Reading the Motor Constants from Typical Performance Characteristics

You can find motor constants by looking at a motor’s performance curves or datasheets. Focus on important values like torque, speed, and efficiency. Knowing these values helps you pick the best motor for your project. This is true if you work with medical devices, consumer electronics, or industrial machines. For example, INEED’s micro motors and encapsulated vibration motors are used in many devices you see every day.

Device Category | Application Description |

|---|---|

Consumer Electronics | Vibration alerts in phones and gaming controllers |

Wearables | Gentle notifications in fitness trackers and smartwatches |

Medical Devices | Waterproof motors for safe use in medical tools |

Industrial Machines | Making equipment easier to use |

Electronics | Helping motion sensors and touchscreens work better |

Healthcare | Giving accurate feedback in advanced medical tools |

You do not have to be an expert to begin. With some practice, you will see the process is easy and helpful.

Key Takeaways

Motor constants like torque, speed, and efficiency are very important. They help you pick the right motor for your project. Knowing these values helps the motor work well.

Always look at the motor's performance curves in datasheets. These curves show how speed, torque, and current are connected. They help you make good choices.

Use the right formulas to find motor constants. For example, you get the torque constant by dividing torque by current. This helps you check your numbers.

Watch out for common mistakes when reading datasheets. Using the wrong voltage or reading data wrong can hurt the motor or make it work badly.

Use a checklist when you look at motor datasheets. This keeps you organized and helps you get all the information you need for your project.

Motor Constants Explained

What Are Motor Constants

You can find motor constants in many datasheets and charts. These constants show how a motor works in different situations. They help you know what a motor can do, like how much torque it gives, how fast it spins, and how much energy it uses. You can look at torque, speed, and efficiency charts to find these constants. Each chart tells you something different, like how speed changes with load or how much current the motor uses at different speeds.

Motor constants are things like the torque constant, speed constant, and motor constant (Km). The torque constant tells you how much torque the motor makes for each ampere of current. The speed constant shows how fast the motor spins for each volt you give it. The motor constant (Km) mixes torque and heat loss, showing how well the motor turns electricity into work. You can use these constants to compare motors and pick the best one for your project.

Why They Matter

Motor constants are important when you pick and use motors. When you look at a motor’s characteristics, you can see how it will work in your device. For example, in robotics or automation, a higher motor constant (Km) means the motor can give more torque without getting too hot. This is good for small spaces, like robotic joints, where you need strong motors that stay cool. Good characteristics help you choose a motor that fits your size and power needs.

In medical and consumer electronics, the right characteristics make devices work better and last longer. You want motors that are quiet, start fast, and stay cool. These things help your devices last longer and work well. If you do not read the characteristics right, you might pick a motor that does not work well. This can make your device work badly or even break the motor. Always check the characteristics to make sure you get the right motor for your project.

Low noise keeps medical places quiet.

Easy control helps devices react fast.

Good heat dissipation helps motors last longer.

Stable characteristics mean fewer problems.

Tip: Always match the motor’s characteristics to your project for the best results.

Motor Performance Curves

Key Curves to Identify

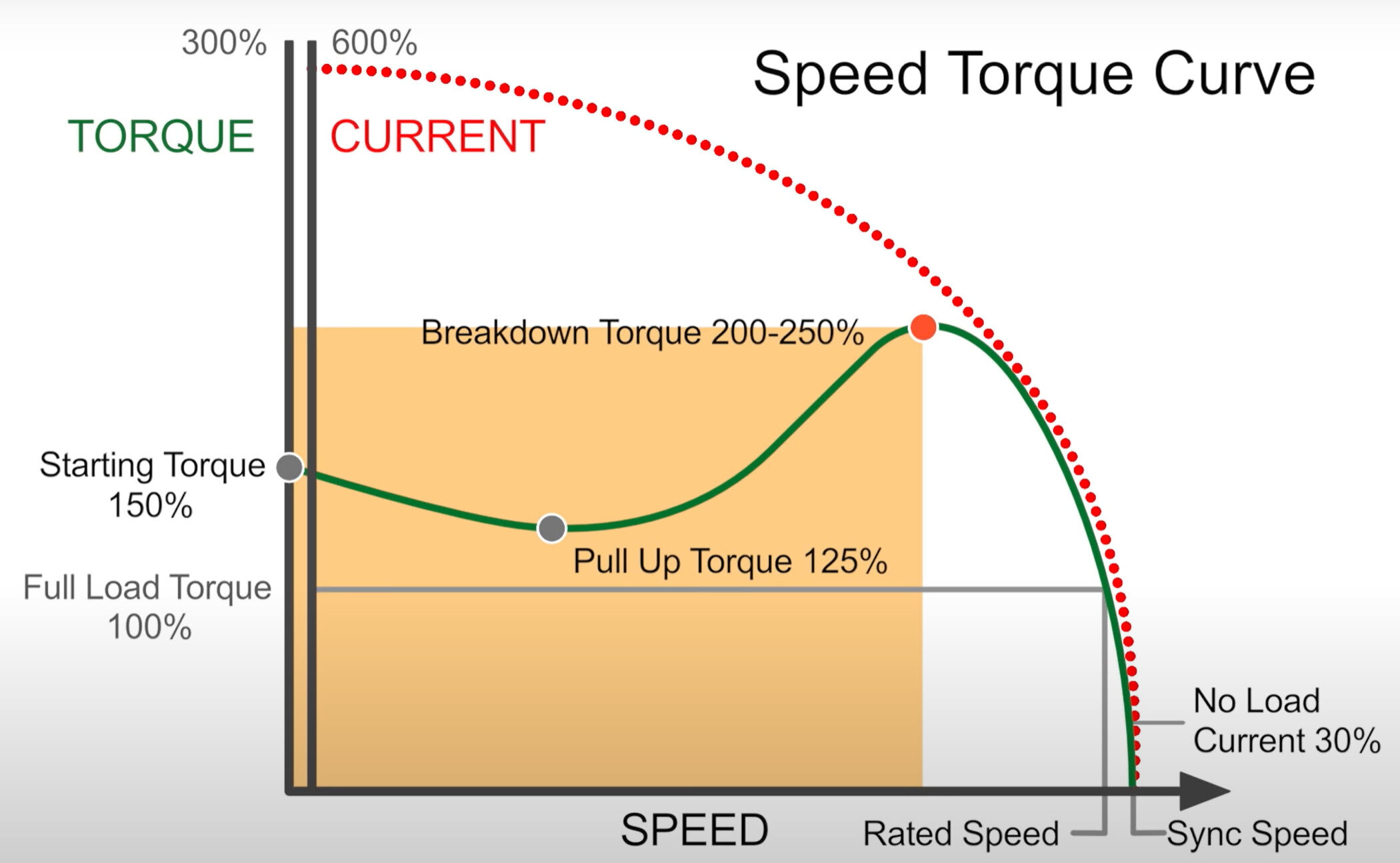

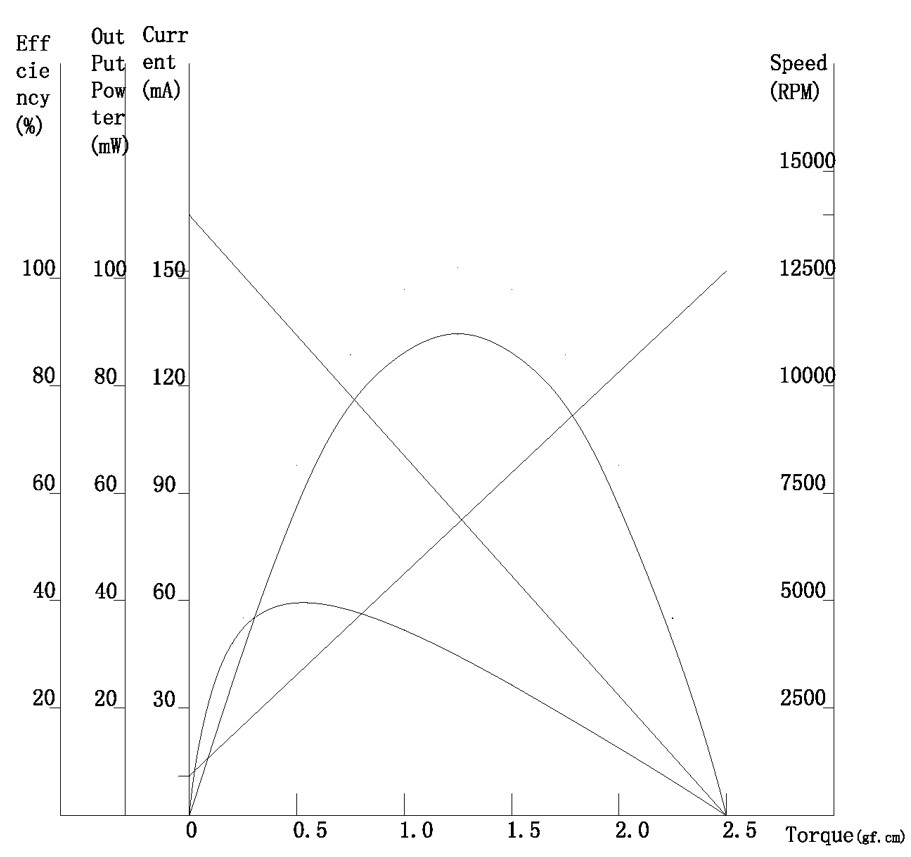

When you look at motor performance curves, you can see how the motor acts in different situations. These curves show how speed, torque, current, and efficiency are connected. You will find many curves in a datasheet. For example, INEED’s micro motors and encapsulated vibration motors have these curves. The speed-torque curve shows how fast the motor spins when the load changes. The current-torque curve shows how much current the motor uses at different torque levels. Efficiency curves help you find out where the motor works best.

INEED product datasheets use simple graphs for these curves. The axes are labeled with speed (rpm), torque (Nm), current (A), and efficiency (%). Each curve gives you a quick look at what the motor can do. When you compare motors, these curves help you choose the right one for your project.

Tip: Always look at the axes and legends on the motor performance curves. This helps you read the data correctly and avoid mistakes.

Data Points to Note

You should focus on important data points when you read motor performance curves. These points help you find motor constants and see how the motor will work in your device. The most important data points are torque, current, speed, and voltage. You find these values at special spots on the curves, like no-load, rated, and stall.

Here is a table that lists the main data points and how you use them:

| Data Point --- | Description --- | Calculation Method --- | | Torque --- | The turning force made by the motor --- | Read the current at a certain torque and divide torque by current --- | | Current --- | The electric current used by the motor --- | Used to find the Torque Constant --- | | Speed --- | How fast the motor spins --- | Read the no-load speed and change it to radians per second --- | | Voltage --- | The electric voltage given to the motor --- | Used to find the Motor Voltage Constant and Speed Constant --- |

You also see common units and ways to measure in INEED datasheets. Here is another table for you to use:

| Parameter --- | Value --- | Unit --- | | No-Load Speed --- | 58 --- | rpm --- | | No-Load Current --- | 0.5 --- | A --- | | Rated Speed --- | 48 --- | rpm --- | | Rated Torque --- | 2.5 --- | Nm --- | | Rated Current --- | 2.5 --- | A --- | | Rated Power --- | 12.8 --- | W --- | | Max. Efficiency --- | 43 --- | % --- | | Max. Power --- | 22.7 --- | W --- | | Stall Torque --- | 15 --- | Nm --- | | Stall Current --- | 12 --- | A --- |

When you read motor performance curves, you should look out for errors. Sometimes, the curves use data from just a few motors. The range might not fit what you need. Manufacturer limits can change what you see. Always check the notes in the datasheet to make sure you use the right data.

Note: INEED’s datasheets use clear graphs and tables. This makes it easier for you to find and use the right curves and data points.

Extracting Motor Constants

If you know how to get motor constants from a datasheet, you can make better choices. You can use INEED’s micro motors and encapsulated vibration motors as examples. There are three main constants you need: torque constant, speed constant, and efficiency.

Torque Constant

The torque constant tells you how much torque the motor makes for each ampere of current. You can find this value by looking at the speed-torque curve and current-torque curve in the motor’s performance data.

Step-by-step guide:

Find the Data Points:

Look at the speed-torque curve and current-torque curve in the datasheet. Pick a point where the motor runs at a steady speed. Do not use stall or no-load points. For example, use the rated torque and rated current from INEED’s micro motor datasheet.Use the Formula:

The torque, current, and torque constant are connected. You can use this table to help:Variable

Description

τ

Torque

K_t

Torque constant

i

Current

Equation

τ = K_t i (Equation 4)

Change the formula to get:

K_t = τ / iCalculate the Value:

If the rated torque is 2.5 Nm and the rated current is 2.5 A:K_t = 2.5 Nm / 2.5 A = 1 Nm/ACheck for Maximum Continuous Torque:

Always use the maximum continuous torque value. Do not use peak or stall torque for most uses. This keeps the motor safe and working well.

Tip: Always check the units. Use Newton-meters (Nm) for torque and Amperes (A) for current.

If you get gear ratios wrong, the torque will be wrong.

If you forget about heat or resistance, you might guess too high.

If you do not think about changing loads, the motor may not work right.

Speed Constant

The speed constant shows how fast the motor spins for each volt you give it. You can find this value by using the speed-torque curve and voltage data from the chart.

Step-by-step guide:

Find the No-Load Speed and Voltage:

Look at the speed-torque curve. Find the no-load speed (when torque is zero) and the voltage used.Use the Formula:

The speed constant (K_v) is the no-load speed divided by peak voltage. Here is a table to help:Parameter

Formula

Description

K_v

K_v = ω_no-load / V_peak

Ratio of unloaded speed to peak voltage

K_e

K_e = V_peak / ω_no-load = 1 / K_v

Inversely related to K_v

K_T

K_T = 60 / (2π K_v(RPM)) = 1 / K_v(SI)

Torque constant derived from K_v

ω_no-load means the no-load speed in radians per second.

V_peak is the voltage used.

Calculate the Value:

If the no-load speed is 7800 rpm and the voltage is 3 V:Change rpm to radians per second:

ω_no-load = 7800 × 2π / 60 ≈ 816.8 rad/sK_v = 816.8 rad/s / 3 V ≈ 272.3 rad/s/V

Cross-Check with the Torque Constant:

The speed constant and torque constant are linked. If you know one, you can check the other with the formulas above.

Note: Always use the same units when you do your math. Mixing rpm and rad/s can cause mistakes.

Efficiency

Efficiency tells you how well the motor changes electrical energy into mechanical work. You can find efficiency at different spots on the speed-torque curve using the performance data.

Step-by-step guide:

Find Output and Input Power:

Output power is torque times speed (in radians per second).

Input power is voltage times current.

Calculate Efficiency:

Efficiency (%) = (Output Power / Input Power) × 100Use the Performance Curves:

Look at the speed-torque curve and current-torque curve. Get the values for torque, speed, voltage, and current at the spot you want to check.Follow Industry Standards:

The IEC 60034-2-1:2014 standard tells you how to measure motor efficiency. These methods help you get better results and match the motor type and rating.

Tip: Efficiency is highest at a certain spot on the speed-torque curve. It is not always at the top speed or torque. Use the spot where the datasheet shows maximum efficiency.

Common pitfalls:

Using data outside the recommended range on the speed-torque curve can give you the wrong efficiency.

High temperature or humidity can change how the motor works. These things can slow reaction times and make your motor constants less accurate.

Quick Recap Table:

Step | What to Do | Where to Look |

|---|---|---|

1 | Find torque, current, speed, voltage | Speed-torque curve, datasheet |

2 | Use formulas for each constant | Tables above |

3 | Calculate and check units | Calculator, datasheet |

4 | Watch for common mistakes | Notes, environment |

Remember: Always use the speed-torque curve and performance data from INEED’s datasheets. This helps you get the right motor constants for your project.

Tips for Interpreting Data

Avoiding Mistakes

When you read motor datasheets, you should be careful. Always check the voltage rating before you use a motor. Using the wrong voltage can make the motor get too hot. It might even break the motor. Do not run the motor above its service factor. This can make the motor wear out fast. Before you put in a motor, check which way it spins. If you wire it wrong, it may spin the wrong way.

Here is a table of common errors you might see:

Error Type | Description |

|---|---|

Incorrect Connection | Wrong voltage can make the motor too hot or break. Always check the voltage rating. |

Service Factor Overload | Running too high makes heat and wears out the motor. Do not keep it at the limit. |

Incorrect Rotation | Wrong wiring can make the motor spin the wrong way. Always check which way it spins. |

You will see torque in units like kgf.cm, N.m, or ozf.in. Always change these units to the one you need. This helps you compare motors better.

Tip: INEED’s team checks every product for correct labels and data. You can trust the numbers in their datasheets.

Handling Incomplete Information

Sometimes, datasheets do not have all the data you need. You can fix this in a few ways:

Delete rows with missing data. This is fast but you might lose something important.

Fill in missing spots with averages or middle values. This helps, but it can make your data less true.

Use smart methods like K-Nearest Neighbors (KNN) to guess missing data. This keeps your data closer to real.

If you want to check motor constants, you can make a model of the motor. Test it by giving it voltage pulses. Measure the current and compare it to the datasheet. This helps you see if the motor works as expected.

If you have questions or need help with missing data, INEED’s support team can help you. Their experts help you read data and pick the right motor for your project.

Quick Checklist

Steps to Analyze a Datasheet

You can use this checklist to help you read and understand any motor datasheet. Follow these steps to make sure you get the right motor constants for your project.

Gather Your Tools

Start by getting the datasheet for your motor. You may want a calculator, a notepad, and a ruler for reading graphs. Some software tools can help you analyze data faster.Tool Name

Description

MOTEON Motor Analysis Tool

Gives you insights into motor limits and shows visualizations based on different conditions.

MotorAnalysis

Free software for electric machine design. It supports many motor types and uses automated simulations.

Identify Key Curves and Data Points

Look for the speed-torque curve, current-torque curve, and efficiency curve. Find important points like no-load speed, rated torque, and stall current.Check Units and Labels

Make sure you understand the units for each value. Convert them if needed. For example, change rpm to rad/s or Nm to kgf.cm if your project needs it.Extract Motor Constants

Use the formulas you learned earlier. Calculate the torque constant, speed constant, and efficiency. Write down your results.Compare with Your Requirements

See if the motor matches what your project needs. Check if the torque, speed, and efficiency fit your device.Watch for Common Mistakes

Double-check your numbers. Make sure you used the right data points and did not mix up units.

Tip: If you find missing or unclear data, reach out to the manufacturer’s support team. INEED’s experts can help you fill in the gaps and choose the best motor.

You can use this checklist every time you review a new motor datasheet. It helps you stay organized and avoid errors. With practice, you will get faster and more confident at picking the right motor for your project.

You can now look at motor datasheets and feel sure. First, find the main curves and important data points. Next, use the formulas to get torque constant, speed constant, and efficiency. Check your answers using the checklist. Brands like INEED give clear and correct data. Good information helps you pick the right motor for your project. For more tips and details, go to INEED’s website. Keep practicing, and you will get better at reading any motor datasheet.

FAQ

How do I find the torque constant on a datasheet?

Look for the rated torque and rated current. Divide the torque by the current.

Example: If torque is 2.5 Nm and current is 2.5 A, then torque constant = 1 Nm/A.

What if the datasheet does not show all the curves?

Check for tables with key values like speed, torque, and current.

You can also contact INEED’s support team for help with missing data.

Why do I need to convert units when reading motor data?

Manufacturers use different units. You need to convert them to compare motors or use formulas.

Example | Conversion |

|---|---|

rpm to rad/s | rpm × 2π ÷ 60 |

Can I use the stall torque for my calculations?

No, you should use the rated or continuous torque for most calculations.

Stall torque is only for short bursts and can damage the motor if used too long.

Who can help if I have trouble reading a datasheet?

You can reach out to INEED’s technical support.

They answer questions.

They help you choose the right motor.

They guide you through datasheet details.

See Also

Mastering Motor Diagrams: A Guide to Effective Reading

Understanding Frequency and Vibration: Key Factors for LRA Motors

Differentiating Vibration and Frequency for Enhanced Motor Specs

Effective Strategies for Diagnosing and Fixing Motor Vibration Issues

Selecting Ideal Configurations for Battery Operated Electric Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry