Simple Ways to Make Vibration Motors Quieter

You can reduce vibration motor noise by changing how you attach the vibration motor. Make sure the motor and its parts are tight and do not touch hard surfaces. Many engineers use simple fixes like rubber grommets or mechanical dampers to absorb vibration motor noise. You should also check for loose parts that might cause vibration motor noise. These easy steps help your device get quieter without special tools.

Key Takeaways

Use soft things like rubber or foam to hold vibration motors. These materials help soak up noise and shaking well. - Hold motor wires in place with clips or ties. This stops them from moving and making more vibration noise. - Look for loose parts and make sure the motor is tight. This helps stop rattling and extra noise. - Keep the motor away from hard things. Use isolation mounts to stop vibration from moving through the device. - Pick good quality motors with balanced parts. Take care of them to make less noise and help them last longer.

Vibration Motor Noise Causes

Main Sources

You might hear noise and feel shaking when electric motors start. The main reason for vibration motor noise is how the motor moves and touches things around it.

Mechanical rattling happens if the motor or its parts bump into things like the mounting clip, the PCB, or the case.

When the spinning weight inside the motor is not balanced, it makes the motor hit things fast and creates noise you can hear.

Wires or leads that touch other parts can also make more noise and shaking.

The size and what the motor is attached to can change how loud the noise and shaking are.

Electric motors can make electrical noise, but most of the sound you hear comes from moving parts.

Tip: If you mount the motor the right way, you can make it quieter and your device will seem better.

Mounting Issues

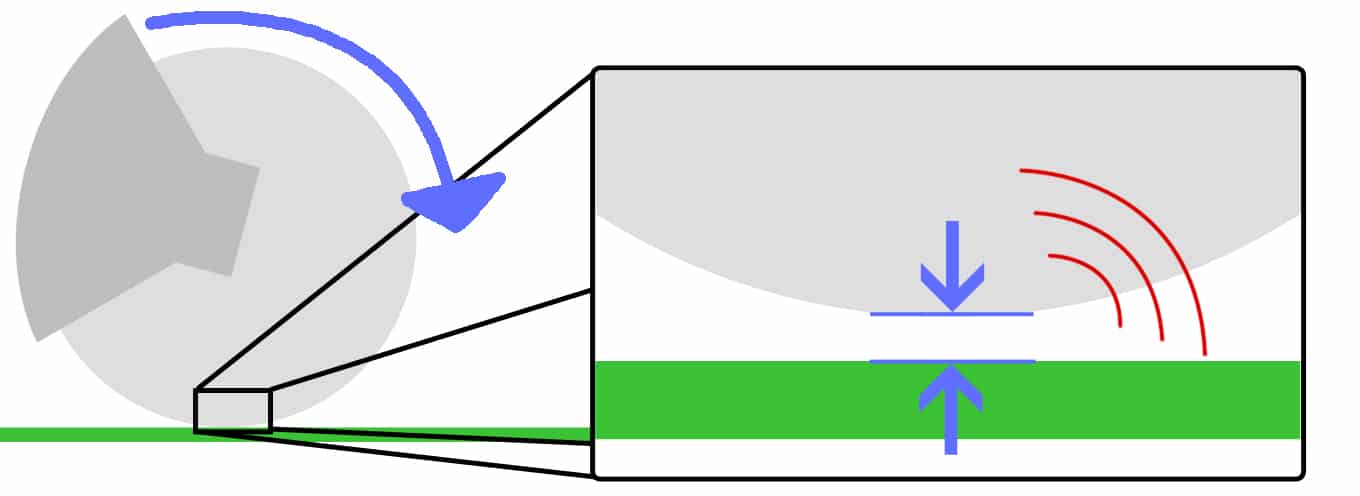

Mounting problems can make electric motors louder and shake more. If you use hard mounts or tighten screws too much, the shaking goes through the frame and bolts, making more noise.

Using soft things like rubber, silicone, or TPU can soak up shaking and make the motor quieter, especially at low sounds.

Even easy fixes, like putting electrical tape under the motor, can help lower vibration motor noise.

If the motor is too loose, you might hear rattling and the shaking will not feel strong, which makes the device seem cheap.

If you use floating or very soft mounts, the shaking almost does not reach the frame, so there is less noise and shaking.

Quality Impact

How good your vibration motor is changes how much noise and shaking it makes. Good electric motors have better bearings and balanced parts, so they make less noise and shaking.

Good bearings last longer and do not make much noise.

Strong magnets and well-made parts help keep the motor balanced, so there is less shaking and noise you can hear.

Bad or old parts, like broken bearings or unbalanced rotors, make more noise and shaking.

Taking care of your motor and installing it right helps keep it quiet and smooth.

Find the Noise Source

Troubleshooting Steps

You can figure out where noise and shaking come from in electric motors by doing a few easy things. First, turn off your device and look for loose parts. Shake the motor, the PCB, and the case gently. If you hear rattling, you found a spot with a problem. Check if the vibration motor moves against other surfaces. Even tiny spaces can make more noise and shaking.

Next, use your senses to help. Listen for weird sounds like grinding or squealing. Touch the device to feel if it shakes a lot. If you have tools like accelerometers or noise meters, use them to check for shaking and loud sounds. These tools show how much the motor moves and help you find strange patterns. Directional microphones can help you know where the sound is coming from inside the device.

Tip: A table can help you see and compare ways to check for noise and shaking in electric motors.

Diagnostic Method | Principle | Application and Effectiveness |

|---|---|---|

Frequency Analysis | Checks vibration frequency and matches it to motor speed | Finds where shaking comes from by linking it to speed and parts |

Order Tracking Analysis | Watches vibration at different speeds | Good for motors that change speed; finds shaking linked to certain parts |

Vibration Amplitude | Measures how far something moves | Shows how strong the shaking is and helps find problems |

Acceleration | Measures how fast something moves | Used with other ways to understand how the shaking acts |

Problem Areas

Noise and shaking in electric motors usually come from a few main spots. Old bearings can make grinding or squealing sounds. Shafts or motor parts that are not lined up right can cause shaking and make the motor run rough. If the rotor is not balanced, you will feel more shaking and hear more noise. Loose bolts can make rattling or banging, which spreads through the device and makes it louder.

Noise and shaking can also travel through your device’s parts. The motor can send shaking into the PCB, the case, or even the table under the device. This can make a small problem seem much bigger and make the whole device louder. Always check these places first if you want to make your vibration motor quieter.

Reduce Vibration Motor Noise

Soft Mounting

You can make your device quieter by using soft mounting. Soft materials help stop noise and shaking before it spreads. Many engineers use rubber, silicone, or special foam for this job. For example, some companies suggest using rubber plates with high mass and thickness, like MP-5 and MP-10. These plates help stop shaking on parts that move a lot. The materials soak up energy and keep it from turning into sound you can hear.

Some mounts use springs shaped like cones or cylinders to block shaking. Parker LORD makes elastomer mounts, like Flex-Bolt sandwich mounts and neoprene grommets. These work well for electric motors that run faster than 30 Hz. These mounts last a long time and can handle strong shaking. Sorbothane is a soft polyurethane that can soak up more than half the shaking energy. It works for many types of devices, both big and small.

When you pick a soft mount, think about its shape and size. A good fit helps the mount block more shaking and noise. Try different materials and shapes to see what works best for your device.

Tip: Even a simple rubber grommet or a piece of foam tape can help make your vibration motor quieter.

Secure Leads

Loose wires can make noise and shaking worse. If wires move or hit other parts, they can spread shaking through your device. You should always keep the leads of your vibration motor in place. Use cable ties, clips, or sticky pads to hold wires still. This stops them from rattling and spreading shaking to the PCB or case.

When you attach the leads, do not pull them tight. Leave a little slack so the wires can move with the motor. If you use soft sleeves or tubes around the wires, you can block even more shaking. This keeps your device quiet and helps the electric motors last longer.

Note: Securing leads is easy, but it can really help lower noise and shaking in your device.

Isolate from Hard Surfaces

Hard surfaces make noise and shaking travel farther and sound louder. You can make things quieter by keeping your vibration motor away from these surfaces. Start by using anti-vibration mounts, pads, or springs under the motor. These parts stop shaking from moving into the case or table.

Here are some good ways to keep your motor quiet:

Pick equipment with low noise and shaking ratings.

Put vibration isolation mounts or pads under the motor.

Use soft connectors and materials to avoid touching hard surfaces.

Add sound insulation, like foam or fiberglass, to soak up noise.

Build boxes or barriers with sound-absorbing stuff to keep noise inside.

You can also move noisy motors away from walls or floors to stop sound from bouncing. Cover hard surfaces nearby with foam or cloth to soak up noise. If you build a box around the motor, seal it tight to keep low sounds from getting out.

A step-by-step plan helps you get the best results:

Use rubber or foam to soak up shaking energy.

Keep the motor off hard surfaces with soft mounts.

Add springs to control how much the motor moves.

Use damping to soak up extra shaking.

Test your setup and change things for the quietest sound.

Some special materials, like Quiet Aluminum, cost more at first but save money later. They cut down on extra noise fixes and make the whole system quieter. Many companies find that spending more on better noise and shaking control makes their products better and causes fewer problems.

Callout: Keeping your vibration motor away from hard surfaces is one of the best ways to lower noise and shaking in any device.

Mounting Tips

On PCBs

You need to plan well when putting a vibration motor on a PCB. The motor should stay in place and not make extra noise. There are many ways to do this. The table below shows some common ways and what you should know:

Mounting Technique Category | Specific Methods | Key Details and Recommendations |

|---|---|---|

Solder Methods | Through-hole pins, Surface mount reflow | Soldering makes strong joints. Surface mount is good for small spaces. Always use the right heat for soldering. |

Glue and Adhesive Methods | Adhesive pads, Epoxy or glue | Adhesive pads are easy for coin motors. Use special epoxy for cylindrical motors. Clean the area before using glue. |

Fasteners and Clips | Cable ties, Screwed mounts, Clips | Cable ties keep motors still. Screws hold tight but need more room. Clips are cheap and simple. Use washers or thread locker to stop parts from coming loose. |

Injection Moulded Mounts | Moulded mounts, Spring pad connectors | Plastic covers can hold the motor all the way. Spring pads save space on the PCB. Plan for these before you build. |

Tip: Hold the motor tight and use anti-vibration frames or edge stops. This keeps shaking from spreading on the PCB.

In Enclosures

The box you put the motor in is important. Soft liners like rubber, urethane, or silicone help block sound and lower noise. You can use rubber isolators or air-filled mounts instead of metal springs for less noise. Putting rubber or urethane at the mounting spots stops metal parts from touching and making noise.

Put soft liners inside the box.

Pick materials with lower durometer numbers for less noise.

Place rubber or foam pads under the motor to stop shaking.

Make sure the box fits well so it does not rattle.

Note: Heat and wet air can change how well the mount works. Closed boxes and checking often help keep noise down in all weather.

For Leaded Motors

Leaded motors need extra care when you put them in. Always look for parts that are not lined up, loose bolts, or weak bases. These problems can make more shaking and noise. Hold the wires with cable ties or clips, but do not pull them tight. Use soft sleeves or tubes to soak up movement.

Line up the motor and its mount right.

Tighten all bolts and check for loose parts.

Use rubber or silicone sleeves on wires to stop shaking from spreading.

Check the mounting spot for damage or wear as time goes on.

Callout: Good mounting keeps your vibration motor quiet and helps it last longer. Bad mounting can make more noise, wear out parts faster, and even cause safety problems.

You can make your device quieter if you hold the vibration motor in place, use soft things, and check for loose parts. Soft things like rubber or felt help stop noise from moving around. They change how the system shakes, so less sound gets out. Many companies have made their devices better and less noisy by doing these things.

Even small fixes, like putting in a rubber pad or making a screw tighter, can make your device quieter and make people like it more.

Benefit | What You Gain |

|---|---|

Less Noise | Up to 20 dB reduction |

Longer Lifespan | Fewer repairs, better reliability |

More Comfort | Smoother, quieter operation |

FAQ

What causes vibration motor noise in devices?

Vibration motor noise happens when the motor shakes on hard things or loose parts. Bad mounting, unbalanced rotors, and old bearings can also make more noise and shaking.

How can I quickly reduce noise from a vibration motor?

Put soft things like rubber pads or foam tape under the vibration motor. These things soak up shaking and help lower noise. Make sure all parts are tight and do not shake.

Why do wires make noise and vibration worse?

Loose wires can touch other parts and spread shaking in your device. This can make both vibration motor noise and sound louder. You should hold wires with clips or ties to lower noise and shaking.

Does the quality of the vibration motor affect noise?

Yes. Good electric motors have better balance and stronger parts. They make less vibration motor noise and last longer. Cheap motors often make more noise and shaking.

Can I stop audible noise without special tools?

Yes. You can use easy fixes like rubber grommets, foam pads, or cable ties. These things help lower noise and shaking from your vibration motor. You do not need special tools for these steps.

See Also

Effective Techniques To Reduce Noise And Vibration In Small Motors

Five Reliable Strategies For Cutting Down Noise And Vibration

Step-By-Step Guide To Detect And Lower Vibration Noise

Understanding The Causes Of Vibrations In 3V DC Motors

Simple Five-Step Process To Control Arduino Vibration Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry