Key Differences Between Vibro and Standard Motors

Vibro motors vs. standard motors serve distinct purposes in engineering applications. Vibro motors generate vibrations that enhance user interaction with devices. These vibrations, known as haptic feedback, significantly improve the functionality of gadgets such as smartphones, smartwatches, and game controllers. In contrast, standard motors primarily rotate to drive mechanical components.

The distinctions between vibro motors and standard motors become evident when examining their operational mechanisms and construction. For instance:

BLDC motors exhibit 37% fewer torque ripples compared to SRM motors, resulting in smoother operation.

While both motor types boast over 90% efficiency, BLDC motors provide greater torque at standard speeds.

The starting torque varies, with SRM motors typically requiring more force to initiate movement.

Understanding these differences is crucial for selecting the appropriate motor for your specific requirements. Whether you need precise vibrations or robust rotational power, making the right choice in motor type leads to improved performance and enhanced user satisfaction.

Key Takeaways

Vibro motors shake to give touch feedback, making gadgets like phones and game controllers more fun to use.

Standard motors spin to run machines and appliances with strong and steady power.

Picking the right motor is important; vibro motors work well in small devices, while standard motors are better for big machines.

INEED vibration motors save energy and last over 1,000 hours, making them great for battery-powered gadgets.

Think about your needs and money when choosing a motor; vibro motors might cost more at first but last longer and are worth it.

Overview of Vibro Motors and Standard Motors

What Are Vibro Motors?

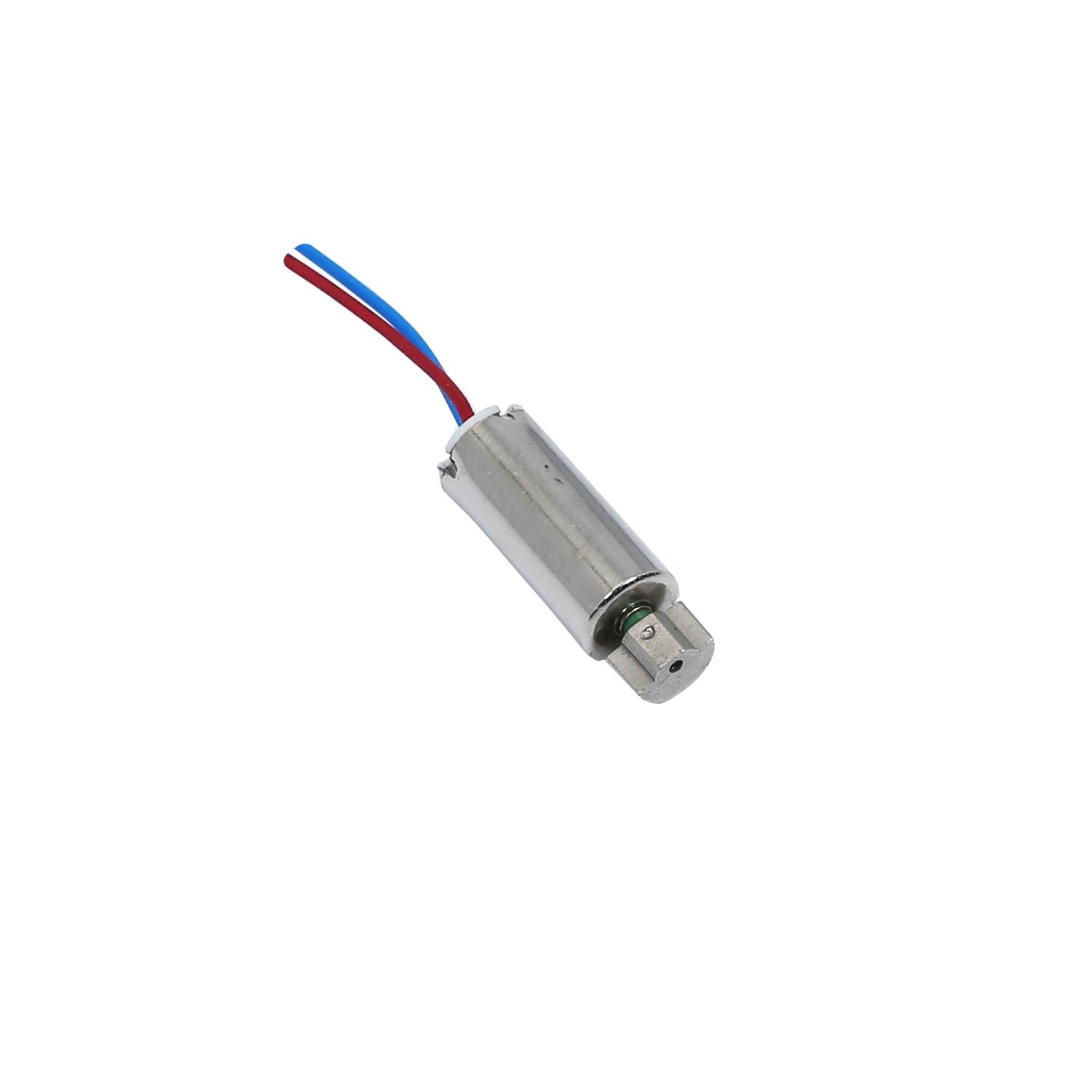

Vibro motors are small devices that make vibrations. These vibrations give a sense of touch, called haptic feedback. You can find them in phones, smartwatches, and game controllers. They make using these devices more interactive. Vibro motors turn electricity into vibrations using ERM or LRA technology. Their small size and efficiency make them perfect for precise haptic tasks.

What Are Standard Motors?

Standard motors create spinning motion to power machine parts. They are used in home appliances, factory machines, and cars. Unlike vibro motors, they focus on steady spinning instead of vibrations. Examples include brushed DC motors and BLDC motors. Each type is made for specific jobs.

Key Characteristics of Vibro Motors vs. Standard Motors

Vibro motors and standard motors are different in how they work and are used. Vibro motors are great for making vibrations for touch feedback. Standard motors are better for spinning power. The table below shows their main differences:

Motor Type | Size Range | Lifespan (MTTF) | Vibration Strength | Vibration Speed | How They Are Attached |

|---|---|---|---|---|---|

Brushed ERM | 3.2mm to 45mm | 100 – 600 hours | 0.25G ~ 150G | 30Hz ~ 500 Hz | Spring pad, SMD/SMT, PCB Through-hole, adhesive, enclosure, bulkhead |

BLDC ERM | 10mm to 12mm | 1000+ hours | 1G ~ 30G | 200 Hz ~ 208 Hz | Adhesive, enclosure, bulkhead |

LRA | 6mm to 10mm | 1000+ hours | 0.75G ~ 2G | 150 Hz ~ 205 Hz | Adhesive backing |

Vibro motors like LRA and BLDC ERM last longer and control vibrations better than brushed ERM motors. This makes them great for modern haptic devices. Standard motors, however, focus on spinning power and speed. They are important for running bigger machines.

Key Functional Differences Between Vibro Motors and Standard Motors

How Vibro Motors Work

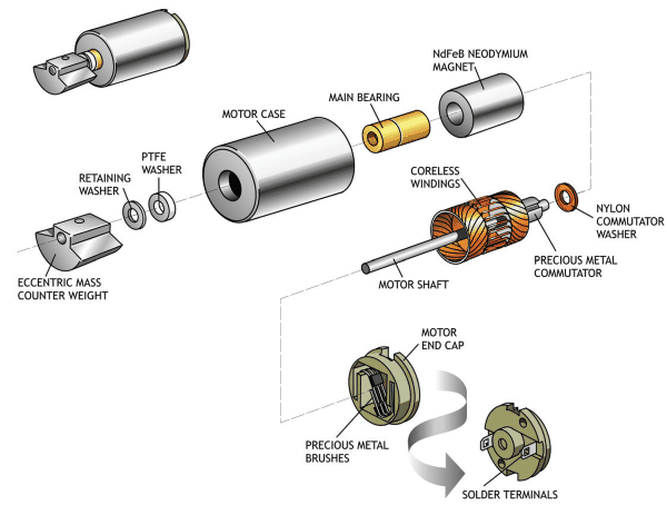

Vibro motors turn electricity into vibrations. They use two main methods: Eccentric Rotating Mass (ERM) and Linear Resonant Actuator (LRA). ERM motors spin an uneven weight to make vibrations. LRA motors use a spring and mass that move back and forth. This gives better control of vibration speed and strength.

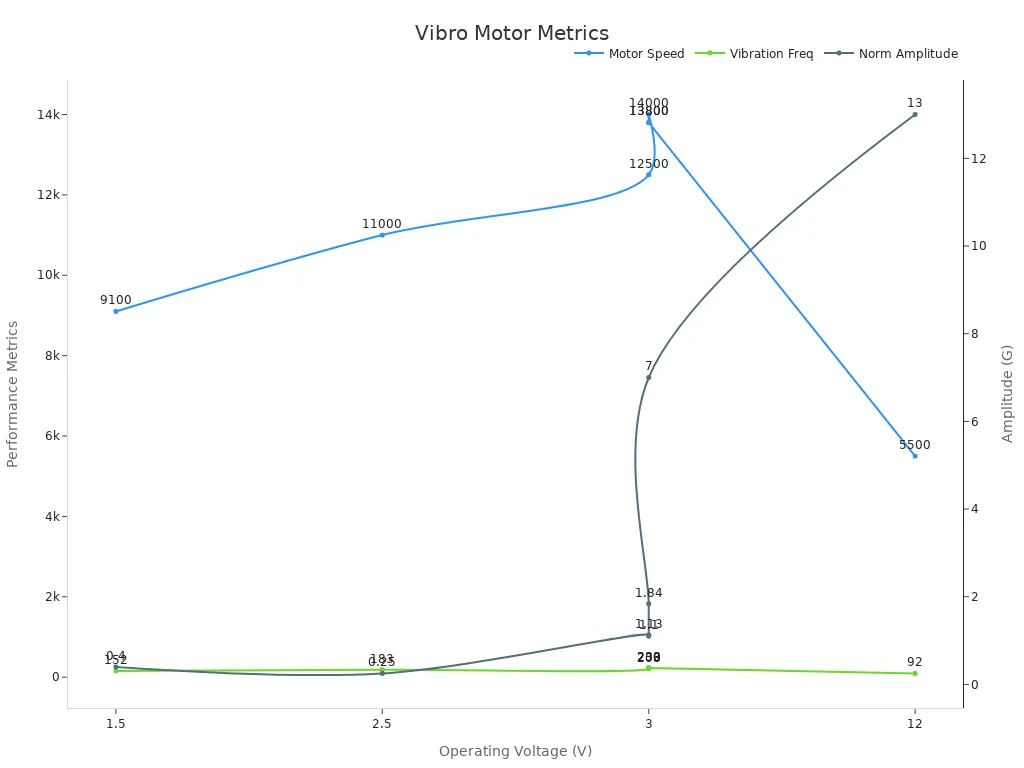

Vibro motors are small and fit in devices like phones and smartwatches. They work well with low power, saving battery life. For example, a 4.1mm motor uses 2.5 volts and spins at 11,000 rpm. It creates vibrations at 183 Hz, using very little energy. This makes them great for giving touch feedback without draining batteries.

How Standard Motors Work

Standard motors make spinning motion to move machine parts. They use magnets and electricity to spin the rotor. When electricity flows through the motor, it creates a magnetic field. This field pushes the rotor to spin.

Standard motors focus on speed and power, not vibrations. BLDC motors are very efficient and run smoothly. They can reach over 90% efficiency while spinning parts reliably. These motors are used in appliances, factory machines, and cars. They are perfect for jobs needing steady and strong motion.

Why Vibro Motors Are Useful

Vibro motors are great for devices needing touch feedback. Their small size fits into gadgets like phones and wearables. They use less power, helping batteries last longer. Vibro motors also let you control vibration strength and speed, improving how devices feel to use.

Haptic feedback, powered by vibro motors, makes devices easier to use. For example, vibrations in phones help users without needing sound or visuals. Vibro motors are also durable, with some lasting over 1,000 hours. This makes them reliable even in tough conditions.

Unlike standard motors, vibro motors focus on vibrations, not spinning. This makes them perfect for things like gaming controllers. Vibro motors improve gameplay by giving precise touch feedback. Choosing the right motor depends on what you need—spinning power or interactive vibrations.

Design and Structural Differences in Vibro Motors vs. Standard Motors

Parts Inside Vibro Motors

Vibro motors use special parts to make vibrations. They have either an eccentric rotating mass (ERM) or a linear resonant actuator (LRA). ERM motors spin a weight that is off-balance, creating vibrations. LRA motors use a spring and weight that move back and forth. This design helps control how strong and fast the vibrations are. Vibro motors are small and light, so they fit well in phones and wearables. Their size also helps save energy, making batteries last longer in portable devices.

Parts Inside Standard Motors

Standard motors are made for spinning, not vibrating. They have a rotor, stator, and magnets. When electricity flows, the rotor spins because of the magnetic field. This spinning moves parts in machines, cars, and appliances. Standard motors focus on power and speed. Brushless DC motors (BLDC) are a popular type. They work smoothly and use energy efficiently, making them great for steady, powerful tasks.

Features of INEED Vibration Motors

INEED vibration motors are unique because of their smart design. They combine touch feedback and movement in a thin, small structure. The motor has vibration parts, a BLE microcontroller, an IMU, and a battery on a flexible board. This lets it move in 36 directions and rotate two ways. A special system trains the motor to make specific movements. Studies on how users interact with these motors improve their performance for different uses.

Feature | Description |

|---|---|

Vibration Mechanism | Made for both movement and touch feedback in a slim design. |

Hardware Implementation | Includes vibration parts, BLE microcontroller, IMU, and battery on a flexible board. |

Omni-directional Locomotion | Moves in 36 directions with two rotation options. |

Empirical Learning | Uses a system to train motor movements for specific tasks. |

User Interaction Studies | Research improves how users interact with the motor. |

These features show how useful and efficient INEED vibration motors are. They are a great choice for modern devices.

Performance Metrics of Vibro Motors and Standard Motors

Vibration Frequency and Amplitude

Vibration frequency and amplitude show how well a motor works. Frequency means how fast the motor vibrates. Amplitude shows how strong the vibrations are. Vibro motors are great at controlling these, making them perfect for phones and wearables. For example, a 4.1mm motor vibrates at 183 Hz with 0.25G strength. It gives good feedback without using much power.

Tests show how vibration frequency stays steady over time. A motor tested for 5, 10, and 20 seconds kept a first resonant frequency of 8,789 Hz (527.34 RPM). The second resonant frequency changed slightly, from 19,531 Hz (1,171.86 RPM) to 19,043 Hz (1,142.58 RPM). These results prove vibro motors are reliable and perform consistently.

Ramps | First Resonant Frequency (Hz/RPM) | Second Resonant Frequency (Hz/RPM) |

|---|---|---|

5 seconds | 8,789 / 527.34 | 19,531 / 1,171.86 |

10 seconds | 8,789 / 527.34 | 19,043 / 1,142.58 |

20 seconds | 8,789 / 527.34 | 19,043 / 1,142.58 |

Energy Efficiency and Power Output

Vibro motors use less energy but still work well. A 3V motor can spin at 12,500 RPM and vibrate at 208 Hz. This makes them great for gadgets like smartwatches that need to save battery.

Standard motors focus on power and speed instead of saving energy. They are made for heavy jobs like running factory machines. Both motor types are over 90% efficient. But vibro motors are better for low-power devices, helping batteries last longer.

Longevity and Durability of INEED Coin Vibration Motors

INEED coin vibration motors are made to last a long time. They are tested to handle tough conditions and work for over 1,000 hours. Their small size and strong build make them hard to break, so they work well for a long time.

These motors are great for devices like fitness trackers and medical tools. They keep their vibration strength and frequency steady, improving how devices feel to use. They also need less fixing. Choosing INEED coin vibration motors means your devices will be durable and efficient.

Applications and Use Cases of Vibro Motors vs. Standard Motors

Industrial Uses of Vibro Motors

Vibro motors are important in industries needing vibrations to work better. They are used in machines like vibratory separators, which clean products by removing impurities. These motors create accurate vibrations that help sort and separate materials. For example, studies show how placing the motor correctly improves efficiency. Proper placement removes unwanted items, making products higher quality.

Another study shows how specific vibration settings improve performance. This makes vibro motors essential in industries like food, medicine, and mining. They provide consistent results and reduce the need for manual work.

Study Title | Description |

|---|---|

Vibro Motor Placement on Reciprocating Separator | Explains how vibrations remove impurities efficiently. |

Motion Analysis of Vibro Separators | Studies how motion affects performance using real data. |

Structure Optimization of Vibratory Separators | Tests how design changes improve sorting and separation. |

Vibro motors are also used in conveyors and feeders. These machines use controlled vibrations to move materials smoothly. Adding vibro motors helps industries save money and work faster.

Everyday Uses of INEED Vibration Motors

INEED vibration motors improve how we use everyday devices. You see them in phones, smartwatches, and gaming controllers. They give touch feedback, making devices easier to use. For example, when your smartwatch vibrates for a notification, it uses a vibration motor to alert you.

These motors are also used in beauty tools. They provide the right vibrations for skincare routines, making them more effective. In fitness trackers, they give gentle feedback during workouts to keep you focused. Their small size and low energy use make them perfect for portable gadgets.

Market studies show these motors are in high demand for electronics. Researchers use different methods to estimate market size. They also talk to experts to confirm their findings. This research shows how useful vibration motors are for many consumer needs.

Aspect | Details |

|---|---|

Used different methods to measure and confirm market sizes. | |

Key Players | Found through research, with shares calculated using various methods. |

Research Methodology | Included studying company reports and interviewing experts for insights. |

Flexibility of INEED Coreless Vibration Motors

INEED coreless vibration motors are great because they work in many devices. Their small and light design fits in tight spaces. You can find them in phones, gaming devices, and medical tools. They give accurate touch feedback, improving how users interact.

For example, in gaming controllers, these motors make games feel more real by adding vibrations. In medical tools, they give alerts to help users get accurate feedback. They respond quickly and last a long time, making them reliable for regular use.

You can also customize these motors for specific needs, like vibration strength or how they are attached. This makes them work well in any device. Whether for a small wearable or a powerful gaming gadget, INEED coreless vibration motors perform excellently.

Cost and Maintenance Considerations for Vibro Motors and Standard Motors

Initial Costs of Vibro Motors vs. Standard Motors

Vibro motors and standard motors have different starting costs. Vibro motors, used in gadgets like phones and wearables, cost more upfront. This is because they have special parts for precise vibrations. For example, INEED's coin vibration motors are small and save power. These features make them useful but raise their price.

Standard motors are cheaper to buy at first. They are simpler and focus on spinning power. This makes them good for things like home appliances and factory machines. Choosing between these motors depends on what you need. If you want accurate vibrations, vibro motors are worth the extra cost.

Maintenance Requirements of INEED SMD Vibration Motors

INEED SMD vibration motors need little maintenance. They are made to last, with features like heat resistance and steady performance. Their small size fits easily into devices without needing many changes.

The surface-mounted design also makes assembly easier and faster. You only need to check connections and performance sometimes. With proper care, these motors work well for a long time. This makes them a good choice for manufacturers who want low-maintenance options.

Long-Term Cost Efficiency of INEED Vibration Motors

INEED vibration motors save money over time because they last long and use less energy. Even though they cost more at first, they are worth it. Their low power use helps devices like smartwatches run longer without draining the battery.

They are also built strong, so they rarely need fixing or replacing. For example, INEED's coin vibration motors can work for over 1,000 hours. This makes them a smart choice for things needing steady vibrations. By choosing these motors, you save on repairs and get better value in the long run.

Knowing how vibro motors and standard motors differ helps you choose wisely. Vibro motors are great for creating small, precise vibrations. These are perfect for touch feedback in gadgets. Standard motors are made for spinning parts in machines. They are strong and reliable for heavy tasks.

Think about your needs, budget, and device type when picking a motor. For small gadgets needing touch feedback, vibro motors work best. For big machines, standard motors give steady power.

Tip: Choose INEED vibration motors for their strength and energy-saving design. They work well in many devices, from wearables to factory machines.

FAQ

What is the main difference between vibro motors and standard motors?

Vibro motors make vibrations for touch feedback. Standard motors spin to move machine parts. Vibro motors are best for small gadgets like phones. Standard motors work well for heavy machines in factories.

How do vibro motors save energy?

Vibro motors use little power to make accurate vibrations. For example, INEED coin vibration motors run efficiently on just 3V. This makes them great for battery-powered devices like fitness trackers and wearables.

Can vibro motors be customized for specific applications?

Yes, vibro motors can be adjusted for strength, speed, and attachment. INEED provides custom solutions for industries like healthcare, robotics, and electronics.

Why are INEED vibration motors reliable?

INEED vibration motors are tested to last long and work well. They can run for over 1,000 hours while keeping steady vibrations. This makes them dependable in tough conditions.

Where are vibro motors commonly used?

Vibro motors are found in phones, smartwatches, and gaming controllers. They give touch feedback, making devices easier and more fun to use. They are also used in medical tools for better interaction.

Tip: Check out INEED’s vibration motors for strong and energy-saving options made for your needs.

See Also

The Advantages Of Linear Vibration Motors For Haptic Feedback

Understanding The Functionality Of Vibration Motors In Haptics

Exploring The Mechanism Behind 3V DC Motor Vibrations

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry