How to Prevent Batteries from Touching in Brushless Coin Vibration Motors

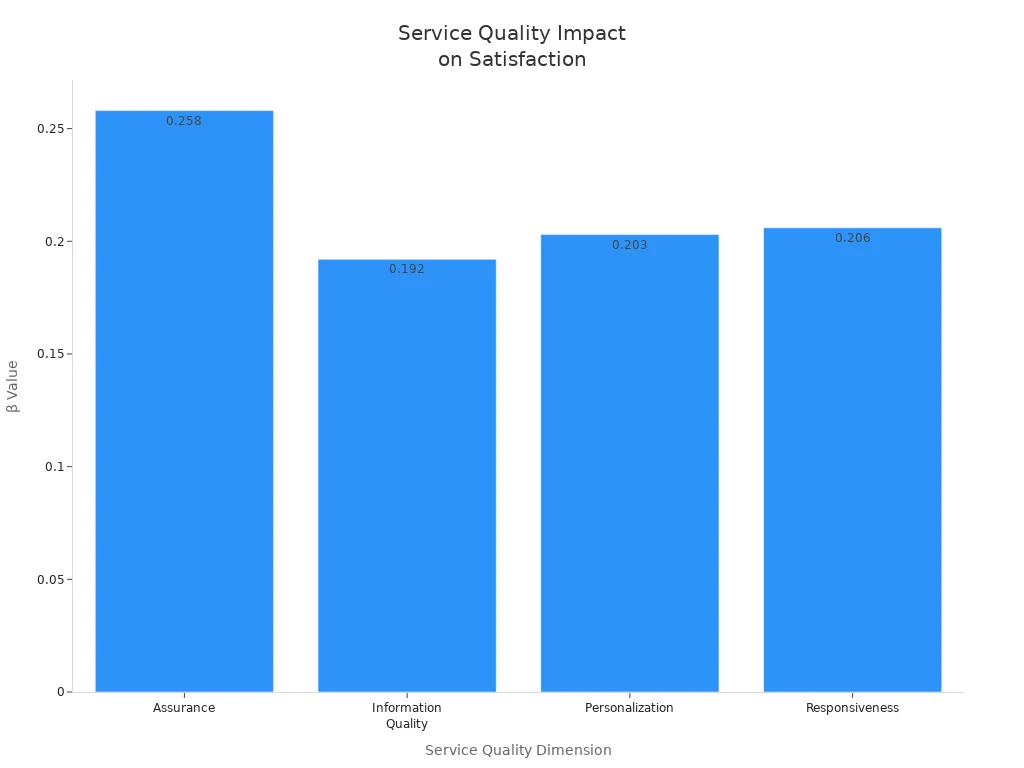

You can prevent batteries from touching in your brushless coin vibration motor setup by using proper insulation and secure mounting. This simple step protects your device from short circuits and keeps it running smoothly. INEED Motors puts a strong focus on quality and reliability. Each product goes through strict testing, which leads to high customer satisfaction and dependable performance. The chart below shows how INEED’s service quality dimensions impact customer satisfaction.

Key Takeaways

Use battery holders to keep each battery in its own compartment. This prevents contact and reduces the risk of short circuits.

Apply insulation materials like tape or foam pads between batteries. This adds protection and helps maintain device safety.

Organize wiring neatly to avoid pushing batteries out of place. Secure wires with clips to prevent accidental contact.

Regularly inspect your device for loose batteries or signs of wear. Early detection helps prevent bigger problems.

Choose high-quality components for your setup. This ensures better performance and extends the lifespan of your vibration motor.

Why Battery Separation Matters

Risks of Contact

When batteries touch each other inside your device, you face several risks. You may see short circuits, which can damage your vibration motor or other electronic parts. If two batteries make direct contact, they can create a path for electricity that bypasses the intended circuit. This can lead to overheating or even fire.

Tip: Always check battery placement before closing your device. A quick inspection can prevent costly mistakes.

Here are some common problems you might encounter if batteries touch:

Short Circuit: The device may stop working or lose power suddenly.

Component Damage: Sensitive parts like the embedded IC in INEED Brushless Coin Vibration Motors can fail.

Battery Leakage: Physical contact can cause batteries to leak chemicals, which may harm your device.

Reduced Lifespan: Frequent contact and movement can wear out both the batteries and the motor.

You should always use proper insulation and secure mounting to avoid these issues. Simple steps like using battery holders or insulation tape can make a big difference.

Device Safety

Keeping batteries separated helps you maintain device safety. You protect your vibration motor from electrical faults and physical damage. INEED Motors designs its Brushless Coin Vibration Motors with quality and reliability in mind, but safe battery installation remains your responsibility.

Safety Benefit | How It Helps You |

|---|---|

Prevents Short Circuits | Keeps your device running safely |

Avoids Overheating | Protects internal components |

Maintains Performance | Ensures stable vibration output |

You should inspect your device regularly. Look for loose batteries or signs of wear. If you spot any issues, fix them right away. This habit keeps your device reliable and extends its lifespan.

Note: Reliable battery separation supports the long service life of INEED Brushless Coin Vibration Motors. You get better performance and fewer repairs.

Prevent Batteries from Touching

Keeping your batteries separated is essential for safe and reliable operation of your INEED Coin Brushless BLDC Vibration motor setup. You can prevent batteries from touching by following these practical steps. This approach protects your device, extends battery life, and ensures consistent vibration feedback.

Use Battery Holders

You should always use a battery holder that fits your battery type and device size. Battery holders keep each cell in its own compartment, which helps prevent batteries from touching. This simple accessory also makes battery replacement easier and safer.

Here are some battery holder options that work well with INEED Coin Brushless BLDC Vibration motors:

Plastic snap-in holders for coin cells

Spring-loaded holders for cylindrical batteries

Custom-fit holders for compact devices

Solderable holders for secure connections

A good battery holder keeps batteries stable, even when your device moves or vibrates. You reduce the risk of short circuits and improve the overall safety of your brushless coin motor setup. You also make it easier to check and replace batteries during regular maintenance.

Tip: Choose a holder that matches your battery size and fits snugly in your device. This step helps prevent batteries from touching and keeps your vibration feedback consistent.

Insulation Materials

Insulation materials add another layer of protection between batteries. You can use insulation tape, foam pads, or advanced materials to separate cells. This step is especially important in compact devices where space is tight.

Here is a comparison of common insulation materials for battery separation:

Insulation Material | Temperature Drop Efficiency | Thermal Spread Suppression | Durability |

|---|---|---|---|

Fiber-based materials | 71.83% | Moderate | Moderate |

Aerogel materials | 13% more efficient than fiber | High | High |

Pre-oxidized silk aerogel | Best thermal suppression | Best | High (withstands high temperatures) |

You can use insulation tape for quick fixes or foam pads for extra cushioning. For high-performance devices, aerogel sheets or pre-oxidized silk aerogel provide excellent thermal and electrical separation. These materials help prevent batteries from touching, even in demanding environments.

Note: INEED Motors recommends using high-quality insulation materials to match the reliability of your brushless coin motor. This practice supports long-term device safety and stable vibration feedback.

Organized Wiring

Organized wiring is another key step to prevent batteries from touching. You should route wires neatly and secure them with clips or ties. This method keeps wires from pushing batteries out of place or causing accidental contact.

Follow these steps for organized wiring:

Plan your wiring layout before assembly.

Use color-coded wires to avoid confusion.

Secure wires with small clips or adhesive pads.

Keep wires away from battery terminals and moving parts.

Check that wires do not cross over battery compartments.

Regular inspection helps you spot loose wires or shifting batteries early. You can fix small issues before they become big problems. This habit keeps your INEED Coin Brushless BLDC Vibration motor setup safe and reliable.

Callout: Organized wiring, quality battery holders, and proper insulation work together to prevent batteries from touching. These steps protect your device and ensure you get the best performance from your brushless coin motor.

By following these steps, you create a safer environment for your batteries and your device. You also support the high standards of INEED Motors, known for quality and reliability in every product.

Brushless Coin Motor Setup Tips

INEED Product Features

You get a major advantage when you use an INEED brushless coin motor in your device. The compact design fits easily into small spaces, making it perfect for wearables and portable electronics. Each brushless coin motor includes an embedded driver IC. This feature improves both safety and performance by simplifying your design and protecting the motor from incorrect voltage polarity.

Here is a quick look at how the embedded IC helps your setup:

Feature | Description |

|---|---|

Embedded driver IC | The driver IC is integrated within the motor, eliminating the need for an external driver IC. |

Polarity Protection | Ensures that voltage polarity is correct to avoid damage to the internal driver IC. |

Simplified Design | The embedded IC reduces complexity in design and lowers overall system costs. |

You benefit from stable vibration feedback and longer device life. The brushless coin motor delivers consistent performance, which is important for applications that rely on precise vibration feedback.

Mounting Techniques

You need to secure your brushless coin motor and batteries to get the best vibration feedback and avoid issues. Follow these best practices for mounting and battery placement:

Manage the heat by placing batteries near enclosure walls with conductive pads. This helps with heat dissipation and protects your brushless coin motor.

Handle battery mounting challenges by considering the battery shape, especially in curved or compact designs. This prevents size issues and keeps your vibration feedback steady.

Define ruggedization strategies. Use clamps and pads to reduce shock and vibration effects on your brushless coin motor.

Plan your battery cabling. Route wires carefully to prevent damage from vibration and provide proper strain relief.

Use latching connectors for strain relief. This keeps connections secure even when your device vibrates.

Choose non-reversible connectors. This step avoids circuit damage and keeps your brushless coin motor safe.

You should always check your mounting and wiring after assembly. This habit helps you catch problems early and keeps your vibration feedback reliable.

Vibration Safety

You protect your device and extend battery life when you focus on vibration safety. Use quality components for every part of your brushless coin motor setup. Regularly inspect your device for loose parts or worn insulation. Replace damaged holders or wires right away.

A well-mounted brushless coin motor gives you stable vibration feedback every time. You avoid short circuits and keep your device running smoothly. Make regular checks part of your routine to maintain the high standards set by INEED Motors.

Tip: Consistent inspection and quality parts help you get the most out of your brushless coin motor and ensure long-lasting vibration feedback.

Troubleshooting Battery Issues

Signs of Contact

You need to recognize the warning signs when batteries touch inside your device. Early detection helps you avoid bigger problems. Look for these common indicators:

Sudden loss of power or device shutdown

Unusual heat near the battery compartment

Visible corrosion or leakage around battery terminals

Flickering or weak vibration feedback from your brushless coin motor

Burn marks or melted plastic near battery holders

You can use a simple checklist to inspect your device:

Symptom | Possible Cause | What to Check |

|---|---|---|

Device shuts off | Short circuit | Battery placement |

Heat buildup | Electrical contact | Insulation and wiring |

Vibration weakens | Power loss | Battery terminals |

Leakage or corrosion | Physical damage | Battery surface and holders |

Tip: Always turn off your device before inspecting the battery area. This step keeps you safe and prevents further damage.

Quick Fixes

You can fix battery contact issues quickly if you act right away. Follow these steps to restore safe operation:

Remove the batteries and inspect each one for damage.

Clean any corrosion using a cotton swab and a small amount of rubbing alcohol.

Replace damaged insulation tape or foam pads.

Reposition batteries in their holders to ensure separation.

Secure loose wires with clips or ties.

Test the device after reassembly to confirm stable vibration feedback.

If you notice repeated problems, consider upgrading to higher-quality holders or insulation materials. Regular maintenance helps you protect your device and improve battery life. You should schedule routine checks to catch issues early and keep your INEED brushless coin vibration motor running smoothly.

🛠️ Quick action prevents long-term damage. You maintain device safety and enjoy reliable performance.

You can keep your device safe by following a few simple steps. Use proper insulation, secure your batteries with holders, and check your setup often. These actions help you avoid short circuits and extend the life of your vibration motor.

Good mounting reduces shaking and noise, lowers friction, and protects your device from dirt and water.

Anti-vibration mounts decrease wear and help your motor last longer.

Benefit | How INEED Motors Helps You |

|---|---|

Brushless design means less wear and tear | |

Minimal Maintenance | Fewer repairs and longer use |

Lower Power Use | More time between charges |

Choose INEED for reliable, high-quality vibration motor solutions.

FAQ

What should you do if your batteries keep shifting inside the device?

You should use a snug battery holder and add insulation tape or foam pads. This keeps the batteries in place and prevents contact. Always check the fit before closing your device.

How often should you inspect your battery setup?

You should inspect your battery setup every month. Look for loose batteries, worn insulation, or damaged holders. Regular checks help you catch problems early and keep your device safe.

Can you use brushless coin vibration motors in wearable devices?

Yes, you can use brushless coin vibration motors in wearable devices. Their compact size and stable performance make them ideal for smartwatches, fitness trackers, and other small electronics.

What is the best way to separate batteries in a compact device?

You should use custom-fit battery holders and thin insulation materials. Organized wiring also helps keep batteries apart. This method works well in tight spaces and supports safe operation.

Why does organized wiring matter for battery safety?

Organized wiring prevents wires from pushing batteries out of place. It reduces the risk of accidental contact and short circuits. Secure wires with clips or ties for best results.

See Also

Top 10 Strategies for Reducing Noise in Small Motors

Essential Maintenance Tips for Enhancing Vibration Motor Lifespan

Brushed Versus Brushless: A Comparison of 3 Volt Motors

Five Simple Steps to Excel with Arduino Vibration Motors

Effective Techniques for Operating Motors Using 9-Volt Batteries

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry