7 Essential Tips for Picking the Right 12 Volt Vibrating Motor

You want the best results when choosing the right vibration motor for your project. The most important factor is matching the 12 volt vibrating motor’s specifications to your application’s demands. For example, sorting and conveying systems rely on vibration motors to keep materials moving smoothly. Packaging machines use vibration motors for accurate product placement. INEED’s vibration motor solutions give you the flexibility to customize features for different industries, ensuring reliable performance and cost-effectiveness.

Application Area | Description |

|---|---|

Sorting and Conveying Systems | Vibrates chutes, hoppers, and conveyor belts for smooth material flow and prevents clogging. |

Testing and Inspection Equipment | Simulates vibrations to ensure product reliability in automotive and electronics testing. |

Packaging and Labeling Machines | Vibrates filling hoppers and labeling heads for efficient product placement. |

Key Takeaways

Match the vibration motor's specifications to your project's needs for optimal performance.

Consider the usage environment, including temperature and humidity, to ensure motor longevity.

Choose the right motor type (ERM or LRA) based on your application for effective vibration.

Check voltage and speed requirements to prevent operational issues and ensure stable performance.

Utilize INEED's customization options to tailor vibration motors for your specific application.

Define Your Application Needs

Usage Environment

When you select a vibration motor, you must consider where you plan to use it. The environment can affect how well the motor performs and how long it lasts. For example, high temperatures may damage insulation and change magnetic properties. This can shorten the lifespan and reduce the output power of your vibration motor. Low temperatures can make lubricants thicker, which increases friction and power consumption. Humidity can also impact motor components over time, affecting vibration performance.

You should ask yourself these questions before choosing a 12 volt vibrating motor:

Will the motor face extreme temperatures or moisture?

Does the motor need to operate in a clean room or outdoors?

Is there enough space for the motor in your device?

Will the motor run continuously or only for short periods?

You must match the motor’s power supply and voltage to your system. This helps prevent operational problems and ensures reliable vibration. In medical devices, you need to think about load capacity, frequency, and the type of vibration required. Compactness is important in consumer electronics, so you should check the available space for integration.

Required Vibration Strength

The strength of vibration you need depends on your application. Some devices require gentle vibration for tactile feedback, while others need strong vibration for moving materials or alerting users. You must decide if you need linear or rotary vibration. Medical devices often need precise vibration to meet safety standards. Consumer electronics may need vibration motors that can handle shocks and temperature changes.

Here is a comparison of vibration requirements:

Category | Vibration Requirements | Purpose |

|---|---|---|

Consumer Electronics | Must endure mechanical shocks and thermal cycling during use. | Ensures product durability and regulatory approval for international markets. |

Medical Devices | Must survive field deployment and shipping, with specific vibration testing protocols. | Ensures regulatory compliance and patient safety in sensitive environments. |

You should define the vibration frequency and amplitude needed for your project. This helps you choose a vibration motor that delivers the right performance. If you need help, INEED offers customizable vibration motor solutions for many industries. You can select the exact vibration strength and features that fit your needs.

Choosing the Right Vibration Motor Type

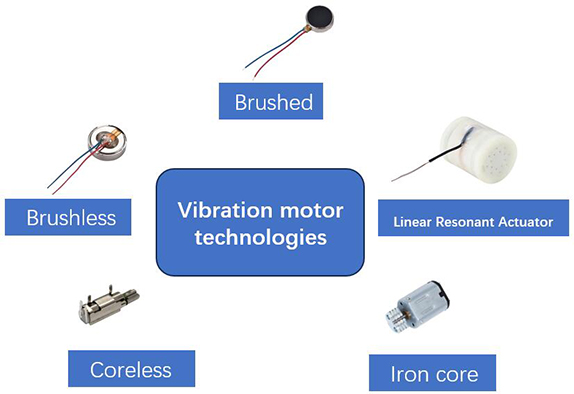

When you select a 12 volt vibrating motor, you must understand the differences between motor types. INEED offers a wide range of vibration motors, including ERM, LRA, brushless coin, and coreless DC motors. Each type delivers unique vibration characteristics and suits specific applications.

ERM vs. LRA Motors

Eccentric Rotating Mass (ERM) motors and Linear Resonant Actuators (LRA) are two popular vibration motor types. ERM motors create vibration by spinning an unbalanced mass. LRA motors use a spring and magnet system to produce vibration in a straight line. You will find ERM motors in devices like cell phones and game controllers. LRA motors work well in medical devices and touchscreens.

Tip: Choose ERM motors for a wide range of vibration patterns. Pick LRA motors for precise vibration and low noise.

Here is a comparison of ERM and LRA motors:

Feature | ERM Motors | LRA Motors |

|---|---|---|

Power Consumption | Typically consume more power due to rotational motion | More efficient, consumes less power with precise vibrations |

Control and Flexibility | Wider range of vibrations, easy to control | Finer control within a specific frequency range |

Response Time | Faster response upon activation | More durable for extended use |

Noise Characteristics | Produces more noise, transmits vibrations to surroundings | Produces smoother vibrations with minimal noise |

Application Areas | Common in cell phones, wearables, game controllers | Used in medical devices, touchscreens, wearables |

Brushless vs. Brushed Motors

You must also decide between brushless and brushed vibration motors. Brushless coin motors from INEED offer high efficiency and long life. Brushed motors use brushes to transfer electricity, which causes wear over time.

Brushless motors can operate between 10,000 and 100,000 hours.

Brushed motors generally have an operating life ranging from 1,000 to 8,000 hours.

The absence of brushes in brushless motors means their lifespan depends on bearing wear and environment.

Brushed motors, even with maintenance, cannot match the longevity of brushless motors.

Coreless DC motors and brushless coin motors both deliver high energy efficiency. Coreless DC motors feature a compact design and reduced friction. Brushless DC motors optimize speed and torque for demanding vibration applications.

Motor Type | Energy Efficiency | Key Features |

|---|---|---|

Coreless DC Motors | High | Compact design, reduced friction |

Brushless DC Motors | High | Optimized for speed and torque |

You should match the vibration motor type to your device’s needs. INEED’s vibration motors give you options for every industry, from healthcare to consumer electronics. Select the right vibration motor to achieve reliable vibration, long life, and efficient operation.

Key Specifications for 12 Volt Vibrating Motor

Choosing the right vibration motor means you need to focus on the specifications that matter most for your application. You want your 12 volt vibrating motor to deliver consistent vibration, reliable performance, and long life. INEED’s vibration motors offer customizable specs, so you can match voltage, speed, frequency, and amplitude to your project’s needs.

Voltage and Speed

Voltage and speed are two of the most important factors when selecting a vibration motor. You must check that the motor’s voltage matches your power supply. Most vibration motors designed for 12 volt systems work well in automotive, industrial, and medical devices. Speed affects how quickly the motor produces vibration. Higher speeds often mean stronger vibration, but you need to balance speed with efficiency and noise.

Tip: Always confirm the voltage and speed requirements for your device before choosing a vibration motor. This helps prevent damage and ensures stable vibration.

Here is a table showing key specifications for automotive applications:

Specification | Description |

|---|---|

Vibration Amplitude | Describes the intensity of vibration produced by the motor. |

Frequency | Refers to how often the motor vibrates per second, affecting performance. |

Indicates the expected operational lifespan of the motor, often measured in hours. | |

Type of Motor | Differentiates between brushed and brushless motors, impacting efficiency and maintenance. |

Vibration Frequency and Amplitude

Vibration frequency and amplitude determine how your vibration motor feels and performs. Frequency measures how many times the motor vibrates each second. Amplitude shows the strength of the vibration. INEED’s vibration motors offer a wide range of frequency and amplitude options, so you can select the best fit for your application.

Parameter | Value/Range |

|---|---|

Frequency | |

Amplitude | 0.45 G to 2.35 G |

You should always match the vibration frequency and amplitude to your device’s requirements. For example, medical devices may need gentle vibration, while industrial tools require stronger vibration. INEED’s vibration motors let you customize these specs for optimal performance.

Manufacturers use several methods to keep vibration consistent across production batches:

Regular calibration of frequency and stroke length maintains accuracy.

Documenting test conditions ensures repeatability and traceability.

Verifying equipment health prevents issues that could affect vibration performance.

You can trust INEED’s vibration motors to deliver reliable vibration, thanks to strict quality control and customizable specifications. When you match the motor’s specs to your application, you get the best results for your project.

Size, Weight, and Integration

Space Constraints

You need to consider the size and weight of vibration motors before you choose one for your project. Small devices like smart rings and watches require compact vibration motors that fit into tight spaces. Lightweight motors help keep wearable technology comfortable and easy to use. If you select a motor that is too large or heavy, it can affect the design and user experience.

The table below shows how size impacts suitability for wearables:

Motor Type | Size (mm) | Suitability for Wearables |

|---|---|---|

5 x 1.8 | Ideal for lightweight devices like smart rings and watches |

You should always check the available space in your device before you pick a vibration motor. Many vibration motors from INEED come in different sizes, so you can find one that fits your needs. Smaller motors often work best for applications where space is limited, but you must also make sure the vibration strength meets your requirements.

Tip: Measure the space in your device and compare it with the motor’s dimensions. This helps you avoid integration problems and ensures reliable vibration.

Mounting Options

Mounting options play a big role in how you install vibration motors. You want a secure and stable setup to get consistent vibration. Industrial machinery often uses several mounting methods to attach vibration motors.

Mounting Method | Description |

|---|---|

Adhesive Mounting | Utilizes glue and adhesive methods for securing motors. |

Mechanical Fasteners | Involves the use of screws, brackets, and clips to attach motors to surfaces. |

Moulded or Machined Enclosures | Features receptacle mounting options in custom enclosures, ideal for compact designs. |

You can choose from these common mounting options:

Glue and adhesive methods

Fasteners and clips

Injection moulded mounts

Each method offers different benefits. Adhesive mounting works well for lightweight vibration motors in small devices. Mechanical fasteners provide strong support for larger motors in industrial equipment. Moulded enclosures help you integrate vibration motors into custom designs.

You should select the mounting option that matches your device’s structure and the type of vibration you need. INEED offers vibration motors with flexible mounting choices, making integration easy for many applications. When you match the right motor size and mounting method, you get reliable vibration and smooth operation.

Best Practices for Choosing Reliable Vibration Motors

When you focus on choosing the right vibration motor, you need to follow best practices for choosing reliable vibration motors. You want your device to work smoothly and last a long time. INEED puts reliability and quality at the center of every vibration motor. You can trust their strict quality control and advanced testing methods.

Quality Materials

You should always check the materials used in vibration motors. High-quality metals and insulation help motors resist wear and keep vibration consistent. Leading manufacturers use several quality control steps to make sure every vibration motor meets high standards.

Immediate testing after installing new or refurbished motors keeps vibration performance steady.

Clear quality control agreements with repair shops help maintain motor reliability.

Well-defined acceptance criteria ensure every vibration motor passes strict checks.

Maintenance plans for spare motors keep vibration motors ready for use.

INEED uses premium materials and follows these best practices for choosing reliable vibration motors. You get motors that deliver strong vibration and last longer.

Durability Features

Durability matters when you want vibration motors to work in tough environments. You should look for motors with features that protect against heat, moisture, and vibration overload. INEED tests every vibration motor for performance and reliability. You can ask for certifications that prove the motor meets industry standards.

Here is a table showing important certifications for vibration motors in medical and automotive industries:

Certification | Relevance |

|---|---|

UL Certification | Required for shops producing or repairing explosion-proof motors in hazardous locations. |

Green Motors Certification | Ensures motor efficiency and is often required for utility rebates. |

EASA Accreditation | Ensures compliance with strict standards in motor repair and maintenance practices. |

You should always check for these certifications when choosing the right vibration motor. INEED’s vibration motors pass strict performance tests and meet international standards. You get motors that work reliably in medical devices, automotive systems, and more.

Tip: Ask for test reports and certifications before you buy a vibration motor. This helps you follow best practices for choosing reliable vibration motors and ensures your device works safely.

Customization and Support from INEED

Tailored Motor Solutions

You want vibration motors that fit your exact needs. INEED gives you the power to customize every detail of your vibration motor. You can adjust performance parameters like voltage, speed, and current. You can also add features such as special connectors, longer wires, rubber boots, or custom brackets. This flexibility helps you create a vibration solution that works perfectly in your device.

Here is a quick look at the customization options INEED offers for vibration motors:

Customization Aspect | Description |

|---|---|

Performance Parameters | Adjust voltage, speed, and current to match your requirements. |

Additional Features | Add connectors, wire lengths, rubber boots, capsules, or brackets as needed. |

Support | Get help from prototype to mass production, including drawings and technical specs. |

You can also request features that many clients value most in vibration motors:

Adjustable frequency settings for different vibration strengths.

Durable construction for long-lasting vibration performance.

Quiet operation for a better user experience.

Easy installation to save you time.

Customizable vibration patterns for unique feedback.

With INEED, you get vibration motors that match your industry’s demands, whether you work in healthcare, robotics, or consumer electronics.

Technical Support and Free Samples

You do not have to figure out vibration motor selection alone. INEED provides expert technical support at every step. You can ask questions about vibration, integration, or performance. The team helps you manage risks and ensures your vibration motors meet all safety and quality standards.

If you want to test a vibration motor before making a big order, INEED offers free samples for prototypes. You can check the vibration strength, fit, and reliability in your own device. This support helps you avoid costly mistakes and gives you confidence in your final product.

Tip: Take advantage of INEED’s technical support and free samples to make sure your vibration motors deliver the right vibration for your application.

You can rely on INEED for both customization and support. This approach ensures your vibration motor performs exactly as you expect, every time.

How to Pick the Best Vibration Motor for Your Budget

Comparing Brands and Reviews

You want to make smart choices when you buy vibration motors. Start by looking at different brands and reading reviews from other users. Reviews can tell you if a vibration motor works well and lasts a long time. Many brands offer similar products, but prices and features can vary. You should compare the cost, performance, and reliability of each vibration motor before you decide.

Here is a table showing the average price range for 12 volt vibration motors from major brands:

Motor Specification | Price |

|---|---|

20W 12 Volt Motor | $377.48 |

100W 12 Volt Motor | $380.30 |

40W 12 Volt Motor | $421.87 |

You can see that prices change based on the power of the vibration motor. Higher wattage often means a stronger vibration, but you should only pay for what your project needs. Reading reviews helps you learn if a vibration motor gives steady vibration or if it has problems over time. Look for brands that have good feedback about their vibration motors’ performance and customer support.

Tip: Make a list of your top choices and compare their vibration strength, size, and price. This helps you find the best value for your budget.

Warranty and After-Sales Service

Warranty and after-sales service matter when you choose vibration motors. A good warranty protects you if your vibration motor stops working early. Some brands offer longer warranties or better service, which can save you money and stress.

Here is a table comparing warranty terms from top manufacturers:

Manufacturer | Warranty Duration | Conditions | Additional Notes |

|---|---|---|---|

Husqvarna | 1 to 5 years | Varies by product; specific terms for concrete vibrators. | Spare parts: 90 days warranty. |

Connex Industrial Corp. | 12 months | Specific conditions for claims; voided if inaccurate information provided. | Excludes consequential damages. |

You should read the warranty details before you buy a vibration motor. Some companies cover only certain parts or have strict rules for making a claim. Good after-sales service means you get help if you have questions or need repairs. INEED offers strong support and clear warranty terms for their vibration motors, so you can trust your purchase.

Note: Always keep your purchase records and follow the warranty instructions. This makes it easier to get help if your vibration motor needs service.

When you know how to pick the best vibration motor for your budget, you get the right balance of cost, performance, and support. Take your time to compare brands, check reviews, and understand the warranty. This way, you make sure your vibration motors deliver reliable vibration for your project.

You now know the seven essential tips for choosing the right vibration motor. When you select a 12 volt vibrating motor, you improve your project’s reliability and performance. INEED’s vibration motors stand out because you can customize vibration amplitude, frequency, and duration.

You match the vibration motor to your exact needs.

You handle different loads and resistance levels with ease.

You get consistent vibration in demanding environments.

Apply these best practices to every project. For expert advice or free samples, visit INEED’s website and discover how the right vibration motors can transform your application.

FAQ

What is a 12 volt vibrating motor used for?

You can use a 12 volt vibrating motor in devices like medical equipment, wearables, and industrial machines. It provides tactile feedback, alerts, or helps move materials smoothly.

How do I choose the right vibration strength?

You should match the vibration strength to your application. For gentle alerts, select lower amplitude. For moving materials, pick higher amplitude. INEED offers customizable options for both.

Can I customize the motor for my project?

Yes! You can request custom voltage, speed, connectors, and mounting options from INEED. This ensures the motor fits your device perfectly.

Tip: Ask for a free sample from INEED to test before you order in bulk.

What maintenance does a vibration motor need?

You should keep the motor clean and check for loose connections. Brushless motors need less maintenance than brushed ones. Regular inspection helps extend the motor’s life.

Motor Type | Maintenance Level |

|---|---|

Brushed | Moderate |

Brushless | Low |

See Also

Five Key Steps for Choosing a Small Vibrator Motor

Choosing the Perfect Vibrating Motor for Your Project

Eight Essential Steps to Choose an ERM Vibrator Motor

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry