How to Attach Vibration Motors Using Glue and Bracket Best Practices

You need to follow Vibration motor glue vs bracket mounting best practices to achieve secure motor mounting and reliable performance. Proper mounting ensures your vibration motor runs smoothly, reduces noise, and protects your device. Industry studies show that secure mounting minimizes wear on electronic parts, improves stability, and keeps your device safe. When you focus on mounting, you extend the life of your electronics and create a quieter environment. INEED offers a wide range of vibration motors, including coin, brushless, encapsulated, and coreless types, designed for easy mounting in many devices. Common mounting challenges include misalignment, poor foundation, imbalance, looseness, and wear. You can overcome these problems by checking alignment, using a strong base, ensuring balance, tightening all parts, and inspecting for wear. Mastering mounting techniques helps you get the best results from your vibration motor.

Key Takeaways

Securely mount your vibration motor to improve device performance and reduce noise.

Choose the right mounting method: use glue for compact devices and brackets for high-vibration environments.

Always prepare the surface before installation to ensure strong adhesive bonds.

Regularly inspect and maintain your vibration motor to extend its lifespan and prevent issues.

Consult INEED for expert support and a variety of vibration motor options tailored to your needs.

Vibration Motor Mounting Essentials

Why Proper Motor Mount Matters

You need to focus on vibration motor mounting to ensure your device works safely and efficiently. A secure motor mount keeps the motor stable, reduces unwanted noise, and prevents damage to other parts. When you use the right motor mounting hardware, you protect your electronics from early wear and tear. You also improve the overall performance of your device.

A proper motor mount helps you avoid common problems like misalignment, looseness, and imbalance. These issues can cause your device to fail or create extra noise. You should always check that your mounting is tight and balanced. This step will help you get the best results from your vibration motor mounting.

You will find vibration motor mounting in many industries. For example:

Automotive: You get intuitive feedback that makes driving safer and more comfortable.

Healthcare: You receive haptic feedback in medical devices, which improves how you use them.

Consumer Electronics: You enjoy better alerts and controls, making your experience smoother.

INEED Vibration Motor Features

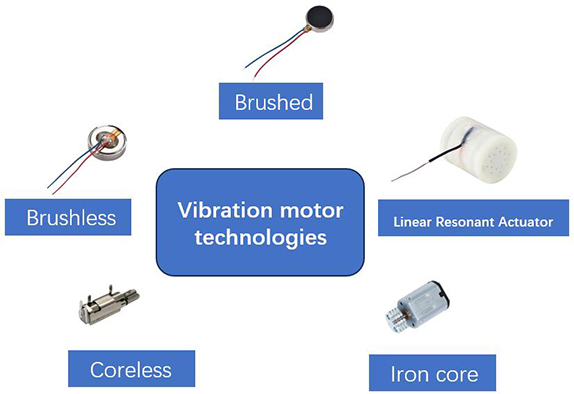

INEED offers a wide range of vibration motors, each designed for easy and reliable mounting. You can choose from coin vibration motors, brushless BLDC vibration motors, encapsulated vibration motors, and coreless vibration motors. Each type supports different mounting methods and motor mounting hardware, so you can match the right motor to your project.

Here is a quick look at the unique mounting options you get with INEED vibration motors:

Mounting Method | Description |

|---|---|

Sew into material | Lets you add motors to flexible wearables for comfort and usability. |

Injection-molded housing | Secures the motor inside your device for better stability and protection. |

Foam housing | Absorbs shocks and improves durability during use. |

Adhesives | Allows for quick and reliable mounting, making assembly easier. |

Waterproofing with potting compound | Keeps the motor working after moisture exposure, increasing its life. |

Recessed pocket mounting | Couples vibration energy with your device, improving feedback and reducing noise. |

Secure mounting | Prevents mechanical chatter and resonance, giving you high-quality feedback. |

You can trust INEED vibration motor mounting because each motor meets ISO 9001:2015 certification. INEED motors go through strict performance tests and comply with international standards. This focus on quality ensures your mounting stays reliable over time.

When you use INEED vibration motors, you benefit from a vibration-reducing design and flexible motor mounting hardware. You get the support you need for proper motor mount installation, no matter your application.

Vibration Motor Glue vs Bracket Mounting Best Practices

Choosing the Right Mounting Method

You need to select the best mounting method for your vibration motor based on your device’s requirements and environment. When you compare vibration motor glue vs bracket mounting best practices, you see clear differences in reliability and performance. Glue mounting uses adhesive pads for a simple and strong hold, which works well for low-vibration environments and compact devices. Bracket mounting provides a solid base for the motor, using durable materials to handle higher vibration levels and mechanical stress.

Here is a table to help you understand the differences:

Mounting Method | Characteristics | Reliability Implications |

|---|---|---|

Glue and Adhesive | Uses adhesive pads for a simple, strong hold—no extra mounting bracket needed. | May be less reliable under extreme vibrations or conditions. |

Bracket Mounting | Provides a solid, reliable base for the motor, made from durable materials. | Generally more reliable due to better vibration handling. |

If your application involves high-vibration environments, such as automotive or industrial machinery, you should choose bracket mounting. Adhesive mounting is not recommended for these situations because it can degrade over time. Bracket mounting, especially with screws and standoffs, offers better stability and long-term reliability. Vibration-resistant PCB mounting techniques also improve performance in tough conditions.

Selecting Glue and Bracket Materials

You must choose the right materials for both glue and mounting bracket to ensure a secure and lasting installation. For adhesives, you can use epoxy, cyanoacrylate (CA) glue, or 3M high-strength adhesives. Epoxy provides a strong bond and works well for most vibration motor glue vs bracket mounting best practices. CA glue cures quickly and is easy to apply, while 3M adhesives offer reliable performance for small motors.

When you select a mounting bracket, you need to consider the material’s strength and resistance to environmental factors. High-strength metals like stainless steel or aluminum provide rigid support and precise alignment. These materials help suppress vibration and extend the lifespan of your motor. Plastic brackets can work for lightweight applications, but you should check their durability. Modern mounting bracket designs allow for quick maintenance and integration with monitoring systems.

Here is a table showing how different bracket materials affect stability:

Aspect | Description |

|---|---|

Stable Support | High-strength materials provide rigid support, ensuring precise alignment and reducing mechanical losses. |

Vibration Suppression | Effective designs absorb vibration energy, extending the lifespan of motors and components. |

Adaptability to Conditions | Materials must resist corrosion and temperature variations, ensuring reliability in diverse environments. |

Modular Integration | Modern designs allow for quick maintenance and integration of monitoring systems, enhancing operational efficiency. |

Environmental factors like temperature and humidity also affect glue and mounting bracket performance. Higher temperatures speed up chemical reactions, making adhesives cure faster. Lower temperatures slow down the process. Humidity can change curing times depending on the adhesive type. Epoxy adhesives may lose strength in hot and wet conditions, so you need to understand how these factors interact over time.

Preparing for Motor Mount Installation

You need to prepare carefully before starting your vibration motor glue vs bracket mounting best practices. Begin by cleaning the mounting surface to remove dust, oil, and debris. This step helps adhesives bond better and ensures the mounting bracket sits flush against the device.

Tip: Always check the alignment of your vibration motor before final installation. Proper alignment reduces unwanted noise and improves vibration feedback.

Safety is important during installation. You should wear safety glasses to protect your eyes from dust and dirt. Use work gloves to shield your hands from sharp objects. If you use loud tools, employ ear protection. A dust mask helps when drilling into metal or concrete. Steel-toed boots protect your feet from heavy objects.

Environmental conditions play a role in installation success. If you work in a hot or humid area, adhesives may cure faster or slower. Plan your installation to match the adhesive’s requirements. For mounting bracket installation, make sure you use the right screws and tools for the bracket material. Tighten all fasteners securely to prevent loosening during vibration.

Follow these vibration motor glue vs bracket mounting best practices to achieve a secure and reliable mounting. You will improve your device’s performance and extend its lifespan.

Step-by-Step Vibration Motor Mounting

Surface Preparation and Adhesive Application

You start every mounting process by preparing the surface. Clean the area where you plan to attach the vibration motor. Remove dust, oil, and debris with a lint-free cloth and alcohol. This step helps adhesives bond tightly and prevents weak spots in your mounting.

Choose the right adhesive for your mounting needs. Epoxy, cyanoacrylate, and 3M high-strength adhesives work well for vibration motor mounting. Each adhesive has a specific curing time and handling strength. You must follow the manufacturer’s instructions to achieve a secure bond.

Here is a table showing how long different adhesives need to cure for maximum strength:

Adhesive Type | Handling Strength Time | Full Curing Time | Additional Notes |

|---|---|---|---|

Two-component epoxies | 10 minutes (at 80°C) | 60 minutes | Can be processed immediately after handling strength is achieved. |

SLOW-CURE™ | 8 hours | 24 hours | Bonded objects can be handled after 8 hours. |

Apply the adhesive evenly to the mounting surface. Press the vibration motor firmly into place. Make sure the motor sits flat and does not tilt. You avoid misalignment by checking the position before the adhesive sets. Allow the adhesive to cure fully before you move to the next step. Proper curing ensures your mounting stays strong and reliable.

Tip: Never rush the curing process. Waiting for the adhesive to reach full strength prevents early failures and keeps your mounting secure.

Bracket Installation and Alignment

Bracket mounting gives you extra stability for vibration motors, especially in high-vibration environments. Select a bracket that matches the size and shape of your motor frame. Use stainless steel or aluminum brackets for strong support. Plastic brackets work for lightweight applications but check their durability before mounting.

You need to focus on alignment during bracket installation. Misalignment can cause unwanted vibration and noise. Follow these best practices to ensure proper alignment:

Check the alignment of the motor and bracket during installation.

Monitor alignment regularly, especially if temperature changes occur.

Use precise measurement tools like dial indicators or laser alignment tools.

Train yourself or your technicians to spot misalignments, even minor ones.

Prefer laser alignment tools for accuracy and speed.

Secure the bracket with the correct screws and fasteners. Tighten each screw evenly to avoid shifting the motor. Double-check the alignment after mounting. You prevent mechanical losses and improve vibration feedback by keeping everything straight.

Note: Matching the bracket size to the motor frame is essential. A bracket that fits well reduces movement and keeps your mounting stable.

Curing and Stability Testing

After mounting and installing a motor mount, you must test the stability of your vibration motor. Begin by allowing adhesives to cure for the recommended time. Do not handle or move the motor until the adhesive reaches full strength.

Once curing is complete, conduct stability testing to ensure reliable vibration performance. Follow these steps:

Position accelerometers or sensors near the motor bearings. This helps you measure vibration speed accurately.

Collect vibration data in three directions: side to side, up and down, and along the shaft. You identify issues early by checking all axes.

Use FFT analysis to examine vibration frequency. This method detects problems like imbalance or misalignment.

If you notice excessive vibration or noise, inspect your mounting and alignment. Make adjustments as needed. INEED provides technical support and quality control to help you solve any mounting challenges. You can contact INEED for advice on installation, mounting hardware, and vibration troubleshooting.

Alert: Always allow adhesives to cure fully before testing. Early testing can weaken the bond and reduce mounting reliability.

You improve device performance and extend motor life by following these step-by-step mounting practices. INEED’s commitment to quality ensures you get reliable results every time you mount a vibration motor.

Troubleshooting Motor Mount Issues

Adhesion and Alignment Problems

You may face adhesion problems after mounting your vibration motor. Weak adhesive bonds often result from dynamic loads, heat, or chemical exposure. If you see metal peeling off rubber mounts, this points to a bond issue. For strong mounting, the rubber should tear before the adhesive fails. Always check for cracks, corrosion, or warps on the motor mount. These signs show excessive wear and can affect vibration isolation.

Cause of Failure | Description |

|---|---|

Dynamic Loads | Large dynamic loads and deflections can compromise adhesion over time, potentially leading to separation from the rubber mount. |

Misalignment during mounting creates internal stress and friction. This can lead to bearing failure, increased wear, and overheating. You should always check alignment before and after mounting. A slightly tilted motor or engine can cause excess vibration sounds and breakdowns.

Tip: Inspect mounting regularly for visual wear and engine play. Early detection helps maintain vibration isolation and prevents costly repairs.

Vibration Performance and Noise

Excessive vibration or noise signals a mounting problem. You should verify wiring between the power supply, capacitor, and motor. Make sure the input voltage matches the motor’s specifications. Inspect bearings for damage or wear. Proper mounting and gearhead installation are essential for vibration isolation.

Check bearing lubrication and replace grease if needed.

Inspect for bearing clearance and replace if you find excessive play.

Ensure the motor shaft is straight and not misaligned.

Noise can come from mechanical issues like bearing wear or loose mounting. Electromagnetic noise may result from uneven current distribution. Aerodynamic noise happens during high-speed rotation. You can reduce vibration and noise by maintaining correct mounting and using vibration isolation techniques.

Maintenance Tips for INEED Motors

You extend the life of your INEED vibration motors by following a regular maintenance routine. Inspect mounting and motor parts every three months. Tighten all parts to avoid sudden problems. Replace old wires and connectors to prevent electrical issues. Test vibration levels regularly to catch noise problems early.

Maintenance Routine | Explanation |

|---|---|

Helps identify potential issues before they lead to failures. | |

Part replacements | Timely replacement of worn parts prevents breakdowns and maintains efficiency. |

Lubrication | Regular lubrication of bearings extends their life and ensures smooth operation. |

Monitoring motor conditions | Keeping track of vibrations and temperature helps in early detection of problems. |

Note: Consistent maintenance and proper mounting keep your vibration isolation effective and your device running smoothly.

You improve device performance when you follow best practices for vibration motor mounting. Use adhesive mounting when drilling is not possible. Cementing pads help you achieve high frequency vibration characteristics. Always select adhesives that offer long-term reliability. Prepare the mounting surface by removing paint and debris, then grind it flat before applying adhesive. Choose mounting methods that match your vibration needs and device environment.

You benefit from INEED’s technical support and product range. The table below shows how INEED helps you with mounting and vibration solutions:

Advantage | Description |

|---|---|

Inquiry and consulting support | You get help understanding your mounting needs. |

Sample testing support | You test vibration products before buying. |

After-Sales Service | You learn mounting and vibration installation. |

Engineers available overseas | You receive on-site mounting support. |

You should follow the step-by-step mounting guide for reliable vibration results. Consult INEED for customized mounting solutions. Explore INEED’s vibration motor offerings to find the best mounting options for your next project.

FAQ

What is the main purpose of a vibration motor?

You use a vibration motor to create movement or feedback in your device. This helps you feel alerts, notifications, or signals. Vibration motors improve user experience in phones, wearables, and medical devices.

How do you choose the right vibration motor for your project?

You should consider the size, power, and type of vibration needed. Think about your device’s space and how strong you want the vibration to feel. INEED offers many options for different needs.

Can you use glue for mounting vibration motors in all devices?

You can use glue for mounting in many small devices. However, strong vibration or harsh environments may require brackets. Always check your device’s needs before choosing the best method.

Why does my device make extra noise during vibration?

Extra noise often means the vibration motor is not aligned or secured well. You should check the mounting and make sure the motor sits flat. Proper installation reduces unwanted vibration sounds.

How do you maintain a vibration motor for long life?

You should inspect your vibration motor every few months. Clean dust, check wires, and listen for odd sounds. Regular care keeps vibration strong and your device working well.

See Also

Identifying and Minimizing Vibration in Motor Mounts

Ten Strategies for Managing Noise and Vibration in Small Motors

Five Simple Steps to Excel with Arduino Vibration Motors

Advantages and Disadvantages of 12V Vibration Motors for Medium Power

Comprehensive Overview of SMD Vibration Motors for Engineers

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry