How Vibrating Equipment Transforms Everyday Industries

Vibrating machines, integral to various vibrating equipment applications, use vibrations to move, sort, or separate items. These machines create specific vibration patterns to achieve desired results, helping materials flow better or separate more efficiently. Engineers study vibration energy using special graphs to identify the best frequencies for different vibrating equipment applications. Short tests with many variables mimic real-life conditions, ensuring the machines operate effectively in challenging environments like factories or aerospace.

Vibrating machines are crucial for making work easier and faster across numerous vibrating equipment applications. They reduce manual labor, save time, and enhance accuracy. These machines are transforming industries with innovative ideas and improved performance.

Key Takeaways

Vibrating machines help by moving, sorting, and packing items fast.

They save time and cut down on hard manual work.

Smart tech in these machines makes them more accurate.

They can also tell when repairs are needed, stopping breakdowns.

Different vibrating tools, like screens and feeders, do special jobs.

These tools are useful and can work in many industries.

Vibration isolation keeps machines safe and working correctly.

It helps machines last longer and keeps workers safe.

Buying vibrating machines saves money by using less energy.

They also reduce waste and help make more products quickly.

Understanding Vibrating Equipment

What is Vibrating Equipment?

Vibrating equipment includes machines that use vibrations for tasks. These machines move, sort, or separate materials quickly and precisely. They are used in industries where speed and accuracy matter. For example, vibrating screens sort items by size, while vibrating feeders keep materials flowing steadily in factories. Adjusting vibration strength and speed makes these machines useful for many jobs.

New technology has made vibrating equipment even better. Automation helps reduce mistakes and saves time. Tools like AI now adjust vibration settings, predict repairs, and improve performance. Electrodynamic shakers, for example, control vibrations perfectly, making them great for testing products.

Types of Vibrating Equipment

Vibrating equipment comes in different types based on their jobs. Here are some examples:

Vibrating Screens: Sort materials by their size.

Vibrating Feeders: Keep materials moving smoothly in production.

Electrodynamic Shakers: Test products with controlled vibrations.

Vibrating Tables: Pack materials tightly or remove trapped air.

Vibratory Conveyors: Move materials easily and efficiently.

Each type has a specific use but works with vibrations. Modular designs are now common. They save space and can handle different tasks.

The Role of Vibration in Industrial Applications

Vibration helps improve how industries work. It makes handling materials easier, improves quality, and reduces waste. For example, in factories, vibration packs materials tightly for stability. In testing, it mimics real-world conditions to check product strength. Standards like MIL-STD-810 and ISO 9001 ensure vibrating equipment is safe and high-quality.

Studies show vibration features are important in industries. Materials like natural fiber composites handle vibrations better, making them more stable. Engineers use this knowledge to design energy-efficient machines. By learning about vibrations, industries can work better and be more eco-friendly.

Vibrating Equipment Applications Across Industries

Manufacturing and Material Handling

Vibrating equipment is important in factories and material handling. Vibrating screens sort items by size, reducing waste and improving accuracy. Vibrating feeders keep production lines moving, avoiding delays and boosting efficiency. These tools make factory work faster and easier.

A key benefit of vibrating equipment is its toughness. Strong sensors and three-way vibration data collection ensure it works well in tough conditions. This technology reduces breakdowns and improves performance, as shown below:

Feature | Description |

|---|---|

Rugged Sensors | Built to handle tough factory conditions, ensuring accurate readings. |

Three-Vector Vibration Data | Tracks detailed data for better maintenance and smoother processes. |

Operational Efficiency Increase | Cuts downtime and improves factory performance. |

But too much vibration can cause problems. It may damage machines, raise repair costs, and create safety risks. Knowing these effects helps you plan better maintenance and improve productivity.

Measurable Impact | Description |

|---|---|

Equipment Damage | Vibrations can wear out machines, causing them to break. |

Increased Maintenance Costs | Repairs and replacements from vibration issues cost more money. |

Operational Disruptions | Vibrations can slow or stop production, wasting time. |

Safety Risks | Too much vibration can harm workers and machines. |

Mining and Quarrying

In mining, vibrating equipment helps process raw materials. Vibrating screens sort minerals by size, and vibrating feeders move materials steadily to crushers. These tools save time and reduce hard labor, making mining safer and more efficient.

Vibrating equipment handles heavy loads and tough conditions. For example, vibrating grizzly feeders remove debris and prepare materials for processing. This protects other machines and keeps operations smooth. Vibration-based systems also sort valuable minerals better, reducing waste.

The strength and flexibility of vibrating equipment are vital in mining. Adjusting vibration settings improves results and extends machine life.

Food and Beverage Processing

In food production, vibrating equipment ensures quality and consistency. Vibrating conveyors move ingredients smoothly, and vibrating sifters remove unwanted bits. These tools improve efficiency and keep hygiene standards high.

Choosing the right vibration technology helps avoid delays. Monitoring equipment ensures smooth work, and real-time data keeps product quality high. Below are some benefits of using vibrating equipment in food production:

Performance Metric | Benefit |

|---|---|

Predictive Maintenance | Prevents big repairs by fixing issues early. |

Efficiency Improvements | Speeds up work by planning maintenance better. |

Downtime Prevention | Avoids costly delays in production lines. |

Focusing on specific machines can improve results:

Mixers and Homogenizers: Steady vibrations keep product quality consistent.

Conveyors: Watching vibrations stops problems before they happen.

Compressors: Finding imbalances early prevents sudden shutdowns.

Using vibrating equipment helps reduce waste, speed up work, and deliver great products to customers.

Construction and Infrastructure

Vibrating tools are important in building and infrastructure work. They help pack soil, smooth concrete, and remove air bubbles. This makes structures stronger and less likely to crack. For example, vibrating plates and rollers press soil tightly, creating a solid base for roads and buildings.

In concrete projects, vibrating tables and pokers make the material even. They remove empty spaces and make the concrete stronger. These tools save time and effort while improving construction quality. Vibrating hammers are also useful for breaking concrete during demolitions, making cleanup faster.

New designs focus on saving energy and being flexible. You can change vibration settings to match different jobs. This helps the machines last longer and work better. Using vibrating tools makes construction easier and gives better results.

Recycling and Waste Management

Vibrating machines are changing how recycling and waste are handled. Vibrating screens sort materials like metal, plastic, and glass by size. Vibrating feeders keep waste moving smoothly into machines, avoiding jams and delays.

The recycling market is growing fast. By 2025, recycled materials worldwide could reach $400 billion. In the U.S., recycling equipment sales may grow from $4.11 billion in 2024 to $5.29 billion by 2030, with a yearly growth rate of 4.3%. This shows the rising need for advanced recycling tools like vibrating equipment.

Metric | Value |

|---|---|

Global recycled materials market | $400 billion by 2025 |

U.S. recycling equipment market | $4.11 billion in 2024 |

Revenue forecast | $5.29 billion by 2030 |

Growth rate | 4.3% yearly from 2024 to 2030 |

Vibrating tools make waste management faster and easier. Vibrating conveyors move materials without needing much manual work. Vibrating compactors press waste into smaller sizes, saving space. These tools also help recover useful items from trash, supporting eco-friendly efforts.

To get the most from these machines, check vibration levels often. Fixing problems early keeps them running well and avoids delays. Using these tools can improve recycling and help the environment.

Benefits of Vibrating Equipment

Improving Efficiency and Productivity

Vibrating equipment helps industries work faster and better. It uses vibrations to move, sort, or pack materials quickly. This saves time and makes work more accurate. For example, vibrating screens and feeders help factories handle more materials with less effort.

A big benefit is finding problems early. Tools that measure vibrations check if machines are working well. Fixing issues early keeps machines running longer and avoids delays. Predictive maintenance uses vibration checks to plan repairs before breakdowns happen. This protects machines, saves money, and reduces waste.

Planning well also boosts productivity. By spotting weak points, you can fix them and improve processes. This keeps work smooth and ensures high-quality results every time.

Saving Money in Industries

Using vibrating equipment can save money in many ways. These machines are made to work efficiently and cut costs. For example, they use less energy to move materials, lowering energy bills. Vibrating tools also stop items from settling during shipping, reducing losses.

The table below shows how vibrating equipment saves money:

Cost Type | How It Saves Money |

|---|---|

Energy Costs | Uses less energy, cutting power bills. |

Shipping Costs | Stops items from settling, reducing damage during transport. |

Equipment Life | Makes machines last longer, lowering replacement costs. |

Labor Costs | Works faster, needing fewer workers. |

Efficiency | Moves items better, increasing output and saving money. |

Damage Prevention | Protects machines, reducing repair costs and downtime. |

By making machines last longer and needing fewer repairs, vibrating equipment saves money over time. It also helps you do more work with fewer resources, making it a smart choice for industries.

Flexible and Useful for Many Jobs

Vibrating equipment is very flexible and useful. It can do many jobs in different industries. Whether sorting items, packing materials, or testing products, these machines can be adjusted to fit your needs. Modular designs let you customize them for specific tasks.

These machines can handle many materials and work in tough places. For example, vibrating screens sort items by size, and vibrating tables pack materials tightly. This flexibility means you don’t need extra machines for different jobs.

Modern vibrating tools also use smart technology like sensors and automation. These features let you check performance and make changes as needed. This keeps the machines reliable and efficient, no matter the task.

Importance of Vibration Isolation

Vibration isolation is key to keeping machines working well. It stops vibrations from spreading between surfaces. This protects machines and the area around them. Without it, vibrations can harm equipment, lower accuracy, or even cause breakdowns.

Why Vibration Isolation Matters

Why is vibration isolation so important? Even small vibrations can affect sensitive tools. In labs, vibrations can mess up instrument readings. In factories, they wear out machines, leading to expensive fixes. Using vibration isolation helps machines last longer and work better.

Common Vibration Isolation Solutions

Industries use different ways to control vibrations, such as:

Seismic accelerometers to measure vibrations precisely.

Heavy concrete bases to keep machines steady.

Isolation mounts made of rubber, steel, or air springs.

Active systems that adjust instantly to reduce vibrations.

Each method fits specific needs, helping machines run smoothly.

Performance Indicators for Vibration Isolation Applications

Industries follow rules to decide how much isolation is needed. These rules ensure machines work well without outside vibrations. The table below shows some common standards:

Vibration Criterion | Description | Application |

|---|---|---|

VC-A | Basic vibration limits | General equipment |

VC-B | Moderate sensitivity | Laboratory instruments |

VC-G | High sensitivity | Precision machinery |

Historical Context | Made in the 1960s, updated for industries | ISO standards guide |

These standards help pick the best isolation tools for each job.

Benefits of Vibration Isolation Technology

Using vibration isolation gives many benefits:

Improved Precision: Tools like microscopes work better with fewer vibrations.

Extended Equipment Life: Less wear means fewer repairs and replacements.

Enhanced Safety: Fewer vibrations lower the chance of accidents.

Energy Efficiency: Active systems save energy by keeping machines stable.

By using vibration isolation, you protect your machines and improve performance.

The Future of Vibration Isolation

As industries grow, vibration isolation gets smarter. New systems use sensors to monitor and adjust in real-time. These tools keep machines steady, even in tough conditions. Whether in factories, hospitals, or construction, vibration isolation is vital for better results.

Innovations in Vibrating Equipment

Emerging Technologies in Vibration Systems

New technologies are changing how vibration systems work in industries. Automation now helps make processes faster and easier. For example, automated testing reduces manual tasks and gives steady results. Advanced data tools also help improve designs by analyzing performance better. These updates make vibration systems smarter and more dependable.

Wireless tools and IoT sensors are improving vibration monitoring. They let you check machines remotely and get live updates. This is helpful in industries like oil and gas, where equipment is far apart. Machine learning and AI also improve maintenance by spotting small vibration changes. This helps plan repairs early and avoid costly stops.

Trend/Technology | Description |

|---|---|

Wireless Technologies and IoT Sensors | Allow real-time checks and updates, useful for spread-out equipment. |

Machine Learning and AI | Spot small vibration changes to plan repairs and avoid shutdowns. |

Hardware and Software Segmentation | Hardware is key for sensing, while software grows with demand for analytics. |

Industry Applications | Oil and gas lead in use, but automotive grows fastest with smart manufacturing. |

Custom vibration isolation systems are becoming popular. Industries like aerospace, healthcare, and manufacturing use them for better precision and stability.

Energy-Efficient Designs

Energy-saving designs in vibrating tools help save resources and work well. New systems use less energy while staying stable. For example, eco-friendly vibration testers meet global green goals. These tools cut costs and lower the environmental impact of industries.

In construction, energy-efficient compactors and rollers use less power but give better results. In recycling, vibrating screens and feeders handle heavy loads with minimal energy use. These improvements help industries stay stable while supporting sustainability.

Smart Sensors and Automation

Smart sensors are changing how vibrating tools are checked and fixed. These sensors give exact data on vibrations, helping find problems early. For example, remote sensors let you monitor machines from anywhere. This reduces sudden breakdowns and makes machines last longer.

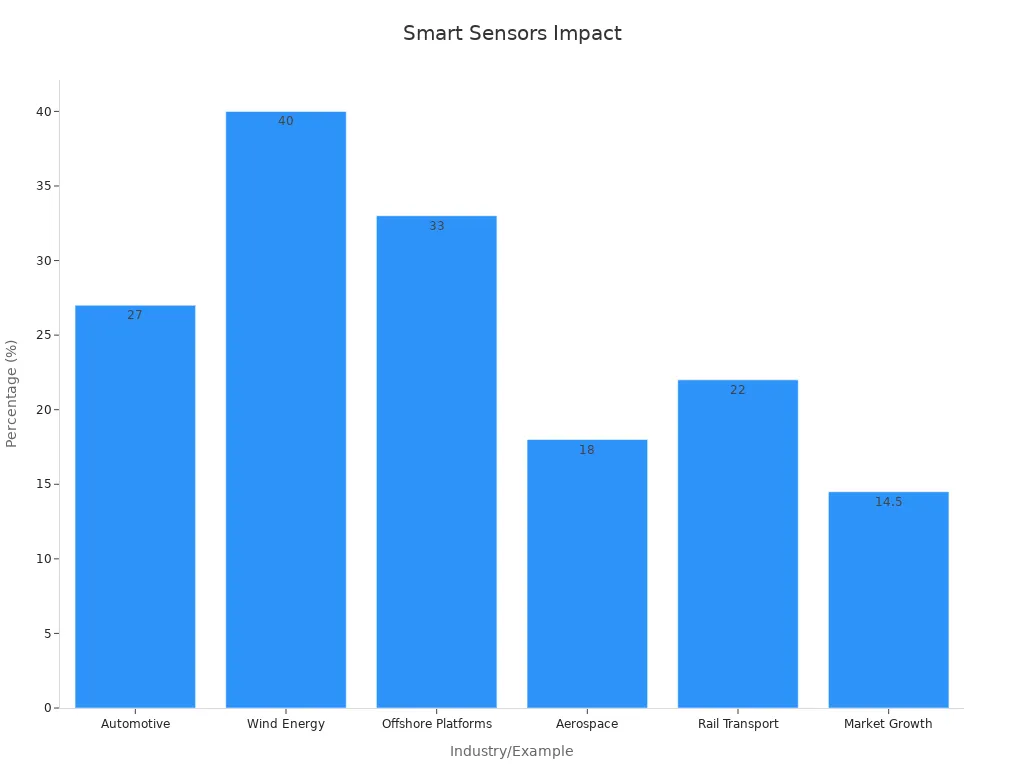

Industries like wind energy and automotive benefit a lot. Factories with sensors have cut unplanned stops by 27%. A wind farm in Europe saved 40% on gearbox repairs using wireless sensors. These examples show how sensors save money and improve efficiency.

Automation makes vibrating tools even better. AI systems study vibration data instantly, helping with early repairs. This keeps machines stable and efficient, even in tough conditions. By using smart sensors and automation, industries can work better and avoid delays.

Vibrating tools have changed industries by boosting speed and creativity. They are used for tasks like checking machines early and moving materials. These tools have shown great results:

A paper factory stopped breakdowns and made machines last longer using vibration checks.

A car factory made products 23% better by fixing welding robots early.

Caterpillar’s tools cut delays in tough places, proving early repairs are helpful.

Fixing machines before they break can reduce delays by half and make them last 40% longer. Using these tools can help improve your work and grow your business in smart ways.

FAQ

What are vibration isolators, and why are they important?

Vibration isolators are tools that lower vibrations between machines and surfaces. They keep equipment safe from harm and make it work better. By reducing vibrations, they also make machines last longer and safer to use.

How do equipment vibration isolators work?

These isolators use materials like rubber, springs, or air to absorb vibrations. They stop vibrations from spreading to other areas, helping machines run smoothly. This is why they are important in factories and construction sites.

What are HVAC vibration isolators used for?

HVAC vibration isolators reduce shaking in heating and cooling systems. They stop noise and protect buildings from damage caused by vibrations. These isolators help HVAC systems work quietly and efficiently.

Can industrial vibration isolators improve machine efficiency?

Yes, they can. Industrial vibration isolators reduce damage to machines. They keep equipment steady, helping it work at its best. This lowers repair needs and boosts productivity.

How do I choose the right vibration isolators for my equipment?

To pick the right isolators, think about the machine's weight, vibration level, and where it will be used. Ask an expert to find the best match for your needs.

See Also

Discovering How Vibration Motors Are Used Across Industries

Ten Key Uses of Vibrating Motors in Today's Tech

Seven Major Applications of Vibration Motors for Manufacturing Gains

Ten Methods Micro Vibration Technology Boosts Precision Instruments

Innovations in Vibration Technology Transforming Haptic Feedback Experiences

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry