Vibration Motors: Types, Applications, and Working Principles

Vibration motors are important in the gadgets you use every day. They change electrical energy into vibrations, giving a touchable response. This makes using technology easier and more fun. For example, the soft buzz of a phone alert or the feel of a game controller is thanks to these motors.

The need for vibration motors is growing fast. In 2023, the market was worth $6.5 billion. By 2032, it might grow to $10.2 billion. This is because more people use smartphones, smartwatches, and other gadgets. Smaller sizes and better features in devices also help this trend. From home gadgets to work tools, vibration motors improve how we use technology.

Key Takeaways

Vibration motors make devices better by giving touch feedback.

Picking the right motor, like Linear Resonant Actuators or Brushless Coin Motors, depends on your device's size and power.

These motors are important in many fields, like making cars safer and helping medical tools work better.

Knowing things like how fast and strong the motor vibrates helps you choose the right one for your device.

Think about how long the motor lasts to keep it reliable and save on fixing costs later.

Types of Vibration Motors

Knowing the types of vibration motors helps you pick the best one. Each type has special features and uses for certain devices. Let’s look at three common types of vibration motors.

Linear Resonant Actuators (LRA)

Linear Resonant Actuators (LRAs) are small and work efficiently. They act like tiny speakers, using magnets to make vibrations. These motors start quickly, in about 40 to 60 milliseconds. They create detailed vibrations, perfect for wearables and phones. For example, your smartwatch vibrating for a notification likely uses an LRA.

LRAs use less power, which is great for battery devices. They are also durable and last a long time, even with heavy use. This mix of efficiency and strength makes LRAs a favorite for modern gadgets.

Brushless Coin Vibration Motors

Brushless coin vibration motors are thin, small, and very efficient. They are used in tight spaces like fitness trackers and medical tools. Unlike older motors, they don’t have brushes that wear out. This makes them last longer and need less fixing.

These motors are quiet, making them more enjoyable to use. They can also create custom vibrations for unique feedback. For instance, a fitness tracker might use one to alert you during exercise without noise.

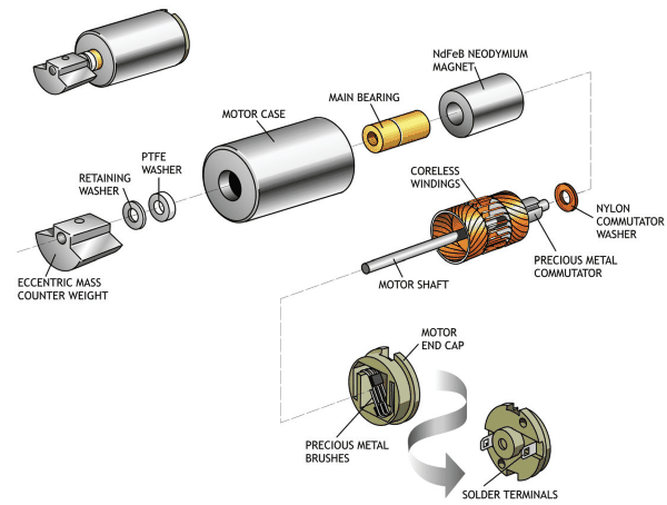

Coreless Vibration Motors

Coreless vibration motors, or pager motors, are light and tube-shaped. They respond fast and last a long time. These motors are great for gaming controllers and phones, where quick feedback matters.

Coreless motors work well with low power, around 2 to 5 volts. They make strong vibrations, improving the user experience. For example, the buzz during a game often comes from a coreless motor. Their small size and reliability make them popular in today’s electronics.

Metric | What It Means |

|---|---|

Frequency | How fast the motor vibrates. |

Amplitude | The strength of the vibration. |

Voltage | Works well between 2 to 5 volts. |

Current | Needs 50 to 100 milliamps to run. |

Longevity | Built to last and stay reliable. |

Noise Levels | Runs quietly for better user experience. |

By comparing these motors, you see their strengths. Whether you need precision, strength, or small size, there’s a motor for you.

Coin vibration motor

Coin vibration motors, also called pancake motors, are small and powerful. They work well in tiny devices like smartwatches, phones, and tools. Their flat shape fits easily into small gadgets without losing performance.

These motors come in three main types: ERM, LRA, and BLDC. ERM motors are simple and affordable. LRA motors give accurate vibrations for better feedback. BLDC motors last longer because they don’t have brushes.

Coin motors have special features that make them stand out. Here’s a table to compare them with other motors:

Feature | Coin Vibration Motors | Other Vibration Motors |

|---|---|---|

Types | ERM, LRA, BLDC | Usually brush type |

Size | 8mm and 10mm diameter | Changes based on type |

Connection | FPC terminals for easy assembly | Standard connections |

Lifetime | Up to 1 million cycles for BLDC | Often shorter |

Applications | Wearables, phones, scanners | Depends on motor type |

Power Rating | Rated at 3V DC | Varies |

Noise Level | Quiet during use | Can be louder |

You’ll see these motors in fitness bands, medical tools, and game controllers. They use little power, so batteries last longer. They also give steady and adjustable vibrations. This improves how users feel alerts, from soft buzzes to stronger signals.

Tip: Pick a coin motor based on your device’s size and vibration needs. This helps it work better and keeps users happy.

Applications of Vibration Motors

Vibration motors are used in many industries to improve devices. They make gadgets easier and more fun to use. Below are some examples of how vibration motors are helpful.

Consumer Electronics (e.g., smartphones, gaming controllers)

Vibration motors make using electronics more enjoyable. They create haptic feedback, which helps you feel alerts or actions. For instance, your phone buzzing for a text is due to the motor. Gaming controllers also use these motors to mimic real-life sensations. You might feel a car rumble or a gun recoil during gameplay.

As phones and gaming devices get better, vibration motors improve too. Makers now use advanced types like linear resonant actuators (LRAs) and eccentric rotating mass (ERM) motors. LRAs give detailed vibrations, making games and alerts feel more real. This shows how important vibration motors are for modern electronics.

Automotive Industry (e.g., haptic feedback, seat vibration)

Cars use vibration motors to keep drivers safe and comfortable. For example, the steering wheel or seat vibrates if you drift out of your lane. This helps you react fast without needing to look away. Motors also confirm actions like gear changes or button presses, making driving less distracting.

Touchscreens in cars often use haptic feedback too. When you tap a virtual button, the motor vibrates to let you know it worked. This makes driving safer and easier by keeping your focus on the road.

Medical Devices (e.g., wearable health monitors)

Medical gadgets use vibration motors to help people stay healthy. Wearable monitors buzz to warn you about heart problems or remind you to take medicine. These gentle vibrations keep you informed without being annoying.

Small and efficient motors are perfect for medical tools. They use little power, so batteries last longer. They also give accurate feedback, making health monitors easier to use and more dependable.

Note: Vibration motors are changing how we use electronics, cars, and medical tools. They make technology smarter and more user-friendly.

Wearables and IoT Devices

Wearables and IoT gadgets have changed how we use technology. These devices use vibration motors to give touchable feedback. This makes them easier and more fun to use. For example, a fitness band might buzz to remind you to move. It can also alert you about your heart rate. Smartwatches vibrate to notify you of calls or texts quietly.

The need for vibration motors in wearables keeps growing. Better haptic feedback and linear motors help this trend. Linear motors work well in small devices and give stronger vibrations. The rise of 5G also improves these gadgets. It allows faster and more accurate feedback. Below is a table showing key trends in this market:

Trend Description | Effect on Market Growth |

|---|---|

More demand for haptic feedback technology | Adds vibration motors to more devices |

Switch from old motors to linear motors | Boosts efficiency and performance |

New uses in different industries | Creates new markets for vibration motors |

Advanced tech like 5G | Improves haptic feedback adoption |

These trends show why vibration motors are important for wearables and IoT devices. Whether it’s a buzz on your wrist or a smart home alert, these motors make gadgets better and easier to use.

Industrial Applications (e.g., conveyors, vibrating screens)

In factories, vibration motors help machines work better and faster. They power tools like conveyors and vibrating screens. These machines are used in mining, building, and manufacturing industries.

Vibrating screens separate materials by size using vibrations. Their success depends on screen angle, length, and material condition. Fixing these factors can bring big benefits, such as:

Lower costs and fewer emissions.

Better material quality and less upkeep needed.

Conveyors also use vibration motors to move materials smoothly. This stops blockages and boosts productivity. Adding vibration motors to these machines helps industries save time and money.

Vibration motors are key in industrial work. They make machines more reliable and efficient, which is vital in tough environments.

How Vibration Motors Work

Knowing how vibration motors work helps you pick the right one. Each motor type works differently and has special uses.

How ERM Motors Work

Eccentric Rotating Mass (ERM) motors vibrate by spinning an uneven weight. When the motor spins, the weight creates a force that makes it shake. This simple design makes ERM motors cheap and dependable.

ERM motors work well with 3V power. They give steady speed and strength for smooth use. For example, a 9K RPM motor spins at 9000 RPM, uses 85mA, and vibrates at 0.80 GRMS. A 10K RPM motor is stronger, vibrating at 0.91 GRMS. These features make ERM motors great for phones and wearables.

Motor Type | Voltage | Max Current | Speed | Vibration Strength |

|---|---|---|---|---|

ERM Motor 9K RPM | 3VDC | 85mA | 9000RPM | 0.80GRMS |

ERM Motor 10K RPM | 3VDC | 100mA | 10000RPM | 0.91GRMS |

ERM motors are also tough. Careful design ensures they last, even in tough conditions.

How LRA Motors Work

Linear Resonant Actuators (LRAs) work differently. They use magnets to move a weight back and forth. This creates exact vibrations, perfect for detailed feedback.

LRAs work best in a small frequency range, saving power. They start fast, in 5-10 milliseconds, compared to ERM motors’ 20-50 milliseconds. This quick start improves user experience in gadgets like smartwatches. For example, Apple uses LRAs in its Taptic Engine for smooth vibrations in iPhones and Apple Watches.

LRAs need an AC signal to work, which makes them harder to set up than ERMs. But their ability to create complex vibrations makes them popular in modern devices.

How Brushless DC Motors Work

Brushless DC (BLDC) motors use electronics instead of brushes to work. This design reduces wear and lasts longer. BLDC motors are quiet and efficient, making them great for places where noise matters.

Feature | Brushless DC Motors | Brushed DC Motors |

|---|---|---|

Commutation | Uses electronic controls | Uses brushes and commutators |

Wear and Maintenance | Low wear, little upkeep needed | High wear, needs repairs |

Noise and Vibration | Quiet and smooth | Noisy with sparks |

Control Mechanism | Easy to control | Harder to control |

Efficiency | High and long-lasting | Lower and wears out faster |

BLDC motors also let you control vibration strength and speed better. They are efficient and use less power, making them ideal for medical tools and fitness trackers.

How INEED Coin Vibration Motors Work

INEED coin vibration motors give accurate and steady vibrations in small gadgets. They use an Eccentric Rotating Mass (ERM) system. This means a spinning off-center weight creates vibrations. These vibrations provide smooth feedback, making devices easier to use.

Main Features of INEED Coin Vibration Motors

Small Size: These motors are flat and tiny, perfect for smartwatches and trackers.

Low Power Use: They run on just 3V DC, saving battery life.

Customizable Design: You can adjust wires, connectors, or mounts to fit your gadget.

Long-Lasting: They can work for up to 1 million cycles.

Did You Know?

INEED coin vibration motors can spin up to 10,000 RPM. This gives strong and steady vibrations for many uses.

How They Function

When powered, the motor spins its off-center weight. This spinning makes vibrations you can feel. The motor’s flat design fits easily into small gadgets. It also has a sticky back for quick and secure setup.

Specification | Details |

|---|---|

Diameter | 7mm to 12mm |

Rated Voltage | 3V DC |

Speed | 8,000 to 11,000 RPM |

Vibration Force | 0.40G to 1.5G |

These motors are great for wearables, medical tools, and portable devices. They are quiet and can be customized, making them popular with makers. Choosing INEED coin vibration motors ensures your gadget gives reliable and efficient feedback.

Tip: Always check the motor's specs to match your gadget’s needs for the best results.

How to Pick the Best Vibration Motor

Choosing the right vibration motor helps your device work well. Think about size, power, and how it vibrates to make the best choice.

Size and Shape

The motor’s size affects how it fits and works in your device. Small motors, like NEMA 8, fit tiny gadgets but have less power. Bigger motors, like NEMA 23 or NEMA 34, are stronger and used in heavy machines.

NEMA Size | What It’s Good For | Power Level |

|---|---|---|

NEMA 8 | Fits small gadgets, low power | Low |

NEMA 17 | Medium size, more power | Very High |

NEMA 34 | Strong for big machines | Extremely High |

Pick a motor that fits your device’s size and power needs. For example, small gadgets like wearables need tiny motors. Big machines need larger, stronger motors.

Tip: Match the motor’s size to your gadget to avoid problems.

Power Needs

Knowing how much power a motor uses is important. Motors like brushless DC (BLDC) ones use less power and last longer. These are great for battery gadgets.

Motor Type | Features | Power Use |

|---|---|---|

BLDC ERM | Saves power, lasts long | Low, good for wearables |

Induction Motors | Reliable, works without syncing | Power depends on speed |

Low-power motors help batteries last longer in portable gadgets. For factories, pick motors that use power steadily for long hours.

Vibration Strength and Speed

How strong and fast a motor vibrates affects its use. Faster vibrations feel smoother, while strength changes how noticeable they are.

Motor Type | Strength Range | Speed Range |

|---|---|---|

Brushed ERM | 0.25G ~ 150G | 30Hz ~ 500Hz |

LRA | 0.75G ~ 2G | 150Hz ~ 205Hz |

For example, LRAs give soft, precise vibrations, great for phones. Brushed ERMs are stronger, better for tools. Always match the motor’s vibration to your device’s job.

Note: Weather like heat or moisture can change how motors work. Pick motors made for those conditions to keep them reliable.

Cost Considerations

When picking a vibration motor, cost matters a lot. You need to find the right mix of performance, durability, and price. Think about the motor type first. For example, coin vibration motors are cheap and work well in small gadgets like wearables. But brushless DC motors cost more and last longer, making them better for expensive devices.

Buying in bulk can lower costs. If you only need a few motors for testing, they might cost more. Custom features like special wires or mounts can also raise the price. These changes make sure the motor fits your gadget perfectly.

Tip: Compare how long a motor lasts and how efficient it is with its price. Spending a bit more now can save money later by avoiding repairs or replacements.

Environmental Factors (e.g., temperature, durability)

The environment affects how well a vibration motor works. Motors must handle heat, cold, or moisture depending on where they’re used. Outdoor gadgets need motors that resist extreme weather. Medical tools may need motors that work well in damp conditions.

Durability tests check how motors perform in real life. Thermal cycling tests how materials react to temperature changes. Vibration tests simulate the stress motors face during use. These tests find weak spots, predict lifespan, and improve designs.

Important Tests for Durability:

Thermal cycling checks material strength and electrical performance.

Vibration testing ensures motors last under tough conditions.

Temperature cycling finds weak areas and estimates lifespan.

Note: Picking a motor tested for durability ensures it works well, even in harsh conditions. This is crucial for industries like automotive or manufacturing, where failures can be expensive.

By thinking about cost and environment, you can choose a motor that fits your budget and works reliably.

Key Performance Metrics for Vibration Motors

Knowing the key performance metrics of a vibration motor helps you decide if it’s right for your device. These include frequency, amplitude, and power use. Each one affects how well the motor works.

Frequency

Frequency shows how fast the motor vibrates, measured in Hertz (Hz). It affects how smooth or strong the vibration feels. Higher frequencies feel softer, while lower ones feel stronger. For example, 200 Hz feels smoother than 50 Hz.

Pick the frequency based on your device’s job. Wearables often need higher frequencies for gentle feedback. Industrial tools may need lower frequencies for stronger vibrations. Choosing the right frequency ensures the motor works as expected.

Amplitude

Amplitude is the strength of the vibration, measured in "G-force" (G). Higher amplitudes give stronger vibrations, great for gaming controllers or heavy tools. Lower amplitudes are better for delicate devices like fitness trackers or medical tools.

For instance, a motor with 0.75 Gpk gives soft feedback, perfect for wearables. Stronger amplitudes make gaming or industrial tools more engaging. Picking the right amplitude ensures the vibration matches the device’s purpose.

Power Consumption

Power use is important, especially for battery gadgets. Motors that use less power help batteries last longer. Most motors use 9 mA to 25 mA at 3 Vdc, which equals about 27 mW. This makes them great for portable devices like smartwatches.

Using less power also keeps the motor cooler, helping it last longer. Check the motor’s energy needs to balance performance and efficiency. This ensures your device works well without wasting power.

Tip: Always review the motor’s frequency, amplitude, and power use to ensure it fits your device’s needs.

Durability and Lifespan

Durability and lifespan are key when picking a motor. These factors show how long it works well and handles wear.

A motor's durability depends on its build, materials, and use. Motors with strong parts last longer in tough conditions. Brushless motors, like those in wearables, last longer than brushed ones. They have fewer parts that can break, making them great for reliable devices.

Motor lifespan is measured in cycles or hours of use. For example, some coin motors last up to 1 million cycles. This means they can work often without failing. But things like heat, moisture, and dust can shorten their life. Picking a motor made for certain environments keeps it dependable.

Taking care of motors helps them last longer. Cleaning and checking them stops problems like overheating. In factories, motors are tested to handle real-world conditions. These tests find weak spots and help improve designs.

When choosing a motor, think about its durability and lifespan. A good motor makes your device work better and avoids frequent replacements. This saves both time and money over time.

Learning about vibration motors helps you pick the best one. These motors make gadgets like phones and tools work better. Choosing the right motor depends on size, power, and vibration strength. You should also think about how durable it is and where it will be used.

Here’s a simple table of key performance metrics to help you decide:

Metric | What It Means |

|---|---|

Accelerance | How fast something moves when a force is applied. |

Mobility | How quickly something moves compared to the force applied. |

Dynamic Stiffness | The force needed to move something a certain distance. |

VC Curves | Vibration levels that show how sensitive a device is. |

NIST-A Criterion | A new standard for very sensitive tools in nanotechnology. |

If you need strong and flexible options, check out INEED’s vibration motors. Their smart designs help devices work well and keep users happy.

FAQ

What does a vibration motor do?

A vibration motor makes vibrations to give touchable feedback or alerts. They are used in gadgets like phones, smartwatches, and game controllers. These motors make using devices easier and more fun by adding physical feelings.

How can I pick the right vibration motor?

Think about size, power, and vibration strength. Small gadgets like smartwatches need tiny motors. Bigger tools need stronger ones. Check details like voltage and vibration strength to match your device’s needs.

Can vibration motors be made to fit my device?

Yes, vibration motors can be adjusted for your gadget. You can change things like wire length, connectors, or how they are mounted. These changes help the motor fit perfectly and work well in your device.

How long do vibration motors usually last?

Most vibration motors can work for hundreds of thousands to over a million cycles. For example, INEED coin motors can last up to 1 million cycles. This makes them reliable for a long time.

Do vibration motors save energy?

Yes, many modern motors, like LRAs and brushless coin motors, use very little power. This makes them great for battery gadgets like fitness trackers. They help batteries last longer while still working well.

Tip: Always check how much power the motor uses. This helps balance energy saving and good performance in your gadget.

See Also

A Comprehensive Overview of Vibration Motors and Their Uses

Understanding How Vibration Motors Are Used in Industries Today

The Functionality of Vibration Motors in Haptic Technology

Battery-Powered Motors: Types and Uses in Vibration Systems

Understanding 3V Motors: Uses and Selection Tips for ERM Systems

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry