Why Use Planetary Gear Motors in Robotics and Automation

Planetary gear motors give important benefits for robots and automation. These motors help with exact movement and strong turning force. They are small and work well. In 2023, the world market for planetary gear motors was about USD 3.5 billion. This number is growing fast. More robots now need advanced planetary gear motors for better work and control. New changes have made dc planetary gear motors work better:

Made smaller to fit in tight spots

Use stronger dc parts and better magnets

Servo drives are now built into robots

Better cooling and sealing for tough places

These things help dc planetary gear motors give exact moves, smooth power, and strong turning force in every use.

Key Takeaways

Planetary gear motors give strong torque and exact movement. They are small and light, so they fit in tight robot spaces. These motors work well and save energy. They last longer because many gears share the load. Less friction helps them last even more. Low backlash lets robots move smooth and correct. This is important for careful and exact jobs. Planetary gear motors are quiet and can lift heavy things. This helps robots work well in busy or quiet places. Picking the right planetary gear motor makes robots work better. It also saves energy and helps them last longer. This supports advanced automation needs.

Advantages

High Torque Density

Planetary gear motors give a lot of turning force in a small size. Their special design lets many gears share the work. This helps each motor handle more force. In robots, a planetary gearbox can give between 1 and 3 Nm/kg of torque. This is more than most other gear types. For example, some single-stage planetary gearboxes in walking robots weigh about 1.3 to 1.4 kg. They still give strong turning force. High torque density means robots can lift heavy things or move with strength. The motor stays light. The power-to-weight ratio gets better. Robots become faster and use less energy.

Planetary gear motors give strong turning force without getting bigger or heavier. This is very important for advanced robots.

Compact and Lightweight

Being small is a big reason engineers pick planetary gear motors for robots. These motors fit into small spaces like robot arms and legs. Their small shape makes it easy to put them in tricky spots. The planetary setup keeps the size and weight low. This matters when space is tight. Compared to other gears, planetary gear motors spread out the load better. They last longer too. This makes them good for tough jobs that need to last.

Planetary gear motors save space when you install them.

They give strong turning force and still work well.

The small build makes them last longer and get less damage.

Low Backlash Precision

Robots need to be exact. Planetary gear motors have low backlash. This means there is almost no extra movement when gears change direction. This helps robots move to the right spot every time. Many gear points make the motor stiff and steady. Robots can do careful jobs, like picking up tiny things or putting parts together. Low backlash also makes the motor run smoothly. It shakes less and lasts longer.

High Efficiency

Planetary gear motors are very good at saving energy. Some models work up to 95% efficiently, especially with three-stage spur-gears. This means less energy turns into heat. More power goes to moving the robot. In factories, these motors help save energy in many ways:

They spread force evenly, so there is less friction and wasted energy.

Speed control lets the robot use only the power it needs.

Regenerative braking saves energy when slowing down.

Less heat means less wasted energy and less cooling needed.

Smart controls help the motor work better all the time.

Gearbox Type | Gear Ratio | Efficiency (%) | Notes |

|---|---|---|---|

Three-stage planetary gearbox | Up to 200:1 | >90 | High transmission efficiency |

Bilateral Drive | 102:1 | 89.9 | Highly backdrivable, under development |

R2poweR Gearbox Technology | 275:1 | 85 | Advanced gear tooth design |

Typical datasheet peak values | N/A | ~85 | Often reported in product datasheets |

Planetary gear motors last longer because they share the load over many gears. This means less rubbing and less wearing out. The motor runs smoother and makes less noise. If you clean and oil the motor often, it will last even longer. Makers build these motors to work all day and night. They are good for machines that never stop.

Tip: Clean and install planetary gear motors the right way. This helps them work their best and last a long time.

Performance in Robotics

Precise Motion Control

Robots must move to the right spot every time. Planetary gear motors help robots do this job well. These motors have special gears that cut down on backlash. Low backlash means the robot arm does not shake or go too far. This helps robots be more exact. Many new robots use dc planetary gear motors for this reason. They can stop and start fast and still stay on track.

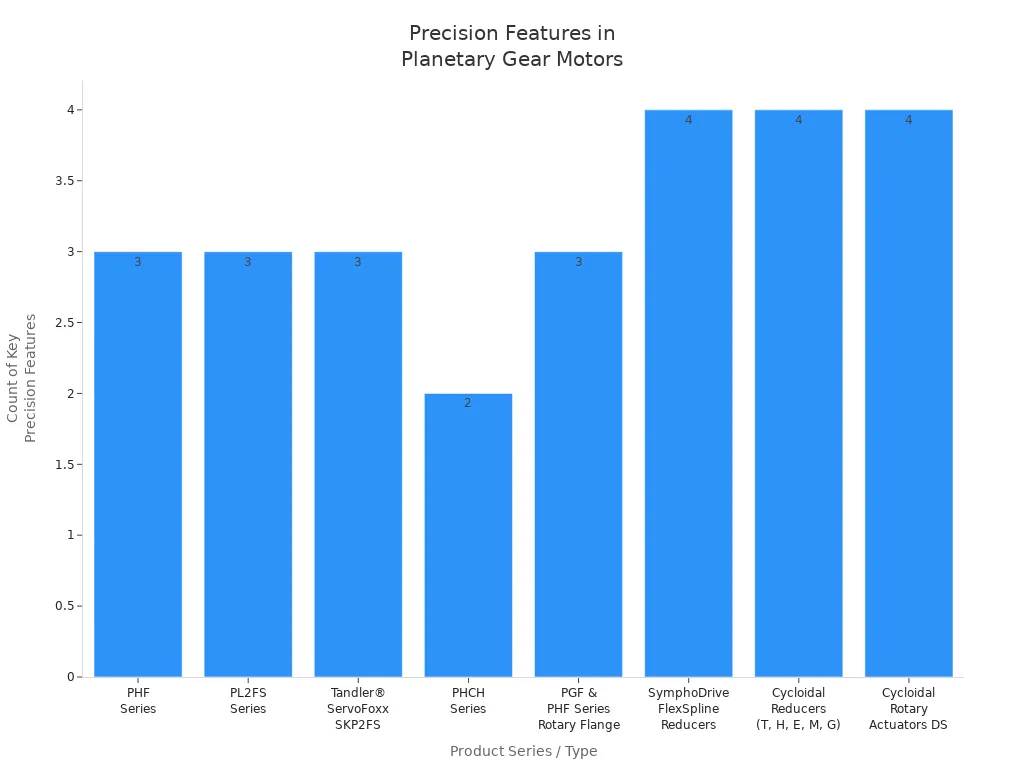

The table below shows how different planetary gear motor products help robots move with accuracy:

Product Series / Type | Key Precision Features and Benefits | Relevance to Precise Motion Control in Robotics |

|---|---|---|

PHF Series | High-precision planetary and helical gears; reduced backlash; enhanced performance | Minimizes backlash and improves smooth, accurate motion control |

PL2FS Series | Ultra-low backlash; optimized rigidity; inline planetary gearhead | Ensures high precision and rigidity for servo-driven automation |

Tandler® ServoFoxx SKP2FS | Two-stage design with matched spiral bevel and precision planetary gears; max torque in small size | Compact size with maximum torque supports precise, space-efficient robots |

PHCH Series | Superior torque capacity; high load resistance | Handles demanding automation tasks with reliable, precise torque output |

PGF & PHF Series Rotary Flange | ISO 9409-1 compliant; smooth motion; torque accuracy | Compliance with robotics standards ensures precise and reliable motion |

SymphoDrive FlexSpline Reducers | Zero-backlash; high torque; lightweight; compact design | Zero-backlash critical for high precision and reliability in robotics |

Cycloidal Reducers (Series T, H, E, M, G) | Zero-backlash; ISO 9409-1 compliance; high torque capacities; robust bearings | Provide smooth, reliable, and precise motion control essential for robotics |

Cycloidal Rotary Actuators DS | Integrated BLDC servo motors; rotary sensors; optional brake; sizes 50-140 mm | Supports precise robotic positioning and automation with integrated control |

Small robots use precision micro gear motors for tiny jobs. These motors help with sorting small parts or drawing lines. In speed control systems, planetary gear motors keep robots moving at the right speed. This lets robots finish work faster and make fewer mistakes.

Note: The drive system’s accuracy in robot arms depends on the quality of the planetary gear motor.

Smooth and Quiet Operation

Robots often work near people and need to be quiet. Planetary gear motors help robots move smoothly and make less noise. The gears inside share the work. This makes the robot move steady and keeps things quiet. Many dc planetary gear motors shake less than other types. This is good for robots in labs, hospitals, and offices.

The planetary design also helps save energy. Less friction means less power is wasted. Robots can work longer without getting too hot. Smooth movement also protects robot parts from damage. This means less time fixing and lower repair costs.

Planetary gear motors help robots stay quiet.

They let robots move with steady power and speed.

The motors use less energy, so they are more efficient.

Handling Heavy Loads

Robots sometimes need to lift or move heavy things. Planetary gear motors give strong torque in a small size. This lets robots handle big loads without a huge motor. Some heavy-duty planetary gearboxes, like the HN805, can handle up to 331,500 Nm of torque. This shows how strong planetary gear motors can be in factories.

Planetary gear motors also handle sudden bumps well. The gears inside spread out the force. This helps robots keep working even if they get hit or stopped fast. Worm gears are best for shock loads, but planetary gear motors still do a great job for most robots.

Planetary gear motors give robots the strength to lift heavy things.

They keep working during long hours and sudden shocks.

The motors help robots stay strong in hard jobs.

Tip: Pick the right planetary gear motor for your robot’s load and speed. This helps your robot work better and use less energy.

Planetary Gear Motor Applications

Robotic Arms

Robot planetary gearboxes are very important in robotic arms. These gearboxes help the arms move with great accuracy and power. Many robotic arms use them because they fit in small spaces and give strong torque. This makes them good for jobs like building, welding, and painting. Engineers often use robot planetary gearboxes with servo motors. This pairing helps the arm move smoothly and hit the right spot. Integrated planetary-geared servoactuators fix common alignment issues. They cut down on extra parts and lower inertia. The arm becomes smaller and easier to use. These things help robotic arms work faster and last longer in factories.

AGVs and Mobile Robots

Automated guided vehicles and mobile robots need robot planetary gearboxes to move well. These gearboxes give the right torque and power for each job. They help stop early wear and system breakdowns. The planetary design keeps the gearbox small and light. This is important for robots that have little space. Low backlash lets the robot move the same way every time. This is needed for quick and exact work in moving goods. Good oil and sealed designs mean less fixing and more work time. Strong gearboxes let AGVs work in tough places, like hot or dusty spots. Newstart Gearbox makes strong robot planetary gearboxes that work better and last longer. Their modular design makes fixing easy and helps with upgrades. These things help AGVs and mobile robots do better in automation and moving goods.

Tip: Doing regular checks and using sealed planetary gearboxes can help AGVs last longer in busy warehouses.

Material Handling Systems

Material handling systems, like conveyor belts and packaging lines, use planetary gear motors for their high efficiency and strength. A single-stage planetary gearbox can be up to 97% efficient. Double-stage systems reach about 94%. This means less energy is wasted. The small design lets them give more torque in tight spaces. This is important for machines that need to be small. Sharing the load over many planet gears cuts down on wear. It also keeps power steady, even when moving fast. These things help material handling systems run well and stop less. Planetary gear motors also let machines work all the time. This helps make more products and keeps lines moving. Their strong and steady work makes them a top pick for many factories.

DC Planetary Gear Motor Comparison

Spur Gear Motors

Spur gear motors have straight teeth and a simple design. Many engineers use them in basic machines. But there are big differences between a dc planetary gear motor and a spur gear motor. A dc planetary gear motor gives more torque because it has many gear contact points. Spur gear motors only have one contact point, so they cannot handle as much force.

A dc planetary gear motor keeps oil inside the gears. This helps it stay efficient and accurate, even when it spins fast. Spur gear motors lose oil at high speeds. This makes them less efficient and louder. In robots, a dc planetary gear motor is better for heavy loads and jobs that need exact moves.

Here is a table that shows the main differences:

Feature | DC Planetary Gear Motors | Spur Gear Motors |

|---|---|---|

Torque Output | Higher torque due to multiple gear contact points | Lower torque; limited by single contact points |

Efficiency | Higher efficiency; lubrication retained within gear teeth | Lower efficiency; lubrication disperses at high speeds |

Load Capacity | Can sustain heavier loads | Limited load capacity |

Noise Level | Lower noise due to better lubrication and gear design | Higher noise at high speeds |

Typical Applications | Robotics, industrial automation, high precision tasks | Low speed, low torque applications |

Durability | More durable due to construction and lubrication retention | Less durable under high load and speed |

Size Considerations | Usually longer and narrower | Generally shorter and wider |

Note: A dc planetary gear motor gives robots more power and lasts longer than a spur gear motor.

Worm Gear Motors

Worm gear motors use a screw-shaped gear to turn a wheel. These motors can make things spin slower in a small space. But a dc planetary gear motor has more benefits for robots and automation. Worm gear motors waste more energy as heat, so they are less efficient. They also have more backlash, so they are less exact for robot arms.

A dc planetary gear motor gives better speed control and more torque in a small size. It is also quieter and lasts longer. In advanced robots, engineers pick dc planetary gear motors because they are more precise and can do harder jobs. Reports show more factories want planetary gear motors for smart robots. These motors work well with sensors and smart controls, so they are great for new technology.

DC planetary gear motors give robots strong torque, high efficiency, and exact moves.

Spur and worm gear motors are good for simple jobs, but they cannot match a dc planetary gear motor in advanced robots.

Tip: If your robot needs exact moves, strong torque, and long life, pick a dc planetary gear motor.

Planetary gear motors are special in robotics and automation. They give strong torque, work very well, and let robots move exactly. These motors are small and easy to fit in tight places. The table below shows why they are a top pick:

Metric | Impact on Robotics and Automation |

|---|---|

High Torque and Load Sharing | Lets robots move with power and accuracy |

Helps robots save energy and work longer | |

Low Backlash | Makes robot moves more exact |

Compact, Lightweight Design | Fits into small spaces in robots |

Durability and Reliability | Makes sure robots work for a long time |

Smooth, Quiet Operation | Keeps noise low for quiet places |

Robotics engineers say to pick planetary gear motors by looking at power, torque, how well they work, and size. You can choose special types, like brushless or brushed DC models. These help robots do hard jobs with steady and exact moves.

FAQ

What makes planetary gear motors better for robots?

Planetary gear motors give strong torque and exact moves. Their small size helps them fit in tight spots. These motors last a long time and are quiet. Engineers use them in robots that need power and accuracy.

Can planetary gear motors handle heavy loads?

Yes. Planetary gear motors spread the weight over many gears. This lets them lift or move heavy things without breaking. Many factories use them for hard work.

How do planetary gear motors reduce noise?

The gears inside a planetary motor fit together well. This makes less shaking and less noise. Robots with these motors stay quiet in offices, labs, and hospitals.

Are planetary gear motors energy efficient?

Planetary gear motors can be up to 95% efficient. Most power moves the robot instead of making heat. This saves energy and cuts costs.

See Also

Selecting The Best Planetary Gear Motor For Accurate Screwdrivers

Choosing The Ideal Rotary Motor For Industrial Uses

Picking The Best Battery Electric Motor Setup For Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry