The Complete Guide to Phone Vibration Testing: Methods, Tools, and Applications

Phone vibration testing is important for making reliable devices. It helps makers test how phones handle real-life situations. This testing finds weak spots in a phone’s design. Fixing these issues makes phones stronger and work better. By following rules, companies can stop problems and make better products. Better testing also makes users happy by ensuring phones handle daily shakes. Good testing creates stronger phones and happier customers.

Key Takeaways

Phone vibration testing checks if phones can handle shaking.

It finds weak points early, saving money and fixing problems.

Testing helps improve features like vibrations, making phones more fun.

Regular checks make sure phones are safe and work well.

Using the right tools gives better results and stronger phones.

Understanding Phone Vibration Testing

What Is Phone Vibration Testing?

Phone vibration testing checks if a phone can handle shakes. It mimics real-life situations like drops or bumps to test durability. This process ensures the phone works even after being shaken. Engineers study how parts like screens and batteries react to vibrations.

Different methods are used to measure vibrations. For instance, spectral analysis changes vibration signals into frequencies to find issues. Another method, shock pulse monitoring, spots metal contact in moving parts. Below is a table of common techniques:

Measurement Technique | Description |

|---|---|

Spectral analysis | Finds important frequencies in a vibration signal. |

Shock pulse monitoring | Spots shock waves from metal contact in moving parts. |

Velocity measurement | Checks vibration strength across many frequencies. |

Displacement measurement | Focuses on low frequencies to find unbalanced spinning parts. |

These methods show how phones handle stress and where they need improvement.

Why Is Vibration Testing Important for Phones?

Vibration testing makes sure phones are strong and work well. Without it, phones might break during daily use, upsetting customers. Research shows regular testing gives reliable results, even in different settings. This helps makers trust the data to improve designs.

Testing also stops long-term damage. Everyday vibrations, like walking or driving, can loosen parts over time. Finding weak spots early avoids costly fixes or recalls. Plus, vibration testing ensures phones meet rules needed for selling worldwide.

Key Benefits of Vibration Analysis

Vibration analysis helps both phone makers and users in many ways:

Improved Durability: Testing finds weak areas so they can be fixed early.

Enhanced User Experience: Studying vibrations improves features like typing or gaming feedback.

Cost Savings: Fixing problems early saves money on repairs or replacements.

Regulatory Compliance: Meeting rules ensures phones are safe and reliable.

Adding vibration analysis to development creates better phones and happier users.

How to Perform Phone Vibration Testing

Common Methods for Vibration Testing

Testing how phones handle vibrations uses different methods. These methods copy real-life situations to check strength and performance. Two popular ways are sinusoidal vibration and random vibration.

Sinusoidal Vibration: This method studies resonance frequencies. It mimics vibrations from spinning or shocks. You can change the test by adjusting frequency, strength, or time.

Random Vibration: This method tests how phones handle unexpected shakes. Examples include shipping or earthquakes. The test's intensity depends on frequency, GRMS (acceleration), and time.

Other specific tests can be done under these methods:

Sinusoidal Fixed Frequency Test: Uses one frequency for a set time.

Sine Frequency Sweep Test: Moves through frequencies to find weak spots.

Broadband Random Vibration Test: Covers many frequencies to copy real-world vibrations.

Broadband Random Superimposed Sinusoidal Vibration Test: Combines random and sinusoidal vibrations for better testing.

These methods show how phones handle different vibrations. They ensure phones are strong and work well.

Step-by-Step Guide to Conducting a Basic Vibration Test

Follow these steps to do a basic vibration test:

Set Up the Equipment: Use a vibration table or similar tool. Make sure it follows rules like ASTM D999 or IEC 60068-3-3.

Secure the Phone: Attach the phone tightly to the platform. This stops it from moving during the test.

Select the Test Parameters: Pick the test type (e.g., sinusoidal or random). Set the frequency, strength, and time based on your goal.

Run the Test: Start the machine. Watch the phone's reaction using sensors or cameras.

Record the Data: Collect information on how the phone reacts. Use software to find patterns or problems.

Analyze the Results: Compare the data to standards like Bellcore GR-63 or IEEE 693. Look for damage or issues.

Make Adjustments: If the phone fails, find weak areas and improve the design.

These steps help ensure phones meet strength and reliability standards.

Troubleshooting Common Issues During Testing

Vibration testing can have problems. Here are common ones and how to fix them:

Inconsistent Results: If results change, check the machine's calibration. Make sure it works correctly.

Phone Slippage: If the phone moves, secure it better. Use clamps or sticky mounts made for testing.

Data Gaps: Missing data happens if sensors are loose. Check all connections before starting.

Overheating Equipment: Machines can overheat with long tests. Let them cool between tests to avoid damage.

Misinterpreted Data: Wrong analysis can cause mistakes. Use trusted software and compare results to standards like ASTM D4728.

Fixing these problems makes vibration tests more accurate and reliable.

Tools for Vibration Analysis

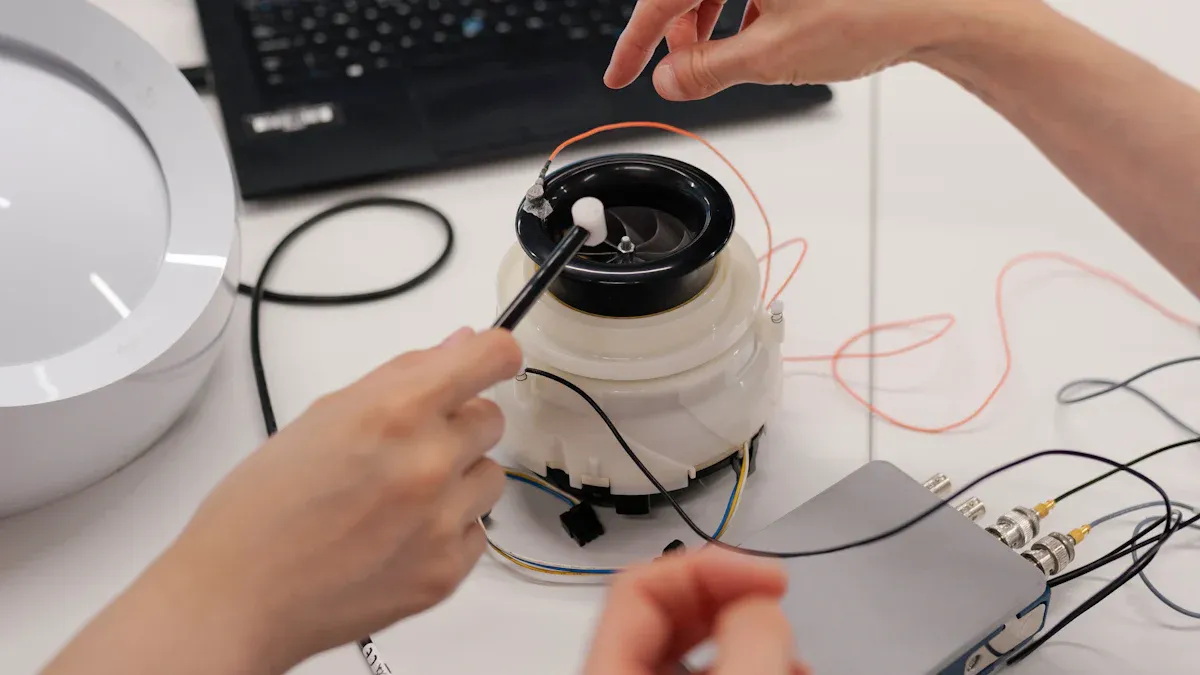

Important Equipment for Vibration Testing

To test vibrations well, you need good tools. The right equipment helps find problems and gives accurate results. Here are some key tools for vibration testing:

Vibration Tables: These create controlled shakes to copy real-life conditions. You can change settings like how strong or fast the vibrations are.

Accelerometers: These sensors measure how strong and fast vibrations are. They can detect even tiny shakes in your phone.

Data Collection Systems: These gather and process signals from accelerometers. They turn raw data into easy-to-read information.

Environmental Chambers: These test how vibrations affect phones in different temperatures or humidity.

Modal Hammers: These tools check how phones react to impacts or hits.

Make sure your tools meet standards like ASTM or ISO. Good tools make testing more accurate and finding problems easier.

Software for Analyzing Vibration Data

After collecting data, you need software to study it. Advanced programs help find patterns, problems, and unusual signals. They also show details about vibration strength and frequency.

Modern software uses math tools like kurtosis and skewness. These tools help spot sudden changes or uneven data. For example, kurtosis shows big spikes, while skewness finds uneven patterns.

Here’s a quick look at the vibration software market:

Feature | Details |

|---|---|

Base Year of the Analysis | 2024 |

Historical Period | 2019-2024 |

Forecast Period | 2025-2033 |

USD 1.7 Billion | |

Expected Growth Rate | CAGR of 5.6% during 2025-2033 |

Key Drivers | Using vibration tools to improve machines and monitor health |

Using the right software makes testing easier. It helps find problems faster and ensures phones meet quality standards.

Tips for Picking the Best Tools

Choosing the right tools can be tricky. Here are tips to help you decide:

Know Your Needs: Decide what kind of vibrations you want to test. For high-frequency shakes, pick an accelerometer with a fast sample rate.

Compare Options: Look for tools that fit your budget and needs. Check the table below for examples:

Product Name | Price | Sample Rate | Key Features |

|---|---|---|---|

HOBO Pendant | $83 | 100 Hz | Long battery life, basic features |

Vibration Sentry | $344 - $379 | Up to 3,200 Hz | Strong design, good triggers |

enDAQ Sensors | $1,250 - $2,500 | Up to 20,000 Hz | Many sensors, large storage |

TSR Pro-HB | N/A | Up to 20,000 Hz | High range, big storage |

Check Compatibility: Make sure the tools work with your system. If not, results might be wrong.

Pick Durable Tools: Choose equipment that can handle tough tests. Strong tools last longer and work better.

By following these tips, you can set up a great testing system. This will help make phones stronger and better for users.

Applications of Phone Vibration Testing

Making Phones Strong and Reliable

Phone vibration testing helps make phones tough and dependable. It copies real-life situations to find weak spots in the design. Fixing these problems before selling makes phones last longer. For example, tests can show how phones handle shipping or daily use.

Different tests help check reliability. These include vibration, environmental, and stress tests. Each test has a special job, as shown below:

Test Type | Purpose |

|---|---|

Vibration Testing | Copies effects of shipping or daily use. |

Environmental Testing | Checks performance in heat, cold, or wet conditions. |

Mechanical Stress Testing | Tests strength under pressure or bending. |

Abrasion Testing | Measures resistance to scratches or wear. |

Controls Testing | Makes sure buttons and switches work properly. |

These tests make sure phones can handle tough conditions and stay reliable.

Improving User Feel with Vibrations

Vibration testing also makes phones feel better to use. It improves haptic feedback, which is the vibrations you feel when typing or gaming. By studying these vibrations, engineers can make them more fun and useful.

Research shows better haptic feedback makes users happier. For example, vibration alerts helped people notice messages faster. This was especially helpful for blind users, who performed better after learning improvements. These studies show how vibration testing makes phones more enjoyable for everyone.

Following Rules and Standards

Phone vibration testing also helps meet important rules. Phones must pass certain tests to be safe and reliable. Testing vibrations ensures phones follow these rules and avoids expensive recalls.

For example, passive vibration control methods work well to reduce shaking. Tests showed a 93% drop at 42 Hz and 57% at 28 Hz. These results show why understanding vibrations is key to meeting standards. Adding these tests ensures phones are safe and exceed expectations.

Real-World Examples of Vibration Testing

Vibration testing helps make phones strong for everyday use. Companies use it to check if phones can handle real-life situations. Here are some ways vibration testing is used in the phone industry:

Shipping and Transportation: Phones travel far from factories to stores. On the way, they face shakes from trucks, planes, and belts. Vibration testing copies these conditions. This ensures phones work perfectly after long trips.

Daily Usage: Phones shake during walking, running, or biking. Engineers test how these movements affect parts inside. For example, they check if the battery stays in place or if the screen stays safe after many shakes.

Haptic Feedback Optimization: Phones vibrate when you type or get alerts. This is called haptic feedback. Vibration testing helps improve these vibrations. Engineers make them feel better and more responsive for users.

Extreme Conditions: Some phones are made for tough places like construction sites. Vibration testing checks if they can handle strong shakes from machines or rough ground.

These examples show how vibration testing makes phones last longer and work better. It ensures phones handle daily use and give you a great experience.

Tip: Next time you use your phone, remember the tests it passed to work so well for you.

Phone vibration testing helps make phones strong and reliable. Using proper tools and methods finds design problems early. Fixing these issues improves how phones work. This testing also ensures phones meet important rules. It makes users happier by creating better products. Adding vibration testing to your process avoids big problems later. Start using these steps now to build tougher, better phones.

FAQ

Why do we test phone vibrations?

Phone vibration testing checks if phones handle real-life shakes. It finds weak spots, makes phones stronger, and improves how they work. This testing also ensures phones follow safety and reliability rules.

When should vibration testing happen during development?

Vibration testing should be done at different stages. Test early to find design problems in prototypes. Test again after changes and before production to ensure the final phone is strong and works well.

Can vibration testing make haptic feedback better?

Yes! Vibration testing helps improve haptic feedback. Engineers study vibrations to make typing, gaming, and alerts feel better. This makes using the phone more enjoyable.

What tools are needed for vibration testing?

You need tools like vibration tables and accelerometers. Data systems and environmental chambers are also helpful. Pick tools that meet standards like ASTM or ISO for accurate results.

Tip: Always check your tools are working properly before testing for the best results.

Do all phones need vibration testing?

Yes, all phones need vibration testing. It ensures they are strong, safe, and reliable. Testing makes sure phones work well in daily life or tough conditions without losing performance.

See Also

Comprehensive Insights on How to Measure Vibration

Top Instruments for Accurate Vibration Measurement Explained

Different Techniques for Effective Vibration Measurement

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry