Small Vibrating Motors: Design Considerations for Space-Constrained Applications

Small vibrating motors are important in today’s small gadgets. They are used in things like smartphones and wearables. The market for phone vibration motors is growing fast. It is expected to go from $2.5 billion in 2023 to $4.1 billion by 2032. This means it will grow about 5.7% every year. This growth shows people want better and smaller technology.

Tiny spaces need special motor designs. Small direct drive motors are popular because they fit well in tight spots and still work great. To get the best results, think about size, energy use, and how much they vibrate. Good design helps these motors work perfectly in your device.

Key Takeaways

Small vibrating motors are important for gadgets like phones and smartwatches. The market for these motors may grow to $4.1 billion by 2032.

Picking the right motor, like ERM for cheaper devices or LRA for better wearables, affects how well they work and feel.

Good motor designs help save battery power, which is key for portable gadgets. New designs can make motors 39% more efficient.

Using proper mounting, like shock-absorbing materials, helps motors last longer and work better in small devices.

INEED makes custom motors that fit different needs, giving great performance in tight spaces for many uses.

Balancing Size, Amplitude, and Power Use in Small Motors

Trade-offs between motor size and vibration strength

Designing small motors needs careful planning. Small motors fit tight spaces but make weaker vibrations. Bigger motors vibrate stronger but may not fit small devices. This is important for wearables, which need to be small and vibrate well.

Tests show motor design matters for balance. Brushless DC (BLDC) motors work smoother and save energy better than Switched Reluctance Motors (SRM). BLDC motors have even air gaps for steady torque and fewer vibration problems. Good motor design helps small motors work better in tight spaces.

Power use in battery-powered devices

Battery life is key for wearables and portable gadgets. Small motors must save power to keep batteries lasting longer. New motor designs use less energy but still work well.

Recent tests show big improvements in motor efficiency:

Resistance changes boosted performance by 24%.

Efficiency improved by 19% in trials.

Other test results include:

Test Type | Improvement Seen |

|---|---|

Constant speed with closed-loop control | 39% better performance |

Frequency response tests | Faster and smoother results |

These upgrades show how better motor designs save energy and improve battery life.

Better motors for wearables and small devices

Wearables need motors that vibrate reliably and stay small. Fitness trackers and smartwatches depend on good motor designs. Studies show compact motors must be precise and dependable.

For example:

Study | Findings | Comparison |

|---|---|---|

MAIJU Wearable System | Reliable motor checks for infants at home | Similar to regular actigraphy |

Automated vs. Manual Detection | Strong match in motor measures | No big differences in results |

These studies show how better motor designs improve wearables. By focusing on size, heat control, and vibration quality, devices can meet user needs and work well.

ERM vs. LRA Motors: Choosing the Right Type for Your Applications

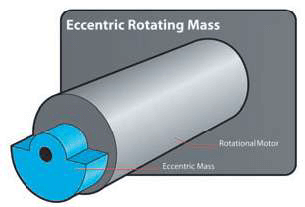

Understanding Eccentric Rotating Mass (ERM) and Linear Resonant Actuator (LRA) motors

Picking the right small vibrating motor is important. Knowing the difference between ERM and LRA motors helps you decide.

ERM Motors: These motors vibrate by spinning a heavy, uneven piece. They are popular because they are cheap and simple. But, they need more space and can’t make many vibration effects. They also respond slower, so they’re not great for precise feedback.

LRA Motors: These motors move a magnetic piece back and forth using an AC signal. This design makes them small and able to create clear vibrations. They work well in tight spaces and use less power. Their quick response makes them perfect for high-tech wearables.

Motor Type | How It Works | Control Method |

|---|---|---|

ERM | Spins a heavy, uneven piece to vibrate. | Uses DC current. |

LRA | Moves a magnetic piece with a spring. | Uses an AC signal. |

Wearables often use LRA motors because they give better feedback. Their small size and efficiency make them great for compact devices.

Advantages of INEED's Coin Vibration Motor and LRA Vibration Motor

INEED Electronics makes advanced vibration motors like coin motors and LRA motors. These motors are built for small spaces and work very well.

Coin Vibration Motors: These motors are tiny and easy to add to devices. They are reliable and affordable, making them great for fitness trackers and smartwatches.

LRA Vibration Motors: INEED’s LRA motors respond faster and use less power. They reach full vibration in 50ms, while ERM motors take over 100ms. This speed improves user experience. They also save battery life, which is important for portable gadgets.

Advantage | Details |

|---|---|

Fewer parts needed | Small design means fewer parts. |

Better durability | Fewer parts make them last longer. |

Lower setup costs | Easy to install, saving money. |

INEED’s motors are small, strong, and work well. They are perfect for modern wearables and small electronics.

Picking the best motor for wearables and small devices

The right motor depends on what your device needs. For wearables, size, battery life, and vibration quality are key. INEED’s motors meet these needs.

For Small Spaces: LRA motors are best because they vibrate well in tight spots. Their design is efficient and doesn’t lose performance.

For Budget-Friendly Devices: ERM motors are cheaper and good for basic vibration alerts. They work well for simple devices.

For Better User Experience: INEED’s LRA motors give fast, clear vibrations. They use less power, which helps batteries last longer.

By improving motor design, you can pick the best one for your device. INEED’s motors are flexible and perform well, making users happy in many industries.

Enhancing User Experience with Haptic Feedback in Wearables

How INEED's vibration motors improve tactile feedback

Haptic feedback makes wearables more fun and easy to use. INEED's motors give accurate and steady vibrations, improving your experience. Motors like the LRA and coreless motor create lifelike feedback. They work across many frequencies, from soft alerts to gaming effects. With quick response times, these motors give instant feedback, perfect for fitness trackers and smartwatches.

INEED's LRA motors respond fast, rising in 50ms and falling in 80ms. This speed makes vibrations feel real and keeps you connected to your device. They also last a long time, making them great for wearables that need to perform well over time.

Uses of haptic feedback in wearables and electronics

Haptic feedback changes how devices interact with users. In wearables, it gives quiet alerts, helps with workouts, and sends updates. Fitness trackers use vibrations to mark goals or guide exercises. For visually impaired users, it mimics textures to help with navigation or shopping.

In electronics, haptic feedback improves keyboards, gaming gear, and phones. Keyboards with vibrations make typing faster and more accurate. Gaming devices use haptics to feel explosions or small changes in the game world. These examples show how haptics make devices more useful and enjoyable.

Designing better wearables with INEED's coreless motor

To make great wearables, you need a motor that is small, efficient, and dependable. INEED's coreless motor is lightweight and fits in tiny spaces. It uses little power, helping batteries last longer.

The coreless design makes the motor spin faster and respond better. This allows for clear and precise vibrations, improving how the device feels. Whether for a smartwatch or fitness tracker, INEED's motor is reliable and efficient. It stays cool and works well, keeping your device comfortable and effective.

Mounting Considerations for Compact Designs

Best practices for securely mounting small vibrating motors

Mounting small vibrating motors correctly is very important. It helps them work well and last longer. Following good practices can stop problems like misalignment or vibration issues. Here are some tips:

Isolation: Use materials that soak up vibrations. This stops nearby parts from being affected and reduces noise.

Heat Dissipation: Don’t run motors at high power for too long. Too much heat can shorten their life and make them less reliable.

Electrical Noise Management: Motors can create electrical noise. Add filters to circuits to avoid interference with other parts.

Best Practice | Description |

|---|---|

Isolation | Use materials to block vibrations from spreading to other parts. |

Heat Dissipation | Limit high-power use to avoid overheating. |

Electrical Noise | Add filters to reduce electrical noise from the motor. |

These tips help motors work better and keep devices running smoothly.

Managing vibration isolation in tight spaces

Small designs make vibration isolation harder because of limited room. But using smart techniques can improve motor performance and device reliability. Studies show material density and wall thickness are key for isolation.

Parameter | Findings | Effectiveness |

|---|---|---|

Burial Depth | Deeper placement improves isolation. | Best results when depth is high. |

Wall Thickness | Thicker walls reduce vibrations well. | Less shaking and smoother operation. |

Composite vs Single-material | Composite walls work better than single-material ones. |

For small devices like wearables, use composite materials or thicker isolation layers. These methods reduce vibrations and help motors work efficiently.

Tips for integrating INEED's SMD Vibration Motor into compact devices

INEED's SMD vibration motor fits easily into small devices. To get the best results, follow these tips:

Mounting Techniques: Attach the motor securely with shock-absorbing materials. This keeps vibrations steady and prevents problems.

Driver Circuit Optimization: Match the motor’s power needs with the circuit. This saves energy and makes batteries last longer.

Testing and Calibration: Test the motor’s vibrations and adjust settings. Regular checks keep the motor working well.

Maintenance: Check the motor often for wear and tear. Fixing small issues early helps it last longer.

Topic | Description |

|---|---|

Mounting Techniques | Shows how to attach motors securely using shock-absorbing materials. |

Driver Options and Circuit Design | Explains how to match motor power needs with circuits for better performance. |

Testing and Calibration | Talks about testing and adjusting motor settings for smooth operation. |

Maintenance and Troubleshooting | Gives tips for checking motors regularly to avoid big problems. |

By using these ideas, you can add INEED's SMD vibration motor to your device easily. This ensures it works well in small spaces and lasts a long time.

INEED's Solutions for Small Spaces

Overview of INEED's Vibration Motor Types

INEED makes many small motors for tight spaces. These include coin motors, LRA motors, coreless motors, and SMD motors. Each motor is made for specific uses, helping devices work better in small areas.

People like how INEED's motors improve health and comfort. For example:

One person felt more energy and better blood flow using vibration devices.

Another said it eased pain and stiffness, helping them exercise more.

A 69-year-old shared that it helped their sore foot heal faster.

These stories show how INEED's motors are useful for wearables and health gadgets.

Custom Options for Different Needs

INEED customizes motors to fit special designs. Over 80% of their projects include changes to size, parts, or settings. You can ask for tweaks to speed, power, or torque to make the motor perfect for your device.

They also offer extras like connectors and encoders to fit your product. Whether for wearables or tools, INEED’s custom options help meet your exact needs.

Real-Life Examples: LRA Motor for Wearables and 4mm Motor for Scanners

INEED’s motors work well in real-world devices. The LRA motor improves wearables by giving quick, clear vibrations. In smartwatches, it uses less power and responds fast, making it user-friendly. Changes to its FPCB connection made assembly easier and cheaper.

In stores, the 4mm motor improved barcode scanners. It fit into current designs, so no redesigns were needed. Better winding and testing made it stronger and more reliable. These motors passed tough tests, proving they work well in busy places.

INEED’s motors are small, strong, and customizable, making them great for many industries.

Making small vibrating motors for tight spaces needs careful planning. Important factors include materials, shape, and how they are mounted:

Design Factor | Explanation |

|---|---|

Material Choice | Pick materials that improve how the enclosure handles vibrations. |

Shape and Size | The design affects how strong and stable the enclosure is. |

Mounting Methods | Use studs or adhesives to get the best vibration performance. |

Modern devices need to balance size, power use, and performance. New technology makes this easier with smaller and more efficient motors. For instance, vibration motors now improve wearables by giving better feedback and saving battery life. INEED's smart designs, like LRA and coin motors, work well in small gadgets for many uses.

FAQ

1. What do small vibrating motors do?

Small vibrating motors make vibrations for alerts or feedback. They help users feel notifications or effects, like in wearables or games. These motors make small gadgets more useful and fun to use.

2. How can I pick between ERM and LRA motors?

Pick based on what your device needs. ERM motors are cheaper and good for simple vibrations. LRA motors respond faster, save energy, and give clear feedback. They are best for wearables and advanced gadgets.

3. Can vibration motors be made to fit my device?

Yes, vibration motors can be adjusted for your device. Changes can include size, power use, vibration strength, and how they are mounted. INEED offers custom options to make motors work perfectly for your needs.

4. How do I attach a small vibrating motor properly?

Use materials that absorb shocks to stop extra vibrations. Make sure the motor is lined up right when installing. For SMD motors, follow soldering rules. Test and adjust often to keep it working well.

5. Why are INEED's motors good for small gadgets?

INEED's motors are tiny, strong, and efficient. They fit in small spaces and still work great. They use less power, helping batteries last longer. Custom options make them perfect for your device's needs.

See Also

Top 5 Compact Vibration Motors for Wearable Devices

Choosing the Perfect Vibrating Motor for Your Needs

Overview of Small Battery-Powered Motors and Their Uses

Understanding the Functionality of Vibration Motors in Haptics

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry