Integrating Small Vibration Motors into Wearable Technology

Small vibration motors have changed wearable tech by using touch. Fitness trackers buzz to remind you to move. Smartwatches vibrate to show notifications. These motors use haptic feedback to make devices feel easier to use. Though studies may not have strong data, users love them. These motors help create new ideas, like health tools or fun gaming. Their tiny size and flexibility make them key in wearables. They mix technology with human touch smoothly.

Key Takeaways

Small vibration motors help wearable devices feel more interactive.

They give feedback that makes the device easier to use.

Picking the right motor is important for your device's needs.

Think about size, energy use, and how strong the vibrations are.

Putting motors in the right spot makes wearables comfy and useful.

Users should feel the feedback clearly without it being annoying.

Motors like Linear Resonant Actuators (LRAs) save energy and last longer.

These motors give accurate feedback and help batteries work better.

Better haptic feedback can improve experiences in healthcare and gaming.

Applications of Small Vibration Motors in Wearables

Improving how users interact with devices

Small vibration motors help make wearable devices easier to use. They send vibrations to give signals, making devices feel natural. For example, fitness trackers buzz to remind you to exercise. Studies show combining sound, visuals, and vibrations helps people do tasks better. One study found that vibrations helped people perform better by giving direct signals. This shows how vibrations can improve your experience with real-time touch feedback.

Helping with speech and communication

Vibration motors are changing how wearables recognize speech. Researchers found these motors can work like microphones to detect talking. With simple processing, they can understand words and phrases for voice commands. Another idea uses electronic skin to sense voice pressure through vibrations. This technology is soft and bendable, making it great for wearables. Devices like humming detectors turn throat vibrations into commands, showing how useful these motors are for communication.

Creative ways to use haptic vibrations

Haptic vibrations are adding new features to wearables. Fitness trackers use vibrations to guide workouts and keep you focused. Smartwatches use gentle vibrations for alerts, staying quiet in meetings. Navigation tools for blind users use vibrations to give directions, making travel easier. Meditation devices use vibrations to help you relax and stay calm. These examples show how vibrations can make wearable tech more helpful and enjoyable.

Types of Vibration Motors for Wearable Technology

Eccentric Rotating Mass (ERM) motors

ERM motors are widely used in wearable devices. They create vibrations by spinning an uneven weight. This movement produces a force you can feel as haptic feedback. These motors are simple and affordable, making them popular for many uses. Fitness trackers often use ERM motors to send alerts or reminders.

Studies show ERM motors work well for all age groups. One study tested 32 people, from young adults to seniors. It showed ERM motors give steady haptic feedback. Their simple design makes them easy to add to wearables. However, they are less precise than advanced motor types.

Age Group | Number of Participants | Mean Age (years) | Standard Deviation (years) |

|---|---|---|---|

Younger Adults | 16 | 23.75 | 4.1 |

Middle-Aged Adults | 6 | 53.5 | 5.9 |

Older Adults | 10 | 74.7 | 7.1 |

Total Participants | 32 |

Linear Resonant Actuators (LRA)

LRAs are another type of motor found in wearables. They use a spring-mounted weight that vibrates with alternating current. LRAs give more accurate and steady vibrations than ERM motors. This makes them great for detailed haptic feedback.

LRAs are small and light, perfect for wearable devices. They respond quickly and save energy, offering high performance. New LRA designs improve accuracy, giving realistic and engaging haptic feedback. These features make LRAs ideal for smartwatches and medical devices.

Coin-type actuators, a type of LRA, are valued for their tiny size.

They are energy-saving and respond fast, ensuring smooth use.

Mini flat coin vibration motors

Mini flat coin motors are a compact version of ERM motors. Their small size and low cost make them useful for wearables. These motors are often used in vibrotactile displays to provide simple haptic feedback.

Mini flat coin motors fit easily into slim, lightweight devices. But they have a downside: you can't adjust vibration strength and speed separately. You can change the intensity by adjusting input voltage with pulse width modulation. Despite this, their low price and energy efficiency make them a favorite for wearables.

Tip: When picking a haptic vibration motor, think about size, power use, and feedback type. Each motor has pros and cons, so choose what fits your needs best.

How to Integrate Haptic Vibration Motors into Wearable Devices

Picking the right motor for size, power, and vibration strength

Choosing the correct haptic vibration motor is very important. Think about size, power use, and vibration strength. Small motors like mini flat coin motors fit slim devices. They are light and easy to use in compact designs. If your device needs precise feedback, LRAs are better. They give accurate vibrations and save energy, making them great for smartwatches or medical tools.

Power use is also key. Wearables use small batteries, so energy-saving motors last longer. LRAs are known for using less power. Vibration strength matters too. Fitness trackers need strong vibrations for alerts. Meditation tools need softer vibrations to help you relax.

Tip: Match vibration strength to your device’s purpose. Strong vibrations work for alerts, while soft ones are better for calming tools.

Where to place motors for comfort and usability

Motor placement affects how comfortable and useful the device is. Put the motor where vibrations can be felt easily. For wrist devices, place it under the wrist for clear feedback. For chest devices, choose areas with less muscle for better vibrations.

Comfort is important in wearable design. Motors should fit without making the device bulky. Lightweight motors like mini flat coin motors work well for slim designs. Tests show vibrations help visually impaired users navigate. Balance placement with comfort to avoid skin irritation or too much vibration.

Feature | Description |

|---|---|

Motor Use | Micro motors give haptic feedback and alerts for wearables. |

Feedback System | Vibrations show obstacle distance, helping users stay aware. |

Testing | Trials checked safety and navigation in different environments. |

Choosing drivers and matching impedance for better performance

Drivers control how motors vibrate. Picking the right driver improves performance. LRAs need drivers for alternating current to give precise feedback. ERM motors use simpler drivers but can’t fine-tune vibrations as well.

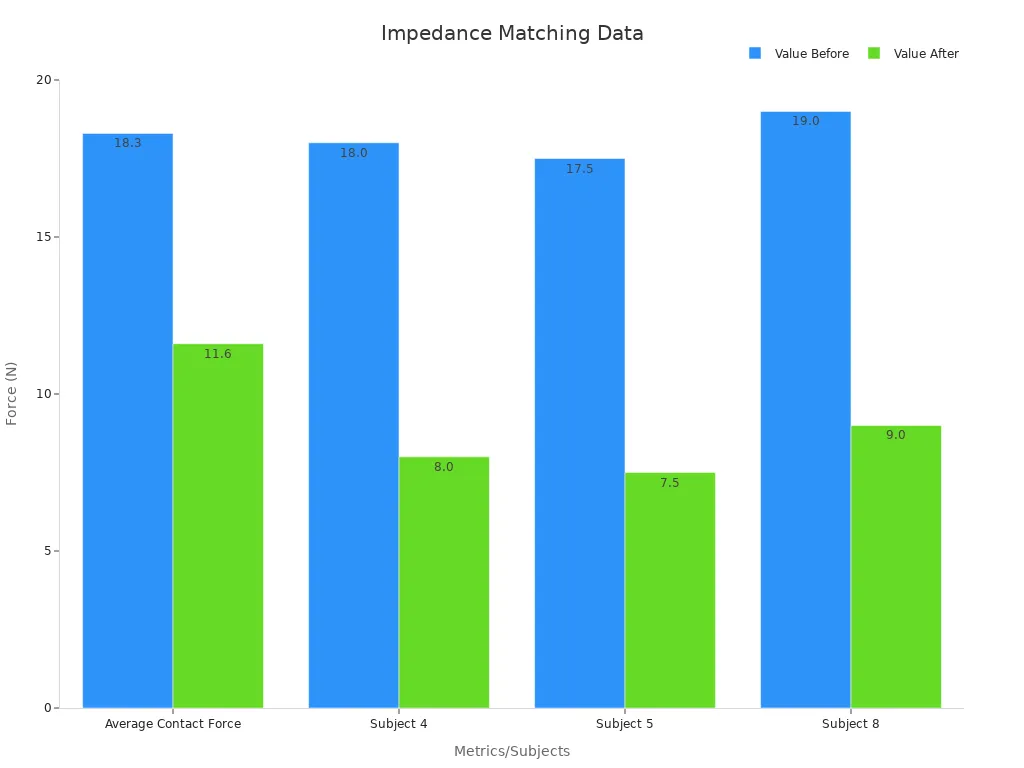

Impedance matching is also important. It reduces energy loss and makes motors work better. Tests show matching impedance lowers contact force by 35%. This improves feedback quality. In trials, users felt better vibrations after impedance matching, making devices work better.

Note: Test drivers and impedance matching in different settings. Indoor tests give reliable results. Outdoor tests may need changes for best performance.

Environment | Feedback | Voice Commands | Safety | Power Use |

|---|---|---|---|---|

Indoor | Reliable | Reliable | Good | Excellent |

Outdoor | Reliable | Okay | Okay | Excellent |

Designing Wearable Devices with Vibration Motors

Algorithms for haptic feedback generation

Good algorithms make haptic feedback feel natural and easy to use. These algorithms control how the motor vibrates for different alerts. For example, a fitness tracker might buzz sharply for reminders. It could also use soft vibrations to help you relax.

Performance tests show haptic feedback helps users work better. People made fewer mistakes and finished tasks faster with vibrations. Combining vibrations with visuals improved results. Here's a table comparing performance:

Metric | Description | Visual Feedback Results | Haptic Feedback Results | Importance |

|---|---|---|---|---|

User Efficiency | Mistakes like drops or collisions | 1.82 faults (SD: 2.28) | 1.43 faults (SD: 2.55) | p = 0.446491 |

User Effectiveness | Time taken to finish tasks | 219.74 s (SD: 108.21) | 215.53 s (SD: 104.51) | p = 0.347996 |

Algorithms should match what users need. For example, a navigation tool for blind users could use vibrations to guide them. Testing in real-life situations ensures the design works well.

Open-loop vs. closed-loop control systems

Control systems decide how motors respond to signals. Open-loop systems are simple and cheap. They send signals but don’t check if the motor vibrated correctly. These systems work for basic devices like fitness trackers. However, they are less accurate.

Closed-loop systems check the motor’s vibrations and adjust them. This makes feedback more precise and reliable. For example, smartwatches use closed-loop systems for accurate alerts. But these systems cost more and are harder to design.

Here’s a comparison of the two systems:

Control System Type | Benefits | Limits |

|---|---|---|

Closed-loop | Accurate feedback, better usability | Higher cost, harder to design |

Open-loop | Simple, low cost | Less accurate, no feedback |

Choose a system based on your device’s needs and budget. Closed-loop systems are best for detailed feedback. Open-loop systems work for simpler tasks.

PCB design tools and techniques for motor integration

Adding a haptic vibration motor to a device needs careful PCB design. The PCB connects the motor to power and controls. It must fit the motor’s size and energy needs.

Simulation tools help improve PCB designs. For example, vibration tests check how the motor affects the device’s structure. TechSAT tools save money by reducing the need for physical prototypes. Here’s a table of common simulations:

Simulation Type | Purpose |

|---|---|

Check design strength using frequency tests. | |

TechSAT Structural Analysis | Improve designs to handle vibrations without prototypes. |

Validation Cases | Compare simulation results with real-world tests. |

Vibration Analysis of Motor Bracket | Test how brackets hold up under vibrations. |

Eddy Current Analysis | Study energy loss in motor parts. |

TechSAT tools saved €15,000 while improving vibration resistance. Validation tests confirm these tools work well.

Place the motor where vibrations are easy to feel but not uncomfortable. Use light materials to keep the device slim. Test the design in different settings to ensure it works for users.

Tip: Use simulations to improve PCB designs and cut costs. Early testing saves time and boosts performance.

Challenges and Future Opportunities in Wearable Technology

Keeping devices safe from hackers

Wearables use wireless signals, which hackers can intercept. Tools like Wi-Fi cards can steal data. Even encrypted signals can show device types and usage. Signal changes can track where users go. Hackers can also group devices to find one person. Medical wearables are at higher risk because they hold private health data.

To stay safe, use strong encryption and hide signal patterns. Change encryption keys often to make hacking harder. Mask signal strength to stop tracking. Update your device’s software to fix weak spots. These steps help protect your device and keep your data private.

Solving size and power problems in wearables

Wearables need to be small and save energy. Tiny batteries don’t last long, and slim designs limit space. These issues can lower how well devices work. For example, fitness trackers need strong vibrations, but powerful motors use too much battery.

To fix this, use energy-saving motors like LRAs. They give good vibrations without wasting power. Place motors carefully to make vibrations work better. Use light materials to keep devices thin and comfy. Try solar panels or movement-powered batteries to make them last longer. These ideas help balance size, power, and performance.

Improving haptic feedback for future wearables

Haptic feedback is getting better with new ideas. Devices now mix touch with other senses for better use. For example, haptic wearables can send quiet signals in busy places. New tech like soft actuators is changing how vibrations feel.

Good designs need to understand how people feel touch. Skin contact and masking effects are tricky problems. Working together across fields helps make better devices. Haptic feedback is growing in healthcare, robots, and fun gadgets. It’s moving from simple buzzes to cool experiences. Using advanced haptic tech can make wearables more useful and exciting.

Key Facts | Details |

|---|---|

Multisensory Haptic Tools | Mix touch with other senses for better user interaction. |

Design Challenges | Solve problems with touch feeling and masking effects. |

Uses | Apply haptic tech in health, robots, and immersive media experiences. |

Small vibration motors are important in wearable tech. They change how we use devices by adding touch feedback. These motors give accurate and energy-saving haptic feedback, making devices more fun to use. For instance, LRA motors in smartwatches help you notice alerts, even in noisy places.

These tiny motors are useful in many fields. In healthcare, they help with recovery and reduce pain. In gaming and virtual reality, they make experiences feel more real with touch. As technology grows, these motors will bring new ideas, making gadgets fit better into our lives.

Did you know? 44% of prosthetic users stop using devices because they lack haptic feedback. Improving this tech can make devices easier and better to use.

FAQ

What type of vibration motor works best for wearables?

The best motor depends on your device's purpose. For accurate feedback, use Linear Resonant Actuators (LRAs). If you need something simple and cheap, Eccentric Rotating Mass (ERM) motors are good. Mini flat coin motors are great for thin devices.

How can wearables save power with vibration motors?

Choose energy-saving motors like LRAs. Place motors carefully for better vibrations. Control vibration strength using pulse width modulation (PWM). Try solar panels or motion-powered batteries for extra energy.

Where should vibration motors go in wearables?

Put motors where vibrations are easy to feel. For smartwatches, place them under the wrist. For fitness monitors, near the chest works well. Make sure the placement is comfy and doesn’t irritate the skin.

Can vibration motors help in medical devices?

Yes, they are useful in medical wearables. They give touch feedback for prosthetics, track health, and guide therapy exercises. Their accuracy and flexibility make them helpful in healthcare.

How do you check haptic feedback in wearables?

Test feedback in real-life situations. Use user trials and vibration simulations together. Change motor settings based on comfort and test results for the best performance.

See Also

Top 5 Compact Vibration Motors for Wearable Devices

Understanding the Functionality of Vibration Motors in Haptics

The Technology Behind Vibration Bracelets and Haptic Feedback

Innovations in Vibration Technology Transforming Haptic Feedback Systems

Design Factors for Compact Vibration Motors in Limited Spaces

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry