Selecting the Right 3 Volt DC Motor for Your Project

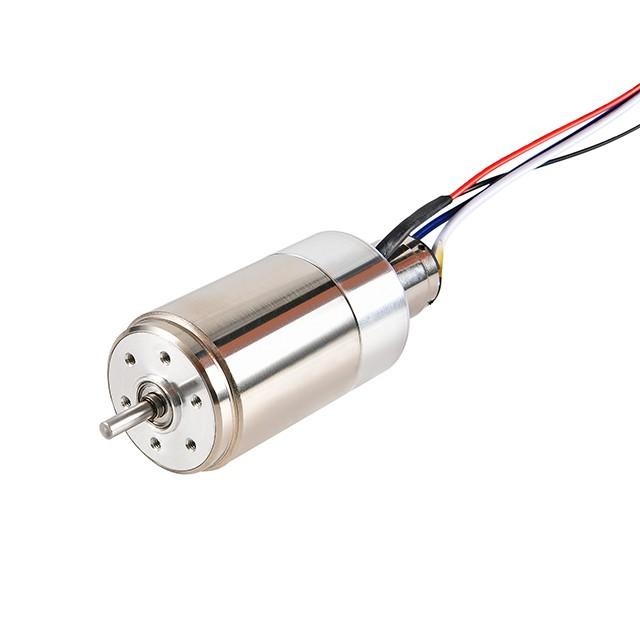

Choosing the right motor is crucial for success. A 3 Volt DC Motor is frequently utilized in various projects. However, not all motors operate in the same manner. INEED’s Micro DC Motors and Micro motors stand out. They provide consistent performance across different motor types. These motors are compact, efficient, and tailored to meet your specific requirements.

Key Takeaways

3 Volt DC motors work well for small projects. They are small, efficient, and used in toys, robots, and gadgets.

Brushless DC motors work better than brushed ones. They last longer, stay cooler, and make less noise. This makes them great for high-performance tasks.

Always test your motor with the right power source. Change torque and speed to fit your project for the best results.

Why 3 Volt DC Motors Are a Popular Choice

Common Uses of 3 Volt DC Motors

3-volt DC motors are in many everyday items. They work well for projects needing speed control or precision. These motors are found in toys, small robots, and portable devices. They’re also used in medical tools and beauty gadgets. Their small size and efficiency make them great for tight spaces.

The need for these motors is growing quickly. In 2023, motors between 1.5 and 3 volts were a big part of the small motor market. This growth will likely continue as robotics and electric vehicles use them more for their reliability.

Benefits of Mini DC Motors

Mini DC motors are perfect for small projects. Their tiny size and light weight fit tight spaces easily. They use power efficiently, which is great for battery-powered devices. Brushless versions save even more energy and work better.

These motors can do many things. Whether it’s a medical tool or a small robot, they adjust to your needs. They give precise control over speed and position, making them popular in cars and electronics.

Downsides of Brushed DC Motors and Why Brushless Motors Are Better

Brushed DC motors are simple and cheap but have problems. They make more heat and noise because of their brushes. They don’t last long, usually 2,000 to 5,000 hours. If your project needs high speed or runs a lot, heat can be an issue.

Brushless DC motors solve these problems. They stay cooler, are quieter, and last longer—over 10,000 hours. These motors are great for projects needing durability and precision. For example, if your device needs speed changes or works in quiet places, brushless motors are the best choice.

Key Things to Think About When Picking a 3 Volt DC Motor

Knowing Power Needs and Voltage Match

When picking a 3-volt DC motor, know its power needs. Make sure it works with your power source, like a 3-volt battery. These motors are great for low-power uses, like toys or sensors. They use little energy, so they’re good for battery-powered gadgets. They usually run at speeds of 100 to 300 RPM. Their torque is under 0.5 Nm, which is fine for light tasks.

Checking Size and Weight for Mini DC Motors

Mini DC motors fit small spaces, but size and weight still matter. For example, a motor with a 42mm diameter and 55mm length weighs 270g. This makes it good for portable devices and robots. Every gram counts in these projects. Always check the size and weight before choosing.

Specification | Value |

|---|---|

Weight | 270g |

Size | D:42mm, L:55mm |

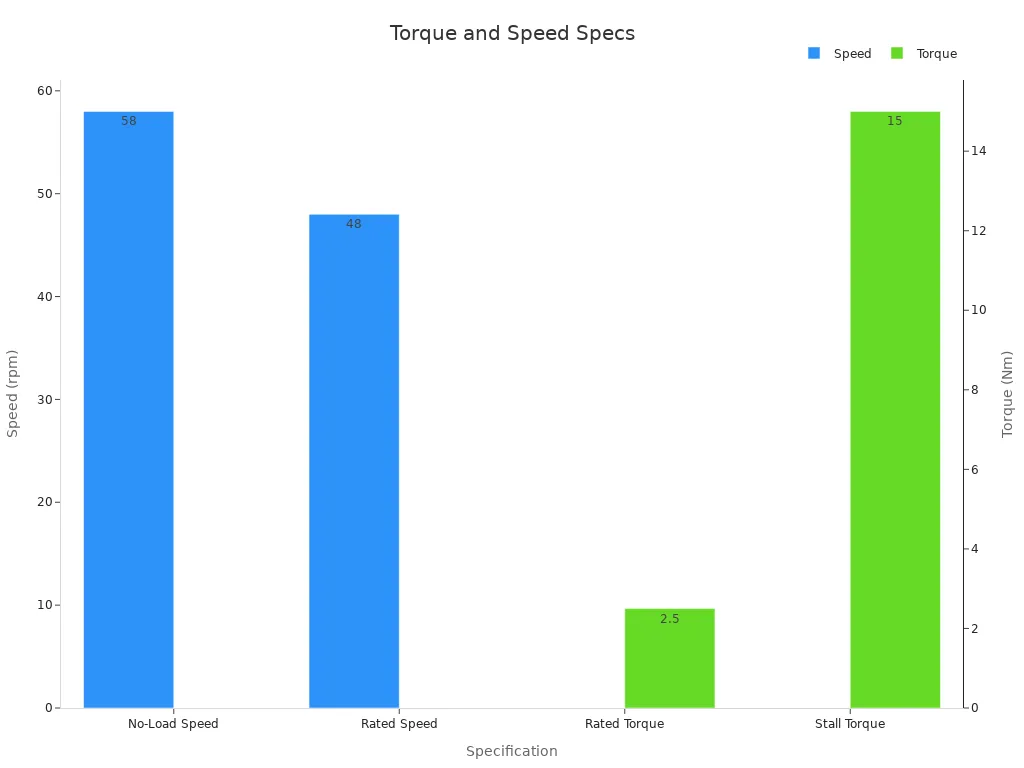

Torque and Speed Details for Brushed DC Motors

Brushed DC motors are simple and dependable. Look at their torque and speed to see if they fit your project. A typical brushed motor might have a speed of 58 RPM. It could have a torque of 2.5 Nm and stall torque of 15 Nm. These numbers show how much load it can handle and how fast it runs.

Efficiency and Heat Control in Brushless DC Motors

Brushless DC motors are efficient and stay cool. They don’t have brushes, so they last longer. Their efficiency can reach 75%, compared to 40% for other motors. They make less heat, which keeps them safe and strong. Inner rotor designs help manage heat, even in tough jobs.

Better efficiency: 75% vs. 40% for other motors.

Less heat, safer to use.

No brushes mean fewer problems and more reliability.

Comparing 3 Volt DC Motors to Other Voltage Options

Why 3 Volt DC Motors Are Better Than Higher Voltage Motors

3 Volt DC motors are simple and work well. They are great for toys, robots, and portable gadgets. These motors use less energy, so batteries last longer. Unlike higher voltage motors, they don’t need complex power setups. This makes them cheaper and easier to use in projects.

Another plus is their small size. Bigger motors can be hard to fit in tight spaces. A 3 Volt DC motor is compact and still works efficiently. If your project needs to save space and energy, this motor is a smart pick.

Best Times to Use Brushless DC Motors for High Performance

Brushless DC motors are great for high-performance tasks. They are quiet and don’t spark because they have no brushes. This makes them safer and more dependable in sensitive places. Their small size and light weight are perfect for drones or medical tools.

These motors are fast and respond quickly. They are cleaner, stronger, and need less care than brushed motors. To get the best results, match the motor’s speed and torque to your project. Using the right control system can also improve how well it works and lasts.

Benchmark | What It Means |

|---|---|

Load Matching | Match torque and speed to your project for better performance. |

Voltage Compatibility | Use the right voltage to avoid overheating and make it last longer. |

Control System Integration | Pick a good control system to adjust settings and improve efficiency. |

When Brushed DC Motors Are a Good Choice

Brushed DC motors are simple and affordable. They are easy to use and work fine when precision isn’t needed. You’ll find them in toys, small appliances, and basic robots. Their simple design makes them reliable for short, easy tasks.

If your project doesn’t run all the time, these motors are a good pick. They need some care because of brush wear, but they’re cheap and easy to use. Many hobbyists like them for DIY projects.

Practical Tips for Testing and Optimizing Your 3 Volt DC Motor

Testing Motor Performance with INEED Micro DC Motors

Testing your motor ensures it works properly. First, connect your mini DC motor to a power source that matches its voltage. Watch how it performs with different loads. Does it keep steady speed and torque? INEED’s Micro DC Motors are reliable and run smoothly. They are precise, so small changes in load or speed are noticeable.

Use a multimeter to check current and voltage while the motor runs. This shows if it’s working efficiently. For more advanced testing, try a motor controller. It can simulate real-world conditions and give better performance insights.

Adjusting Torque and Speed for Specific Project Needs

Each project needs specific torque and speed settings. Start by figuring out the torque needed to move your load. Use torque/speed charts to find the motor’s maximum speed. For instance, at 15 revolutions per second, a motor might give 19 oz-in torque.

Here are tips to adjust your motor:

Pick parts that match your torque and speed needs.

Use variable frequency drives (VFDs) to control speed and torque.

Check packaged control systems for project compatibility.

Knowing your project’s needs helps you adjust without wasting energy or losing performance.

Ensuring Proper Power Supply and Connections

A steady power supply is important for motor performance. Make sure connections are tight and safe. For example, electrical isolation monitoring warns if DC high-voltage sources lose isolation. Follow these rules:

Rule | Description |

|---|---|

S5.4.4 | Monitor electrical isolation for DC high-voltage sources. |

S5.4.5 | Ensure earth grounding before applying voltage to prevent electric shocks. |

S5.4.2 | Protect against indirect contact by meeting resistance requirements. |

S5.4.3 | Follow isolation standards for AC and DC high-voltage sources. |

These steps protect your motor and make it last longer.

Troubleshooting Common Issues in Mini DC Motors

Even good mini DC motors can have problems. If your motor isn’t working well, check for loose wires or worn parts. Too much heat might mean it’s overloaded or not ventilated. For brushed motors, check the brushes and replace them if worn.

Here’s a quick troubleshooting guide:

Motor won’t start: Check power and connections.

Overheating: Lower the load or improve airflow.

Unusual noise: Look for debris or misaligned parts.

Inconsistent speed: Test the controller and adjust settings.

Fixing these problems quickly keeps your motor working well and lasting longer.

Picking the right 3-volt DC motor is very important. You need to balance size, efficiency, and performance. INEED’s Micro DC Motors are dependable and can be customized for your needs.

Pro Tip: Always test your motor. Match it with your power source and adjust it for top performance.

FAQ

How are continuous rotation servos different from standard servo motors?

Continuous rotation servos spin fully in both directions. Standard servos only turn to set angles. Continuous ones work well for wheels or moving belts.

See Also

Resolving Frequent Issues With 3 Volt Motors

Frequent 3 Volt Motor Problems And Effective Fixes

Utilizing 3V DC Motors Across Five Different Devices

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry