Small DC Motors for Robotics and Electronics A Comprehensive Comparison

Choosing the right small DC motor is very important. Motors help with movement, energy use, and accuracy in projects. Picking the wrong motor can cause overheating, loud noise, or failure.

Here are key things to think about:

Duty cycle shows if the motor works nonstop or in breaks.

Efficiency saves power by turning more energy into motion.

Noise and vibration make the motor work better and quieter.

Pick a motor that matches your project’s needs for success.

Key Takeaways

Picking the right small DC motor is very important. Think about torque, how long it will run, and efficiency to avoid problems like overheating.

Brushed motors are cheap and simple to use but need regular care. Brushless motors last longer and work better, great for tough jobs.

Coreless motors are light and accurate, good for quick tasks. But they don’t work well for very fast jobs.

Knowing the balance between cost and performance helps you choose. Spending more on good motors can save money on energy and repairs later.

Use a guide to pick the best motor: check your needs, match the motor to the job, and balance price with quality.

Overview of Small DC Motors

What Are Small DC Motors?

A small DC motor is a tiny machine that changes electricity into movement. It uses direct current (DC) and works well in small projects. These motors come in types like brushed, brushless, and coreless, each with special benefits. Their small size makes them perfect for tight spaces.

Small DC motors are very flexible. You can use them with a speed controller to adjust how fast or slow they go. This makes them useful for many tasks. Whether you need careful control or fast action, these motors work dependably. They can handle different speeds and power levels to fit various jobs.

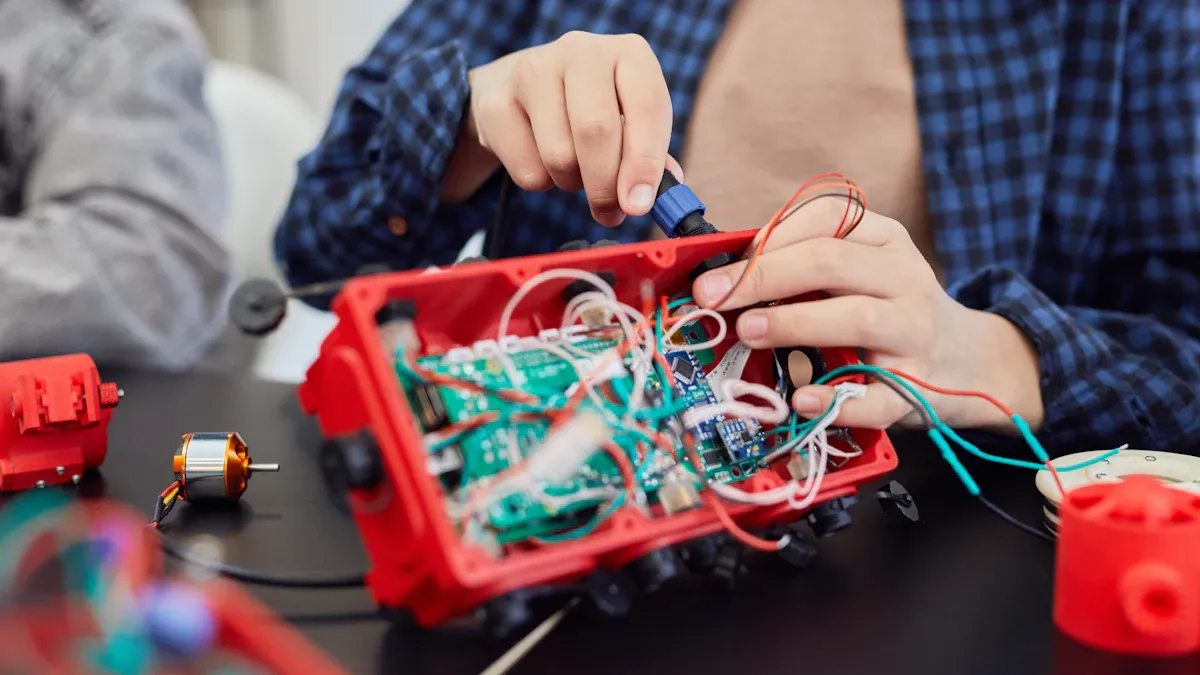

Applications in Robotics and Electronics

Small DC motors are important in robotics and electronics. In robots, they move wheels, arms, and other parts, helping robots do tasks accurately. For example, a robot arm might use a motor to pick up items or do delicate work. In electronics, these motors are used in things like fans, pumps, and drones, where controlled movement is needed.

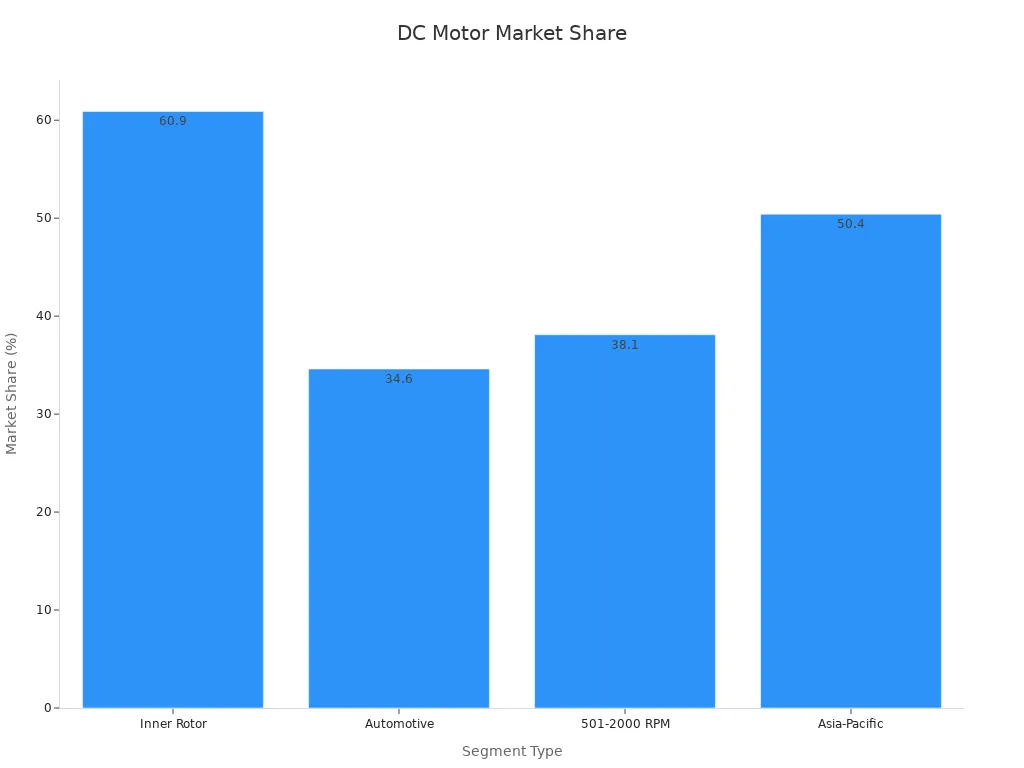

The need for small DC motors is growing in many industries. In the U.S., brushless DC motors are becoming more popular because of automation. Asia-Pacific leads the world with 50.4% of the market, thanks to manufacturing and electric cars. The car industry makes up 34.6% of the market, driven by electric vehicle growth.

Here’s a closer look at market trends:

Segment Type | Market Share (%) | CAGR (%) | Key Insights |

|---|---|---|---|

Inner Rotor | 60.9% | N/A | Great for cars and robots; saves energy and cuts costs. |

Outer Rotor | N/A | 7.5% | Quiet and strong; popular in electronics and medical tools. |

Automotive | 34.6% | N/A | Growth due to electric cars; helps save on oil use. |

Consumer Electronics | N/A | 10% | Smart devices drive growth; better efficiency in appliances. |

501-2000 RPM | 38.1% | N/A | Common in cars and electronics; good for fans and pumps. |

2001-10000 RPM | N/A | 8.5% | Used in medical tools and factories; offers power and accuracy. |

Asia-Pacific | 50.4% | N/A | Leads due to manufacturing and electric cars; key global player. |

Small DC motors are essential for many uses, from robots to gadgets. Their ability to work with speed controllers gives precise control, making them a trusted choice for new technologies.

Types of Small DC Motors

Brushed DC Motors

A brushed DC motor is simple and commonly used. It works by using brushes to send electricity to the motor's moving parts. This powers the rotor and makes the motor spin. These motors are cheap and easy to use, making them great for beginners.

Brushed motors are found in toys, small machines, and basic robots. They are easy to control and provide decent power. However, they need regular care because the brushes wear out. This makes them less durable than other motors. They also make more noise and shake more when running.

Here’s a quick comparison of brushed and brushless motors:

Feature | Brushed Motor | Brushless Motor |

|---|---|---|

Lifetime | Shorter | Longer |

Maintenance Needs | Brushes wear out | Minimal care needed |

Speed & Acceleration | Slower | Faster |

Efficiency | Lower | Higher |

Noise & Vibration | More | Less |

Torque | Moderate | Higher |

Weight & Size | Lighter | Heavier |

Cost | Cheaper | More expensive |

If your project has a small budget and you don’t mind fixing it sometimes, a brushed motor is a good choice.

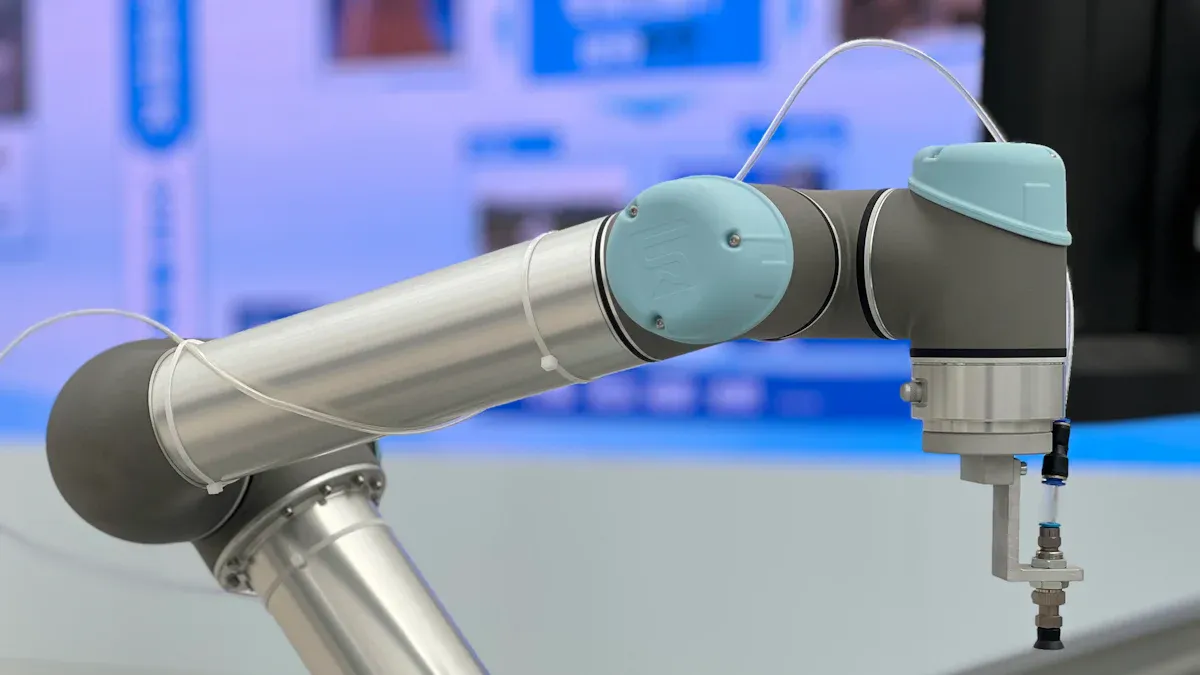

Brushless DC Motors (BLDC)

A brushless DC motor, or BLDC, is more advanced. It doesn’t use brushes but relies on electronic controls to work. This makes it stronger and more efficient. BLDC motors are used in robots, drones, and electric cars because they perform well and last long.

BLDC motors save energy by turning more electricity into movement. They are quieter and vibrate less, which is great for precise tasks. Unlike brushed motors, they don’t need much care since there are no brushes to wear out.

Here’s how BLDC motors compare to brushed and coreless motors:

Feature | Brushed Motor | Brushless Motor | Coreless Motor |

|---|---|---|---|

Lifetime | Short | Long | Depends on bearings |

Speed | Slower | Very fast | Gradual speed increase needed |

Control | Needs speed control | Easy torque control | Open-loop control possible |

If your project needs high efficiency, quiet operation, and durability, a BLDC motor is a great pick. But remember, it costs more than brushed motors.

Coreless DC Motors

Coreless DC motors are lightweight and precise. They don’t have an iron core inside, which makes them lighter. Instead, they use special windings that help them move faster and smoother.

Coreless motors are used in medical tools, drones, and precision robots. They are perfect for tasks where weight and quick response matter. But they aren’t good for very fast speeds. You must increase their speed slowly to avoid damage. They also cost more because of their unique design.

Coreless motors are easy to control with open-loop systems. Their lifespan depends on the bearings, which can last tens of thousands of hours. If you need a motor for a light and accurate job, a coreless motor is a smart choice.

DC Motor Efficiency and Performance

What Affects Motor Efficiency?

Knowing what impacts motor efficiency helps in picking the right motor. Several things affect how well a small DC motor turns electricity into movement:

Torque: More torque lets the motor handle heavier loads. But too much torque can lower efficiency if not balanced.

Speed: Faster speeds can boost performance but might waste energy.

Internal Resistance: Resistance inside the motor creates heat, wasting energy and lowering efficiency.

Thermal Effects: Heat from parts like copper windings can hurt performance. Poor cooling can make the motor less efficient over time.

Temperature is very important for motor efficiency. For example, brushed motors make more heat because of friction. BLDC motors, however, handle heat better. When choosing a motor, think about its design and how well it manages heat.

BLDC Motors vs. Brushed Motors in Efficiency

BLDC motors are more efficient than brushed motors. They use electronic controls instead of brushes, which saves energy. This makes them great for tasks needing high efficiency, like drones and robots. Brushed motors lose more energy because of friction and wear.

Here’s a simple comparison of their performance:

Feature | Brushed Motors | Brushless Motors (BLDC) |

|---|---|---|

Efficiency | Lower | Higher |

Speed and Acceleration | Slower | Faster |

Noise Levels | Louder | Quieter |

Maintenance | Frequent | Minimal |

Lifetime | Shorter | Longer |

BLDC motors also save more energy. The International Energy Agency says using brushless motors could cut global electricity use by 10% by 2030. This makes them a smart and eco-friendly choice.

Comparing Motor Efficiency

Here’s a table to show the differences between brushed and BLDC motors:

Factor | Brushed Motors | Brushless Motors (BLDC) |

|---|---|---|

Internal Resistance | Higher | Lower |

Heat Dissipation | Less Effective | More Effective |

Energy Conversion | Less Efficient | Highly Efficient |

Suitability | Basic Applications | High-Performance Tasks |

Think about your project’s needs when picking a motor. If you want high efficiency and long-lasting performance, a BLDC motor is worth the extra cost.

Performance Metrics of Small DC Motors

Torque and Speed

Torque and speed are key for motor performance. Torque shows how much weight a motor can handle. Speed tells how fast the motor spins. Motors with high torque start quickly and lift heavy loads. Brushless motors work better than stepper motors for many tasks. They are faster and use less energy. Studies show optimized DC motors can reach 3141.5 rad/sec torque. They can also achieve 31.415 rad/sec speed with good controls. Picking the right motor helps balance torque and speed for your project.

Noise and Vibration

Noise and vibration affect how well a motor works. Too much noise means wasted energy. Vibration can damage parts and shorten the motor's life. Research on machines gives tips to reduce vibration. For example, tracked vehicles and rotor systems offer useful data. This data helps improve small DC motors. The chart below shows studies on motor noise and vibration:

Less noise and vibration make motors last longer and run smoother.

Durability and Maintenance

Durability and maintenance keep motors working longer. Strong motors break down less and save repair costs. Brushed motors need more care because brushes wear out. Brushless motors last longer and need little upkeep. Coreless motors rely on good bearings to stay durable. Regular checks and cooling systems help motors last even longer. Choosing a motor that is durable and easy to maintain ensures it works well for years.

Cost vs. Performance Trade-offs

Cost Implications of Small DC Motors

When picking a small DC motor, cost matters a lot. The price depends on the motor's type, efficiency, and durability. Brushed motors are cheaper but need more repairs. Brushless motors cost more upfront but last longer and need less care. Coreless motors are the priciest because they are made for precise tasks.

Electricity prices also affect how much it costs to run a motor. For example, in 2028, electricity is expected to cost $0.092 per kilowatt-hour. Even if repair costs stay the same, efficient motors can save energy money. By 2029, motor costs are not expected to rise much, making efficient motors a good long-term choice.

Year | Average Electricity Price ($/kW) | Efficiency Level Impact on Costs |

|---|---|---|

2028 | 0.092 | No change in maintenance costs |

2029 | 0.085 | Incremental costs not expected to change significantly |

2021 | N/A | No significant advancements in motor technology leading to cost changes |

Choosing the right motor means balancing its price with its savings. Spending more on an efficient motor can lower energy bills and repair costs.

Balancing Budget with Motor Efficiency

Balancing your budget with motor efficiency takes careful thought. First, figure out what your project needs. If you need precision and durability, a brushless or coreless motor is worth the cost. For simpler jobs, a brushed motor might work, especially if money is tight.

Think about long-term savings. Efficient motors waste less energy, saving money over time. Brushless motors are great for projects that run a lot because they save energy. Brushed motors, however, may cost more in repairs later.

Weigh the pros and cons. Spending more on a strong, efficient motor can save on energy and repairs. But for short-term or easy projects, a cheaper motor might be better. Always match your motor choice to your project’s needs and budget.

Choosing the Right Small DC Motor

Key Considerations for Robotics Applications

Picking a small DC motor for robots needs careful thought. Robots often need strong motors for lifting and moving. First, figure out how much torque and speed your robot needs. For example, a robotic arm lifting items needs high torque. A wheeled robot might need more speed instead.

Think about where the robot will work. If it’s in dusty or wet places, use a sealed motor like a BLDC motor. These motors resist damage and stay efficient longer. Also, check the power source. Battery-powered robots need efficient motors to last longer. BLDC motors are great because they save energy better than brushed motors.

Weight is also important. Lightweight motors, like coreless ones, are good for drones or small robots. But they don’t lift heavy things well. Always balance weight and power to make sure your robot works properly.

Key Considerations for Electronics Applications

Small DC motors are used in fans, pumps, and tools. To pick the right motor, know the speed, torque, and voltage your device needs. For example, a fan needs moderate speed and low torque. A pump needs higher torque to move liquids.

Size matters in electronics. Small devices need tiny motors, but they must still work well. Brush DC gear motors are good for tight spaces. They use gears to boost torque, making them great for pumps or actuators.

Duty cycle is also key. If your device runs all the time, pick a motor made for long use. BLDC motors are efficient and last longer, so they’re good for nonstop tasks. If your device works off and on, brushed motors might be enough and cost less.

Decision-Making Guide for Motor Selection

Follow these steps to choose the best motor:

Know Your Needs: Figure out the torque, speed, and voltage needed. Robots need strong motors. Electronics need small, efficient ones.

Pick the Right Type: Match the motor to your task. BLDC motors are durable and efficient. Brushed motors are cheaper but need more care. Coreless motors are light but can’t lift heavy loads.

Check the Environment: Pick a motor that works in your conditions. Sealed BLDC motors are good for tough places.

Balance Cost and Quality: Think about your budget. Spending more on a good motor saves money later.

Test It Out: Try the motor in your device. Adjust settings for the best results.

These steps help you pick a motor that fits your project and saves money.

Picking the right motor helps your project work well and last. Brushed motors are cheap but need more upkeep. Brushless motors are strong and save energy. Coreless motors are light and precise. Each motor type works best for certain tasks, so choose wisely.

For robots, focus on torque and speed. For electronics, pick small motors that run smoothly. Use these tips to match a motor to your needs:

Low cost: Stepper motor or DC Brush

Smooth operation: DC Brush or Brushless DC

High speed: Brushless DC

High torque to size ratio: Step motors and Axial Flux motor

Different jobs need specific inertia ratios for the best results:

Application | Inertia Ratio Jl/Jm |

|---|---|

Direct Drive/Minimal Compliance | >100 |

Damped | >5 |

Typical Servo | 3-5 |

Responsive | 1 |

High Bandwidth | 0.70 |

Choosing the right motor saves time, money, and energy. Think about what your project needs to get the best motor for the job.

FAQ

What motor is best for robots?

The best motor depends on your robot's job. Brushless motors are strong and last long. Coreless motors are good for light robots. Brushed motors are cheap but need more care. Pick a motor that fits your robot's torque and speed needs.

How can you make small DC motors quieter?

To make motors quieter, use brushless ones. They shake less and make less noise. Install them properly and check them often. Add dampers or mounts to reduce shaking and improve performance.

Can small DC motors lift heavy things?

Small DC motors can lift medium weights. For heavier jobs, pick motors with more torque. Brushless motors are great because they give more power for their size.

How do you take care of a brushed motor?

Check the brushes often and replace them if worn out. Clean the motor to remove dirt. Add oil to moving parts to stop friction and heat. Good care makes the motor last longer.

Are coreless motors good for long use?

Coreless motors are best for short, precise tasks. They are not good for running fast all the time. Slowly increase their speed to keep them safe and working well.

See Also

How to Choose Mini DC Motors for Industrial Use

A Comprehensive Overview of Mini Motors and Their Uses

Ten Key Uses of 3V DC Motors in Electronics

Investing in Mini Brushless Motors for Accurate Applications

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry