The Complete Guide to Vibration Motors: Types, Applications, and Selection Criteria

A vibration motor is a tiny machine that changes electrical power into shaking movements. You can find these motors in things like phones, smartwatches, and game controllers. They help by giving touch feedback, making devices easier and more fun to use.

The need for vibration motors has grown a lot lately. For example:

The world market for these motors may grow from $10,253 million in 2025 to $43,318 million by 2035.

Phones and smart gadgets, which depend on these motors, push this growth.

With over 6.3 billion phone users globally, the demand for these parts keeps rising.

These motors make devices work better by giving accurate vibrations, creating a smooth user experience.

Key Takeaways

Vibration motors make devices better by giving touch feedback. Phones and smartwatches use them.

Pick the right motor for your needs: ERMs are cheap, LRAs are accurate, and brushless motors last longer.

Think about size, power, and environment when choosing a motor. This helps it work well.

Check and care for motors often to avoid problems. This makes them last longer and work better.

Companies like INEED let you customize motors. This helps them fit your device and work better.

Types of Vibration Motors

Knowing the types of vibration motors helps in choosing one. Each type has special features for different uses. Let’s look at the three main types of vibration motors.

Eccentric Rotating Mass (ERM) Motors

ERM motors are the most popular vibration motors. They vibrate by spinning a weight on the motor's shaft. This simple design makes them cheap and dependable. ERM motors are used in phones, game controllers, and cars.

In 2022, the ERM motor market was worth $4.5 billion. By 2030, it may grow to $7.2 billion, with a 7.5% yearly growth rate. North America led the market in 2022, holding 35% of the global share. This is due to car industry innovations. The Asia-Pacific region is also growing fast because of demand for small, efficient motors in gadgets.

Type of Vibration Motor | Market Segment Description |

|---|---|

Eccentric Rotating Mass |

Linear Resonant Actuators (LRA)

LRAs are precise and efficient motors. Unlike ERMs, LRAs use a magnetic weight and spring to vibrate. This design gives quick feedback without delay. They are great for wearables and phones needing detailed feedback.

The Internet of Things (IoT) has increased LRA demand. These motors are now in many smart devices, showing their flexibility. Research is improving their strength for tough conditions.

LRAs give accurate feedback, perfect for modern gadgets.

They use less power, ideal for battery-powered devices like smartwatches.

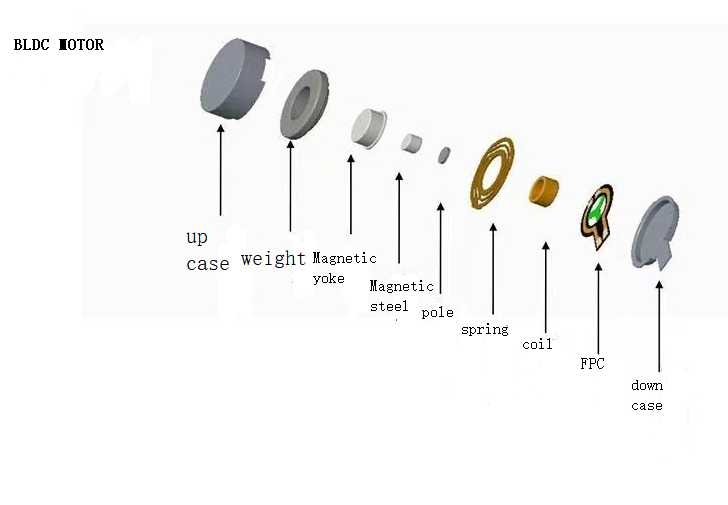

Brushless DC Vibration Motors

Brushless DC motors are newer than brushed motors. They last longer and work better because they don’t have brushes. These motors are used in industrial tools and high-end gadgets.

Coin brushless vibration motors are designed for devices that require vibration alarm or haptic feedback. Due to the low vibration force generated by small brushless vibration motor, they are ideal solution for lightweight devices, such as smart watches and other wearable devices.

Applications of Vibration Motors

Vibration motors are important in many industries. They improve how things work and make them easier to use. Let’s see how they help in gadgets, cars, and healthcare.

Consumer Electronics

Vibration motors are key in gadgets for touch feedback. They make devices vibrate for alerts, messages, and games. Phones, smartwatches, and game controllers depend on these motors.

Phones make up 40% of the market because of haptic systems.

DC motors lead with 60% of the market due to portable gadgets.

These motors make devices simple and fun to use. A smartwatch buzzing for a message or a controller shaking in a game shows their value.

Automotive Industry

Cars use vibration motors for safety and comfort. Driver assistance systems use them to warn about dangers. Electric cars and entertainment systems also use them for better interaction.

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | 1.2 | - |

2032 | 2.3 | 7.1 |

More electric cars and better car systems increase demand. These motors keep drivers alert and make driving safer and easier.

Medical Devices

In healthcare, vibration motors change how devices work. They help in surgery training by giving touch feedback. Health wearables use them to warn about health issues like heart problems.

Massage chairs and therapy tools use vibrations to relax muscles and ease pain. These uses show how vibration motors improve health care and training.

Wearable Technology

Wearable gadgets have changed how we use technology daily. From smartwatches to fitness bands, they are now must-have items. A small but important part of these devices is the vibration motor. It helps you stay updated without checking a screen.

Vibration motors in wearables give gentle and clear alerts. They notify you about calls, messages, or health updates. This feature makes using wearables easy and private. For example, a fitness band can buzz to remind you to move or celebrate your activity goals.

The wearable market has grown a lot recently. Small vibration motors are key to this growth. They give accurate feedback in tiny gadgets, making them essential. These motors use little power, so your device lasts longer. They also work quietly, keeping wearables sleek and simple.

Vibration motors do more than just send alerts. They help with health tracking too. For example, smartwatches vibrate to warn about unusual heart rates or other health issues. This makes wearables useful for staying healthy and informed.

As wearables improve, vibration motors will stay important. Their small size, low power use, and flexibility make them perfect for modern devices. Adding these motors helps create gadgets that are helpful and easy to use.

Vibration Motor Comparison Guide: Selection Criteria

Size and Form Factor

The size and shape of a motor are very important. The motor must fit your device without causing problems. Small motors, like coin motors, work well in slim gadgets like smartwatches. Bigger motors, like cylindrical ones, are better for tools needing more power.

The shape also affects how the motor is attached. Surface-mounted motors are easy to add to circuit boards. Motors with sticky backs can fit unusual designs. By thinking about size and shape, you can pick a motor that works for your device's needs.

Power Requirements

How much power a motor uses affects battery life. Low-power motors, like LRAs, are great for gadgets like smartwatches. They use little energy but still give strong vibrations. Brushed ERM motors need more power but work well for things like game controllers.

You should also check voltage and current needs. Motors using low voltage, like coreless motors, save energy and are good for portable devices. Knowing the power needs helps your motor work well without draining the battery.

Vibration Amplitude and Frequency

A motor's vibration strength and speed decide how well it works. Amplitude shows how strong the vibrations are. Frequency shows how fast they happen. Different devices need different levels of these features.

Motor Type | Vibration Strength Range | Vibration Speed Range |

|---|---|---|

Brushed ERM | 0.25G ~ 150G | 30Hz ~ 500Hz |

BLDC ERM | 1G ~ 30G | 200Hz ~ 208Hz |

LRA | 0.75G ~ 2G | 150Hz ~ 205Hz |

LRAs are great for steady and clear vibrations. Brushed ERM motors have a wide range of strength, making them useful for many tasks. BLDC ERM motors give smooth vibrations with less noise, perfect for reliable use. By checking strength and speed, you can find the right motor for your device.

Cost and Budget Considerations

When picking vibration motors, knowing costs and budgets is key. A motor's price depends on its type, size, and features. For instance, DC motors usually cost more than AC motors. But new manufacturing methods are lowering this price difference. If you want energy-saving motors, they may cost more at first. However, these motors save money over time by using less energy.

Eco-friendly choices also affect costs. Companies using green methods might spend more initially. Over time, these methods can boost their reputation and sales. For example, using eco-materials or energy-saving designs attracts eco-conscious buyers. While these options seem pricey at first, they often increase product value and customer trust.

To choose wisely, compare motor costs and benefits. Think about energy use and how long they last. A pricier motor that lasts longer can save money later. Here's a simple comparison to help:

Aspect | Details |

|---|---|

Cost Difference | DC motors cost more than AC motors. |

New Technology | Better manufacturing is lowering DC motor prices. |

Energy Savings | Eco-friendly designs cost more upfront but save later. |

By weighing upfront costs against long-term savings, you can pick a motor that fits your budget and needs.

Environmental Factors (e.g., temperature, humidity)

The environment affects how vibration motors work. Things like temperature and humidity can change their performance. If your device works in very hot or cold places, pick a motor made for those conditions. Some motors work well between -20°C and 70°C, making them reliable in tough weather.

Humidity is also important. Too much moisture can harm the motor's parts and cause it to fail. To avoid this, choose motors with protective coatings or sealed designs. These features keep water out and make the motor last longer.

Think about where the motor will be used. Outdoor devices need motors that handle temperature changes and water. Indoor devices may not need such strong protection. By matching the motor to its environment, you ensure it works well and lasts longer.

Tip: Always check the motor's specs for temperature and humidity limits. This ensures it works properly in your chosen setting.

Key Performance Metrics for Vibration Motors

Frequency and Amplitude

Frequency and amplitude show how well a motor vibrates. Frequency tells how fast it shakes, and amplitude shows its strength. Together, they decide how good the feedback feels.

Three main metrics help measure these:

Peak: The highest vibration strength over time.

RMS: The average vibration strength overall.

Crest Factor: Compares the strongest shake to the average.

Parameter | Description |

|---|---|

Peak | Shows the highest vibration strength during a set time. |

RMS | Average strength of vibrations, showing overall load. |

Crest Factor | Ratio of the strongest shake to the average strength. |

Different devices need different vibration styles. For example, LRAs give steady, soft shakes, while ERMs can vibrate stronger. Knowing these metrics helps you pick the right motor for your device.

Voltage and Current Requirements

Voltage and current decide how well a motor works. Most motors use 2 to 5 volts and need 50 to 100 milliamps.

Low-voltage motors, like LRAs, save energy and are great for gadgets with batteries. ERM motors use more power but vibrate harder. Always check your device's power supply to match the motor. This avoids problems and keeps the motor running smoothly.

Longevity and Durability

How long a motor lasts depends on its design and use. Testing and care can make it last longer. Tests like start-stop cycles and long-term use check its lifespan.

Regular checks are also important. Look for rust, wear, or loose parts. Keep track of normal vibrations to spot problems early. Fixing issues early stops bigger failures.

Brushless DC motors last longer because of their better design. Picking a durable motor ensures it works well, even in tough conditions.

Noise Levels

Think about noise when picking vibration motors. Noise affects how users feel, especially with wearables and phones. A quieter motor makes using devices more enjoyable. This is why noise is an important factor to consider.

Different motors make different amounts of noise. For example, iron shell motors are louder because of their design. Plastic motors are quieter, so they work well in devices needing less sound. Here's a simple comparison of the two:

Motor Type | Vibration Strength (m/s²) | Noise Reduction (dB(A)) | Vibration Pattern |

|---|---|---|---|

Iron Shell Motor | -5 | Stronger vibration in front and back | |

Plastic Motor | 0.22 | -4 | Even vibration in all directions |

The table shows plastic motors are quieter than iron shell ones. They also vibrate evenly, making them great for small gadgets like smartwatches.

How you attach the motor also matters for noise. Bad mounting can make vibrations louder. Using sticky mounts or surface-mounted designs can lower noise by stopping vibrations from spreading.

Choosing a quiet motor improves your device's quality. Whether it's a wearable or a handheld gadget, quieter motors make the experience better for users.

Integration Tips for Vibration Motors

Mounting Techniques

Mounting your vibration motor correctly helps it work well and last longer. There are different ways to mount motors based on your device's design. Coin motors often use adhesive backing, which sticks easily to flat surfaces. Surface-mounted motors are great for circuit boards because they save space and are simple to attach.

Make sure the motor is tightly secured to avoid extra noise or weak vibrations. If your device faces strong vibrations, use shock-absorbing materials. These materials protect the motor and make it last longer. Always follow the maker's instructions for the best results.

Driver Options and Circuit Design

The driver circuit controls how the motor works. Picking the right driver keeps the motor running smoothly. Small gadgets like wearables need low-power drivers to save energy while keeping vibrations strong. Bigger devices need stronger drivers for higher power.

Match the motor's voltage and current needs with the driver when designing the circuit. Too much power can harm parts, while too little power lowers performance. Smart systems, like predictive maintenance tools, can be added to the circuit. These tools check the motor's condition and warn you about problems, making it more efficient.

Testing and Calibration

Testing and calibration are key steps for setting up vibration motors. First, test the motor's vibration strength and speed. Use tools like accelerometers to measure these features. Compare the results to your device's needs to make sure they match.

Calibration adjusts the motor for better performance. Change the driver settings to get the right vibration level. Regular testing finds problems early and avoids expensive fixes. New methods focus on eco-friendly and energy-saving designs during testing. These practices improve the motor's reliability and help the environment.

Tip: Write down your testing and calibration steps. This keeps things organized and makes fixing problems easier later.

Maintenance and Troubleshooting

Taking care of vibration motors helps them last longer. Simple steps can keep them working well and avoid expensive fixes.

Maintenance Tips

Record Normal Vibration: Write down how the motor usually vibrates. This helps you notice problems later.

Regular Checks: Check vibrations often to find strange patterns early. Fixing small issues stops bigger problems.

Study Data: Look at vibration data to find problems like imbalance. This shows where to focus your repairs.

Fix Specific Issues: Use your findings to fix problems. Tighten loose screws or replace broken parts.

Improve Over Time: Learn from past repairs to make better maintenance plans. This keeps the motor dependable.

Troubleshooting Strategies

If the motor acts up, fixing it fast avoids delays. Here are common problems and how to solve them:

Strange Noise: Look for loose screws or worn-out parts. Tighten or replace them.

Weak Vibrations: Check the power source. Make sure the voltage is correct.

Gets Too Hot: See if the motor is working too hard. Lower the load or add airflow to cool it.

Shaky Vibrations: Check for dirt or misalignment. Clean the motor and adjust it to fix the issue.

Tip: Keep a record of all repairs and checks. This helps you spot patterns and improve the motor's performance.

By caring for and fixing your motor properly, it will work better and give steady, reliable vibrations.

Vibration Analysis and Control in INEED Vibration Motors

Why Vibration Analysis Matters

Vibration analysis is important for keeping motors working well. It checks how a motor vibrates to find problems like imbalance or wear. This helps fix issues early, saving time and money on repairs.

Watching vibration levels keeps motors running smoothly. Regular checks show changes in vibration patterns. For example, weaker vibrations might mean a part is worn out. Fixing these problems early makes motors last longer and work better.

Predictive maintenance depends on vibration analysis. It uses data to find problems before they happen. Repairs can be planned ahead, reducing downtime and keeping devices running smoothly.

How Control Systems Improve Performance

Good control systems help motors work their best. Position control keeps motors from overworking or underperforming. Smart algorithms, like the honey badger algorithm, improve motor settings. This makes vibrations more stable and consistent.

Real-time systems adjust motor settings based on current needs. For example, genetic algorithms can reduce extra vibrations and boost efficiency. These systems make motors last longer and perform better.

Evidence Description | Key Findings |

|---|---|

Real-time control optimization for PMSM systems | |

Fault suppression mechanism using honey badger algorithm | Faster results and steadier performance |

Genetic algorithm for vibration control in pressure reducers | 9.14% less center distance, improving performance |

INEED's Custom Vibration Motor Options

INEED makes motors you can customize for your needs. You can change vibration strength, speed, and how they are mounted. LRAs, for example, give quick responses and accurate feedback, perfect for touchscreens and games.

These motors work well in many conditions. Whether for wearables or tools, INEED motors are reliable. You can adjust their position and vibration style to fit your needs exactly.

Choosing INEED means getting high-quality motors that improve devices. Their focus on innovation and precision makes them a great choice for vibration motor solutions.

Knowing about the types, applications, and how to pick a vibration motor helps you choose the best one. Each kind has special advantages, like being precise, strong, or affordable. Understanding these details can make your device work better and feel easier to use.

INEED makes top-quality vibration motors for many needs. They offer dependable options for industries like wearables and healthcare. Check out INEED's products to find motors that are both efficient and easy to customize.

Tip: Visit INEED's website to see how their motors can improve your devices.

FAQ

What is a vibration motor, and how does it work?

A vibration motor is a small machine that makes things shake. It changes electricity into movement by spinning a weight or using magnets. These shakes help devices like phones, watches, and game controllers give feedback you can feel.

How do I choose the right vibration motor for my device?

Think about these points:

Size: Make sure it fits your gadget.

Power: Match the motor's needs to your device.

Vibration strength: Choose the right shake level and speed.

Environment: Check if it works in hot or wet places.

Tip: Always check the motor's details to ensure it fits.

Can vibration motors be customized for specific applications?

Yes, you can change vibration motors to fit your needs. You can adjust how strong they shake, how fast they move, and how they attach. For example, INEED makes motors for wearables, healthcare, and gadgets that match exact needs.

How long do vibration motors typically last?

How long they last depends on the type and use. Brushless motors last longer, often over 10,000 hours. Cleaning and checking them often can make them work even longer.

Are vibration motors energy-efficient?

Yes, many motors, like LRAs, use little power. They are great for battery gadgets because they last longer without using too much energy.

Note: Energy-saving motors may cost more at first but save money later.

See Also

Understanding 3V Motors: Uses, Features, And Selection Tips

Investigating How Vibration Motors Are Used Across Industries

The Ultimate Guide To Top Vibration Measurement Tools

Unveiling The Mechanism Behind 3V DC Motor Vibrations

LRA Vibration Motors: Key Elements For Haptic Feedback Technology

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry