The Science Behind Tiny Brushless Motors

Tiny brushless motors are special in science. They use electronic commutation and do not have brushes. This lowers friction and heat. Electromagnetism powers these motors. Electronic controllers change the current in stator windings. This makes a magnetic field that spins the rotor. This way gives very good speed control. It also makes the motor work better and last longer. Many industries pick tiny brushless motors for their good performance. These motors are also very reliable. In 2024, the global market for these motors was $5.8 billion. There is strong growth in cars, healthcare, and electronics.

Key Takeaways

Tiny brushless motors use electronic controllers, not brushes. This lowers friction and heat. The motors last longer and work better.

These motors are small, efficient, and quiet. They are great for drones, robots, and medical tools. Many modern devices use them.

Brushless motors save energy and need less care than brushed motors. This helps devices work well and last longer.

Smart designs and strong magnets help these motors give high torque. They also give precise control in small spaces.

New materials and smart sensors make these motors more reliable. They are ready for future technology.

Tiny Brushless Motors

What Are Tiny Brushless Motors

Tiny brushless motors are small electric motors. They work well when space is tight and high performance is needed. These motors have very small diameters and are compact. You can find them in products like the B-Micro and B-Flat series. Engineers use permanent magnets on the rotor. The stator has electromagnets. This setup lets the motors give strong power in a small size.

Note: The stator does not move. The rotor spins inside it. Position sensors tell the controller when to switch the current. This helps the motor run smoothly.

The table below lists some common features of tiny brushless motors:

Characteristic | Description |

|---|---|

Size Range | Diameters from 42 mm up to 110 mm; some as small as 42 mm. |

Rotor Structure | Inner rotor with permanent magnets. |

Rotor Features | Thin design for low inertia and fast response. |

Stator Placement | Close to rotor for compactness and good heat dissipation. |

Power Ratings | 30 W to 200 W, fitting the mini motors category. |

Additional Features | Low cogging torque, vibration suppression, and resistance to uneven loads. |

These small motors often work with gearheads and controllers. This makes them useful for many jobs.

Key Features

Tiny brushless motors have special features. They do not have brushes inside. This means moving parts do not touch each other. Less friction and heat are made. The motors last longer and work better. Mini motors with brushless technology are also much quieter than brushed motors.

Compact design keeps friction and wear low, even in hard conditions.

Strong permanent magnets help the motors make more torque for their size.

Good magnetic circuits turn more electricity into movement, so they are efficient.

Advanced gear systems spread out the load, making the motors last longer.

Brushless motors need less care. There are no brushes to change. Mini motors can run for thousands of hours with little work. This makes them great for drones, robots, medical tools, and other places where you need them to work well.

Tip: Picking the right mini motors means thinking about torque, size, speed, and efficiency for each job.

Industry rules test these motors for how well they work. They check efficiency, torque, speed, noise, and heat. Tiny brushless motors pass tough tests. This makes them a top pick for new technology.

How Brushless Motors Work

Electromagnetism and Commutation

Brushless motors use electromagnetism to make things move. The stator stays still and has coils. When current goes through the coils, they act like electromagnets. The rotor spins and holds permanent magnets. The stator’s magnetic field pushes on the rotor’s magnets. This makes the rotor turn. That is how brushless motors get their power and work so well.

Electronic controllers are very important in brushless motors. They take the place of old brushes in other motors. The controller sends current through the stator windings in a set order. This makes a magnetic field that moves around. The rotor follows this field and spins. The controller uses sensors, like Hall effect sensors, to know where the rotor is. Sometimes, it uses back EMF instead of sensors. Back EMF is a voltage made when the rotor spins. This helps the controller know when to switch the current.

Brushless motors use six-step commutation. The controller powers two of three windings at once. Each step is 60 electrical degrees. Six steps make a full turn.

Hall effect sensors find the rotor’s position. They send signals to the controller for good timing.

Sensorless control uses back EMF to guess the rotor’s position. This can make the motor cost less and be simpler.

Pulse Width Modulation (PWM) changes the speed. The controller changes the average voltage by changing the duty cycle. This gives smooth speed and torque control.

Electronic commutation lowers wear and energy loss. This helps brushless motors last longer and work better.

Note: Electronic commutation is why brushless motors do not need brushes. This design cuts down on friction, heat, and how much care the motor needs.

The controller switches current at just the right time. This lets brushless motors give high torque and control speed well. That is important for things that need to run smoothly and reliably.

Main Components

A tiny brushless motor has several main parts. Each part does a special job to help the motor work well and last long.

Stator: The stator does not move. It has iron cores and copper windings. When current flows, the stator makes a magnetic field that spins around. This field makes the rotor move.

Windings: These are copper wire coils on the stator. When powered, the windings become electromagnets. The way current flows sets the north and south poles.

Rotor: The rotor spins inside the stator. It has permanent magnets made from strong materials like neodymium. The rotor’s magnets work with the stator’s field to make motion.

Magnets: Permanent magnets in the rotor give a steady magnetic field. Their strength and where they are placed affect torque and speed.

Sensors: Hall effect sensors or similar devices find the rotor’s position. They help the controller know when to switch current in the windings. Some motors use back EMF instead of sensors.

Electronic Controller: This device controls when and how current goes to the windings. It reads signals from sensors or back EMF to keep the motor running smoothly.

Component | Description | Function |

|---|---|---|

Stator | Stationary iron core with windings | Makes a magnetic field that spins around |

Windings | Copper coils on the stator | Make electromagnetism for movement |

Rotor | Rotating part with permanent magnets | Spins because of the stator’s magnetic field |

Magnets | Permanent magnets in the rotor | Give a steady magnetic field for high torque and efficiency |

Sensors | Hall effect or back EMF detection | Tell the controller the rotor’s position for good timing |

Controller | Electronic circuit | Switches current, controls speed and torque, replaces mechanical brushes |

The way these parts are made and what they are made from matters. For example, slotted stators can boost magnetic flux and help cooling. This gives more torque and better reliability. Slotless stators make the motor smaller and smoother at high speeds, but may lower torque. Good materials, like strong magnets and copper wire, help the motor handle heat and last longer.

Tip: Engineers choose the best stator design, winding layout, and magnet type for each job. That is why brushless motors are used in so many things, like drones and medical tools.

Brushless motors are special because their parts work together. They give high torque, low noise, and last a long time. Careful design makes these electric motors reliable and efficient in today’s technology.

Brushless vs. Brushed

Operation Differences

Why do engineers pick brushless motors instead of brushed ones? The reason is in how each motor works and what it can do. Brushed motors have brushes and a commutator that touch each other. This makes friction, sparks, and causes the parts to wear out. Brushless motors use electronic controllers to switch the current. There is no touching inside, so they run smoother and quieter.

The table below shows how these motors are different:

Aspect | Brushed Motors | Brushless Motors |

|---|---|---|

Commutation Method | Mechanical brushes and commutator causing friction and wear | Electronic controllers for commutation, no physical brushes |

Control Complexity | Simple control by varying DC voltage | Requires complex electronic controllers for precise speed and torque control |

Efficiency | Lower efficiency due to brush friction and electrical losses | Higher efficiency with minimal friction and better energy conversion |

Speed Capability | Limited speed range due to mechanical constraints | Higher speed and acceleration enabled by electronic commutation |

Noise Generation | Generates electrical noise and audible mechanical noise from brushes | Reduced electrical and mechanical noise, quieter operation overall |

Maintenance | Requires brush replacement due to wear | Minimal maintenance, longer service life due to lack of brushes |

Application Suitability | Suitable for simple, cost-sensitive applications | Ideal for precision, high-speed, and low-noise applications |

Brushed motors are easy to use. You just change the voltage to control them. But the brushes wear out fast because they rub on moving parts. Brushless motors need special electronics, but they last longer and need less fixing. Many e-bikes and scooters use brushless hub motors for this reason. These motors are also quieter, which is good for places where you want less noise.

Brushed motors are simple and cheap, but the brushes wear down.

Brushless motors do not have brushes, so they almost never need repairs.

Brushless hub motors make less noise and do not make sparks.

You control brushed motors by changing the voltage, but brushless hub motors use digital controls to change how they switch.

Efficiency and Durability

Why do brushless motors use less energy and last longer? The answer is in their design. Brushless motors have lower resistance inside and get rid of heat better. This means they waste less energy and work more efficiently. In many cases, brushless hub motors help save energy, which is important for electric cars and small devices.

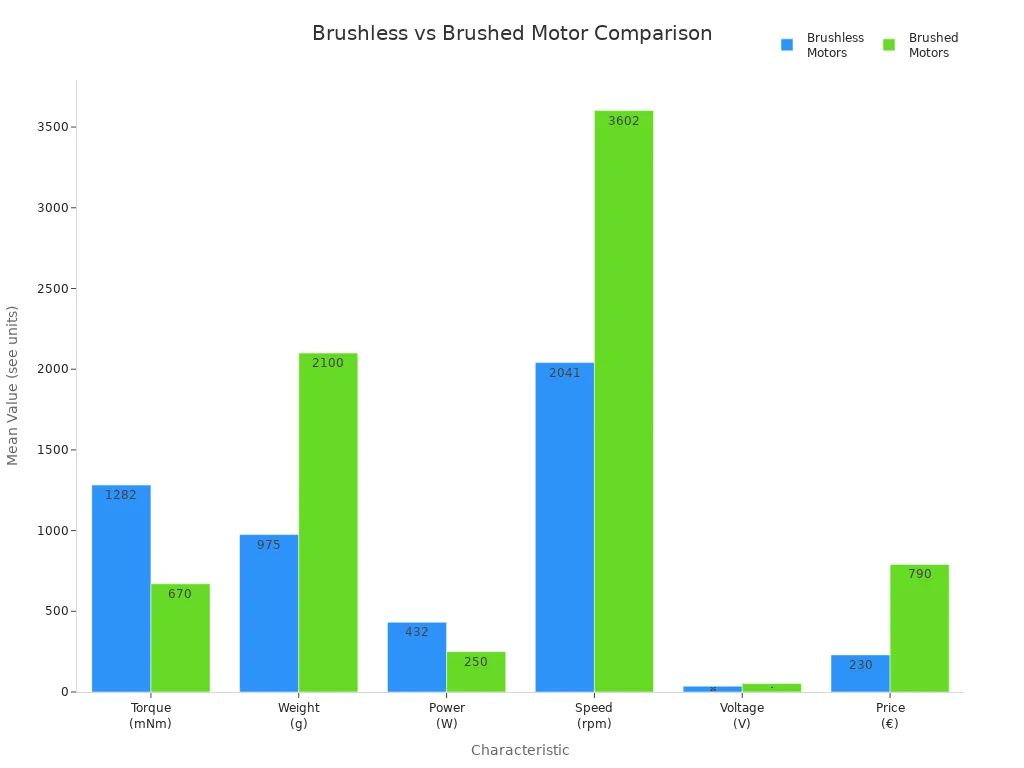

The chart below compares important things about brushed and brushless motors:

The table below shows how efficient and tough these motors are:

Factor | Brushed Motors | Brushless Motors (BLDC) |

|---|---|---|

Efficiency | Lower | Higher |

Internal Resistance | Higher | Lower |

Heat Dissipation | Less Effective | More Effective |

Energy Conversion | Less Efficient | Highly Efficient |

Maintenance | Frequent | Minimal |

Lifetime | Shorter | Longer |

Brushless hub motors can give more torque with less weight and money. They also save energy by turning more electricity into movement. Studies say using brushless motors everywhere could save up to 10% of the world’s electricity by 2030. This makes them a smart pick for people who want to use less energy.

Brushless hub motors are also very tough. Brushed motors need new brushes often, which is hard for small motors. Brushless motors do not have this problem. They last longer and need less care. Hub motors with brushless designs can work for thousands of hours without much attention. This is why many companies use brushless motors in their products.

Tip: Picking brushless hub motors means fewer repairs, more energy saved, and better results over time.

Applications of Mini Electric Motors

Modern Devices

Mini electric motors are used in many new devices. They work well in small spaces and are very reliable. Engineers pick these motors for things that need to last a long time and work exactly right. Some common uses for mini electric motors are:

Drones and UAVs help them fly steady and use less battery.

Robotics use them for quick moves and good control.

Medical tools like arthroscopic shavers, orthopedic drills, and surgical staplers use them.

Computer fans and cooling systems use them for quiet, cool air.

Cordless power tools like drills and saws use them for strong power in a small size.

RC cars use them to go fast and speed up quickly.

Home appliances like vacuum cleaners, printers, and coffee makers use them.

Device Category | Specific Roles and Examples |

|---|---|

Industrial Automation | Give exact motion and strong power in CNC machines, robotic arms for building, welding, and painting |

Home Appliances | Help vacuum cleaners, coffee makers, hairdryers, and printers run quietly and save energy |

Cordless Power Tools | Give strong power and work well in drills, wrenches, saws, and grinders |

RC Cars | Make cars spin fast and speed up for racing |

Drones and UAVs | Help drones fly light, steady, and use less battery |

Surgical Devices | Give exact moves in shavers, drills, and staplers used in surgery |

Mini motors are also important in electric bikes and cars. These vehicles use hub motors to run quietly and smoothly. More and more mini electric motors are made each year. Over 2 billion are made every year for electronics and medical tools.

Advantages

Why do engineers like mini electric motors for so many things? The answer is in their small size, light weight, and easy setup. These motors fit in tight spots and make devices lighter. Hub motors help electric bikes and cars run quietly and save energy.

Mini electric motors come ready to use with housing, bearings, and shafts.

The brushless design means less rubbing and less fixing.

Built-in controllers and sensors keep the motors from getting too hot and help control speed and position.

Hub motors give lots of power for their weight, which helps cars, bikes, and robots.

The all-in-one design makes it easy to put mini motors into products and saves time and money.

Note: Thermal sensors and smart controllers help mini electric motors stay cool and work well, even when used a lot.

Companies pick mini electric motors because they work well and last long. These motors help make products smaller, smarter, and use less energy. Hub motors are now very important in electric cars, robots, and medical machines.

Challenges and Innovations

Current Limitations

Mini electric motors have some problems that make them less reliable. Sometimes, engineers rate these motors for more power than they can handle all the time. If people use them too hard, they can get too hot. Small rotors spin fast, but they do not always give steady power. Many mini electric motors are made for short use, not for heavy work all the time. This means they are not the best for tough jobs.

The environment can also cause trouble. High heat makes the motors lose power and work less well. Cold weather makes them slow because the oil inside gets thick. Electromagnetic interference from fast switching or other devices can mess up the control system. This can make the motor get wrong signals or push with the wrong force. Vibration can break sensors, and bad cooling can make the motor overheat.

Limitation Category | Description |

|---|---|

Control Circuit Complexity | Brushless motors need tricky control circuits, which makes design harder and takes up more space. |

Torque and Magnetic Flux | Small motors have less force and need strong magnets to work well. |

Magnet Durability at High Speed | Fast spinning can make magnets come loose if they are not made well. |

Thermal Management | Small motors get hot fast, so they cannot give full power for long. |

Note: Good shields, filters, and cooling are needed to help mini electric motors work well in hard places.

Recent Advances

New ideas have helped mini electric motors get better. Engineers use strong magnets like neodymium to make more power and work better. Better cooling, like special plastics and new ways to cool, stops them from getting too hot. New ways to build motors, like 3D printing and light materials, make them smaller and stronger.

Smart computer programs and IoT let people watch motors and fix problems before they break. Some motors do not need sensors, so they are smaller and cheaper but still work well. Hybrid ceramic bearings and PCB stators help the motors last longer. Smart controllers and built-in sensors keep the speed and position right, even when things get rough.

Superconductors and nanomaterials like graphene help motors be stronger and stay cool.

Additive manufacturing lets people make special hub motors for cars, robots, and medical tools.

Digital connections let hub motors check themselves and change to save energy and work better.

These new ideas are why mini electric motors are now in things like smart watches and electric cars. They help cars and hub motors use less energy, last longer, and work better.

Tiny brushless motors are special because of how they work. The stator makes a spinning magnetic field. The rotor has strong magnets that help things move. Smart controllers and sensors help control speed and torque exactly. These motors are very efficient and quiet. They last a long time. Many companies use them because they save energy and are reliable. Tiny brushless motors make devices smaller and lighter. They also make devices more powerful. These motors help new technology in robots, medical tools, and electronics. As scientists learn more, these motors will help create new inventions.

Engineers like these motors because they last long and are quiet. They also work well in tough places. Tiny brushless motors will keep helping many industries grow.

Motors use better materials and smart programs to work better.

Motors do not need much care and waste less energy.

Motors give exact control in delicate machines.

Motors change to fit new automation and digital trends.

FAQ

Why do tiny brushless motors last longer than brushed motors?

Tiny brushless motors last longer because they do not have brushes that wear out. The electronic controller takes the place of brushes. This design makes less friction and heat. With less wear, these motors can run for thousands of hours without repairs.

Why do engineers choose brushless motors for drones and robots?

Engineers pick brushless motors for drones and robots because they are efficient and easy to control. These motors stay cool and quiet. This helps drones fly longer and robots move smoothly. Their small size lets them fit in tight spaces.

Why do brushless motors save more energy compared to brushed motors?

Brushless motors save more energy because they have less resistance inside. The electronic commutation system cuts down on energy loss. These motors turn more electricity into movement. This makes them a better choice for saving power.

Why do tiny brushless motors work well in medical tools?

Tiny brushless motors work well in medical tools because they are quiet and reliable. They give smooth and accurate motion. Doctors trust these motors for delicate jobs. Their small size fits inside surgical devices and other medical equipment.

Why do companies use brushless motors in new technology?

Companies use brushless motors in new technology because they work well and need little care. These motors help make products smaller and lighter. They also support smart features like built-in sensors. This helps devices work better and last longer.

See Also

Investing in Mini Brushless Motors For Accurate Performance

Differences Between Brushed And Brushless Motors At 3 Volts

The Role Of Mini Motors In Portable Device Innovation

A Comprehensive Overview Of Mini Motor Types And Uses

Selecting Battery Powered Motors For Best Electric Performance

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry