The Relationship Between Resonance and Frequency: Key Concepts for Vibration Engineering

Understanding resonance and frequency is important in vibration engineering. Resonance makes vibrations stronger and can cause damage. For example, at twice the natural frequency, vibrations drop to 3.3% of their highest point at resonance. This shows why controlling these effects is so important. Tools like the Frequency Response Function (FRF) help predict how systems react to different frequencies. This helps create safer designs. INEED makes great vibration motors to solve these problems. Their solutions help you build systems that work better and last longer.

Key Takeaways

Knowing about resonance is important in vibration engineering. It can make vibrations stronger and cause damage. Control resonance to keep things safe and working well.

Frequency is key to resonance. When an outside force matches a system's natural frequency, vibrations get bigger. Engineers study these forces to avoid problems.

Damping helps control vibrations. It makes vibrations weaker and keeps machines and structures steady. Pick the right damping for what you need.

Tools like Frequency Response Functions (FRF) show how systems react to frequencies. Use these tools to make safer and better designs.

INEED's vibration motors are made to handle resonance well. Their flexible designs work for many uses, improving performance and lasting longer in projects.

What Is Resonance and How Does It Relate to Frequency?

Defining Resonance in Mechanical Systems

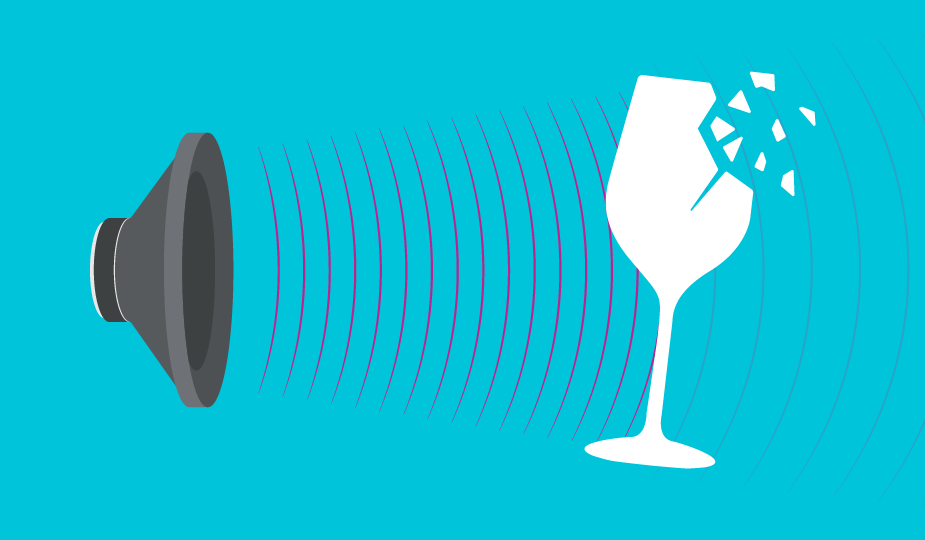

Resonance happens when something vibrates at its natural frequency. This is caused by an outside force. Resonance makes vibrations stronger and can have big effects. For example, think of a swing. If you push it at the right time, it goes higher. This happens because the timing matches the swing's natural frequency.

In machines, resonance can help or harm. When an outside force matches the system's natural frequency, vibrations grow bigger. This idea is used in musical instruments to make beautiful sounds. But in engineering, uncontrolled resonance can break things. Knowing about resonance helps you design systems to use or stop its effects.

Definition | Example |

|---|---|

Resonance happens when vibrations match the system's natural frequency, making them stronger. | Swings, pendulums, and machines that vibrate at certain frequencies. |

The Role of Frequency in Resonance

Frequency is very important for resonance. Everything has a natural frequency, which is how fast it vibrates when moved. When an outside force matches this frequency, resonance happens. This makes vibrations much stronger.

Think about a pendulum. If you push it at its natural frequency, it swings higher. But if you push at a different speed, it barely moves. This idea works for many things, like bridges and tall buildings. Engineers study outside forces to stop dangerous resonance. For example, they check a building's resonance frequency to keep it safe during earthquakes or storms.

Examples of Resonance in Vibration Engineering

Resonance is used in many engineering projects. In cars, engineers use special tools called tuned mass dampers (TMDs) to control vibrations. For instance, Renault's Formula 1 R25 car in 2005 used a TMD to reduce shaking, making it faster. Tall buildings like Taipei 101 also use TMDs to stay steady during earthquakes or strong winds. These tools keep people safe and comfortable.

Bridges can also have problems with resonance. Walking or wind can cause vibrations that match the bridge's natural frequency. This can make the bridge shake dangerously. Engineers use dampers to stop this from happening. By learning how resonance and frequency work together, engineers can build safer systems.

Tip: INEED's vibration motors are made to control resonance. Their designs work well for many uses, like medical tools and factory machines.

Structural Resonance and Its Impact on Vibration

What Is Structural Resonance?

Structural resonance happens when vibrations match a structure's natural frequency. This makes the vibrations stronger and can cause damage. It's like tuning a radio to a station. The structure absorbs energy, leading to too much movement.

Engineers use tools like FEA and FRF to find natural frequencies. These tools predict how structures react to moving forces. Changing stiffness or mass can move the resonant frequency to safer levels. Adding damping reduces vibration strength, making systems steadier.

Problems Caused by Structural Resonance

Structural resonance can create big problems in engineering. Vibrations grow stronger at certain speeds, damaging parts. If ignored, these vibrations can cause failures during RE and RI tests. Small parts, like circuit boards, may stop working due to resonance.

To fix this, engineers use damping materials or redesign parts. EMC shielding also helps reduce resonance effects. Tools like spectrum analyzers find problem areas. Fixing resonance ensures systems work well in different conditions.

Real-Life Examples of Structural Resonance Failures

Structural resonance has caused major failures. One example is London's Millennium Bridge. People walking on it matched its natural frequency. This made the bridge wobble dangerously. Limiting walkers didn’t fix it. Engineers added dampers, which stopped the wobbling.

This shows why understanding resonance is important. Fixing resonance early avoids costly repairs and keeps designs safe. Whether it’s bridges, buildings, or machines, controlling resonance prevents failures.

Rotor Critical Speed vs. Structural Resonance

What Is Rotor Critical Speed?

Rotor critical speed happens when a rotor spins at its natural frequency. At this speed, the rotor vibrates the most, which can bend it and cause problems. For example, in a shaft-disc system, the first and second critical speeds might be at 710 and 1965 RPMs. Engineers use tools like finite element analysis to find these speeds.

Critical speed is important in machines like turbines, pumps, and motors. Running close to this speed can cause too much vibration. This lowers efficiency and wears out parts faster. By knowing critical speed, engineers can design systems to avoid these issues.

Comparing Rotor Critical Speed and Structural Resonance

Rotor critical speed and structural resonance both deal with vibrations but are different. Rotor critical speed affects spinning parts, while structural resonance impacts non-spinning parts like frames. The table below shows their differences:

Aspect | Rotor Critical Speed | Structural Resonance |

|---|---|---|

Definition | Happens when a spinning part's speed matches its natural frequency. | Happens when non-spinning parts vibrate too much, often from small forces. |

Behavior at Speed | Rotor bends and vibrates more due to unbalance forces. | Vibrations change with speed, even from small unbalanced forces. |

Common Applications | Found in pumps, turbines, and large motors. | Found in machine parts and structures near the machine's speed. |

Vibration Characteristics | High vibration occurs when rotor speed hits its resonant frequency. | Strong vibrations happen even with small misalignments or unbalances. |

Solution | Fix unbalance forces; operate above critical speed to detect issues. | Change structure or balance parts to reduce vibrations. |

Knowing these differences helps engineers fix each problem and improve system performance.

Solutions for Managing Rotor Critical Speed in Vibration Systems

To handle rotor critical speed, engineers use ways to lower vibrations. For example, a steam turbine-generator had bad vibrations during load changes. Engineers replaced its bearings with special 6-pad journal bearings, fixing the issue. Another example is a boiler feed pump that stopped working due to critical speed problems. Engineers added proximity probes to measure vibrations and adjusted the system, moving the critical speed higher than the working range.

Other fixes include adding damping, changing rotor weight, or using computer models to predict and adjust speeds. For instance, at a nuclear plant, engineers added weight to a disk, lowering the critical speed and stopping vibration spikes. These methods help machines run smoothly and last longer.

Tip: INEED's vibration motors are built to handle critical speed problems. Their flexible designs work well for precise vibration control.

The Relationship Between Stiffness, Mass, and Natural Frequency

How Stiffness and Mass Affect Natural Frequency

Natural frequency depends on stiffness and mass. Stiffness shows how hard it is to bend or stretch something. Mass is the amount of material in an object. Together, they decide how something vibrates when moved.

If stiffness increases, natural frequency goes up. Stiffer materials vibrate faster because they resist movement more. If mass increases, natural frequency goes down. Heavier objects vibrate slower because they take longer to move.

For example:

A study found that adding more fibers made materials stiffer. This raised their natural frequencies, especially in early vibration modes.

Computer tests showed that higher stiffness changes how materials vibrate.

Study | Results |

|---|---|

Created a formula for natural frequency using force and stiffness tests. | |

Liu et al. | Studied shapes and forces to find how stiffness changes. |

Xie | Found a link between stiffness and force using model tests. |

Knowing this helps engineers stop unwanted vibrations and resonance.

How Natural Frequency Links to Resonance

Natural frequency is key to resonance. Resonance happens when outside forces match a system's natural frequency. This makes vibrations much stronger. It can help or harm, depending on the situation.

Tools like Frequency Response Functions (FRFs) and Bode plots show this link. Bode plots highlight resonance as peaks at natural frequencies. These tools help engineers predict and control resonance. This keeps systems safe and working well.

Using INEED Vibration Motors in Engineering

INEED's vibration motors show how stiffness and mass control natural frequency. Their Linear Resonant Actuators (LRAs) adjust stiffness and mass for quick responses and better feedback. These motors work well in wearables, medical tools, and factories.

By changing vibration strength and frequency, INEED makes motors fit different needs. This reduces resonance problems and boosts performance. Their designs solve many vibration engineering challenges reliably.

The Role of Damping in Controlling Resonance

What Is Damping and Why Is It Important?

Damping reduces vibrations by using up energy in a system. It is very important for controlling resonance, which happens when something vibrates at its natural frequency. Without damping, vibrations can grow too big and damage machines.

Think of damping like a brake for vibrations. It keeps systems steady by lowering how much they shake. For example, in a spring system, damping decides how it acts near its natural frequency. More damping means weaker vibrations. This makes damping key for keeping machines, buildings, and other structures safe.

Damping lowers how strong vibrations are during resonance.

The Q factor shows how resonance behaves. A low damping ratio makes higher peaks, while a high ratio lowers them.

By learning about damping, you can design safer systems with fewer vibration problems.

Types of Damping in Mechanical Systems

There are different types of damping for various uses. Each type works differently, so picking the right one is important. Here’s a simple guide:

Type of Damping | What It Does | Where It’s Used |

|---|---|---|

Overdamping | No shaking; takes longer to settle. | Heavy doors; safety tools. |

Underdamping | Some shaking that slowly fades away. | Car suspensions; musical instruments. |

Critical Damping | Stops shaking quickly without overshooting. | Camera lenses; electronic circuits. |

Overdamping is best for systems needing no shaking, like safety machines. Underdamping works in cars, where small shakes make rides smoother. Critical damping is great for things like cameras, where quick steadiness is needed.

Choosing the right damping type helps systems work better and last longer.

Practical Examples of Damping in Vibration Engineering

Damping is used in many engineering projects to stop vibration problems. Here are some examples:

TechSAT Aerospace Engineering: Engineers studied how a device vibrated on an airplane. They changed the design to cut part movement by 18%, making it more reliable.

Electric Vehicle (EV) Battery Module: Engineers tested how the battery vibrated. They added damping to make it safer and work better.

These examples show how damping helps stop resonance and improve designs. Whether it’s for cars, buildings, or devices, damping keeps systems safe and steady.

Tip: INEED's vibration motors include damping features. These help control vibrations and work well for many uses.

Knowing about resonance and frequency is key in fixing vibration issues. These ideas help predict and control how systems react in different situations. Learning them lets you create safer and better designs. INEED's vibration motors are great for handling resonance. Their flexible designs work well for many uses, like medical tools and factory machines. With INEED, you get tools that make systems stronger and last longer. This helps your engineering projects succeed.

Note: Choosing the right vibration tools leads to fewer problems and better results.

FAQ

Why is it important to know about resonance in engineering?

Resonance makes vibrations stronger, which can harm machines or buildings. By learning about it, engineers can stop these problems. This keeps designs safe and working well. It also saves money by avoiding big failures.

Why do engineers care about natural frequency?

Natural frequency shows how something vibrates when moved. If outside forces match this frequency, resonance happens. Engineers study it to stop too much shaking. This helps machines and buildings stay strong and last longer.

Why is damping needed to control vibrations?

Damping slows down vibrations by using up their energy. It stops resonance from getting too strong and causing damage. Without damping, vibrations could grow too big and break things.

How do INEED vibration motors help with resonance?

INEED motors are made to control how much things vibrate. You can adjust them for different jobs. This lowers the chance of resonance and makes them work better in areas like healthcare and robotics.

How does stiffness change natural frequency?

Stiffness shows how hard it is to bend something. More stiffness makes vibrations faster by raising natural frequency. Changing stiffness helps control vibrations and stops problems from resonance.

See Also

Exploring Resonant Systems: Impact on Vibration Motor Efficiency

Four Essential Insights on Applications of Resonant Frequency

Defining Resonant Frequency: Measurement Techniques Explained

Managing Resonance Frequency in Vibration Motors for Consistent Performance

A Comprehensive Guide to Using Vibration Calculators Effectively

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry