A Beginner’s Guide to Selecting the Best DC Gearmotor

Choosing the best dc gearmotor for your project starts with knowing what you need. Think about how much torque, speed, and voltage your project requires. Pay attention to the size and how you plan to mount the dc gearmotor. Many beginners make mistakes like picking the wrong voltage, ignoring torque, or using a motor that is too small. Watch out for these common issues:

Using the wrong voltage may damage your motor.

Ignoring size and weight can cause balance problems.

Take it step by step, and you will find the right match for your project.

Key Takeaways

First, write down what your project needs. Think about torque, speed, and voltage. This helps you choose the best DC gearmotor. - Know that a DC gearmotor has a motor and a gearbox. It gives more strength but moves slower. - Pick a gear ratio that fits your project. This helps balance speed and power. - Make sure your motor’s voltage and current match your power supply. This stops damage and keeps it from getting too hot. - Think about the motor’s size and how you will attach it. Also, check if it needs protection from dust or water. This helps it last longer and work well.

DC Gearmotor Basics

What Is a DC Gearmotor

When you look at a dc gearmotor, you see a smart combination of two main parts: a dc motor and a gearbox. The dc motor creates spinning motion using electricity. The gearbox connects to the motor and changes how fast or strong that spinning motion is. This setup helps you get the right speed and power for your project.

Here’s what makes up a dc gear motor:

The motor, which uses electromagnetic force to spin.

The gearbox, which slows down the spinning but makes it stronger.

Gears inside, like spur, planetary, or worm gears, that help control speed and torque.

Some dc gear motors have extra parts like encoders for feedback or brackets for easy mounting.

Tip: You will find dc gear motors in robots, conveyor belts, and even green energy devices. They help you move things with the right force and speed.

Let’s look at the main parts and what they do:

Component/Aspect | Description |

|---|---|

Motor | Makes things spin when you add electricity. |

Gearbox | Slows down the spin but makes it stronger, so you can lift or push heavier things. |

Key Parameters | Speed (RPM), Torque, Efficiency, Gear Ratio, Voltage, Current. |

Working Principle | Turns electrical energy into spinning motion using magnets and wires. |

Efficiency | Usually between 70% and 90%, so you waste less power. |

Motor Types | Brushed (simple) and brushless (lasts longer and saves energy). |

Gear Ratio Effect | A big gear ratio means slower speed but more strength. |

Accessories | Things like encoders or brackets to help with control and mounting. |

DC Gear Motors vs. DC Motors

You might wonder how dc gear motors are different from regular dc motors. The main difference is the gearbox. A dc motor by itself spins fast but does not have much strength. When you add a gearbox, you get a dc gear motor that spins slower but can push or pull with much more force.

Here’s a quick comparison:

Feature | DC Motor | DC Gearmotor |

|---|---|---|

Structure | Just the motor, no gearbox. | Motor plus gearbox for more control. |

Speed & Torque | Fast spin, not much strength. | Slower spin, much more strength. |

Size & Weight | Smaller and lighter. | Bigger and heavier because of the gearbox. |

Efficiency | Good for simple jobs. | Better for jobs needing more power at low speeds. |

Application | Good for fans or toys. | Great for robots, machines, and things that need to move heavy stuff. |

If you use a dc motor 3v or 5v dc motors without a gearbox, you get fast spinning but not much pushing power. When you use dc gear motors, you can move heavy things slowly and with control. That’s why dc gear motors are popular in robotics and machines that need to lift or move objects.

You will see many types of dc motors, like brushed and brushless. Small electric motors, such as dc motor 3v or 5v dc motor, are great for simple projects. But when you need more control, dc gear motors are the way to go. If you want to know how dc motors work, just remember: electricity makes the motor spin, and the gearbox changes how that spin works for your needs.

How to Choose the Right DC Motor

Identify Application Needs

Do you want to pick the right dc motor? First, think about what your project needs. Every project is different. You should collect all the important details before choosing. Here’s a simple way to begin:

Write down what your project needs. Think about speed, torque, horsepower, efficiency, useful life, starting torque, and noise.

Use a checklist so you do not forget anything. This helps you stay organized.

Decide which dc gear motors work best for your project. Compare different types and see which one fits.

Pick the most important things for your project. Maybe you want high torque or quiet operation.

See if you need a gearbox. Sometimes, dc gear motors help you get the right speed and torque.

Make sure the motor and gearbox work well together. They must be compatible for smooth performance.

Tip: If you build a robot, conveyor, or smart home device, your needs will change. Always match the motor specs to your project.

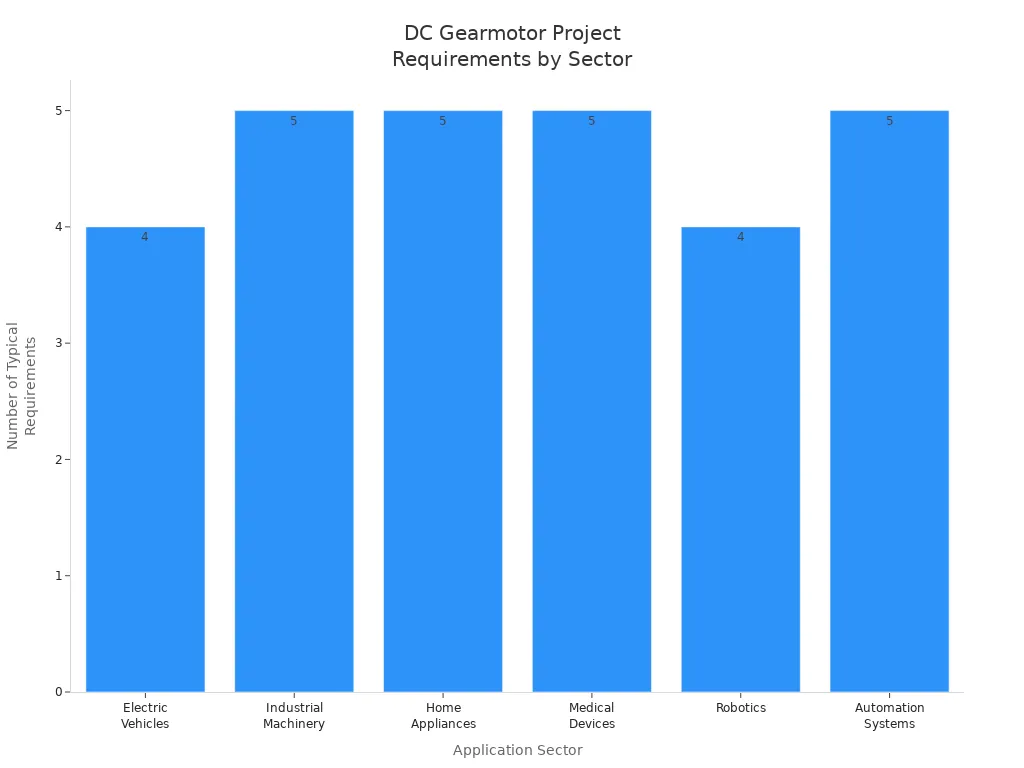

Check this table to see what different projects need from dc gear motors:

Application Sector | Typical Project Types and Uses | Typical Requirements and Characteristics |

|---|---|---|

Electric Vehicles | E-bikes, scooters, micro-mobility devices | Compact size, high torque, efficient power, sometimes regenerative braking |

Industrial Machinery | CNC tables, mixers, pumps, conveyors | Heavy-duty, precise positioning, high torque, quiet, continuous duty |

Home Appliances | Blenders, smart home devices, blinds | Compact, powerful, quiet, cost-effective, holding capability |

Medical Devices | Infusion pumps, surgical tools, patient lifts | High precision, compact, quiet, safety-critical holding and positioning |

Robotics | Joints, grippers, wheel drives | High precision, high torque density, smooth, compact mounting |

Automation Systems | Conveyors, automatic doors, packaging machinery | Controlled movement, reliability, self-locking, quiet, high-load handling |

Projects with dc gear motors need careful planning. You must think about torque, speed, voltage, current, and how the motor fits. Duty cycle is important too. If your motor runs all the time, pick one made for that. If it runs sometimes, you can use a lighter motor.

Torque and Speed

Torque and speed are very important for dc gear motors. You need to know how much force your motor must give and how fast it should spin. Here’s how to figure out torque:

Find out what you are moving. Is it heavy or light?

Measure the forces. Use this math: force equals mass times acceleration.

Calculate torque. Multiply the force by the shaft or gear radius.

Think about running torque and peak torque. Add extra for safety.

Choose a motor with more torque than you need. This keeps your project working well.

Speed and torque work like riding a bike. A big gear ratio gives high torque but lower speed. A small gear ratio gives higher speed but less force. You need to balance both for your project.

Note: The speed of dc gear motors depends on voltage. More voltage means more speed and more current. Too much current can hurt the motor.

Here’s a simple formula for torque:

Torque (Nm) = Force (N) × Radius (m)

And for power:

Power (W) = Torque (Nm) × Speed (rpm) / 9.55

If you use dc motor 3v or 5v dc motors, remember they have lower torque and speed than bigger motors. Low-voltage motors are good for small projects, but check if they meet your speed needs.

Voltage and Current

Voltage and current are just as important as torque and speed. You must match your dc gear motors to the power supply. Most low-voltage motors run between 1.5V and 24V. Hobby projects often use dc motor 3v or 5v dc motors. Industrial machines may need higher voltages.

Here’s a table showing common voltage and current ratings:

Motor Type | Rated Voltage (VDC) | No Load Current (mA) | Application Examples |

|---|---|---|---|

N20 Brushed DC | 1.5 to 12 | ~50-60 | Hobbyist projects, robotics |

3V Brushed DC | 2.5 to 12 | ~60 | Industrial automation, modeling |

Planetary Gear | 1.5 to 12 | ~50 | Industrial and hobbyist low-torque |

General DC Gear | 1.5 to 24 | Tens to hundreds mA | Varies by size and torque requirements |

If you use the wrong voltage, your dc gear motors can overheat or break. Too much voltage makes the motor spin faster and use more current. This can wear out the motor quickly. Too little voltage means weak performance. Always check the ratings and use voltage regulators or current limiters if needed.

Alert: Starting current can be up to 8 times higher than running current. Make sure your power supply can handle it, especially with low-voltage motors.

Check your motor with a multimeter often. This helps you find problems early and keeps your dc gear motors working longer.

Size and Mounting

Size and mounting are the last steps when picking a motor. You need to make sure your dc gear motor fits your project. Shaft diameter is important. Most 12V dc gear motors have shafts between 3 mm and 8 mm. Pick the right size for your couplings or pulleys.

Mounting options include flange mounting and foot/base mounting. You can choose inline or right-angle output. How you mount your motor affects lubrication and lifespan. Oil works best for standard positions, but grease lets you mount the motor in more ways.

Tip: Always check the mounting position. If you mount an oil-filled gearbox with the shaft up, it might leak.

Common shaft types are hollow shafts and solid shafts with keyways. These help you attach sprockets or pulleys easily. Make sure your mounting keeps the shaft stable and stops wear.

When you choose dc gear motors, think about the environment. High temperatures, moisture, and dust can hurt your motor. Pick motors with the right IP rating for your project. If you use dc motor 3v or 5v dc motors outside, look for waterproof or dustproof features.

Keep the temperature within safe limits.

Use corrosion-resistant materials for humidity and moisture.

Inertial loads, shock loads, and vibration affect motor life.

Bearings must handle radial and axial loads.

If you follow these steps, you’ll know how to pick the right dc motor for any project. Match your dc gear motors to your needs, and you’ll get good, long-lasting performance.

Gear Ratios in DC Gear Motors

Gear Ratio Impact

When you look at dc gear motors, the gear ratio is one of the most important things to understand. The gear ratio tells you how many times the motor turns for each turn of the output shaft. For example, if you have a 10:1 gear ratio, the motor spins ten times for every one turn of the output shaft. This setup changes both the speed and the strength (torque) of your motor.

A higher gear ratio means your dc gear motors will turn slower but push with more force. This is great when you need to lift heavy things or move something slowly and carefully. On the other hand, a lower gear ratio gives you more speed but less torque. You might use this when you want something to move fast and do not need much force.

Here’s what happens when you change the gear ratio:

If you increase the gear ratio, you get more torque but less speed.

If you decrease the gear ratio, you get more speed but less torque.

The gear ratio helps you balance between moving fast and moving with power.

Tip: Picking the right gear ratio helps your dc gear motors work better for your project, whether you want quick movement or strong pushing power.

Selecting Gear Ratios

Choosing the best gear ratio for your dc gear motors depends on what you want them to do. You need to think about how much weight you want to move, how fast you want it to go, and if you need precise positioning. If you want your project to move heavy loads slowly, pick a high gear ratio. If you want it to move quickly with less force, go for a low gear ratio.

Check out this table to see how different gear ratios affect your motor:

Gear Ratio | Torque Output | Speed (RPM) | Efficiency | Application Guidance |

|---|---|---|---|---|

Low (3:1) | Low torque | High speed | Higher efficiency | Good for fast tasks with light loads |

Medium (20:1) | Moderate torque | Moderate speed | Moderate efficiency | Balanced for mixed load and speed needs |

High (1500:1) | High torque | Low speed | Lower efficiency | Best for heavy loads and slow, careful movement |

When you select a gear ratio, always match it to your project’s needs. Think about the size and weight of your dc gear motors, the voltage you plan to use, and the environment where you will use them. Make sure your motor can handle the load and run at the right speed. If you need your project to stop at an exact spot, like in a robot arm, choose a gear ratio that helps with precise positioning.

Note: Always check the motor’s rated voltage and torque. This keeps your dc gear motors safe and running smoothly.

Efficiency & Noise

Brushless vs. Brushed DC Gearmotors

When you pick a DC gearmotor, you see two main types. These are brushed and brushless motors. You might ask which one is better for your project. Brushless DC gearmotors work with higher efficiency. They usually save more energy, between 85% and 90%. Brushed motors use about 75% to 80% efficiency. This means brushless motors waste less power. You can save money on energy costs. Brushless motors also last much longer. They can run for over 10,000 hours. Brushed motors may only last 2,000 to 5,000 hours.

Check out this table to compare them:

Feature | Brushed DC Gearmotors | Brushless DC Gearmotors |

|---|---|---|

Efficiency | Typically 75–80% | Typically 85–90% |

Maintenance Needs | Frequent brush replacements | Minimal maintenance |

Lifespan | 2,000–5,000 hours | 10,000–20,000+ hours |

Noise and Heat | Higher due to brush friction | Lower due to no brushes |

Long-term Cost | Lower at first, higher later | Higher at first, lower later |

Brushless motors help you control speed better. You can change the speed easily. The speed stays steady even if the load changes. Brushed motors may speed up or slow down if the load changes. This can make your project less reliable. Brushless motors also make less noise and heat. They are a smart choice if you want quiet and cool motors.

Tip: Brushless DC gearmotors need less fixing. You spend less time on repairs and more time working on your project.

Noise and Reliability

Noise can be a big issue in DC gearmotors. You might hear grinding, humming, or buzzing sounds. These noises come from different places.

Mechanical noise comes from gears, bearings, and fans. It happens when parts are not oiled well or are worn out.

Vibration noise comes from rotor imbalance or loose parts.

Aerodynamic noise comes from air moving around fans and motor parts. This is worse at high speeds.

Electromagnetic noise comes from changing currents and magnetic forces.

Gear mesh noise happens when gears hit and slide against each other.

Harmonic noise comes from changes in the electrical system.

All these noises can make your motor less reliable. Too much vibration can wear out bearings and gears faster. This means more repairs and less time for your project. You can lower noise by using good oil, picking strong gears, and making sure parts fit tightly. Good speed control helps too. If your motor runs at a steady speed, you get less vibration and fewer problems.

Note: If you want your DC gearmotor to last, watch out for noise and reliability. Small changes in design and setup can help a lot.

Environmental & Compatibility Factors

Environmental Protection

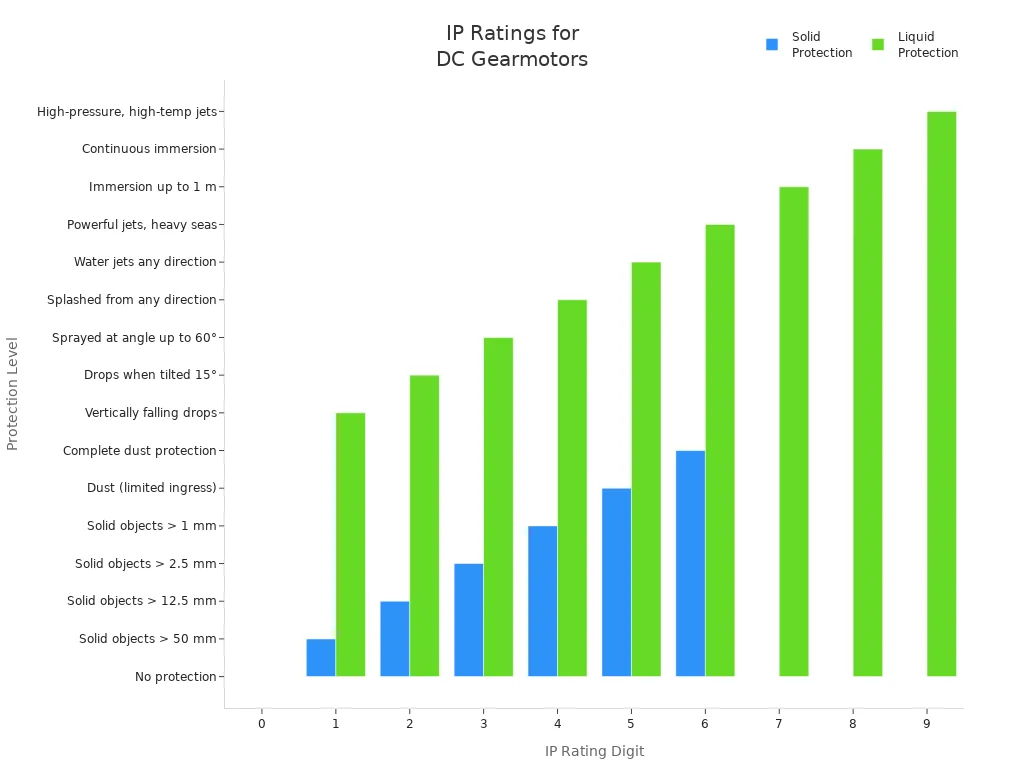

You want your DC gearmotor to last, right? Environmental protection matters a lot. Motors face dust, water, and even chemicals in many places. IP ratings help you know how tough your motor is. These ratings use two numbers. The first number shows how well the motor keeps out solids like dust. The second number shows how well it keeps out water.

Check out this table to see what each digit means:

IP Rating Digit | Protection Against Solids | Protection Against Liquids |

|---|---|---|

0 | No protection | No protection |

5 | Some dust protection | Water jets |

6 | Total dust protection | Powerful water jets |

7 | N/A | Immersion in water |

Motors with IP65, IP66, or IP67 ratings can handle tough jobs. IP67 motors are dust-proof and can even work after getting sprayed or dunked in water. You see these in outdoor conveyors and washdown areas. Manufacturers use special seals, O-rings, and coatings to reach these ratings. Some motors go through salt water spray tests to prove they can survive harsh conditions.

If you use low-voltage motors outside or in wet places, pick ones with high IP ratings. These motors last longer and keep working even when things get messy.

Tip: Always check the IP rating before you buy. It helps you avoid problems with dust, water, or rust.

Mechanical & Electrical Compatibility

Getting your DC gearmotor to fit your project is key. You need to match the motor’s size, shaft type, and mounting style to your setup. Make sure the shaft lines up with your gears or pulleys. Use strong bearings and solid mounts to keep everything steady. If you want to change speed or torque, pick the right gear ratio.

Electrical compatibility means your motor works with your power supply. Look at voltage and current ratings. Low-voltage motors are great for small projects and safe for kids or beginners. You need to check stall and running currents so your power supply does not get overloaded. Brushed motors are simple and easy to use. Brushless motors give you better speed control and last longer.

Here are some things to check for compatibility:

Match shaft size and mounting holes to your frame.

Pick gear ratios that fit your load and speed needs.

Use accessories like encoders or brackets for better control.

Make sure your power supply matches the motor’s voltage and current.

Think about noise and temperature. Some motors work better in hot or cold places.

Low-voltage motors work well in tight spaces and with battery-powered devices. You can use them in robots, toys, or smart home gadgets. They are easy to connect and safe to handle. If you need more power or speed, try pairing low-voltage motors with planetary or spur gearheads.

Note: Always test your motor setup before running your project. This helps you spot problems early and keeps your system safe.

Motor Drivers for DC Gearmotors

Driver Selection

You need a motor driver to control your DC gearmotor. The driver connects the power supply to the motor. It helps you start, stop, and change speed or direction. Some drivers use simple switches. Others work with microcontrollers like Arduino or Raspberry Pi for advanced control.

When picking a driver, check the voltage and current ratings. If your motor needs more current than the driver gives, the driver can get too hot or stop working. Look for drivers with speed and direction control. Some drivers have braking and protect against short circuits or overloads.

Think about these things when choosing a driver:

Match voltage and current ratings.

Decide if you need speed or direction control.

Look for safety features built in.

Make sure the driver works with your control system.

Tip: If you want to use a microcontroller, pick a driver that supports PWM. PWM helps you change speed smoothly.

Power Supply Considerations

Your power supply is important for your motor and driver. The right power supply keeps everything working safely. If you use the wrong one, your motor may run slow, get too hot, or break.

Here’s a table showing how power supplies affect performance and safety:

Power Supply Type | Performance Impact | Safety Considerations |

|---|---|---|

AC Adapters and Converters | Give steady voltage and good current; prevent overheating; work efficiently | Built-in voltage control stops damage from spikes; right size prevents overheating |

USB Power Supplies | Good for small motors; low current can hurt big motors | Low current means you must choose carefully to avoid damage |

Battery Packs | Portable; watch voltage to match motor specs | Prevent overcharging and voltage swings to avoid damage |

Solar Panels | Renewable; works best with sunlight | Needs extra safety steps and battery management for steady power |

Always check your power supply matches your motor’s voltage and current. Use supplies with protection circuits. These help stop overcharging, short circuits, and other problems. A good power supply keeps your project safe and working well.

Application Checklist

Common Uses for DC Gearmotors

DC gearmotors are used in many places. You might not notice them, but they are everywhere. They help robots move and make smart gadgets work at home. In robots, DC gearmotors turn wheels and move arms. They also control actuators in machines. On assembly lines, DC gearmotors do careful jobs all day. In cars, they move windows up and down. They adjust seats and run windshield wipers. At home, DC gearmotors open blinds and lock doors. They even make toys move. Medical tools use DC gearmotors for smooth and steady motion. Wheelchairs use them too.

Here’s a quick list of where DC gearmotors are used:

Industry | Typical DC Gearmotor Applications |

|---|---|

Robotics & Automation | Robot wheels, actuators, automated systems |

Automotive | Window lifts, seat adjusters, windshield wipers |

Industrial Machinery | Conveyor belts, material handling |

Consumer Electronics | Toys, power tools, home automation assistants |

Medical Industry | Surgical tools, powered wheelchairs |

Tip: DC gearmotors are great when you need strong and steady movement in a small space.

Quick Selection Table

It is easier to pick a DC gearmotor if you compare features. Use this table to help match your project with the right motor:

Parameter | What It Means for You |

|---|---|

Voltage | Works with your power source safely and smoothly |

No Load Speed (r/min) | Shows how fast it spins with nothing attached |

No Load Current (A) | Tells you the power used when not working hard |

Max Efficiency Load Speed | Best speed for saving energy while working |

Max Efficiency Load Current | Power needed when running at best efficiency |

Torque (kgf.cm) | The strength to move or lift things |

When you pick a DC gearmotor, check the size and weight. Make sure it fits your project. The gear ratio should give you the right speed and strength. Think about where you will use the motor. Motors last longer if you keep out dust and water. Always match how often you use the motor to its duty cycle.

Remember: Picking the right motor means fewer problems and a longer-lasting project.

You now know the key steps for picking the right DC gearmotor. Start by listing your project’s needs and double-check design limits like torque and heat. Always test your setup before final use. Using the checklist and table helps you avoid mistakes and get better results. If things get tricky, reach out to experts or check product guides, FAQs, and support pages. Careful selection means your motor runs longer, saves energy, and needs fewer repairs. You’ve got this—your next project will run smoother than ever! 🚀

FAQ

What is the difference between a DC gearmotor and a regular DC motor?

A DC gearmotor has a gearbox attached. This gearbox lets you get more torque and control the speed. A regular DC motor spins fast but cannot move heavy things easily.

How do I know what voltage my DC gearmotor needs?

Check the label or datasheet for your motor. You should match your power supply to the motor’s rated voltage. Using the wrong voltage can damage your motor or make it run poorly.

Can I run a DC gearmotor with batteries?

Yes, you can use batteries. Make sure the battery voltage matches your motor’s needs. Rechargeable batteries work well for small projects. Always check the battery life and current rating.

Why does my DC gearmotor get hot?

Your motor gets hot if you overload it or use the wrong voltage. Too much current can also cause heat. Let your motor rest if it feels hot. Use the right size motor for your project.

How do I reduce noise from my DC gearmotor?

Try adding oil to the gears and making sure all parts fit tightly. Brushless motors run quieter than brushed ones. You can also use rubber mounts to lower vibration and noise.

See Also

How To Select Battery Electric Motor Configurations For Efficiency

Guide To Picking Mini DC Motors For Industrial Use

Tips For Choosing Planetary Gear Motors For Accurate Screwdrivers

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry