Frequency Vibration Fundamentals: Engineering Principles for Coin Vibration Motor Design

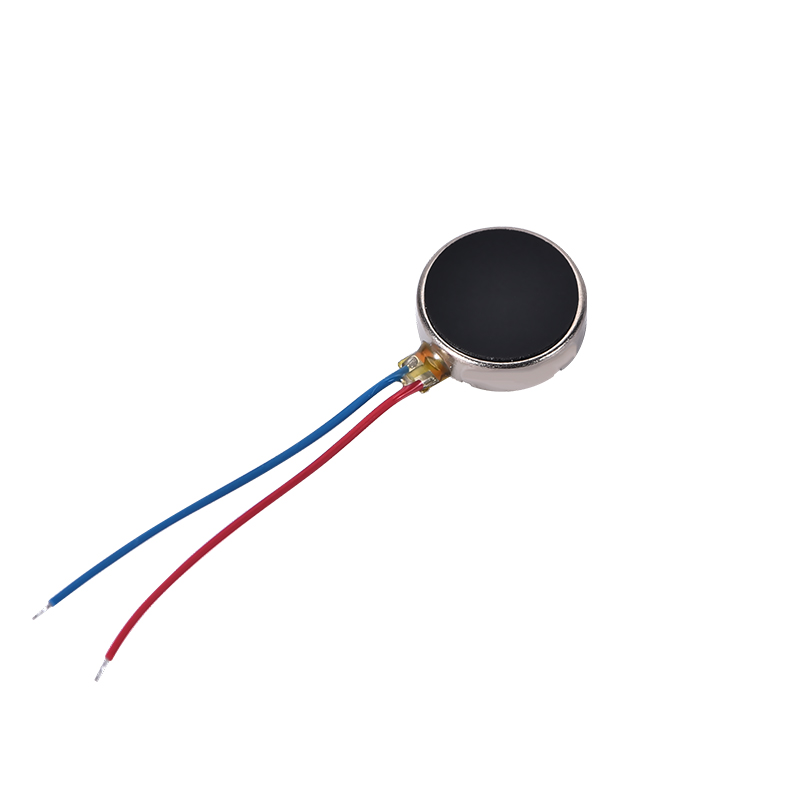

Frequency vibration is a key aspect of vibration fundamentals that is crucial for coin vibration motor design. It significantly influences how effectively these motors provide feedback in devices such as wearables and smartphones. For instance, a frequency of 175 Hz combined with a force of 1.50 Grms delivers robust feedback. These motors are compact, measuring approximately 10 mm in diameter and 3.6 mm in thickness. They operate efficiently with a voltage of 2.0 Vac RMS. Understanding vibration fundamentals enhances motor efficiency, ensuring accurate and reliable performance in small devices.

Key Takeaways

Knowing how fast and strong vibrations are is important. It helps design motors that give clear and steady feedback.

Picking the right materials affects how well motors work. Light materials save energy, and strong metals make them last longer.

Changing how fast a motor vibrates is very important. Engineers test speeds to make sure motors work well without wasting power.

Coin motors make devices like watches and phones more fun to use. They give touch feedback, making actions feel real and exciting.

INEED makes coin motors that can be customized for needs. They focus on quality to ensure the motors work well in many devices.

Understanding Vibration Basics in Motor Design

Main Ideas: Vibration Speed, Strength, and Matching Frequencies

Vibration basics focus on three main ideas: speed, strength, and matching frequencies. Vibration speed means how many times something shakes in one second, measured in Hertz (Hz). For coin motors, this speed shows how fast they vibrate, which affects how they feel to touch. Strength, or amplitude, shows how strong the shaking is. Stronger shaking is needed for things like phones or game controllers to feel noticeable.

Matching frequencies, or resonance, happens when the shaking speed matches the motor's natural speed. This makes the shaking the strongest, which can help or harm the motor if not managed. For coin motors, knowing these matching speeds helps avoid damage and keeps them working well. Studies on tiny spinning parts show how small changes in design can improve motor performance, proving how important it is to study vibrations carefully.

How Speed Affects Coin Motor Work

How well coin motors work depends a lot on their shaking speed. The right speed makes sure the motor gives steady and clear feedback. For example, a coin LRA motors shaking at 240 ± 10 Hz with 1.2 V power create a strength of 0.7 G, working well in small gadgets. Faster motor spinning means faster shaking.

Shaking speed also helps motors give accurate feedback. Devices like fitness trackers and medical tools need exact vibrations to work well for users. By setting the right speed, designers make sure motors save power while working efficiently. This is very important for portable gadgets that need long battery life.

How Vibration Improves User Experience

Vibration makes using devices easier and more fun. Motors that vibrate give touch feedback, making interactions feel real. Phones use vibrations for alerts, and game controllers use them to make games more exciting. People want more of this touch feedback in electronics because it improves how devices feel.

Flat coin motors are great for giving clear touch feedback. They are small and shake precisely, making them perfect for tablets and fitness trackers. More advanced touch systems are being added to these devices to make them even better. Besides electronics, cars and healthcare tools also use vibration to work better and make users happy. These motors are useful in many ways, making them important in today’s tech world.

Engineering Principles for Coin Vibration Motors by INEED

Choosing Materials and Their Impact on Vibration

Picking the right materials is key for motor efficiency. Materials affect how the motor vibrates, lasts, and performs. Lightweight materials like aluminum and plastic make motors lighter and run smoother. Strong metals like stainless steel last longer, especially in parts that wear out.

Standards for materials help motors work the same every time.

These details show how materials affect motor performance. For instance, the shaft end play keeps the motor running smoothly. Tolerance levels ensure accuracy even at high speeds. Picking the right materials helps motors vibrate better and last longer.

Improving Frequency in Motor Design

Getting the frequency right is important for motor performance. The motor’s frequency must give steady feedback without wasting energy. Engineers test different frequencies to find the best one for each use.

Studies show how frequency affects touch feedback. For example, a test device with a feedback system worked better. The results are shown below:

Evidence Description | Key Findings |

|---|---|

A haptic device with a new feedback system was tested. | Normal feedback had fewer errors and worked better than no feedback. |

The feedback used frequencies from 5 Hz to 100 Hz. | 5 Hz was the lowest for sending info, and 100 Hz was the highest. |

Users controlled a virtual wrist tool with the feedback system. | Users hit targets fast without knowing the starting point. |

These findings show why picking the right frequency matters. For small motors, 5 Hz to 100 Hz works best for feedback. Adjusting the frequency makes motors respond better and reduces mistakes in gadgets like wearables and medical tools.

INEED's Custom Coin Vibration Motors

INEED Electronics makes coin motors you can customize for different needs. You can change things like wire length, connectors, and vibration styles. This makes it easy to use these motors in small devices like fitness trackers and phones.

INEED focuses on accuracy and flexibility. Their motors are designed to vibrate strongly but use little energy. They have advanced parts to work well even in tough conditions. For example, they can spin up to 10,000 RPM and give steady feedback for many uses.

You can also adjust how much and how fast the motor vibrates. This lets you match the motor to what users want, making devices feel better to use. INEED ensures every motor meets high standards, giving you strong and efficient options for your projects.

Practical Uses of Coin Vibration Motors

Touch Feedback in Wearables and Phones

Coin vibration motors make devices easier and more fun to use. They give touch feedback, helping users feel alerts and actions. For example, fitness trackers vibrate to show activity goals. Phones use them for quiet alerts. These small motors fit well in tiny gadgets without losing power.

A study showed how these motors help wearables work better. Five motors were used in a system, shaking at 10 to 55 Hz. They were placed 2 cm apart to create different vibration patterns. The table below shows the details:

Feature | Details |

|---|---|

Number of Motors | Five |

Frequency Range | 10 to 55 Hz |

Distance Between Motors | 2 cm |

Application | Used in a motion capturing system for enhancing user interaction in wearables |

Purpose of Multiple Motors | To create diverse vibrotactile patterns for user experiments |

This study proves that vibration motors make wearables more useful and fun to use.

Healthcare and Medical Device Uses

In healthcare, vibration motors make medical tools easier to use. They give clear feedback in devices like insulin pumps. For example, they vibrate to tell patients when a task is done. Their small size and custom features make them perfect for accurate tools.

These motors also help in therapy. Therapy devices use vibrations to move muscles and improve blood flow. Their special design keeps them working well, even in tough conditions. Adding these motors makes medical tools more helpful and user-friendly.

Use in Factories and Electronics

Vibration motors are also used in factories and electronics. In factories, they power tables that shake to sort or pack materials. These motors are strong and last long under heavy use. In electronics, they make gaming controllers more exciting by adding shaking effects.

The market for these motors is growing fast. It was worth $2.5 billion in 2022 and may reach $5.7 billion by 2033. This growth shows how more gadgets like phones and wearables are using these motors. The market is expected to grow 7.5% yearly from 2023 to 2030, showing how important these motors are becoming.

Overcoming Challenges in Vibration Motor Design

Fixing Frequency Problems

Getting the right frequency is very important for vibration motors. The motor needs to vibrate at the correct speed to work well. If the frequency is wrong, the motor might vibrate too weakly or waste energy. Engineers often struggle to balance these issues, especially for small devices like smartwatches or phones.

To fix this, advanced systems can adjust the motor's frequency. These systems help match the motor's vibrations to what the device needs. For example, medical tools might need slow, soft vibrations, while game controllers need fast, strong ones. Testing is very important. By testing a lot, engineers can find the best frequency for the motor to work well in real life.

Making Motors Stronger and More Efficient

Motors need to last long and work well. To do this, designers should use strong materials like stainless steel or tough plastics. These materials help the motor handle wear and tear over time.

Another way to improve motors is by using special techniques to block outside forces. This helps the motor last longer. Also, good vibration systems can save energy, making the motor more efficient. Regular checks and fixes keep the motor working its best and meeting quality standards.

INEED's Testing and Quality Checks

INEED makes sure its motors are reliable by doing many tests. Each motor goes through checks for materials, performance, and durability. These tests include making sure the motor vibrates steadily and lasts under tough conditions.

INEED’s motors are trustworthy because of these careful tests. For example, they test how well the motor blocks outside vibrations to keep it running smoothly. They also use advanced systems to fine-tune how the motor works. By focusing on testing and quality, INEED creates motors that are strong, efficient, and built to last.

Knowing how frequency vibrations work is key to making good coin motors. These ideas help motors give accurate feedback, improving how devices work. INEED's smart designs and custom options let you build motors for your needs. Their focus on top quality and new ideas makes their motors work well in many devices.

Want better designs? Check out INEED's vibration motors now for great performance and dependability.

FAQ

How long does a coin vibration motor last?

A coin vibration motor can work for 864,000 cycles. This equals 72 hours of nonstop use. Its lifespan depends on how well it is cared for. INEED makes sure their motors are high-quality and last a long time.

Can coin vibration motors be changed for specific devices?

Yes, coin vibration motors can be adjusted to match your device. You can change wire length, connectors, or how strong they vibrate. INEED offers custom options for wearables, medical tools, and other small gadgets.

How do coin vibration motors improve user experience?

Coin vibration motors give touch feedback to make devices easier to use. For example, they vibrate for phone alerts or fitness tracker goals. This feedback makes devices more fun and helpful for users.

What voltage do coin vibration motors use?

Most coin vibration motors run on 3V DC power. Some can start at 2.3V. This low power use saves energy, making them great for portable devices like phones and wearables.

Can coin vibration motors handle tough conditions?

Yes, coin vibration motors are built to work in hard environments. Their closed design keeps out dust and water. INEED tests them carefully to ensure they last in medical tools and factory machines.

See Also

Exploring Vibration Motors: Varieties, Uses, And How They Work

Understanding Frequency And Vibration For Enhanced Motor Efficiency

Unveiling The Mechanism Of Vibration In 3V DC Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry