Small Motors: Types, Applications, and Selection Criteria

You use small motors every day, even if you do not see them. These small machines make things like fans and robots work. Picking the right small motor is important. The right choice can save energy and stop things from breaking. It can also help things work better. Efficiency classes go from IE1 to IE4. Higher classes save more energy. But they may need more space or special setups.

The global AC electric motor market was worth USD 18.57 billion in 2023. It may grow to USD 31.38 billion by 2032. This growth is mostly because of cars and factories.

Knowing about electric motors helps you choose better. This can make things last longer and cost less.

Key Takeaways

Small motors have many types. These include brushed DC, brushless DC, stepper, AC, geared, and servo motors. Each type is good for different jobs and needs.

Picking the right motor saves energy. It helps things work better. It also makes your equipment last longer. You should match power, torque, speed, and size to your project.

Robotics, HVAC, cars, and factories use small motors. These motors meet special needs for accuracy, speed, and space.

Think about the environment, protection, efficiency, and cost when you pick a motor. This helps the motor work well and last longer in your place.

Use a simple process. First, know what you need. Next, compare motor types. Then, check ratings. Last, test your choice to find the best motor for your project.

Types of Electric Motors

Small motors often have 75 watts or less power. Mini and micro motors can be as low as 3 watts. Learning about each electric motor type helps you choose the right one. Every type has special features. Each one works best for certain jobs.

Brushed DC Motors

Brushed DC motors are simple and easy to use. You can change their speed by changing the voltage. These motors have brushes that touch the spinning part. The brushes wear out after some time.

You get steady results because speed, torque, and current change together.

These motors are used in toys, small fans, and battery devices.

If you use dc brush motors too much, they lose efficiency. The brushes wear down, so they do not last as long.

Brushless DC Motors

Brushless motors do not have brushes, so they last longer. They need less care. They are more efficient than dc brush motors, with 85% to 90% efficiency.

You find these motors in drones, electric vehicles, and robots.

Over 60% of robots and many car parts use them.

They give high torque for their weight and are easy to control.

Brushless motors cost more at first, but you save money on care.

Motor Type | Efficiency | Typical Use Cases |

|---|---|---|

Brushed DC | 75-80% | Toys, fans, small tools |

Brushless DC | 85-90% | Drones, EVs, robotics |

Stepper Motors

Stepper motors move in tiny steps. You can control their position very well.

They are used in 3D printers and CNC machines.

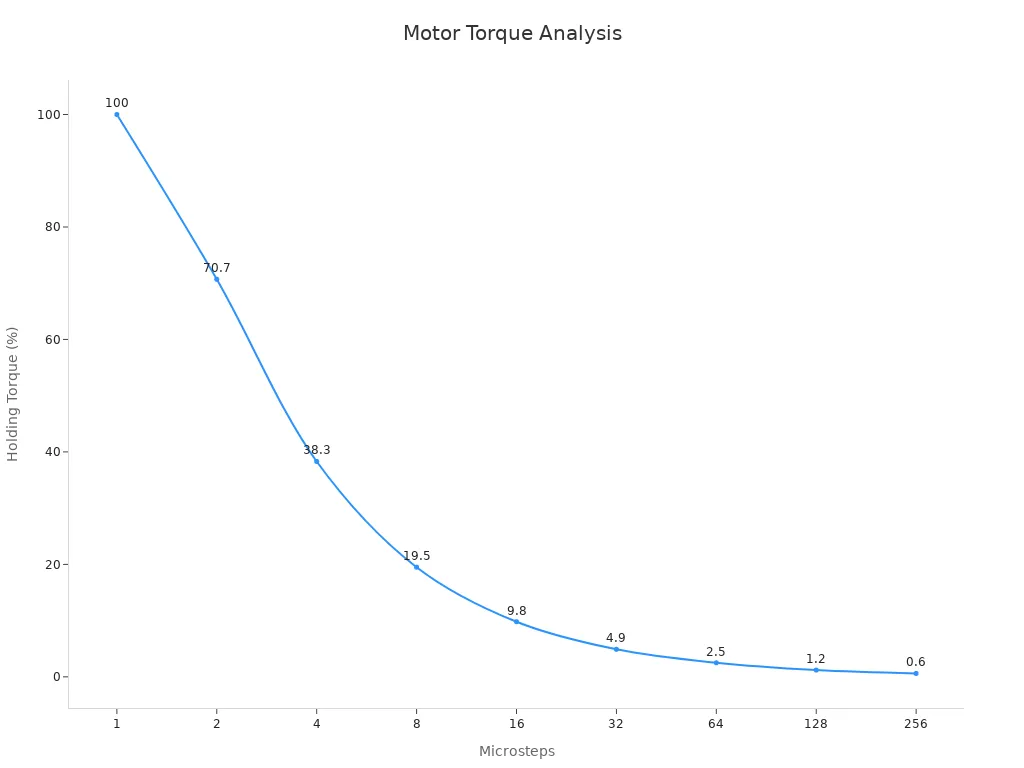

They give strong torque at slow speeds, but torque drops with more microsteps.

The chart below shows how torque goes down as microsteps go up:

AC Motors

AC motors use alternating current. You see them in most home and factory machines.

They do not have brushes, so they need less care and last longer.

AC motors can run a long time without getting too hot.

You find them in pumps, compressors, and conveyor belts.

They work well with variable frequency drives to save energy.

Geared Motors

Geared motors have a motor and a gear system together. This gives more torque in a small space.

These motors are great for robots and medical tools where space is small.

Gear reduction can make torque up to 100 times stronger.

Permanent magnet DC motors are used when space is tight.

Servo Motors

Servo motors let you control position and speed very well.

You use them in robots, packaging lines, and places that need fast, exact moves.

Servo motors use feedback systems for high accuracy and quick moves.

Tip: When picking a type of electric motor, always match it to your needs for torque, speed, and space.

Small Motors Applications

Robotics

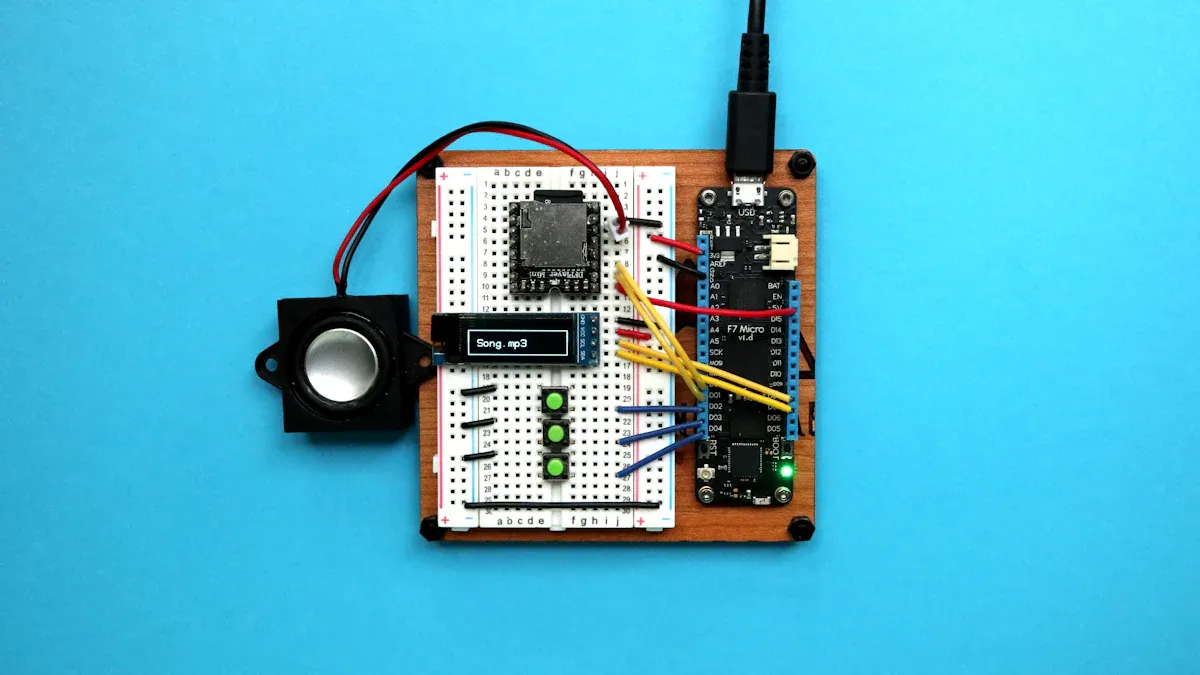

Small motors are used a lot in robotics. They help robot arms move fast and very accurately. Some robots can be as exact as ±0.02 mm. Fast robots can pick things up to 180 times each minute. This is possible with the right motors, like ironless brushed DC, brushless DC, or stepper motors. These motors work with sensors and encoders. The sensors give feedback right away. This helps control how the robot moves and how fast it goes. Robots use this for jobs like moving chips, doing surgery, and using electric grippers.

Robots need motors that fit their job. You have to check torque, speed, and size for every task.

Sensors and serial interfaces help control many parts and keep robots safe.

HVAC

HVAC systems use small AC motors to move air and change temperature. Many motors run at full speed even when it is not needed. This wastes energy. You can save money by picking the right motor size and type. High-efficiency motors, like NEMA Premium or permanent magnet types, can pay for themselves in a few years.

Metric/Aspect | Statistic/Value |

|---|---|

Portion of residential motor energy used by HVAC | ~87% |

Portion of residential energy for HVAC | ~30% |

Typical motor size in HVAC | Under 5 horsepower |

Full load efficiency range | 85% to 88% |

Payback period for upgrades | 1 to 5 years |

You should always match the motor to the job for best results.

Automotive

Small motors are very important in cars. They act as actuators and turn signals into movement. These motors help control engine parts, windows, and seats. Electronic control units use motors to make cars use less fuel and work better. Data from these motors helps stop breakdowns and lowers repair costs. Mechatronic systems with small motors also use fewer moving parts. This makes cars work better and last longer.

Cars need motors that can be controlled quickly and last a long time.

Industrial Automation

Factories use small AC and DC motors for things like conveyor belts, packaging, and sorting. These motors must run for a long time and move heavy things. Geared motors give more torque in small spaces. Servo motors help with jobs that need exact moves and speed. You must pick motors that match how often they run and where they are used.

Space-Constrained Devices

Devices like medical tools, drones, and aerospace equipment need very small motors. These motors must be small, light, and handle heat well. Engineers look at things like heat transfer area density and power-weight ratio to choose the best motors.

Criterion / Index | Description / Relevance |

|---|---|

Heat Transfer Area Density | Shows how compact the motor is |

Power-Weight Ratio | Measures performance for lightweight design |

Heat Transfer Coefficient | Tells how well the motor handles heat |

Note: Always check the size, torque, and cooling needs when you pick motors for small spaces.

You must always pick a motor that fits your needs. The right motor helps things work better, saves energy, and makes equipment last longer.

Motor Selection Criteria

When you pick a small motor, you need to think about a few things. You want the motor to work well and last a long time. It should also fit what you need it to do. Here are some ways to make good choices when picking a motor.

Power and Torque

First, check how much power and torque your project needs. Power is how much work the motor can do. Torque is the force that turns things. Both are important for lifting, moving, or spinning stuff.

Motors have two ratings: peak and continuous. For example, a strong RC motor weighs 655 grams. It can reach 12 kW at its highest but only runs safely at 7 kW for a long time. If you only look at the highest number, the motor can get too hot or break. Always use the continuous rating for your real needs.

If you want more torque, speed and efficiency can go down. For example, a motor with 3.75 lb-in torque at 2100 rpm works at about 70% efficiency. If you try for more torque, the motor slows down and uses more energy. This is an important thing to remember when picking a motor.

Tip: Always check both the highest and safe power and torque ratings. Use the safe numbers for daily use so the motor does not get too hot.

Here is a table that shows how torque and speed change if power stays the same:

Power (kW) | Speed (rpm) | Torque (Nm) |

|---|---|---|

0.75 | 3450 | 2.08 |

0.75 | 1725 | 4.16 |

0.75 | 500 | 14.32 |

10 | 3450 | 27.7 |

10 | 1725 | 55.4 |

10 | 500 | 190.9 |

You can see that when speed goes down, torque goes up for the same power. This helps in robots and electric cars that need strong force at low speeds.

High torque can make it harder to control the motor.

If you need steady torque, pick a motor that keeps torque steady.

Motors with high torque density give more power in a small size but can get hotter and cost more.

Speed and Control

Speed and control are important for how your motor works. You want the motor to run at the right speed and change quickly when needed. Sometimes, you need very exact control to keep things safe and working well.

Modern speed controllers, like PWM DC motor controllers, help you set the speed you want. These controllers also save energy by giving just the right amount of power. In factories, better speed control means less wasted energy and more work done. In cars, good controllers make motors run smoother and use less energy.

Servo motors help you control position and speed very well.

Good feedback devices, like encoders, help control and lower mistakes.

If you use advanced controllers, you can save energy and make less heat.

Note: If your project needs exact moves, pick motors with good feedback and smart control systems.

Environment and Protection

Where you use your motor changes how long it lasts. Hot, cold, wet, or dusty places can hurt motors. You need to pick motors with the right protection for where you use them.

Climate Zone | Temperature (°C) | Humidity | Main Risk | Protection Used | Durability |

|---|---|---|---|---|---|

Desert (Hot & Dry) | 30 to 50 | Low | Bearing failure from heat | High-temp polymers, better cooling | Moderate |

Coastal (Humid) | 15 to 25 | High | Corrosion, electrical faults | Corrosion-resistant coatings, sealing | Good |

Arctic (Cold & Dry) | -20 to 10 | Low | Brittle parts, poor lubrication | Special lubricants, heat-resistant | Good |

Temperate (Mild) | -10 to 30 | Moderate | Normal wear and tear | Standard materials, robust design | Excellent |

If you use motors in tough places, look for sealed cases, special coatings, or better cooling. These things help motors last longer and work better.

Tip: Always check the IP rating. Higher numbers mean better protection from dust and water.

Efficiency and Lifespan

Motors that use less energy last longer. Energy-efficient motors can lose 30–50% less energy than normal ones. This means they stay cooler, so parts last longer.

If you pick a high-efficiency motor, you get:

Lower energy bills.

Less heat and longer life for the motor.

Fewer times the motor breaks and less fixing needed.

Most energy-saving motors pay for themselves in less than two years if you use them a lot. They also work better when things get tough.

Note: Look for motors with high efficiency ratings like IE3 or IE4. These motors save money and last longer.

Cost and Availability

You need to think about both price and how well the motor works. Advanced motors, like brushless DC types, cost more at first but last longer and use less energy. Old-style motors are cheaper but may not last as long or work as well.

High material costs, like rare earth metals, can make some motors cost more.

New materials and 3D printing help lower costs and make motors better.

More companies selling motors can lower prices, but quality must stay high.

In some places, price matters more than fancy features.

Tip: For most projects, look at the total cost over the motor’s life, not just the price tag. Sometimes, paying more at first saves money later.

How to Balance These Factors

When you pick a motor, make a list of what matters most for your project. Think about power, torque, speed, control, where you use it, efficiency, how long it lasts, and cost. Use this list to compare different motors. Always check if the motor fits your space and protection needs.

If you need help, ask for datasheets or talk to suppliers. They can help you find the best motor for your job.

How to Choose Electric Motors

Choosing the best motor for your project can feel hard. You want your machines to work well and last a long time. You also want to save energy and money. You can follow a simple step-by-step process to select the right motor for any job. Here is how you can do it:

Define Requirements

Start by writing down what you need your motor to do. This step helps you avoid mistakes later. You should:

List the main things your system must do. Focus on speed, torque, and how exact the movement needs to be.

Look at speed and torque charts from motor makers. These charts show how motors work at different speeds and loads.

Know that some needs may not be clear until you build a test model. If you are not sure, use what you know from old projects or pick a bigger motor first. You can always use a smaller one later.

Decide if you need a stepper or servo motor. Think about how fast, how accurate, and how strong the motor must be.

Check the size and shape of the motor. Make sure it fits in your machine. Look at mounting standards like NEMA sizes.

Think about the loads on the motor’s bearings. Too much force can break the motor.

Use computer models or build a prototype to test your choices. This helps you see if the motor meets your needs.

Tip: Always write down your needs before you look at motors. This makes it easier to select the right motor.

Compare Motor Types

Now you can look at different motors and see which one fits your needs. You should compare how each motor works, how much energy it uses, and how long it lasts. Use tables and charts to help you see the differences.

Motor Type | Max Torque (Nm) | Torque Ripple (pu) | |

|---|---|---|---|

Brushed DC Motors | 75 - 80 | N/A | N/A |

Brushless DC Motors | 85 - 90 | 11.5 | 0.73 |

AC Induction Motors | 90 - 93 | N/A | N/A |

Synchronous Motors | Up to 99 | N/A | N/A |

Switched Reluctance Motors (SRM) | 94.6 | 3.8 | 1.19 |

You can see that brushless DC motors use less energy and have less torque ripple than brushed motors. AC induction and synchronous motors can reach even higher efficiency. If you want smooth and quiet motion, brushless DC motors work well. If you need the highest energy savings, look at synchronous motors.

Here is another table to help you compare:

Feature | Brushed Motors | Brushless Motors (BLDC) |

|---|---|---|

Efficiency | Lower | Higher |

Speed & Acceleration | Slower | Faster |

Noise Levels | Louder | Quieter |

Maintenance | Frequent | Minimal |

Lifetime | Shorter | Longer |

You should also think about how easy it is to control the motor, how much noise it makes, and how often you need to fix it. Brushless motors last longer and need less care. Brushed motors cost less but wear out faster.

Note: Always compare the main features of each motor. This helps you select the right motor for your project.

Make the Final Selection

After you compare your options, you can select the right motor. Use your notes and test results to make your choice. Here is a simple example to show you how:

Example: Building a Small Robot Arm

You need the arm to move fast and stop at exact spots. You also want it to lift small parts.

You check your needs: high speed, high accuracy, and enough torque.

You look at speed and torque charts for stepper and servo motors.

You see that servo motors give better speed and accuracy. They also last longer and use less energy.

You check the size of the servo motor. It fits in your robot arm.

You test a prototype. The servo motor moves the arm smoothly and stops at the right spots.

You select the right motor: a small servo motor with feedback control.

Callout: Always test your choice if you can. A prototype helps you see if the motor works as you want.

You can use this same process for any project. Write down your needs, compare the motors, and test your top choice. This helps you select the right motor every time.

Remember: Many countries have rules for how much energy motors can use. Pick motors that meet these rules to save money and help the planet.

You now know how to choose the right small motor for your applications. Start by learning about different motor types and how they work. Always match the motor to your specific applications and test your load requirements. Use this simple checklist:

List your application needs first.

Compare motor types and their pros and cons.

Check power ratings and test with your load.

Think about gear ratios and control methods.

Careful planning leads to better performance and longer-lasting equipment.

FAQ

What is the best way to size a small motor for my project?

You should list your load’s weight and speed. Check the motor’s torque and power charts. Pick a motor that meets or slightly exceeds your needs. Always test with your real load before final installation.

How do you know if a motor is energy efficient?

Look for efficiency ratings like IE3 or IE4 on the label. High-efficiency motors use less electricity and stay cooler. You can also ask the supplier for test data or check the datasheet.

Can you use the same motor for different applications?

You can use some motors in many devices. Always check if the motor’s power, speed, and size match your new project. Motors for heavy loads or high speed may not work well in small or slow devices.

What should you do if your motor overheats?

Stop the motor right away. Check for blocked airflow, too much load, or wrong voltage. Clean the motor and remove dust. If it still gets hot, try a bigger motor or add cooling.

How often should you maintain a small motor?

You should check your motor every few months. Clean dust and dirt. Listen for strange noises. Replace worn parts like brushes if needed. Regular checks help your motor last longer.

See Also

Understanding Different Rotating Motors And How To Choose

Everything You Need To Know About Mini Motor Uses

A Comprehensive Overview Of Vibration Motors And Their Uses

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry