Lorentz force).

This push makes torque, which spins the rotor.

DC motors use direct current and commutators to keep spinning.

AC motors use alternating current to make spinning magnetic fields.

Stepper and servo motors use these ideas with extra controls for exact moves.

You see these ideas every time you use a fan or blender. The way an electric motor works is what makes these things move.

Fundamental Principle | Description | Role in Electric Motor Operation |

|---|---|---|

Electromagnetic Induction | Changing magnetic flux creates voltage in a coil. | Makes current and voltage changes for motor work. |

Magnetic Fields | Made by magnets or coils. | Give the place for force and movement. |

Lorentz Force Law | Current in a magnetic field feels a sideways push. | Makes torque and spinning. |

Commutation (DC motors) | Switches current direction as rotor turns. | Keeps spinning going. |

Rotating Magnetic Field (AC) | Alternating current makes the stator’s field spin. | Turns the rotor by induction. |

Main Parts

If you look inside an electric motor, you see many important parts. Each part has its own job. Here is what you find inside an electric motor:

Rotor: This part spins and gives mechanical energy.

Stator: This part stays still and makes the magnetic field.

Windings: These are copper wire coils that carry current.

Commutator (in DC motors): This switches current to keep the rotor moving.

Bearings and Shaft: These hold the rotor and help it spin smoothly.

Magnets: These can be permanent or electromagnets for strong magnetic fields.

Insulating Materials: These protect windings and stop short circuits.

Copper is used for windings because it carries electricity well. Steel, like silicon steel, is used for the rotor and stator cores. These materials help electric motors work better. Permanent magnets use rare earth elements for strong fields. Insulating materials like rubber, enamel, mica, and glass fiber keep the motor safe.

Material | Common Use in Electric Motors | Key Properties and Advantages |

|---|---|---|

Copper | Windings | Carries electricity well, easy to shape |

Steel (Silicon Steel) | Rotor, stator, bearings, shafts | Strong, magnetic, not too expensive |

Composites | Structural parts | Light, strong, does not rust |

Rare Earth Elements | Permanent magnets | Makes strong magnetic fields |

Insulating Materials | Windings and parts | Stops unwanted current flow |

When you know what is inside an electric motor, you can see how it works and why it matters in daily life.

How Electric Motors Work

Magnetic Fields

A magnetic field is a force you cannot see. It surrounds magnets and electric currents. In electric motors, magnetic fields help things move. When electricity goes through wire coils, a magnetic field forms around them. This field meets other magnetic fields inside the motor.

Magnetic poles that are alike push away from each other. Opposite poles pull together.

The stator does not move. It has magnets or coils that make a steady magnetic field.

The rotor spins. It has coils with electric current that make their own magnetic field.

When these fields meet, they push and pull. This makes the rotor spin.

The motor keeps spinning because the current in the rotor coils changes direction at the right time.

Different electric motors use these ideas in special ways. The main idea stays the same.

You see this happen when you use a fan, blender, or toy car. The magnetic fields inside the motor work together. They change electrical energy into movement.

Rotor and Stator

The rotor and stator are the two main parts in electric motors. The stator does not move and makes a magnetic field. The rotor sits inside the stator and spins when the motor works. Think of the stator as the shell. The rotor is the spinning part inside.

Component | Common Configurations | Notes |

|---|---|---|

Stator Windings | Star (Wye) or Delta | Motors switch between star and delta for different voltages. Small motors use star for efficiency. Big motors use delta for balance. |

Rotor in Squirrel-Cage Induction Motors | Bars connected like Delta | Rotor bars make a closed circuit. |

Rotor in Wound Rotor Motors | Star (Wye) | Lets you use outside resistors for torque control. |

Rotor Types by Motor | Squirrel Cage, Wound Rotor, Permanent Magnet | Rotor design changes with motor type. |

Stator Role | Has windings in AC and brushless motors | Makes a spinning magnetic field. Winding setup changes torque and current. |

How the rotor and stator are made changes how well the motor works. Good materials and careful shapes mean less energy loss and more power. Thin steel layers in the stator and rotor help stop energy from turning into heat. Keeping the gap between rotor and stator small and even helps too. Better materials and careful building make motors last longer, run cooler, and save energy.

Laplace Force

The Laplace force is why electric motors spin. When electric current goes through wires in the rotor, and those wires are in a magnetic field, a force pushes on them. This force always goes at a right angle to the current and the magnetic field. Fleming’s left-hand rule helps you find the direction of this force.

This force makes torque, which spins the rotor. The commutator or controller changes the current direction at the right time. This keeps the rotor spinning the same way. The torque size depends on the current and the magnetic field strength. More current or stronger magnets make the motor spin faster or with more force.

Tip: Try a simple experiment at home. Put a wire between the poles of a magnet. Connect the wire to a battery. The wire will move or jump. This shows the Laplace force, just like in electric motors.

When you put these ideas together, you see how electric motors work. Magnetic fields and electric current make a force that spins the rotor. This turns electrical energy into mechanical energy. It powers many things you use every day.

Types of Electric Motors

AC Motors

AC motors are in homes and factories. They use alternating current. This means the electricity changes direction many times each second. AC motors work because of electromagnetic induction. The stator makes a magnetic field that keeps changing. This changing field makes the rotor spin.

Most home appliances use induction motors. You see them in washing machines, fans, and refrigerators. Air conditioners also use them. Induction motors last a long time. They run quietly and need little care. Homes use single-phase induction motors. Factories use three-phase types for bigger machines. Synchronous motors are another kind of AC motor. They keep a steady speed. They are good when you need exact timing.

Tip: To understand how an AC motor works, remember this. The stator’s changing magnetic field pushes the rotor. This makes the machine move.

Feature | AC Motors | DC Motors |

|---|---|---|

Power Supply | Use alternating current (AC) which periodically reverses direction | Use direct current (DC) which flows in a constant direction |

Operating Principle | Rely on electromagnetic induction; rotor current induced by stator's AC magnetic field | Use brushes and commutator (or electronic commutation) to maintain unidirectional torque |

Motor Types | Synchronous (rotor speed synchronized with AC frequency) and Induction (rotor speed slightly less than synchronous) | Brushed and brushless types |

Speed Control | Controlled by varying AC frequency (requires variable frequency drives) | Easier and more precise speed control by varying input voltage |

Construction | Simpler, brushless design relying on stator's alternating magnetic field | More complex due to commutator and brushes to handle constant current |

Maintenance | Generally simpler and more durable | Brushed types require maintenance; brushless types require less maintenance |

Starting Capability | Induction motors are self-starting; synchronous motors may require additional mechanisms | Always self-starting |

Efficiency & Usage | More efficient for continuous operation at constant speed; lower noise | More efficient for applications requiring frequent speed changes and precise control |

AC motors are used in over 70% of industry. You see them in irrigation pumps and HVAC systems. Robots also use them. They are efficient and cost less. That is why they are chosen for many jobs.

Common AC Motors in Homes:

Induction motors (single-phase and three-phase)

Synchronous motors (for steady speed)

Used in: fans, washing machines, refrigerators, air conditioners, and microwave ovens

DC Motors

DC motors use direct current. This current flows in only one direction. DC motors use brushes and a commutator. These parts keep the rotor spinning the same way. You can control the speed easily. Just change the voltage.

DC motors are found in toys and electric bikes. Some washing machines use them too. They are good for devices that need quick starts or stops. DC motors work well with batteries. They handle low voltage.

Note: DC motors give better speed control. They make less electromagnetic noise. But they need more care. Brushes wear out over time.

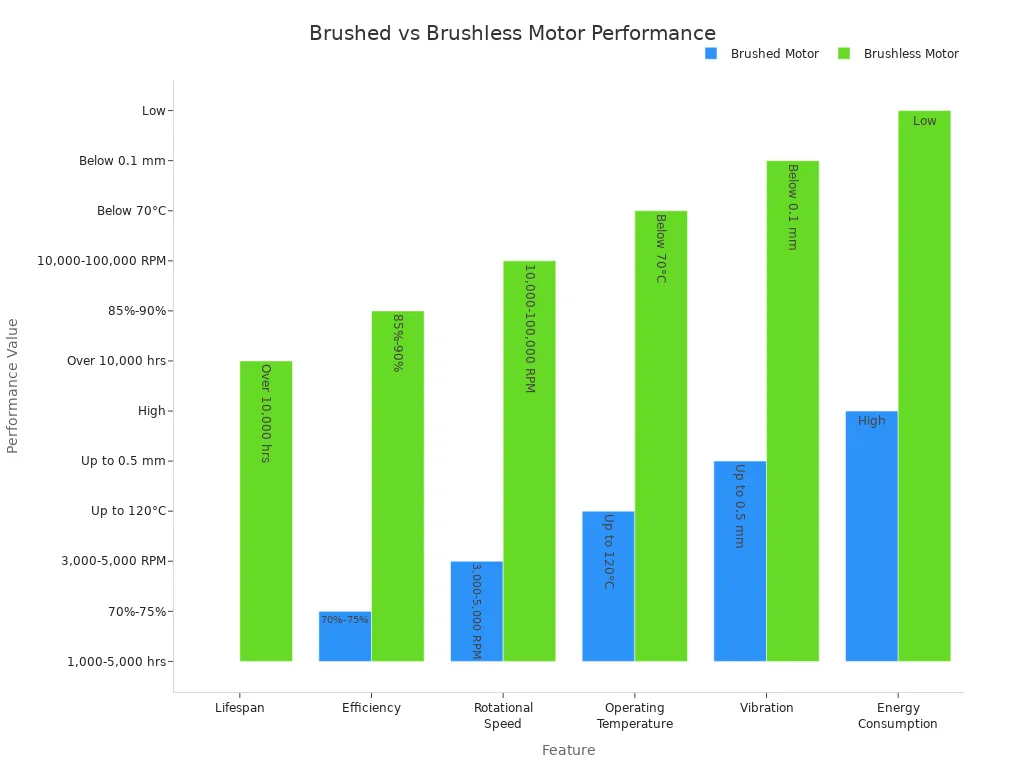

Brushless DC motors fix this problem. They use electronic parts instead of brushes. This makes them last longer. They need less fixing. Look at the chart below. It shows how brushless motors compare to brushed ones:

Other Types

Some motors are made for special jobs. Stepper motors move in small steps. You see them in 3D printers and robots. They help when you need exact moves. Linear motors make straight-line motion. They push or pull loads without spinning.

New motors use advanced designs. Axial flux motors are small but powerful. In-wheel motors fit inside car wheels. Electric vehicles use them. Switched reluctance motors use fewer rare materials. They last a long time. Stepper motors and new types help you get better control. They also save energy.

Emerging Motor Type | Unique Features & Applications | Key Challenges / Notes |

|---|---|---|

Axial Flux Motors | High power density, lighter weight, used in electric vehicles and aircraft | Production and cooling challenges |

In-wheel Motors (Hub Motors) | Direct drive at the wheel, modular, saves space, used in new electric cars | Complex integration, brake changes needed |

Switched Reluctance Motors | No rare earths, reliable, improved by new electronics | Growing use in commercial vehicles |

SynRM-IPM | High torque, good for small electric vehicles | New alternative for traction motors |

Power Motor Applications

Home Uses

You can find power motors in many things at home. When you open your fridge, a power motor runs the compressor. This keeps your food cold. Your washing machine has a power motor. It spins the drum and moves water. A vacuum cleaner uses a power motor to make suction. This helps pick up dirt from the floor. Ceiling fans have power motors that spin the blades. This moves air and cools your room. Blenders use power motors to chop and mix food fast.

Here are some household items that use a power motor:

Refrigerator: The power motor makes the compressor work to cool food.

Washing machine: Power motors spin the drum and move water.

Vacuum cleaner: Power motors make suction for cleaning floors.

Ceiling fan: Power motors turn the blades to move air.

Blender: Power motors spin blades to mix and chop food.

Power motors help you do chores faster and easier. You save time and energy because these machines work well. Many new home devices use power motors that save energy. This helps lower your electric bill and is better for the planet.

Industry Uses

Factories and businesses use power motors for many tasks. You see power motors in pumps, fans, and compressors. They also work in gears and pulleys. These motors move conveyor belts and lift heavy things. They run machines that shape or pack products. Power motors help robots move quickly and exactly.

In factories, power motors help make work faster and more correct. You see them on assembly lines and in machines that move materials. They are also in CNC machines. Power motors help save energy. New designs waste less energy and cost less to run. More than 80% of machines in oil and gas use power motors for pumps and fans.

Application | Power Motor Role | Benefit |

|---|---|---|

Pumps & Compressors | Move liquids and gases | Reliable and efficient |

Conveyor Belts | Carry products on assembly lines | Faster work |

Robotics | Make careful movements | More accurate |

Fans & Blowers | Move air or cool machines | Better temperature control |

Power motors help make cleaner technology. They are quieter and make less pollution than fuel engines. When you pick devices with power motors, you help the environment.

You have learned that electric motors change electricity into movement. They make things like fans and electric cars work. You can find electric motors in many places. They are in home appliances, factories, and clean energy systems. New electric motors use smart controls and better materials. This helps them work better and waste less energy. Electric motors also help cut down on pollution. They make transportation cleaner.

When you use something that moves, think about the electric motor inside. Electric motors are important for modern life. They will keep helping new technology grow.

FAQ

What is the main job of an electric motor?

You use an electric motor to turn electrical energy into movement. This movement powers things like fans, blenders, and cars. Electric motors help you do work faster and easier every day.

How do you know if a device uses an electric motor?

Look for parts that spin or move when you turn on the device. If you hear a humming sound or see moving blades, gears, or wheels, you likely have an electric motor inside.

Can you repair a small electric motor at home?

You can fix simple problems like loose wires or dust buildup. Use a soft brush to clean the motor. If you see broken parts or smell burning, you should ask an expert for help.

Tip: Always unplug the device before you try to check or clean the motor.

Why do some motors get hot during use?

Motors get hot because they use electricity, which creates heat as a byproduct. If your motor feels very hot or smells bad, turn it off. Too much heat can damage the motor.

See Also

A Complete Guide To Interpreting Motor Wiring Diagrams

Understanding Motor Brushes And Their Role In ERM Motors

Exploring ERM Motor Diagrams: Components, Types, And Uses

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry