PWM Motor Magic How It Controls Speed

You control motor speed and vibration using PWM. This technique sends pulses to the motor, which lets you adjust how strong or soft the vibration feels. INEED specializes in micro motors that use pwm motor technology for precise feedback. When you choose INEED’s Micro Coin BLDC Vibration Motor C1234, you get smooth and reliable performance in your devices.

Key Takeaways

PWM, or Pulse Width Modulation, controls motor speed and vibration by sending electrical pulses. Adjusting pulse width changes the motor's energy and performance.

Using PWM improves energy efficiency and reduces noise. This technology allows for precise control over motor speed, making devices run smoother and last longer.

INEED’s Micro Coin BLDC Vibration Motor C1234 offers stepless speed control. You can customize vibration intensity for a better user experience without fixed levels.

Adjusting the duty cycle of a PWM signal directly affects motor speed. Higher duty cycles increase speed, while lower duty cycles slow it down, giving you fine-tuned control.

PWM technology is widely used in various industries, including healthcare and consumer electronics. It enhances device reliability and performance, making it a top choice for engineers.

PWM Motor Basics

What Is PWM?

You can control a motor’s speed and vibration using a technique called PWM, which stands for Pulse Width Modulation. PWM sends a series of electrical pulses to the motor instead of a steady stream of power. The width of each pulse, known as the duty cycle, determines how much power the motor receives. When you increase the pulse width, the motor gets more energy and runs faster. When you decrease the pulse width, the motor slows down.

PWM controls the average value of a signal by changing the pulse width or duty cycle.

Traditional motor control uses continuous analog signals, but PWM uses digital pulses for better precision.

PWM improves power efficiency by reducing energy loss in switching devices.

PWM signals resist noise and interference, making them reliable for micro motors.

Many people think that all motor controllers work the same way. In reality, PWM offers more control and efficiency than older methods. You get smoother operation and less wasted energy.

How PWM Works

When you use PWM to control a micro motor, you adjust the average power by changing the pulse width. This affects the motor’s speed and vibration strength. You can see the difference in performance right away. PWM lets you fine-tune the motor’s response, which is important for devices that need precise feedback.

PWM changes the average voltage and current sent to the motor.

You get accurate speed control and better energy efficiency.

PWM reduces noise and electromagnetic interference, so your motor runs smoothly.

INEED Motors uses advanced PWM technology in its micro motors. The Micro Coin BLDC Vibration Motor C1234 is a great example. You can achieve stepless speed control and customize vibration intensity for your application.

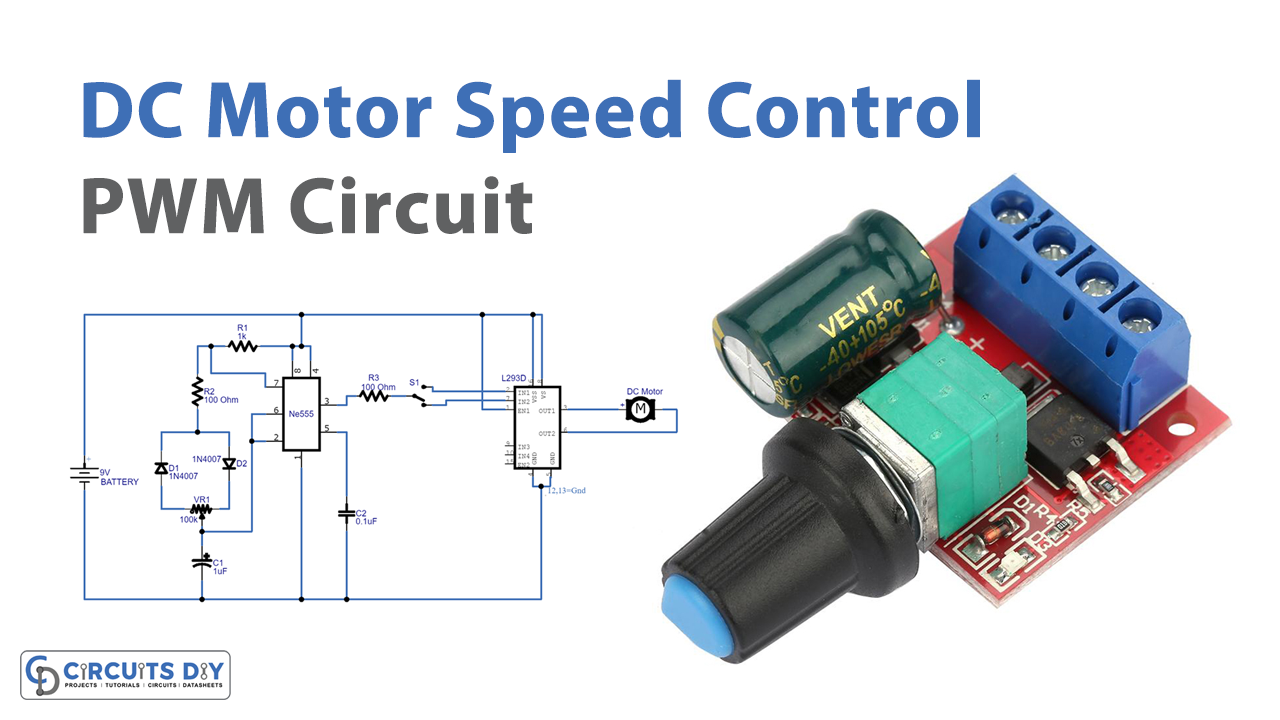

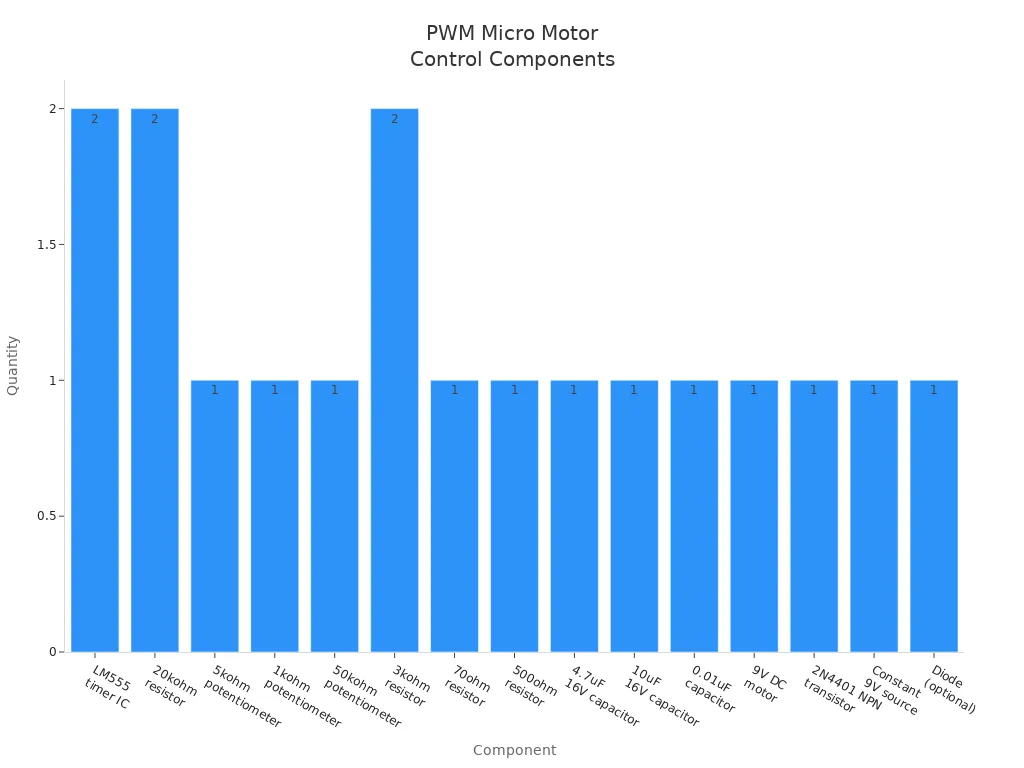

Here are some common components you need for a PWM motor control circuit:

Component | Quantity |

|---|---|

LM555 timer IC | 2 |

20kohm resistor | 2 |

5kohm potentiometer | 1 |

1kohm potentiometer | 1 |

50kohm potentiometer | 1 |

3kohm resistor | 2 |

70ohm resistor | 1 |

500ohm resistor | 1 |

4.7uF 16V capacitor | 1 |

10uF 16V capacitor | 1 |

0.01uF capacitor | 1 |

9V DC motor | 1 |

2N4401 NPN transistor | 1 |

Constant 9V source | 1 |

Diode (optional for motor) | 1 |

Tip: You can avoid common misconceptions about PWM motor control by learning how it really works. For example, not all motor controllers produce a pure sine wave, and not every controller can run a motor at any speed. Always check the motor’s specifications before making adjustments.

PWM Motor Speed Control

Duty Cycle and Speed

You can control the speed of a pwm motor by adjusting the duty cycle of the PWM signal. The duty cycle tells you how much time the signal stays ON compared to the total cycle time. When you increase the duty cycle, the motor receives more voltage and spins faster. When you decrease the duty cycle, the motor slows down because it gets less voltage.

The PWM signal controls the voltage delivered to the motor.

The duty cycle indicates how long the signal is ON, affecting the effective voltage.

A higher duty cycle increases voltage and thus speeds up the motor, while a lower duty cycle decreases voltage and slows it down.

You can see this effect in real time. If you set the duty cycle to a higher percentage, the motor vibrates more strongly. If you lower the duty cycle, the vibration becomes softer. This method gives you precise control over the motor’s speed and vibration strength. You do not need to change the hardware or use complicated circuits. PWM motor technology makes dc motor speed control simple and efficient.

Stepless Control with INEED

INEED’s Micro Coin BLDC Vibration Motor C1234 uses PWM to give you stepless speed control. You can adjust the vibration intensity smoothly, without jumping between fixed levels. This feature helps you create a better user experience in your devices.

The typical duty cycle range for speed control in INEED's Micro Coin BLDC Vibration Motor C1234 is between 60% and 90%. This range allows for various output vibration effects.

You can set the motor to run at any speed within this range. You do not have to settle for just “low,” “medium,” or “high.” You can choose exactly how strong you want the vibration to be. This flexibility is important for applications like medical devices, gaming controllers, and consumer electronics. You get reliable performance and smooth transitions every time you use a pwm motor from INEED.

Tip: If you want to fine-tune the feedback in your device, try adjusting the duty cycle in small steps. You will notice how the vibration changes instantly. This level of control is possible because of advanced pwm motor technology.

PWM Motor Benefits

Efficiency and Precision

You get more from your motor when you use PWM control. PWM helps you save energy and run your devices smoothly. When you adjust the duty cycle, you change the average voltage sent to the motor. This lets you control speed and vibration with great accuracy. You can make the motor run faster or slower by changing the pulse width. This method reduces power loss and keeps your motor working efficiently.

PWM technology gives you precise control over motor speed and vibration. You can set the motor to any speed you want, from gentle to strong. This level of control is important for devices that need exact feedback, like medical tools or gaming controllers.

You also benefit from long-term maintenance advantages:

Reduced wear: Lower speeds mean less stress on motor parts, so your motor lasts longer.

Lower power consumption: Slower speeds use less energy, which helps battery-powered devices run longer.

Quieter operation: Motors running at lower speeds make less noise, improving comfort in quiet environments.

Experiments with variable frequency drives show that PWM can boost system efficiency. You may see drive system efficiency increase by 2–12% compared to older control methods. This means you use less energy and get better performance.

Application in INEED Products

INEED Motors designs micro motors with your needs in mind. You can customize motor controllers to fit your project. INEED offers:

Modifications to DC motor controllers for special requirements.

Adjustments in output shafts and gear ratios for better speed control.

Connectors and encoders for advanced feedback and control.

Expert technical support to help you design the perfect motor solution.

INEED’s commitment to quality means you get reliable motors that work well in many applications. You can trust INEED to deliver motors that meet your exact needs, whether you build medical devices, consumer electronics, or robotics. With PWM control, you achieve smooth operation, energy savings, and precise feedback every time you use an INEED motor.

Real-World PWM Applications

INEED Micro Coin BLDC Vibration Motor C1234

You experience the benefits of PWM technology every time you use a device powered by INEED’s Micro Coin BLDC Vibration Motor C1234. This motor gives you precise control over vibration strength and speed. You can adjust feedback instantly, which makes your device feel more responsive. The C1234 motor uses brushless technology, so you get a longer lifespan and higher efficiency. You do not need to worry about frequent maintenance. The motor runs quietly, which is important for devices you use every day.

You can rely on the C1234 motor for consistent performance. It lasts up to 1,000 hours and delivers smooth vibration feedback. You can customize the vibration settings to match your needs, whether you want a gentle buzz or a strong pulse.

Industry Uses

You see PWM motor technology in action across many industries. INEED’s micro motors power devices that help people in healthcare, entertainment, and daily life.

CPAP machines use PWM to keep airflow stable and quiet, helping you sleep better.

Oxygen concentrators depend on precise speed control for safe and effective air delivery.

Negative pressure wound therapy devices use PWM to fine-tune suction levels, which supports faster healing.

In consumer electronics, brushless motors from INEED stand out for their reliability. You get longer-lasting devices with less maintenance. These motors run quietly, making them perfect for smartphones, wearables, and gaming controllers. In 2023, manufacturers sold over 4.2 million gimbals, showing how much people trust brushless motors for accuracy and dependability.

INEED’s PWM motor solutions offer quick response times and customizable feedback. You can set vibration patterns that fit your application, unlike other brands that limit your options. You get motors that work well in many environments, from medical devices to gaming accessories. This versatility and reliability make INEED a top choice for engineers and designers who want the best performance.

You gain precise control over motor speed and vibration when you use PWM technology. Adjusting the duty cycle lets you set vibration strength and save energy. INEED’s Micro Coin BLDC Vibration Motor C1234 delivers smooth, reliable feedback for your devices. Experts recommend choosing the right PWM frequency, configuring your controller, and testing your setup for best results. Future trends include smarter algorithms and IoT integration. If you want efficient, customizable motor solutions, INEED Motors gives you the tools to succeed.

FAQ

What is a pwm signal and how does it control motor speed?

A pwm signal is a series of electrical pulses. You change the width of these pulses to control how much power the motor gets. This lets you adjust the speed and vibration strength easily.

Can you use a pwm signal with any type of motor?

You can use a pwm signal with many DC motors, especially brushless and brushed types. Some motors work better with pwm signal control. Always check your motor’s specifications before using a pwm signal.

Why does a pwm signal make motors more efficient?

A pwm signal sends power in short bursts instead of a steady flow. This reduces wasted energy and heat. You get smoother operation and longer battery life when you use a pwm signal for motor control.

How do you adjust vibration strength using a pwm signal?

You change the duty cycle of the pwm signal. A higher duty cycle means stronger vibration. A lower duty cycle gives you a softer vibration. This method gives you precise control over feedback in your device.

What devices benefit most from pwm signal motor control?

Devices like medical tools, gaming controllers, and wearables benefit from pwm signal control. You get accurate feedback and smooth performance. Many industries use pwm signal technology to improve user experience and device reliability.

See Also

Adjusting Vibration Motor Strength Using Arduino PWM Techniques

Managing Motor Systems' Rotation Direction Effectively

Understanding Motor Brushes: Key Parts for Vibration Motor Efficiency

Decoding Motor Diagrams: A Guide to Understanding Them

Managing Resonance Frequency in Vibration Motors for Consistent Performance

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry