Speed Control of DC Motor: Comparing Armature Control vs. Field Control Methods

You want your dc motor to run efficiently and handle changes in speed or load with ease. Many engineers prefer advanced speed control methods for dc motors because these methods offer quick response, low overshoot, and almost no error after sudden speed changes. For example, controllers like ANN and POA-FOPD(1+PI) can achieve high phase stability and bandwidth, which means your motor can react fast and stay steady. Good speed control of dc motor helps you reduce energy loss and improve performance. When you use the right control for your motor, you keep your dc system running smoothly and reliably.

Key Takeaways

Armature control changes voltage or resistance in the motor's armature to lower speed quickly and accurately, making it ideal for fast and dynamic tasks.

Field control adjusts the magnetic field strength to increase speed above the rated value, offering better energy efficiency and longer motor life for steady, long-term operations.

Armature control provides constant torque below rated speed with fast response but wastes energy as heat and causes more wear on motor parts.

Field control maintains constant power above rated speed with less heat loss but can become unstable at very high speeds and is less effective for small motors.

Choose the control method based on your motor’s needs, load, environment, and cost to ensure efficient, reliable, and smooth motor performance.

DC Motor Speed Control Methods

When you want to manage the speed of a dc motor, you usually choose between two main methods: armature control and field control. These methods help you adjust how fast your motor runs and how much power it uses. Understanding both options gives you better control over your dc drives and helps you pick the best way to get the performance you need.

Armature Control

Armature control methods let you change the speed of your dc motor by adjusting the voltage or resistance in the armature circuit. When you use armature control, you keep the field current steady. This method works best when you want to lower the speed below the rated value. For example, if your motor runs at 1000 RPM, you can use armature control to slow it down to 800 RPM by adding resistance. The armature in your dc motor acts like an electromagnet. When current flows through it, the armature interacts with the magnetic field from the stator. The commutator and brushes help keep the motor spinning by reversing the current at the right time. You use armature control in many dc drives where you need solid speed regulation and quick response.

Field Control

Field control methods help you increase the speed of your dc motor above its rated value. You do this by changing the strength of the magnetic field, usually by adjusting the current in the field winding. When you weaken the field, the speed goes up because speed is inversely related to the magnetic flux. Field control methods are more energy efficient and cost less than armature control. You often use field control in applications where you need steady output for long periods, like in some industrial dc drives.

Control Method | Speed Range | Efficiency | Cost | Typical Use |

|---|---|---|---|---|

Armature Control | Below rated speed | Lower | Higher | Quick speed changes |

Field Control | Above rated speed | Higher | Lower | Long, steady operations |

Why Compare Methods?

You need to compare armature control and field control methods because each one fits different needs. In real-world situations, you may face changes in load or need fast speed control. Studies show that armature voltage control can give you better delay time and less overshoot than field control. This means your dc motor reacts faster and stays stable. By understanding the strengths and limits of each method, you can choose the best speed control for your dc motor. This helps you get the most out of your dc drives and solid state speed control systems. Knowing the basics of dc motor speed control theory lets you make smart choices for any application.

Armature Control

How Armature Control Works

You use armature control to change the speed of a dc motor by adjusting the voltage or resistance in the armature circuit. In armature resistance control, you add extra resistance to the armature. This reduces the current and lowers the speed. In armature terminal voltage control, you change the voltage applied to the armature. Both methods keep the field current steady. When you use armature voltage control, you can get smooth speed changes. You often use armature control for speed control of dc shunt motor and armature controlled dc series motor.

Researchers have tested armature control using IR sensors and Arduino boards to measure motor speed. They use MATLAB and Simulink to estimate key motor parameters like friction and back emf. The results from experiments match closely with simulations. This means the armature control model works well in real dc motor systems. You can trust armature control for accurate speed control of dc shunt motor.

Advantages of Armature Control

You get several advantages of armature controlled dc shunt motor when you use armature control.

You can achieve precise speed control, especially below the rated speed.

Armature voltage control gives you fast response and low overshoot.

Armature resistance control is simple to set up.

You can use armature control for both armature controlled dc shunt motor and armature controlled dc series motor.

The method works well for applications that need quick speed changes.

Disadvantages of Armature Control

You also face some drawbacks with armature control.

Armature resistance control wastes energy as heat in the added resistance.

The efficiency drops at lower speeds.

Armature voltage control needs a variable voltage supply, which can cost more.

The method is less efficient than field control for long, steady operations.

You may see more wear on the armature and brushes.

Applications of Armature Control

You use armature control in many dc motor applications.

It is common in speed control of dc shunt motor for cranes, hoists, and elevators.

You find armature controlled dc shunt motor in rolling mills and printing presses.

Armature controlled dc series motor works well in electric trains and trams.

In real-world tests, armature control shows high accuracy and fast response, even with changing loads.

The method supports dynamic speed control, making it ideal for systems that need frequent speed adjustments.

Tip: If you need fast and accurate speed control in your dc motor, armature control gives you reliable results, especially for armature controlled dc shunt motor.

Field Control

How Field Control Works

You use field control to change the speed of a dc motor by adjusting the current in the field winding. When you lower the field current, the magnetic field becomes weaker. This causes the motor to run faster. If you increase the field current, the field gets stronger, and the speed drops. In a typical setup, you might use a controller board, sensors, and software like MATLAB or Simulink to monitor and adjust the field. The system measures the motor’s speed and torque in real time. You can see how changes in field current affect the motor’s behavior. This method gives you a clear way to manage both speed and torque in your dc motor.

Advantages of Field Control

Field control gives you several important benefits.

You can extend the speed range of your dc motor above its rated value.

Field control allows you to keep the motor running at constant horsepower when you go above base speed.

You get stable speed control, especially when you use feedback devices like encoders.

Modern dc drives make field control easy and safe by controlling how fast the field current changes.

You reduce heating and wear on the motor, which means less maintenance and longer life.

Field control works well for both speed control of dc shunt motor and field controlled dc series motor.

You can use field control for rapid speed or load changes, making it flexible for many dc applications.

Note: Field control helps you avoid problems like speed runaway and high back EMF, which can damage your dc motor.

Disadvantages of Field Control

You also need to know the limits of field control.

You cannot increase the field flux above its rated value, so the speed range has an upper limit.

At very high speeds, the field becomes weak, which can make the motor unstable.

Low field current can cause high armature current, leading to more heat and lower efficiency.

High armature reaction at low field current can reduce the field even more, risking dangerously high speeds.

Field control does not work well for small dc motors.

You may find it hard to control speed in small motors using this method.

Applications of Field Control

You find field control in many real-world dc motor systems.

Many industries use field control for long, steady operations where you need to keep the speed above the rated value.

Field controlled dc series motor is common in electric traction, such as trains and trams, where you need a wide speed range.

You see field control in rolling mills, paper machines, and other heavy-duty dc applications.

Field control supports mobile air pollution monitoring tools, like microAethalometers, which need reliable speed and control in different environments.

Many modern navigation and sensing apps use field control principles to manage data and performance in real time.

Speed Control Comparison

Operation and Performance

When you want to control the speed of a DC motor, you need to know how each method works and why it matters for your application. Armature control changes the voltage or resistance in the armature circuit. This lets you lower the speed below the rated value. You get smooth and quick speed changes, which helps when you need fast response in your system. Field control, on the other hand, adjusts the current in the field winding. This weakens the magnetic field and increases the speed above the rated value. You use field control when you want to run your motor faster, but you lose some torque as a result.

You should compare these methods because each one gives you different performance. Armature control offers constant torque below the rated speed. Field control gives you constant power above the rated speed. If you need your motor to react quickly to changes, armature control usually performs better. Tests show that using a good controller can improve dynamic performance by over 23%. This means your motor can handle sudden load changes without losing accuracy. Field control can sometimes cause instability or overspeeding, so you need to add protection to keep your system safe.

Tip: Choose armature control if you want fast and stable speed changes. Pick field control if you need to run your motor faster for long periods.

Side-by-Side Operation Differences

Armature Control:

Changes voltage or resistance in the armature.

Keeps field current steady.

Controls speed below rated value.

Maintains constant torque.

Responds quickly to speed changes.

Field Control:

Adjusts current in the field winding.

Weakens magnetic field to increase speed.

Controls speed above rated value.

Maintains constant power.

May reduce torque and cause instability at high speeds.

Efficiency and Power

You care about energy efficiency because it affects how much power your system uses and how much heat it produces. Armature control often wastes energy as heat, especially when you use resistance to lower the speed. This makes it less energy efficient, and you may see higher power losses in your dc drives. Field control is more energy efficient when you want to increase speed. It does not waste as much energy as heat, so your system runs cooler and uses less power.

If you use advanced controllers, you can boost the efficiency of both methods. For example, a well-designed controller can improve power quality and reduce static error. This means your motor speed stays accurate, and your system uses power more effectively. You should pick the method that matches your need for energy efficiency and power savings.

Cost and Complexity

You want a cost-effective control method that fits your budget and is easy to maintain. Armature control can be simple if you use resistance, but it becomes more expensive if you need a variable voltage supply. The extra parts can add to the cost and make the system more complex. Field control usually costs less for basic setups, but it can get complicated if you need precise control or protection against overspeeding.

The Ward-Leonard system gives you fine control over both speed and torque, but it is bulky and expensive. Most users avoid it unless they need top performance in demanding applications. You should weigh the cost and complexity against your needs. If you want a simple and cost-effective control, armature resistance control works for basic tasks. If you need wide speed range and high precision, field control or advanced systems like PWM may be better.

Control Method | Operation Type | Efficiency | Cost | Complexity | Suitability |

|---|---|---|---|---|---|

Armature Control | Open/Closed Loop | Lower | Higher | Moderate | Fast, dynamic changes |

Field Control | Open/Closed Loop | Higher | Lower | Moderate | Long, steady operations |

Ward-Leonard System | Closed Loop | High | Highest | High | Demanding industrial use |

PWM Control | Closed Loop | Highest | Moderate | Moderate | Robotics, automation |

Application Suitability

You need to match the control method to your application for the best results. Armature control works well in dc drives that need quick speed changes, like cranes, hoists, and elevators. You get reliable performance and fast response. Field control fits applications where you want to run your motor above the rated speed for long periods, such as rolling mills or electric trains. You get better energy efficiency and less wear on the motor.

PWM control stands out as the most effective method for many modern applications. It gives you high efficiency, wide speed range, and precise control. If you need simple on/off control, you can use basic voltage or resistance methods, but these are less efficient and precise. Closed-loop control with sensors gives you the best accuracy and adaptability, but it costs more and requires more maintenance.

Note: Always choose the control method that matches your need for speed range, energy efficiency, cost, and performance. This helps you get the most out of your dc drives and keeps your system running smoothly.

Choosing the Right Control Method

Key Factors

When you choose a speed control method for your DC motor, you need to look at several important factors. Each factor helps you decide if armature control or field control will work best for your needs.

You must match the motor specifications. Check if your motor is brushed or brushless. Make sure the voltage range and power rating fit your controller. The connection must be compatible for the controller to work well.

Think about your load and performance needs. If your application needs high torque or a wide speed range, you must pick a method that can handle these demands. For example, an armature controlled dc shunt motor gives you good control at lower speeds.

Look at the environment. Motors in hot, dusty, or wet places need protection. You may need sealed cases or cooling systems to keep the armature and field safe.

Consider the control method. You can use PWM, variable resistance, or H-Bridge circuits. Each method offers different levels of precision, noise resistance, and cost. Armature control often gives you fast response, while field control can be more energy efficient.

Feedback systems help you keep speed and torque steady. Devices like encoders or sensors can improve accuracy for both armature and field control.

Protection features are important. Overheating, overload, and electrical damage can shorten the life of your motor. Good controllers protect both the armature and the field windings.

The operating lifetime matters. Brushed motors have more wear on the armature, while brushless motors last longer. Ball bearings last longer than sleeve bearings.

The size and accuracy of your system must fit your space and needs. Sometimes you need gearboxes or encoders for better control.

Your application type changes your priorities. Stationary machines can use larger motors and controllers. Portable devices need small, energy-efficient solutions.

Tip: Always weigh these factors before you pick armature or field control. The right choice helps your system run longer and more efficiently.

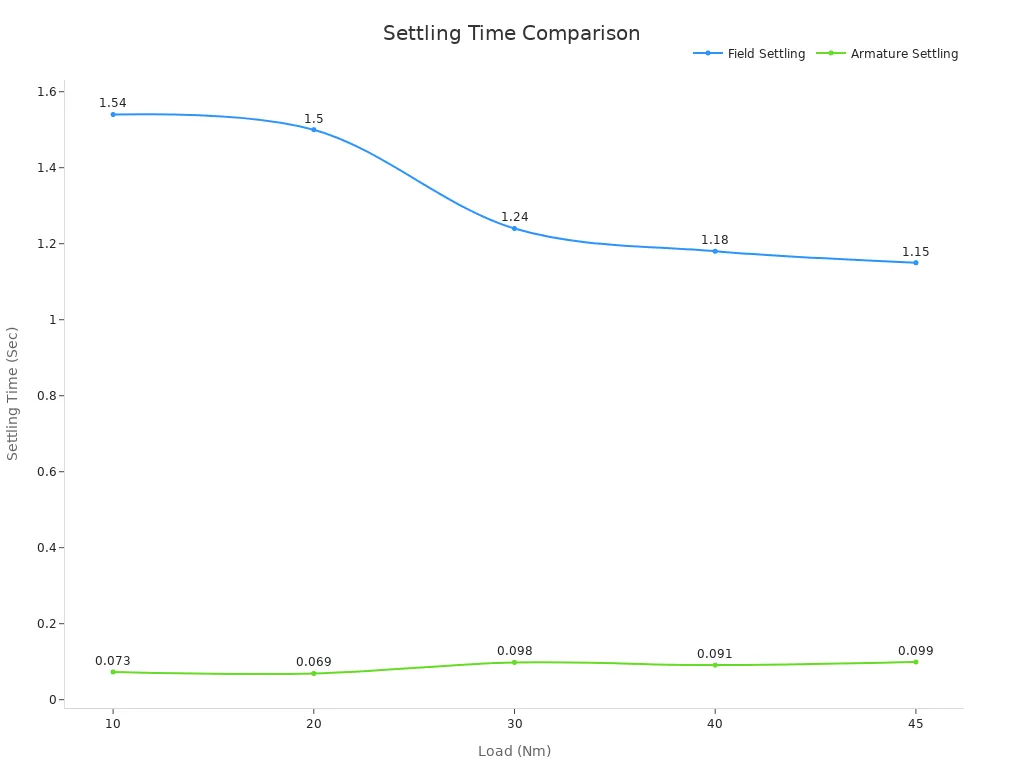

You want fast and accurate speed control for your DC motor. Armature control gives you quicker response, lower overshoot, and shorter recovery times than field control. The table below shows how armature control reacts faster and stays more stable under different loads.

Load (Nm) | Settling Time (s) Field | Settling Time (s) Armature | Overshoot (%) Field | Overshoot (%) Armature |

|---|---|---|---|---|

10 | 1.54 | 0.073 | 191 | 1.773 |

If you need steady speed for long periods, field control works well. For most quick and dynamic tasks, armature control is the better choice. Always match your method to your motor’s job and your system’s needs.

FAQ

Why should you choose armature control for quick speed changes?

You should choose armature control because it lets you change speed fast and accurately. This method responds quickly to load changes. You get better control when your system needs to speed up or slow down often.

Tip: Armature control works best for dynamic tasks.

Why does field control save more energy at higher speeds?

Field control saves energy because it does not waste power as heat. When you weaken the field, the motor runs faster without extra resistance. This makes your system more efficient, especially when you need to keep high speeds for a long time.

Why can armature control cause more wear on your motor?

Armature control can cause more wear because it uses the brushes and commutator more. The extra current and heat from added resistance can damage these parts. You may need to replace them sooner if you use armature control often.

Why is field control not good for small DC motors?

Field control does not work well for small DC motors because it is hard to control the field current in tiny windings. Small motors can become unstable or overheat if you try to use field control.

Why do you need to compare both methods before choosing?

You need to compare both methods because each one fits different jobs. Armature control gives you fast changes. Field control gives you better efficiency at high speeds. By comparing, you pick the method that matches your needs and keeps your system running well.

See Also

How To Manage Motor Rotation Direction Effectively

Selecting The Best Setup For Battery Powered Motors

Differences Between Brushed And Brushless 3V Motors

Understanding The Main Contrasts Of Vibro Versus Standard Motors

Best Methods To Enhance Frequency Vibrations In Small Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry