Vibration vs Frequency: Understanding the Distinctions for Better Motor Specifications

Motors operate based on two key concepts: vibration vs frequency.

Vibration refers to the shaking motion caused by imbalances or external forces.

Frequency indicates how many times this motion occurs each second, typically measured in hertz (Hz).

Both vibration vs frequency are crucial for the proper functioning of motors.

Excessive vibration can damage the motor or lead to premature wear.

Incorrect frequency settings can disrupt the motor's speed.

Certain frequencies, such as 8,789 Hz or 19,043 Hz, can exacerbate vibrations.

This can result in performance issues for the motor.

Understanding the relationship between vibration vs frequency is essential for designing better motors.

It also aids in troubleshooting motor issues more effectively.

Key Takeaways

Vibration means the shaking movement in motors. Frequency shows how many times this shaking happens each second. Knowing both helps motors work better.

Too much vibration can harm motors and waste energy. Check vibration levels often to find problems early and make motors last longer.

Frequency changes motor speed. Changing frequency can help motors work better and save energy. This is important for certain tasks.

Variable Frequency Drives (VFDs) let you control motor speeds exactly. They make motors more reliable and save energy in many industries.

Special tools like vibration testers and monitoring systems find problems early. These tools keep motors running well and reduce work delays.

Frequency in Motor Operation

What Is Frequency?

Frequency means how many cycles happen in one second. It is measured in hertz (Hz). In motors, frequency controls how often the magnetic field changes. This affects how the motor works. Think of it like the motor's heartbeat, setting its speed and rhythm.

Frequency is very important for how motors perform in industries. Changing frequency can adjust motor speed, power, and efficiency. For example, higher frequency makes motors run faster. Lower frequency slows them down and reduces power. Industries use this to control motor speeds for better results.

Frequency and Motor Speed

Frequency and motor speed are closely connected. Changing the frequency changes how fast the motor runs. Higher frequency increases speed but lowers locked-rotor torque. This can cause more friction and energy loss. Lower frequency slows the motor and raises locked-rotor torque. This is useful for jobs needing precise control, like textile mills.

This works because of the voltage-to-frequency ratio. Magnetic strength depends on this ratio. It affects torque and horsepower. Knowing this helps you adjust motors to fit specific needs.

Role of Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) help control motor speeds. They let you change the motor's frequency for exact speed control. For example, a slurry pump case showed a motor overheating. A VFD helped find the motor was too small. Resizing the motor and adjusting frequency improved energy use and reliability.

VFDs also make motors more reliable. They keep frequency steady and voltage stable. This stops problems during light loads. VFDs are very useful for saving energy and keeping motors running smoothly.

Vibration in Motors

What Causes Vibration?

Motor vibration happens because of mechanical or electrical problems. Common reasons include imbalance, misalignment, and bearing issues. Loose parts or resonance can cause electromagnetic imbalance. Mechanical imbalance comes from poor balancing or worn cooling fans. Misalignment occurs when parts are not lined up right or expand from heat.

Here’s a simple list of causes and fixes:

Cause of Vibration | How to Fix |

|---|---|

Electromagnetic imbalance | Tighten loose parts and check bearings and resonance. |

Mechanical imbalance | Balance cooling fans and inspect couplings carefully. |

Misalignment | Check alignment steps and watch for heat expansion. |

Bearing problems | Use proper lubrication and check assembly methods. |

Eccentricity | Measure uneven movement in rotors and couplings. |

Rotating looseness | Check sizes of bearings and housing parts. |

Structural issues | Tighten anchor bolts and inspect the motor base. |

Electrical issues | Test power quality and check gaps between rotor and stator. |

Fixing these problems quickly can stop vibration and make motors last longer.

Effects of Vibration on Motor Performance

Too much vibration can hurt how motors work. It wears out parts like bearings, shafts, and couplings faster. Over time, vibration lowers efficiency, uses more energy, and causes overheating.

For example, motors with high vibration often make noise and shake. These problems can interrupt work and raise repair costs. Watching vibration levels and fixing issues early keeps motors running well.

Resonance and Amplified Vibration

Resonance happens when a motor's natural frequency matches outside forces. This makes vibration worse and can damage parts. Mechanical resonance increases shaking and energy use. Electrical resonance stresses windings and shortens motor life.

Type of Resonance | What Happens | Effects on Motors |

|---|---|---|

Mechanical Resonance | Vibration gets stronger when natural frequency is excited. | More shaking, instability, energy use, and broken parts. |

Electrical Resonance | Voltage or current increases due to power system harmonics. | Stressed windings, rotor heating, shorter motor life, and system failure. |

Solutions | Fix resonance by stiffening parts or avoiding certain frequencies. | Better stability and fewer mechanical or electrical problems. |

Watching vibration data helps find resonance early. Setting alarms for unusual vibration levels can stop problems before they grow. For example, alarms set at two standard deviations from normal can catch issues early.

Knowing about resonance helps prevent big vibration problems and keeps motors reliable.

Vibration vs Frequency: Key Comparisons

How Vibration and Frequency Work Together

Vibration and frequency are closely linked in motors. Frequency shows how often the motor's magnetic field changes each second. This affects vibration, especially if the motor's natural frequency matches outside forces. For example, torsional analysis checks how the drivetrain's natural frequencies match the motor's speed. Lateral critical speed analysis looks at whether the shaft's natural frequencies align with operating speeds, which can cause resonance.

Resonance makes vibration worse, leading to stress and damage. Reed critical frequency analysis studies flange-mounted motors to avoid harmful resonance. By learning about these connections, you can stop vibration problems before they grow.

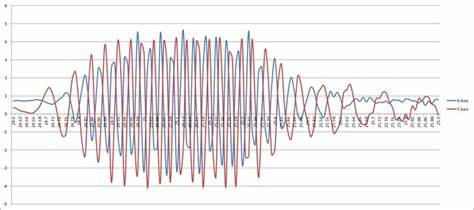

How Frequency Affects Vibration

Changing frequency changes how much motors vibrate. Higher frequencies often make motors vibrate more, especially if parts are unbalanced or misaligned. Tools like vibration analyzers track these changes by studying vibration patterns. These patterns show important details about the motor's condition, like how strong and frequent the vibrations are.

For instance, accelerometers measure vibration and turn it into signals for study. This data finds problems early, tracks ongoing issues, and sets repair rules. Watching vibration all the time helps fix problems before motors break.

Studies show that different frequencies change how things vibrate. For example, chainsaw blades and aluminum sheets vibrate differently at various frequencies. Picking the right frequency lowers vibration and improves performance.

Balancing Vibration and Frequency in Motor Design

Good motor design balances vibration and frequency for better performance. Special materials, like soft magnetic alloys, help control heat and reduce vibration. Thin motor laminations also improve performance in high-frequency uses.

Testing is important too. Vibration and resonance tests check if motor parts can handle real-world stress. Simulations help engineers fix vibration and frequency problems before making the motor. For example, finding noise and vibration issues early lets engineers adjust designs.

System-level testing looks at how all parts work together. This improves motor performance. Cloud tools test many designs quickly to find the best one. Using these methods creates motors that work well, even in tough conditions.

Practical Applications for Motor Specifications

Picking Motors Based on Frequency

Choosing the right motor depends a lot on frequency. Frequency controls how fast and efficient a motor runs. The NEMA Energy Management Guide gives helpful tips for this. It explains how fixed-frequency AC motors work in different situations. Charts in the guide compare motor models to help you decide.

For example, studies on three-phase motors show how frequency matters. At 60 Hz, these motors work best with less energy loss. Checking performance data ensures the motor runs well in specific tasks. This saves energy and makes the motor last longer.

Finding and Fixing Vibration Problems

Vibration can harm how motors work and make them less reliable. Spotting and fixing these problems early is very important. Research shows that reducing vibration involves four main steps:

Collecting data

Cleaning up the data

Building a model

Testing the results

Among tested methods, the Random Forest model was 99.3% accurate. It found imbalances in pump-motor systems. This shows how useful advanced tools are for spotting vibration issues.

Also, picking the right materials and designs helps reduce vibration. For instance:

Lightweight but strong materials lower vibration levels.

Balancing parts evenly reduces stress on motor pieces.

A study compared two engine designs to show these effects:

Engine Design | Noise Level (dB) | Vibration Level (mm/s) |

|---|---|---|

Original | 90 | 1.8 |

Improved | 80 | 1.2 |

Modern solutions like Active Magnetic Bearings (AMBs) also help. AMBs cut down rotor vibrations almost completely. Using these ideas improves motor performance and avoids expensive repairs.

Tools for Watching Vibration and Frequency

Advanced tools help balance vibration and frequency in motors. These tools collect live data to find problems early. For example, piezoelectric sensors measure vibration, and cloud systems analyze the data.

Here are some useful tools for motor maintenance:

Tool Type | What It Does |

|---|---|

Vibration Analysis Tools | Finds problems in rotating parts like shafts and gears. |

Condition Monitoring Systems | Watches machines in real time to give accurate updates. |

Motor Current Signature Analysis | Spots motor issues and checks how well it’s working. |

These tools improve maintenance and keep motors running smoothly. They also reduce downtime and boost efficiency. By using these systems, you can keep motors working well, even in tough conditions.

Tip: Regular checks of vibration and frequency data can catch problems early. This saves time and money in the long run.

Knowing how vibration and frequency differ helps with motor choices. Vibration means shaking caused by imbalances in the motor. Frequency shows how many cycles happen each second. Both are important for motors to work well. Too much vibration can break parts. Wrong frequency settings can make motors less efficient.

To improve motor performance, check vibration levels often. Pick the right frequency for your motor's job. Use tools like vibration analyzers to find problems early. These actions help motors last longer and work better.

FAQ

What is the difference between vibration and frequency in motors?

Vibration means shaking caused by imbalances or outside forces. Frequency shows how many times this shaking happens each second. It is measured in hertz (Hz). Think of vibration as the movement and frequency as how fast it happens.

How can you reduce motor vibration?

To lower vibration, balance spinning parts and align components correctly. Lubricate bearings to keep them working smoothly. Regular checks can find loose parts or other problems. Tools like vibration analyzers help spot issues early so you can fix them quickly.

Why does frequency affect motor speed?

Frequency decides how often the motor’s magnetic field changes. Higher frequency makes the motor run faster. Lower frequency slows it down. Changing frequency helps match the motor’s speed to the job, making it work better and use less energy.

What tools help monitor vibration and frequency?

Tools like vibration analyzers and condition monitoring systems track motor health. Motor current signature analysis also finds problems. These tools collect live data to catch issues early and keep motors running well.

Can resonance damage a motor?

Yes, resonance makes vibration worse when natural frequency matches outside forces. This can break parts, cause overheating, and lower efficiency. You can stop resonance by strengthening parts or avoiding certain frequencies during use.

See Also

Understanding Frequency And Vibration For Enhanced Motor Efficiency

The Synergy Of Vibration And Frequency In Motor Precision

Managing Resonance Frequency In Vibration Motors For Dependability

Distinguishing Features Of Vibro Motors Versus Standard Types

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry