How to Quickly Understand the Complete Guide to Vibration

Vibration means the back-and-forth movement of something in place. You see it every day, like your phone buzzing or a car shaking. But vibration is important for more than just these things. Big industries, like making cars or planes, test vibration to check if parts can handle pressure. Vibration checks also help find cracks and stop problems in oil and gas machines. Old buildings and artifacts need vibration tests too, so they don’t get damaged. This Complete Guide to Vibration will help you understand these ideas easily and usefully.

Key Takeaways

Vibration is the back-and-forth motion of things. It is important for testing machines and keeping industries like mining and construction safe.

Knowing vibration types—mechanical, natural, forced, random, and periodic—helps find machine problems and make better designs.

Checking vibrations often can stop expensive repairs and delays. It finds issues early, saves money, and makes machines last longer.

Using proper tools, like accelerometers and vibration meters, is key to checking vibrations and keeping machines working well.

INEED vibration motors improve devices by reacting fast, saving energy, and offering custom options. They work great for many uses.

What Is Vibration?

Definition and Basic Principles of Vibration

Vibration means an object moves repeatedly around a center point. This movement can be side-to-side, up-and-down, or spinning. You can see vibration in things like a buzzing phone or guitar strings. In science, vibration is called oscillation, which is a regular change between two positions.

Here are examples of oscillation:

A swinging clock pendulum

Electric current switching directions

Musical instrument strings vibrating

Your heart beating in a rhythm

Predator-prey cycles in nature

Studying vibration explains how systems move from their resting position. Engineers use math to study machine vibrations. They focus on simple systems and look at damping and outside forces. Tests like modal analysis check if these ideas work.

Aspect | Description |

|---|---|

Studies simple and complex movements, including damping effects. | |

Historical Context | Shows important discoveries about vibration over time. |

External Factors and Responses | Looks at how outside forces change a system's vibration. |

Comprehensive Framework | Gives tools to understand vibration in science and engineering. |

Learning these basics shows how vibration affects small gadgets and big machines.

Why Vibration Is Crucial in Modern Applications

Vibration is very important in industries and technology. It makes things safer, faster, and better. For example, vibration checks help find problems in mining, oil, and factories. By studying vibration patterns, you can spot issues early. This stops big problems and saves money.

Here’s how vibration helps industries:

Predictive Maintenance: Vibration checks plan repairs during downtime, improving equipment.

Condition Monitoring: Sensors watch machines like motors to avoid delays in production.

Remote Monitoring: Cloud systems use vibration data to fix problems from far away.

Industry 5.0 Integration: Smart tools use vibration data to make work easier and faster.

Vibration also improves everyday devices. Phones use vibration for alerts and feedback. Fitness trackers vibrate to send reminders. Even beauty tools use vibration for better skin care. These examples show how vibration makes devices more useful and fun.

Knowing about vibration helps you see its value in science and daily life. Whether fixing machines or creating new gadgets, vibration knowledge helps you make smart choices.

Types of Vibration in the Complete Guide to Vibration

Mechanical Vibration

Mechanical vibration happens when machines or structures move back and forth. This movement is caused by forces acting on them. Examples include engines, turbines, and bridges. Engineers study this to stop damage and improve how things work. For instance, vibration checks can find issues like looseness or imbalance in machines.

Problem | Frequency Range | Measurement Type |

|---|---|---|

Misalignment, looseness, imbalance, belt issues | Displacement or Velocity | |

Misalignment and looseness | 2.5 to 4.5 times the RPM | Displacement or Velocity |

Bearing faults, electrical issues | 4.5 to 50 times the RPM | Acceleration |

Early-stage bearing problems | 1 kHz to 20 kHz | High-Frequency Acceleration |

Mechanical vibration can be good or bad. It helps in tools like vibration motors. But too much vibration can harm machines. Knowing these frequency ranges helps find problems early. This keeps machines working well.

Tip: Checking vibration often can stop expensive repairs later.

Natural Vibration

Natural vibration happens when systems move without outside forces. It’s common in nature and buildings. For example, earthquakes cause vibrations in the Earth’s crust. Scientists study these to predict earthquakes and understand geology.

Earthquakes often start with slow movements, like in 2011’s Tohoku-Oki quake.

Slow ruptures show how seismic zones and slip zones connect.

These studies help make buildings stronger against natural vibrations.

Natural vibration also happens in daily life. A guitar string vibrates naturally when plucked, making sound. Learning about natural vibration shows how things move and how to control them.

Forced Vibration

Forced vibration happens when an outside force makes something move. Machines vibrate because of motors or impacts. Engineers study this to improve designs and avoid resonance, which can cause failures.

Aspect | Description |

|---|---|

Study Focus | Nonlinear forced vibration in sandwich plates |

Key Findings | New core models improve stability and performance |

Methodology | Hamilton’s principle checks nonlinear behavior |

Parameters Analyzed | Rib thickness, core height, stiffener angles |

Forced vibration is key in engineering. For example, phones use it for haptic feedback. Controlling forced vibration improves designs and keeps structures safe.

Note: Learning about forced vibration helps create better and safer systems.

Random and Periodic Vibration

Random and periodic vibration show two ways things move. Random vibration is unpredictable, while periodic vibration repeats in a pattern. Knowing these types helps you understand how systems act in real life.

Random Vibration

Random vibration happens when motion has no clear order. It comes from unexpected forces. For example, a car shakes on a rough road. Each bump causes different movements, making it hard to guess. Engineers study random vibration to make machines last longer. Tools like vibration meters measure this motion.

Examples of random vibration include:

Wind making a bridge move.

Earthquakes shaking buildings.

Airplane turbulence causing sudden jolts.

Studying random vibration finds weak spots in structures. This makes them safer and stronger.

Periodic Vibration

Periodic vibration repeats in a steady cycle. A clock pendulum is a good example. It swings back and forth at the same speed. Engines and fans also create periodic vibration. This motion is easier to predict and control.

Periodic vibration is useful in many ways:

Musical instruments make sound through regular vibration.

Phones vibrate for alerts using periodic motion.

Factory machines use it for smooth running.

Understanding periodic vibration helps design systems that work well and last longer.

Tip: Use tools like accelerometers to measure random and periodic vibration. This helps find problems early and improve how things work.

Learning about these vibrations shows how objects move. Whether studying nature or building machines, this knowledge is important.

Applications of Vibration and INEED Vibration Motor

Industrial Applications (e.g., machinery, construction)

Vibration is very important in industries like mining and construction. It helps find problems in machines before they break down. For example, vibration checks can spot misaligned parts or worn-out areas. This prevents expensive repairs and keeps work running smoothly. Construction workers often deal with whole-body vibration (WBV), which can cause pain and health issues. Newer machines reduce WBV, making work safer and more comfortable.

Study | Findings | Year |

|---|---|---|

Paddan et al. | High levels of WBV reported | 1999 |

Cann et al. | Lower WBV risk with newer tools | 2023 |

INEED vibration motors improve machines by finding key vibration frequencies. These motors help machines work better and last longer. They are reliable and easy to customize for different needs.

Tip: Checking vibration often keeps machines safe and working longer.

Consumer Devices (e.g., smartphones, wearables, beauty products)

You use vibration in everyday gadgets like phones and smartwatches. Vibration motors make notifications feel real and fun. For example, wearables vibrate to send health alerts. Beauty tools use vibration to improve skincare routines.

Application Type | Description |

|---|---|

Smartphones | |

Wearables | Discreet alerts and real-time health monitoring |

INEED makes small, energy-saving vibration motors for electronics. These motors help batteries last longer and allow unique designs. They make devices easier and more enjoyable to use.

Technological Innovations Using Vibration Motors

New vibration motor technology is creating exciting possibilities. Tiny motors now power robots used in homes and hospitals. AI-controlled motors improve how cars and gadgets interact with users. For example, cars use vibration alerts to keep drivers safe.

INEED’s motors are small, strong, and adaptable. They work well in smart devices and robots. These motors give you the accuracy and dependability needed for advanced technology.

Note: Using INEED vibration motors helps you create better and smarter products.

How to Perform Vibration Analysis Effectively

Learning how to do vibration analysis well can help you find early signs of machine problems. It also helps fix alignment issues and stop failures before they happen. To do this, you need the right tools, smart methods, and solutions for common problems.

Tools for Vibration Analysis (e.g., accelerometers, vibration meters)

You need good tools to measure and study vibrations. These tools check machine health and find hidden problems.

Accelerometers: These sensors measure how fast something vibrates. MEMS and IEPE accelerometers are accurate and work well under repeated loads. They are great for testing structural vibrations.

Vibration Meters: These small devices measure vibration levels. They are simple to use and give quick results.

Laser Displacement Sensors: These tools measure vibrations very precisely. They are useful in research and during earthquake-like conditions.

Data Loggers: These devices save vibration data over time. This helps you see patterns and trends.

Online Condition Monitoring Systems: These systems use IoT to give real-time vibration data. You can monitor machines remotely and fix problems early.

Using these tools helps you find cracks, voids, or other hidden issues. This saves money on repairs and makes machines last longer.

Techniques for Measuring and Interpreting Vibration

After getting the tools, you need to use the right methods. These methods help you understand your machine’s condition and make smart choices.

Frequency Analysis: This finds the vibration frequency to spot problems like imbalance. For example, bearing issues show up at certain frequencies.

Amplitude Measurement: This checks how strong the vibrations are. High amplitudes often mean serious damage.

Time Waveform Analysis: This looks at vibration patterns over time. It helps find early wear in rotating parts.

Phase Analysis: This compares vibrations between parts to find loose or misaligned components.

Resonance Testing: This finds natural frequencies to avoid resonance, which can cause big damage.

Calibrating your tools regularly ensures accurate results. Industries like aerospace and healthcare need precise vibration data for safety. Calibration reduces errors and meets standards.

Purpose | Frequency |

|---|---|

Ensures reliable and consistent results | Regular calibration minimizes errors |

By using these methods, you can fix alignment, monitor machines better, and make them last longer.

Common Challenges and Solutions in Vibration Analysis

Vibration analysis can be tricky, but knowing the problems and fixes helps.

Challenges Addressed | Solutions Applied | |

|---|---|---|

Fan Diagnosis in the Field | Resonance, rotor unbalance, gearbox wear, bearing faults | Spectral analysis, operating deflection shape (ODS) analysis |

Gearbox Fault Diagnosis | Misaligned gearboxes, teeth resonance, casing distortion | Time waveform analysis, envelope analysis, phase analysis, resonance testing |

Diagnosis of a Recurring Pump Shaft Failure | Frequent shaft failures in large pumps | Dynamic analysis, including resonance testing and rotordynamic analysis |

These examples show how advanced methods solve tough problems. For instance, fixing fan issues often means finding resonance and fixing alignment. Pump shaft failures need dynamic tests to find and fix the root causes.

Key metrics like acceleration, displacement, and velocity are important for checking machine health. Studies show that predictive maintenance using vibration analysis can cut breakdowns by 70% and reduce repair costs by 25%. Adding AI and IoT makes analysis even better, allowing real-time monitoring and smarter decisions.

Tip: Always write down your findings and update your maintenance plans. This keeps your machines running well and saves money over time.

Practical Tips for Quickly Understanding Vibration

Easy Steps to Learn About Vibration

Understanding vibration is simple with the right steps. Use tools that mix learning and practice. For example, the Vibration Fundamentals Training System lets you try virtual experiments. It shows how vibratory systems work in a clear way. Combine this with a Hands-on Experimental Device. This device uses wireless sensors to connect ideas to real-life uses. These tools make learning fun and interactive.

Tool Name | Description |

|---|---|

Vibration Fundamentals Training System | Software for virtual experiments, showing how vibratory systems work through visuals. |

Hands-on Experimental Device | A physical tool with wireless sensors for real experiments, linking theory to practice. |

Learn one idea at a time to keep it simple. Start with terms like oscillation and amplitude. Then, learn how vibration affects machines and gadgets. Use pictures or videos to help you understand better. Practicing with hands-on tools will make these ideas stick.

Best Resources to Learn More

You can learn more by using helpful resources. Reviews of 11 top vibration data loggers explain costs, sample rates, and ranges. These reviews also share expert opinions, helping you pick the best tools. Professionals also share tips from their own experiences, giving you real-world advice.

Reviews compare prices, sample rates, and recording lengths.

They show which tools give the best value for money.

Expert tips make these recommendations more trustworthy.

These resources give you both knowledge and skills, making learning easier and more useful.

How INEED Vibration Motors Make Applications Easier

INEED vibration motors help in many ways. They respond in less than 20 milliseconds, matching actions quickly. Their energy-saving design uses low power, making batteries last longer. Small sizes fit into tiny gadgets without losing performance.

Feature | Description |

|---|---|

Quick Response Times | Works in under 20 milliseconds for real-time actions. |

Energy Saving | Uses low power, helping batteries last longer. |

Small Size | Fits into small gadgets while staying effective. |

Adjustable Features | Lets you change frequency and amplitude for specific needs. |

Strong and Durable | Fewer moving parts mean less wear and lower repair costs. |

These motors let you adjust settings like frequency and amplitude. They are strong and need less fixing, saving money. Whether for wearables or smart tools, INEED motors make designs easier and work better.

Learning about vibration helps solve problems in industries and makes devices better. You now know its meaning, types, and uses, plus how to study it well. Vibration analysis lowers pain levels a lot, as studies show with an effect size of -0.71 (95% CI: -1.02, -0.39; P < 0.0001). Stories and examples show how vibration motors make machines more reliable, reduce downtime, and last longer. INEED’s motors are easy to customize and fit into many designs. Use these solutions to improve your projects with better performance and smart ideas.

FAQ

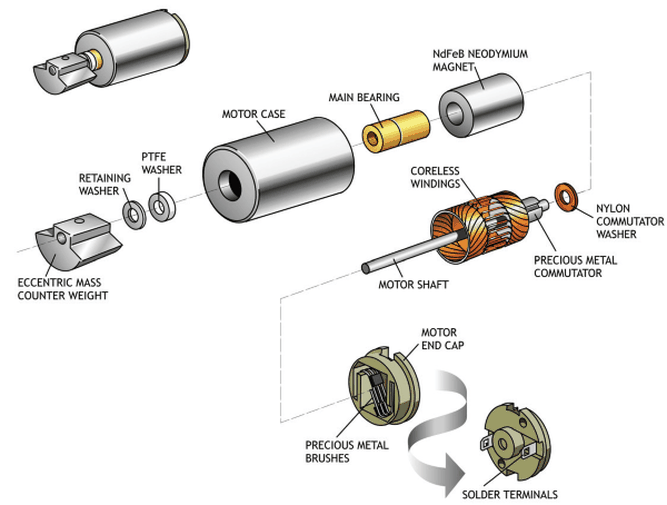

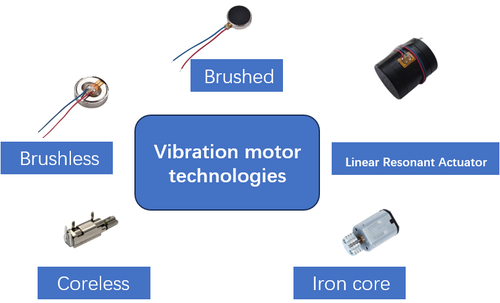

What makes ERM and LRA vibration motors different?

ERM motors vibrate using a spinning unbalanced weight. LRA motors use a spring and magnet for exact vibrations. ERM motors are good for general tasks. LRAs are better for detailed feedback. Use ERM for basic needs and LRA for high-quality touch responses.

How do vibration motors make devices better?

Vibration motors give touch feedback, making devices more fun to use. They improve alerts, gaming, and beauty tools. INEED motors let you change vibration patterns. This makes devices more engaging and easy to use.

Can INEED vibration motors be adjusted for special uses?

Yes, you can change INEED motors to fit your needs. Adjust vibration strength, speed, and time. You can also modify wires, connectors, and mounts. This makes them perfect for your specific projects.

How do I pick the best vibration motor for my project?

Think about your device’s size, power, and vibration type. Small gadgets work well with coin motors. LRAs are great for precise touch feedback. INEED experts can help you choose the right motor for your project.

Do vibration motors use a lot of energy?

No, INEED motors save energy. They use very little power, which is great for battery devices like smartwatches and phones. This helps batteries last longer without losing performance.

See Also

Comprehensive Insights on How to Measure Vibration

Top Instruments for Accurate Vibration Measurement Explained

All You Need to Know About Vibration Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry