How to Select the Right Vibrating Motor for Your Project

Choosing to select the right vibrating motor significantly impacts the effectiveness of your project. Each application requires specific features such as force, frequency, and amplitude to perform optimally. Aligning the motor with design and technical specifications, including voltage and size, ensures a seamless integration. Vibrating motors, like those offered by INEED, deliver customized solutions for various sectors, including healthcare and robotics.

Application

Inertia Ratio Jl/Jm

Direct Drive/Minimal Compliance

>100

Damped

>5

Typical Servo

3-5

Responsive

1

High Bandwidth

0.70

By choosing to select the right vibrating motor, you enhance performance, reduce risks, and increase user satisfaction.

Key Takeaways

Picking the right vibrating motor improves how your project works. Think about force, speed, and movement size to fit your needs.

Check the motor's voltage, power, and size to match your project. This avoids problems and keeps things running smoothly.

Different motors work best for certain tasks. ERM motors are good for toys, while LRA motors are better for wearables and phones.

Look at datasheets and instructions from makers to learn about the motor. This helps you choose wisely.

Test samples from INEED to see how the motor works before finishing your design.

Understanding Vibrating Motors

What Are Vibrating Motors and How Do They Work?

Vibrating motors are small devices that turn electricity into vibrations. These vibrations help create movement or give feedback in different tasks. They work by spinning a weight that is off-center, which makes the motor shake. This simple design is why vibrating motors are used in many industries.

A common way vibrating motors work is through floating circle motion. This uses a shaft with uneven parts to create vibrations. When the shaft spins, the motion moves through bearings to the motor’s frame. This creates steady vibrations. Fewer bearings are needed, which lowers upkeep costs and boosts efficiency. Below is a table showing important parts of vibrating motors:

Specification | Description |

|---|---|

Driven Sheave | Placed on the shaft’s center line for flexible drive direction. |

Bearings | Needs only two strong bearings, making it simpler and easier to maintain. |

Floating Circle Motion | Suspended screen body creates even vibrations using uneven motion. |

Construction | Simple design saves power and improves screening ability. |

Knowing how these motors work helps you understand their importance in modern devices.

Types of Vibrating Motors: ERM, LRA, and More

Different motors make vibrations for specific uses. The two main types are Eccentric Rotating Mass (ERM) motors and Linear Resonant Actuators (LRA).

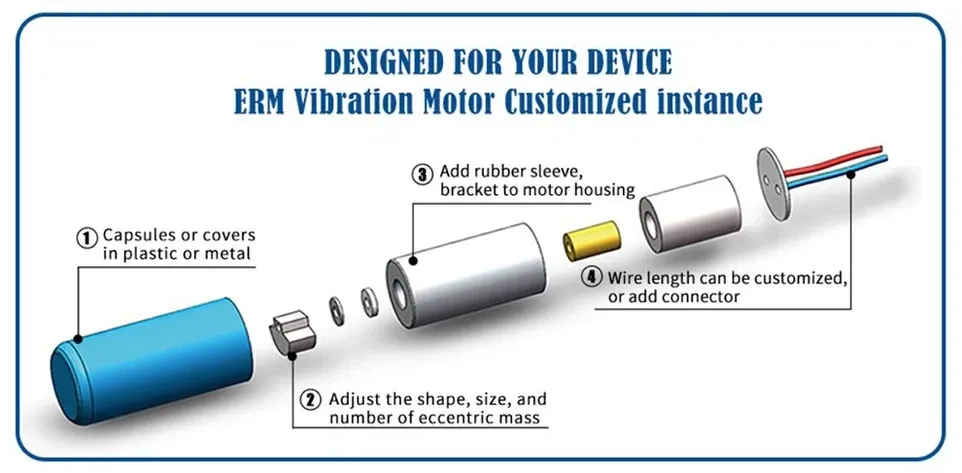

ERM Motors: These motors have a weight attached to a spinning shaft. As the shaft turns, the weight makes vibrations. ERM motors are cheap and easy to use, great for toys and basic gadgets.

LRA Motors: These motors use magnets instead of spinning weights to vibrate. LRAs use less energy, react faster (20-50 ms vs. 100-200 ms for ERMs), and give better feedback. They are ideal for phones and smartwatches.

Other motors include brushless coin motors and coreless vibration motors. Each type has benefits like better energy use, smaller size, or longer-lasting parts. Picking the right motor depends on what your project needs.

Applications of Vibrating Motors Across Industries

Vibrating motors are important in many fields. They improve user experience, make work smoother, and give helpful feedback. Here are some examples:

Industry | Description |

|---|---|

Pulp and Paper | Vibration tools made for tough paper factory conditions. |

Rail | Maintenance systems to improve rail car performance. |

Water and Wastewater | Vibration checks to avoid pump breakdowns and delays. |

In electronics, vibrating motors give touch feedback in phones, wearables, and games. In healthcare, they provide accurate vibrations for medical tools. Factories use them for monitoring and moving materials. Picking the right motor ensures great results in many areas.

Key Factors to Select the Right Vibrating Motor

Evaluating Performance Metrics: Force, Frequency, and Amplitude

Picking the right vibrating motor means knowing how it works. Three main factors—force, frequency, and amplitude—decide how well the motor fits your needs.

Force: This is how strong the motor vibrates. Big vibrations work for factories, while small ones suit gadgets like smartwatches.

Frequency: This shows how many times the motor shakes each second. Faster vibrations feel smoother, which is great for phones.

Amplitude: This measures how far the motor moves when it vibrates. Stronger movements are better for gaming controllers or tools needing clear feedback.

Engineers test these factors to make sure the motor works well. For example:

Resonance tests check how the motor reacts to forces.

Vibration tests find weak spots by using different frequencies and amplitudes.

Here’s a table showing ways to measure these factors:

Metric | Description |

|---|---|

Peak | Shows the strongest vibration during a set time. |

RMS | Gives the average vibration strength to assess overall load. |

Crest Factor | Compares the strongest vibration to the average to show intensity. |

By studying these factors, you can pick a motor that works best for your project.

Ensuring Compatibility with Your Project's Design

The motor must fit your project’s design to work properly. Checking compatibility avoids problems like redesigns or poor performance.

Start by looking at the motor’s voltage and power needs. These affect how well it runs with your device. For example, motors using less power are great for battery-powered gadgets like fitness trackers.

Next, think about the motor’s size and how it attaches. Small motors, like coin motors, fit tight spaces. Surface-mounted motors save space and are easy to install on circuit boards.

Noise is also important, especially for electronics. Quiet motors improve user experience, making them good for medical tools or beauty devices.

Durability matters too. Regular checks help the motor last longer, especially in tough environments. By considering these points, you can make sure the motor fits your project perfectly.

Application Suitability: Matching Motor Type to Use Case

Choosing the right motor depends on how you’ll use it. Different motors have special features for specific tasks.

ERM Motors: These are affordable and flexible, great for toys, simple gadgets, and factory tools.

LRA Motors: These give accurate feedback and use little power, ideal for wearables and phones.

Coreless Motors: These work well in small devices like game controllers, offering quick and efficient vibrations.

Matching the motor to your project ensures it works as needed. For example, LRA motors are perfect for wearables because they respond fast and save energy. In factories, ERM motors handle heavy tasks easily.

By focusing on the right type, you can choose a motor that meets your goals and performs well.

Technical Specifications: Voltage, Power, and Size Considerations

When picking a vibrating motor, knowing its technical details is key. Voltage, power, and size affect how well it works in your project. Each factor helps ensure the motor fits and runs efficiently.

Voltage: Match the Motor to Your Power Source

Voltage shows how much electricity the motor needs. Picking the right voltage keeps the motor running safely. For example, a motor made for 3V DC won’t work with 5V. It could overheat or break. Always check your device’s power supply and match it to the motor’s voltage. This avoids damage and keeps things working smoothly.

Low-voltage motors, like those in wearables, use less energy. They are great for battery-powered devices. Higher-voltage motors are better for big jobs, like in factories. Choosing the right voltage helps the motor last longer and work better.

Power: Balance Efficiency and Performance

Power is the energy the motor uses to vibrate. It affects how strong the motor is for your project. If the motor doesn’t have enough power, it won’t vibrate well. Too much power wastes energy and makes extra heat.

Soft starters are good for motors needing less power. They are smaller and save energy compared to other options. For bigger power needs, variable frequency drives (VFDs) work better, even though they cost more. Knowing your project’s power needs helps you pick the best motor.

Size: Make Sure It Fits

The motor’s size should match your project’s design. Small motors, like coin motors, are great for tiny devices like fitness trackers. They save space and fit into tight spots. Surface-mounted motors attach easily to circuit boards, making setup simple.

For bigger machines, size matters for strength and durability. Large motors handle heavy tasks but need more room. Measure your device’s space and compare it to the motor’s size. This ensures a good fit and avoids redesigning your project.

Combine Voltage, Power, and Size for Best Results

Choosing a motor means balancing voltage, power, and size. For example, a wearable might need a small, low-power motor. A factory machine might need a big, high-power motor. By checking these factors, you can find a motor that works well and fits perfectly.

Tip: Always read the motor’s datasheet. It has important details about voltage, power, and size to help you decide.

Comparing Vibrating Motors to Other Actuators

Vibrating Motors vs. Linear Actuators: Key Differences

You may wonder how vibrating motors differ from linear actuators. Both are actuators, but they work in different ways.

Functionality: Vibrating motors make vibrations for movement or feedback. Linear actuators move objects in a straight line.

Applications: Vibrating motors are great for phones, wearables, and medical tools. Linear actuators are better for precise tasks like robotics or machines.

Size and Power: Vibrating motors are small and use little energy. Linear actuators are bigger and need more power because of their design.

Feature | Vibrating Motors | Linear Actuators |

|---|---|---|

Motion Type | Vibrational | Linear |

Power Consumption | Low | High |

Common Use Cases | Haptic feedback, alerts | Robotics, lifting mechanisms |

Knowing these differences helps you pick the right actuator for your project.

Vibrating Motors vs. Rotary Actuators: Pros and Cons

Rotary actuators and vibrating motors are also different in how they work. Rotary actuators spin, while vibrating motors create vibrations.

Pros of Vibrating Motors:

Small size fits tight spaces easily.

Low energy use saves battery life.

Simple design means less maintenance.

Cons of Vibrating Motors:

Only useful for vibration-based tasks.

Pros of Rotary Actuators:

Strong torque for heavy-duty jobs.

Useful for spinning movements.

Cons of Rotary Actuators:

Bigger size and higher energy use.

Rotary actuators are great for factories, while vibrating motors are best for gadgets.

Why INEED's Vibration Motors Stand Out

INEED's vibration motors are high-quality and customizable. They offer many types, like coin motors, LRAs, and coreless motors. These motors are small, strong, and energy-saving, making them useful for many projects.

Tip: INEED gives free samples and support to help you choose the right motor. Check their options to find the best fit for your project.

Practical Tips for Picking the Right Vibrating Motor

Using Datasheets and Manufacturer Instructions

Datasheets and manufacturer instructions are helpful when choosing a motor. They explain how the motor works and its technical details. Reading these helps you pick a motor that fits your project.

Check the motor’s voltage, power, and speed first. These show how well the motor will work for your needs. For example, low-power motors are great for battery devices like wearables. Datasheets also list the motor’s size, mounting options, and vibration strength. This helps you see if it matches your design.

Manufacturer instructions explain how to install and care for the motor. Following these tips makes the motor last longer and work better. Always use these resources to avoid problems and make smart choices.

Testing Frequency for Best Results

Testing frequency is important to make sure the motor works well. Resonance happens when the motor’s natural frequency matches outside vibrations. This can cause problems or even damage the motor.

Field tests and vibration checks help find resonance issues. Special tests, like modal analysis, show the motor’s natural frequencies. Other methods, like Operating Deflection Shape (ODS), reveal how the motor acts under pressure. Watching the motor during quick changes gives useful data about its performance.

Knowing the motor’s natural frequencies lets you adjust settings to stop harmful vibrations. This keeps the motor running smoothly, even in tough situations.

Trying INEED’s Free Samples for Prototypes

Prototyping is key to picking the right motor, and INEED helps by giving free samples. Testing these samples shows how the motor works with your project before finalizing your design.

Feedback from prototypes often shows how well the motor performs. For instance, users in a study completed tasks faster with haptic feedback. They also made fewer mistakes using vibration cues alone.

Using INEED’s free samples lets you improve your design and ensure the motor fits your needs. This reduces risks and makes your final product better.

Using INEED's Help to Customize Motors

Picking the right vibrating motor often means making changes to fit your project. INEED offers great support to help you adjust motors for better results. Their help makes it easier to change motor settings, saving time and effort.

INEED’s team helps you tweak important features like vibration strength, speed, and how the motor is attached. For example, if your project needs a motor of a certain size or weight, they can suggest the best option. They also help change wires, connectors, and other parts to make sure the motor works well with your design.

Customizing motors doesn’t just make them fit better; it also helps them last longer. By spotting problems early, you can fix them before they get worse. This saves money and keeps your equipment running longer. INEED’s support ensures your motor works well, even in tough conditions.

Improvement Area | Description |

|---|---|

Predictive Maintenance | Finds problems early to avoid breakdowns. |

Operational Efficiency | Plans repairs to keep the motor working its best. |

Equipment Longevity | Makes machines last longer by fixing issues early. |

INEED also helps you plan maintenance to avoid surprises. Finding problems early keeps your motor safe and working well. Regular check-ups stop expensive repairs and keep the motor running smoothly. These benefits show why INEED is a great partner for your project.

With INEED’s help, you can control how your motor performs. Their advice makes sure the motor fits your needs and works reliably over time.

Picking the right motor helps your device work its best. Look at things like force, frequency, and amplitude. The motor must also match your design and technical needs. Testing in real situations helps find the perfect motor.

INEED has many motors, like coin and SMD vibration motors. These motors make feedback better and improve how devices work. First, set clear goals for your project. Check datasheets to learn about motor details. Test samples to see if they work well before making a final decision.

FAQ

What is an LRA vibration motor, and how does it work?

An LRA motor makes vibrations using a magnetic field. It has a small mass on a spring that moves back and forth. This design gives accurate and efficient vibrations, perfect for wearables and phones.

How do you choose the right LRA for your project?

Look at the motor's size, power, and vibration strength. Make sure it fits your device's design and purpose. Testing samples helps you see if the motor works well before deciding.

Why is the weight of an LRA important?

The motor's weight changes how it vibrates. Heavier motors make stronger vibrations but use more energy. Pick a motor that balances weight, size, and power for the best results.

Can an LRA vibration motor be customized?

Yes, you can change an LRA motor to fit your needs. You can adjust its size, vibration strength, or how it connects. Companies like INEED can help customize motors for your project.

What are the advantages of using an LRA?

LRA motors respond quickly, use little power, and vibrate precisely. They improve devices like smartwatches and game controllers. Their durability and efficiency make them a great choice for many uses.

See Also

Choosing The Perfect 3V DC Motor For Your Needs

Guidelines For Choosing The Ideal Rotating Motor In Industry

A Comprehensive Overview Of Vibration Motors And Their Uses

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry