Rotating Motors: Types, Applications, and Selection Criteria

Rotating motors are key parts of many tools and systems. These machines change electrical power into movement, powering things like factory machines and home gadgets. They are very important in fields like robots, healthcare, and green energy, where accuracy and saving energy matter a lot.

Knowing the types and uses of rotating motors helps you pick the right one. For instance, the world’s electric motor market was worth $142.2 billion in 2020. It is expected to grow to $373.9 billion by 2032, showing how widely they are used. INEED, a top micro motor maker, uses over 10 years of skill to make high-quality, custom motors for many industries.

Key Takeaways

Learn about types of electric motors like DC, brushless, and coreless. Pick the one that fits your needs best.

Think about how motors are used in cars, healthcare, and green energy. They help improve work and save energy.

Check how much torque and speed your project needs. Choose a motor that can handle the job well.

Use energy-saving motors to cut costs and work better. These motors use less power and last longer.

Take care of motors to make them last. Keep them clean and fix problems early to save money.

Types of Electric Motors

Electric motors come in different kinds for various tasks. Knowing these types helps you pick the best one.

DC Motors

DC motors are popular because they work well and are flexible. They are great for jobs needing exact speed control and strong power.

Brushless DC Motor

Brushless DC motors use electronics instead of brushes. This makes them last longer and work better. They are perfect for gadgets like drones and electric cars. These motors need less fixing and cause less electrical noise, making them run smoothly.

Studies show brushless DC motors are used in solar-powered water pumps. They don’t need extra equipment, proving their usefulness in eco-friendly systems.

Brushed DC Motor

Brushed DC motors are simple and dependable. They work well in tough conditions, so they’re used in factory tools and car systems. But, their brushes wear out and need replacing sometimes.

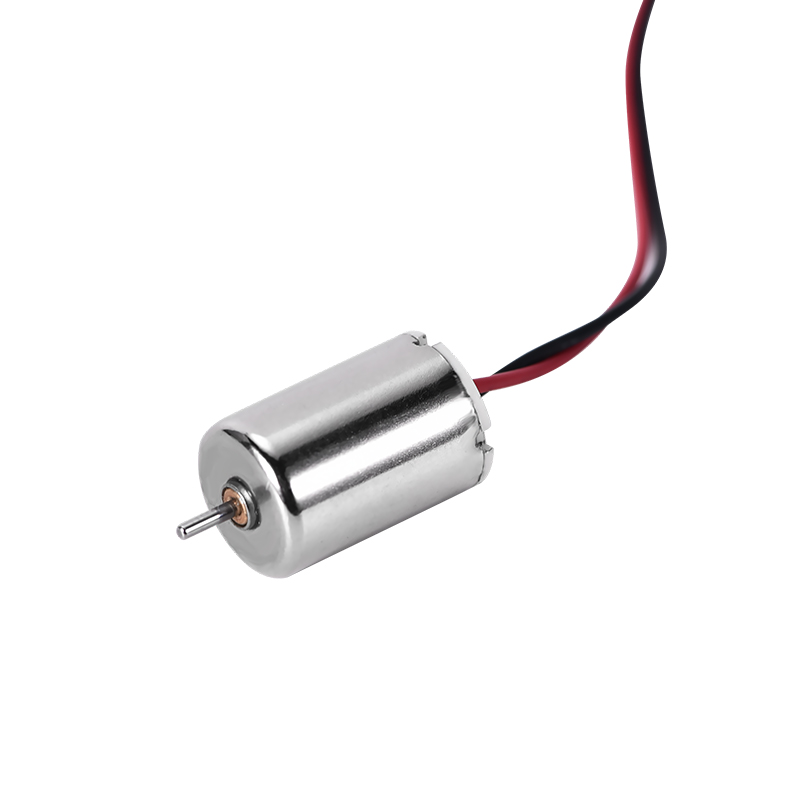

Coreless DC Motor

Coreless DC motors are light and have no iron in the rotor. This stops energy waste and makes them quiet and efficient. They are ideal for medical tools and robots where accuracy is key.

Core DC Motor

Core DC motors have an iron core in the rotor. This makes them strong and steady. They are often used in things like conveyor belts and air systems that need reliable performance.

Specialized Motors

Specialized motors are made for special tasks and offer advanced features.

Brushless Motors

Brushless motors are efficient and last a long time. They are common in electric cars and factory machines.

Synchronous Motors

Synchronous motors keep a steady speed. They are great for precise tasks like stepper and servo motors.

Motor Type | How It Works | Where It’s Used | Key Features |

|---|---|---|---|

Permanent Magnet Synchronous | Uses magnets in the rotor for steady magnetic fields. | Electric cars, factory machines | High power and torque, great for strong tasks. |

Linear Motors | Moves in a straight line instead of spinning. | Cameras, conveyor belts, maglev trains | Precise straight motion, good for many uses. |

Axial Flux Motors | Creates magnetic force sideways, making it compact. | Electric cars, airplanes | Strong and light, perfect for advanced uses. |

These motor types show how electric motors can fit many needs.

Applications of Rotating Motors

Rotating motors are important in many industries today. They power machines, improve cars, and make gadgets better to use.

Industrial Automation and Robotics

In factories, motors help machines work faster and better. They move conveyor belts, lift cranes, and control robotic arms. Geared motors are useful in factories for rolling and refining materials. These motors are small but strong, saving space in tight areas.

Robots need motors to move and work. Strong motors let robots carry heavy things. Small motors help make tiny, quick robots. These motors make factories more productive and efficient.

Automotive Industry

Electric motors are changing how cars work. In electric cars, they save energy and control speed smoothly. They also act as generators, helping cars go farther. Hybrid cars use these motors to drive, showing their importance in new car designs.

Using electric motors in cars helps the environment. They cut pollution and support clean energy goals. These motors also make cars faster and quieter, improving the driving experience.

Consumer Electronics

Rotating motors make gadgets more fun and easy to use. Tiny motors in phones, tablets, and gaming devices give vibrations for feedback. In cars, they improve touchscreens and entertainment systems.

The need for these motors is growing fast. By 2032, their market could reach $2.8 billion. This shows how important motors are for future gadgets.

HVAC Systems

Heating and cooling systems need motors to work well. These motors power fans, pumps, and compressors. They help control airflow, temperature, and save energy in buildings.

Brushless DC motors are common in HVAC systems. They use less energy and control speed well. For example, air conditioners use these motors to keep rooms cool. This saves energy and lowers power bills.

Small motors are also used in compact HVAC units. These motors are tiny but strong, fitting into tight spaces. They reduce noise and make HVAC systems work better. Advanced motors make these systems more reliable and eco-friendly.

Renewable Energy Systems

Wind and solar energy systems depend on electric motors. Wind turbines use motors to turn wind into electricity. These motors handle high power and changing speeds.

Solar panels use motors to follow the sun. This helps them get more sunlight all day. Brushless DC motors are great for this because they last long and need little fixing. They work well even in tough weather.

Motors are also used in energy storage systems. They help manage battery charging and improve energy setups. With better motors, renewable energy systems become greener and cheaper.

Medical Devices and Healthcare (Featuring INEED Micro Motors)

Tiny motors are important in medical tools. They power things like pumps, surgical tools, and scanners. Their small size and accuracy make them perfect for healthcare.

For instance, a small motor was made for a one-time-use medical tool. It worked well despite challenges with size and power. This shows how these motors make medical tools better.

INEED makes top-quality small motors for healthcare. These motors fit in small spaces and work precisely. They are used in robotic surgery tools and portable devices. INEED’s motors are trusted for their great performance.

Picking the right motor improves medical tools. INEED customizes motors to meet healthcare needs. Their motors are a reliable choice for the medical field.

Motor Selection Criteria

Torque and Speed Needs

Picking a motor means knowing its torque and speed needs. Torque shows how well the motor can turn a load. Speed tells how fast it works. These two things affect how the motor performs in different tasks. For example, a stepper motor in robots needs exact torque and speed for accurate moves.

To choose the right motor, think about:

What it will do: Know the tasks the motor must handle.

Load details: Check the weight and resistance it will face.

Speed/torque charts: Match the motor's ability to your needs.

Using gearboxes and encoders: These improve torque and control.

Use this formula for calculations:Output Torque = Motor Output Torque × Gearbox Ratio × Gearbox Efficiency.

This helps ensure the motor works well without being overloaded.

Efficiency and Power Use

A motor’s efficiency lowers energy costs and boosts performance. Efficiency shows how well it turns electrical power into movement. Use this formula to find it:η = Output Power / Input Power.

Efficient motors, like brushless DC motors, use less power and stay cooler. They are great for HVAC systems and green energy setups. Regular checks keep motors efficient and lasting longer.

Topic | What It Covers |

|---|---|

Measuring Energy | Learn how to check energy use and motor efficiency. |

Efficiency Formula | Use math to find ways to improve efficiency. |

Maintenance Tips | Regular care keeps motors working well for a long time. |

Environmental Factors (like heat and moisture)

The environment affects how motors work and last. Heat and moisture can change the motor’s parts and cooling ability. For instance, heat from copper windings spreads through the motor and into the air. Picking the right motor ensures it works well in tough conditions.

Follow these tips for motor enclosures:

NEMA MG 1-2016: Protects motors from dust and water.

IEC 60034-1: Keeps motors efficient in different environments.

Enclosure types: Use explosion-proof ones for risky areas.

Testing helps check how much heat motor parts can handle. Choose enclosures with coatings and cooling to make motors last longer and work better.

Cost and Budget Considerations

When picking a motor, think about cost and budget. You need to find a balance between price and performance. This ensures the motor works well without costing too much. A helpful tool is Earned Value Management (EVM). It tracks what you’re paying for and its value. Big projects, like the Navy A-12 Avenger II Program, used EVM to spot problems and make smart choices. Many industries trust EVM for better buying decisions.

To stay within your budget, follow these tips:

Compare Upfront Costs and Savings: A pricier motor might save money later with less upkeep.

Check Energy Efficiency: Efficient motors use less power, cutting electricity costs.

Think About Customization: Custom motors, like INEED’s, may cost more but work better for your needs.

By looking at these points, you can pick a motor that fits your budget and goals.

Maintenance and Longevity

Taking care of your motor helps it last longer and work well. Regular maintenance stops small problems from becoming big ones. For example, following schedules for oil changes and checks keeps the motor in shape. Fixing issues early also avoids major breakdowns.

Here are ways to make your motor last:

Keep It Clean: Dirt can harm parts. Cleaning often stops rust and damage.

Watch for Problems: Strange noises or shaking mean something’s wrong. Fix it fast.

Follow Instructions: Use the right oils and parts for the best performance.

INEED’s micro motors are built to last. They need little care but still work reliably. Their strong design makes them great for tough jobs.

Step-by-Step Guide to Choosing the Right Motor (Highlighting INEED Micro DC Motors)

Picking the right motor means matching your needs to the motor’s features. Use this guide to choose wisely:

Step | Action | Why It Matters |

|---|---|---|

1 | Know what the motor will do. | Understanding load, speed, and torque helps find the right motor. |

2 | Learn about motor types (e.g., brushed, brushless, coreless). | Each type has special benefits like precision or energy savings. |

3 | Think about the environment. | Motors like INEED’s micro DC motors work well in many conditions. |

4 | Look into custom options. | Custom motors solve specific problems for unique tasks. |

5 | Compare prices and long-term value. | Spending more now can save money later with better efficiency. |

For example, INEED’s micro DC motors are small and precise. They can be customized with different speeds and gear ratios. This makes them perfect for healthcare and robotics. By using this guide, you can find a motor that meets your needs and budget.

Knowing motor types, uses, and how to choose them is important. Different industries need specific motors for the best results. For instance, electric cars use motors that are 25% smaller and 30% more efficient. In aerospace, motors are built to handle heat changes and vibrations. The table below shows how picking the right motor helps industries succeed:

Industry | Main Needs | Benefits |

|---|---|---|

Electric Vehicles | High power and efficiency | Makes motors 25% smaller and 30% more efficient |

Aerospace | Strong and lightweight motors for tough conditions | Works well in eVTOL aircraft, handling heat and vibrations |

Industrial Applications | Motors for heavy work and changing loads | Strong cooling and high torque for tough jobs |

Consumer Electronics | Small motors for home gadgets | Powerful motors with low energy loss for devices like washers and fridges |

Medical | Tiny motors for precise medical tools | High power and low energy loss for accurate surgeries |

Defense | Lightweight, strong motors for planes and ships | Top performance for critical defense systems |

INEED’s micro motors and DC motors offer custom solutions for your needs. Their motors are reliable, efficient, and perfect for many industries.

FAQ

What makes brushed and brushless DC motors different?

Brushed motors use brushes to work, while brushless ones use electronics. Brushless motors last longer, need less care, and work better. Brushed motors are simpler and cheaper for basic uses.

How do you figure out a motor's torque?

To find torque, use this formula:Torque = Force × Distance from the turning point.

For motors with gearboxes, multiply the motor's torque by the gearbox ratio and efficiency. This gives the right torque for your task.

Why are micro motors great for small devices?

Micro motors are tiny but strong. They fit in small spaces and give exact control. They use little power, making them great for portable tools like medical devices, robots, and gadgets.

How can motor efficiency be improved?

Pick a motor that fits your job. Keep it clean and oiled to avoid damage. Use efficient motors like brushless DC ones to save energy and reduce heat.

Which industries use INEED micro motors the most?

INEED micro motors are used in healthcare, robotics, and gadgets. Their custom designs meet special needs with accuracy and dependability. These motors improve medical tools, robots, and portable devices.

See Also

Understanding Vibration Motors: Varieties, Uses, and Choosing Tips

A Comprehensive Overview of Mini Motors: Types and Uses

Guide to 3V Motors: Uses, Specs, and Selection Tips

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry