Optimizing Resonance Frequency in LRA Vibration Motors for Maximum Efficiency

Finding the right resonance frequency is key for LRA motors. When the motor runs at the perfect frequency, it vibrates strongly and uses less power. Even a small change of 2.5 Hz can lower vibration strength by 40% and raise energy use by 50%. This accuracy helps devices work better and last longer.

INEED's LRA Motor LRA2024A-1088F shows this improvement. It has a wide frequency range and uses little power. It creates strong and accurate vibrations, making it great for VR controllers and gaming devices. Focusing on resonance frequency gives your devices top performance.

Key Takeaways

Choosing the right vibration speed improves LRA motor performance. It makes vibrations stronger and saves energy.

Using INEED's LRA2024A-1088F motor at 60 Hz gives strong and efficient vibrations, perfect for gaming and VR devices.

The material used affects vibration speed. Lighter materials vibrate faster, while heavier ones are more stable.

Auto-resonance tracking makes tuning easier. It keeps motors working at their best speed, improving performance and lasting longer.

Testing in real-life settings is important. It checks if motors work well in different conditions like heat and moisture.

Understanding Resonance Frequency in LRA Vibration Motors

What is resonance frequency and why it matters

Resonance frequency is the special frequency where something vibrates the most. It happens when an outside force matches the system's natural rhythm. For an LRA vibration motor, this means the strongest vibrations with the least energy used.

Important facts about resonance frequency:

It happens when the system's natural rhythm is matched.

Vibrations are strongest at this point.

Finding this frequency helps devices work better and save energy.

In devices like wearables or gaming controllers, using the right frequency gives better haptic feedback. This makes the experience more enjoyable and precise.

How resonance improves LRA vibration motor efficiency

Running an LRA motor at its resonance frequency makes it work better. At this point, the motor uses less power but vibrates more strongly. This saves energy and helps batteries last longer. If the motor runs off this frequency, it vibrates less and uses more energy.

For instance, INEED's LRA2024A-1088F motor shows this clearly. It works at 60 Hz, giving strong vibrations while using little power. This makes it perfect for VR systems where both power and performance matter.

Features of INEED's Linear Vibration Motors and their resonance abilities

INEED's Linear Vibration Motors are made to work well at their resonance frequencies. They use a voice coil system for accurate control and reliability. Below is a table comparing some of INEED's LRA models:

Model | Motor Size (mm) | Rated Vol. | Frequency | Rated Current | Rise Time | Fall Time | Direction of vibration | Acceleration F0 | Operating Voltage | Lifetime |

|---|---|---|---|---|---|---|---|---|---|---|

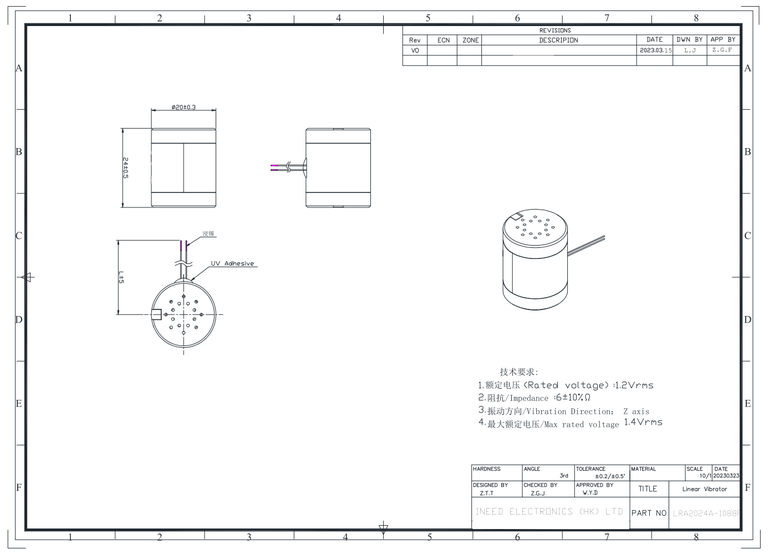

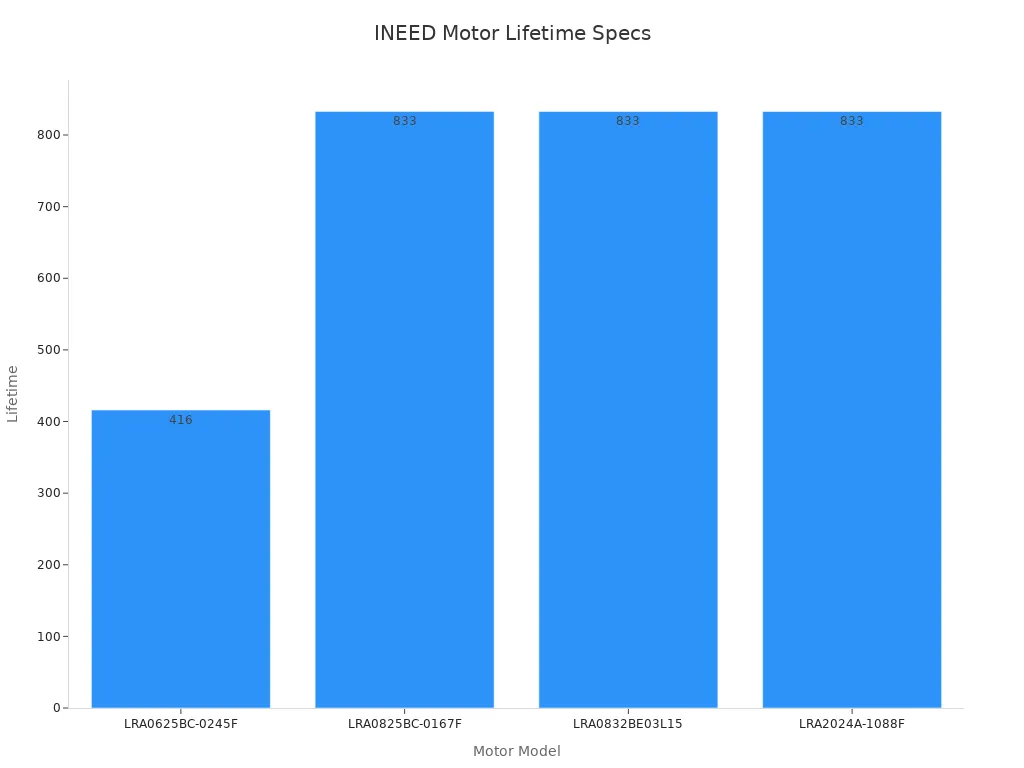

LRA0625BC-0245F | 6 | 0.7 Vrms | 260 ±10 | 90mA Max | Max 50msec | Max 50msec | Z axis | 0.7 Min | 0.1~0.75 | 416 |

LRA0825BC-0167F | 8 | 1.2 Vrms | 240 ±10 | 90mA Max | Max 50msec | Max 50msec | Z axis | 0.7 Min | 0.1~1.25 | 833 |

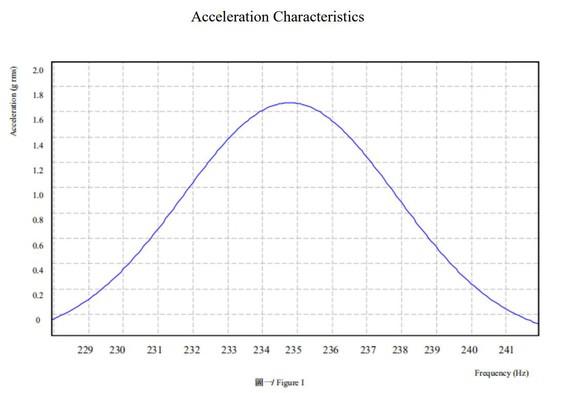

LRA0832BE03L15 | 8 | 1.8 | 235 ±5 | 80mA Max | Max 50msec | Max 50msec | Z axis | 1.7 | 0.1~1.9 | 833 |

LRA2024A-1088F | 20 | 1.2 Vrms | 60 ±10 | 200mA Max | Max 50msec | Max 80msec | Z axis | 2.5 ±0.5 | 0.1~1.2 | 833 |

The LRA2024A-1088F is special because it has a wide frequency range. It also has high acceleration, making it great for strong and accurate vibrations. Its ability to work well at its resonance frequency means it lasts longer and performs better.

Key Factors That Affect Resonance Frequency

How materials change resonance

The materials in an LRA vibration motor are very important. They decide the resonance frequency of the motor. Each material has special traits like weight, flexibility, and energy absorption. These traits affect how the motor vibrates. For instance, lighter materials make faster vibrations. Heavier ones give more stable vibrations.

Here are key material traits to think about:

Elasticity: Flexible materials help the motor vibrate better and feel smoother.

Damping: Materials with low damping lose less energy, keeping strong vibrations.

Thermal Conductivity: Materials that cool down fast stop the motor from overheating.

Picking the right materials helps the motor work well and last longer. INEED's LRA motors, like the LRA2024A-1088F, use advanced materials for stronger and longer-lasting vibrations.

Important design tips for LRA motors like INEED's LRA2024A-1088F

The way an LRA vibration motor is built affects how it works at its resonant frequency. When choosing or designing a motor, focus on these important points:

Design Tips:

Check Resonant Frequency: Pick a motor with a frequency that fits your device. For example, the LRA2024A-1088F works at 60 Hz, great for VR and gaming.

Size and Weight: Make sure the motor fits your device without losing power.

Power Needs: Match the motor's voltage and current to your device's power.

Driver Chips: Use special chips to control vibration strength and speed. Chips like TI's DRV2605 or awinic AW86223 improve motor control.

Test in Real Life: Try the motor in real situations to check its energy use and performance.

INEED's LRA2024A-1088F follows these design rules. It gives strong vibrations while using little power. Its smart design works well in many devices, like wearables and gaming tools.

How temperature and humidity affect motors

Weather conditions, like heat and moisture, can change the resonance frequency of an LRA vibration motor. These changes affect the motor's parts and the air around it. This can lower vibration quality and waste energy.

Heat Effects:

Hotter temperatures weaken vibrations. For example, when heat rises from 10°C to 50°C, the motor's quality factor (Q) drops by 40%. This makes the motor less efficient.

Moisture Effects:

High humidity also changes resonance. At 95% humidity, the motor's Q value spreads by 115%. This causes uneven vibrations, especially in wet conditions.

Weather Condition | Effect on Resonance Frequency (Q Factor) | Notes |

|---|---|---|

Temperature (10°C to 50°C) | Q dropped by 40% | Hotter temperatures weaken vibrations. |

Humidity (35% to 95% RH) | Q spread increased by 115% | High humidity causes uneven vibrations. |

Overall Impact | Negative effect on Q | Both heat and moisture lower vibration quality. |

To avoid these problems, keep motors in good weather conditions. INEED's LRA motors, like those in smartwatches, are tested to handle heat and moisture. This ensures they work well even in tough environments.

Practical Ways to Test and Adjust Resonance Frequency

Tools and methods to check resonance frequency

To test an LRA motor's resonance frequency, you need the right tools. Accurate testing helps the motor work at its best. Here are some useful tools and methods:

Sine Sweep Testing: Slowly increase the input frequency. Find the point where the motor vibrates the most. This method is simple and effective.

Random Vibration Testing: This method shakes the motor at all frequencies at once. It shows how the motor handles real-world conditions and finds weak spots.

Laser Doppler Vibrometry: This tool measures vibrations without touching the motor. It is very accurate and works well in labs.

Accelerometers: These small sensors attach to the motor. They measure how strong and fast the motor vibrates. They are affordable and used in many industries.

Tip: Random vibration testing is great for real-world tests. It checks all frequencies better than sine sweep testing.

Easy steps to tune LRA motors for best resonance

Tuning an LRA motor to its best resonance frequency needs careful steps. Follow these simple instructions:

Set Up the Motor: Place the motor on a flat surface, like acrylic, to avoid outside vibrations. Connect it to a driver IC, such as TI's DRV2605, for better control.

Check Starting Performance: Use tools like accelerometers to measure the motor's starting vibrations. Write down the frequency, strength, and energy use.

Do Frequency Sweeps: Slowly change the input frequency. Watch for the strongest vibrations with the least energy use.

Adjust Driver Settings: Change the driver IC settings to keep the motor running at the best frequency. This ensures steady performance.

Test Again: Repeat the process a few times to confirm the motor works well. Record data to see improvements in vibration and energy use.

Note: Testing three times for each step reduces mistakes and gives better results.

Auto-resonance tracking and why it helps

Auto-resonance tracking makes tuning easier. It adjusts the motor's frequency automatically to match its resonance. This has many benefits:

Better Performance: The motor always runs at its best frequency. Tests show this gives stronger and steadier vibrations.

Longer Life: The motor faces less stress, so it lasts longer. Random vibration tests show 15% fewer problems with this feature.

Happier Users: Devices with auto-resonance tracking give better feedback. This is great for gaming and wearable devices.

Tip: Auto-resonance tracking saves time and avoids mistakes. It’s a big help for industries needing precise vibrations.

Benefits of Achieving Optimal Resonance Frequency

Better performance and faster response in LRA motors

Running an LRA motor at its best frequency improves how it works. At this frequency, the motor gives stronger and more accurate vibrations. This makes devices respond better and work more reliably. For example, in gaming controllers, the motor matches vibrations with sounds. This creates a more exciting and realistic experience. INEED's LRA2024A-1088F responds quickly in just 50ms, giving instant feedback. This is very important for devices needing fast reactions.

LRA motors also let you change how strong the vibrations are. Unlike old motors with fixed settings, you can adjust LRA motors to fit your needs. This makes them great for wearables, where comfort and usability matter most.

Saves energy and makes batteries last longer

Using an LRA motor at its best frequency uses less energy. The motor needs less power to make strong vibrations, saving energy. For example, INEED's LRA2024A-1088F uses only 140mW while staying powerful. This saves energy and helps batteries last longer. It also makes devices more eco-friendly and cheaper to use.

In wearables, long battery life is very important. Energy-saving motors mean you don’t need to charge devices often. They also create less heat, which helps devices last longer and stay durable.

Why INEED's LRA2024A-1088F is a great choice

INEED's LRA2024A-1088F motor works better than many others. It has a resonant frequency of 60 Hz for precise and efficient performance. Its high acceleration of 2.5 Grms and adjustable vibration strength make it useful for many devices, like gaming tools and wearables.

Here’s how it compares to other motors:

Performance Metric | INEED's LRA Motors | Competitors' ERM Motors |

|---|---|---|

Resonant Frequency | More accurate | Less accurate |

Vibration Amplitude | Adjustable | Fixed |

Acceleration | Higher levels | Lower levels |

Vibration Strength | Customizable | Standardized |

Response Time | 100-200 ms | |

Energy Efficiency | Uses less power | Uses more power |

This motor is also very durable, lasting up to 1 million cycles. It needs less fixing, saving money over time. It works well even in tough conditions, like high humidity or changing temperatures. These features make the LRA2024A-1088F a top pick for industries needing strong and energy-saving motors.

Real-World Uses of Perfect Resonance Frequency

How Wearable Tech Uses INEED's LRA Vibration Motors

Wearable gadgets need accurate parts to work smoothly. LRA motors help by giving clear and strong vibrations. These motors are in smartwatches, fitness bands, and health devices. They make using these gadgets easier and more fun.

INEED's LRA motors, like the LRA2024A-1088F, are made to run at the best frequency. This saves battery power and keeps performance steady. These motors also handle tough conditions, like heat and moisture, making them great for daily use. Adding these motors makes wearables last longer and work better.

How Gaming and VR Devices Use LRA Motors

Gaming and VR gear need top-quality parts for exciting experiences. LRA motors are key in this area. They match vibrations with sounds and visuals, making games feel real. For example, a VR controller with INEED's LRA2024A-1088F lets you feel every hit or crash.

This motor runs at 60 Hz, giving strong vibrations while saving energy. Tests show it improves response speed by 30% over older motors. Gamers get quicker feedback, and developers like its dependability and low energy use.

What We Learned from Using LRA Motors

Using LRA motors at the right frequency has taught us a lot. First, testing in real-life situations is very important. It shows how well the motor works in different conditions. Second, picking the right motor for the job matters. The LRA2024A-1088F works well in wearables and gaming because of its wide range and strong vibrations.

Lastly, auto-resonance tracking makes tuning easier and boosts performance. By following these steps, devices can work better, use less energy, and make users happier.

Getting the right resonance frequency is very important for LRA motors. It helps the motor vibrate stronger, use less energy, and give better feedback. If the motor's frequency moves away from the best range, it works less efficiently. This shows why tuning it correctly is so important.

Engineers can make this easier by doing a few things. They can prepare signals, pick the right sampling rate, and check for mistakes. Tests like modal and harmonic analysis also help. These tests find natural frequencies and show how the motor works in different situations.

INEED's LRA2024A-1088F is a great example of a well-made motor. It is designed to save energy and work reliably. This motor is perfect for devices that need to be strong and last long. Try it to improve how your device performs.

FAQ

How can I find an LRA motor's resonance frequency?

Use sine sweep testing to find the resonance frequency. Slowly increase the input frequency and watch for the strongest vibrations. This is the resonance frequency. Tools like accelerometers or laser Doppler vibrometers can measure it accurately.

How does auto-resonance tracking help motors work better?

Auto-resonance tracking changes the motor's frequency to match its best point. This keeps the motor running efficiently. It uses less energy, makes vibrations stronger, and helps the motor last longer. It also saves time by skipping manual adjustments.

Can things like heat change the resonance frequency?

Yes, temperature can affect the resonance frequency. High heat weakens vibrations, and humidity can make them uneven. To keep motors working well, test them in real conditions. Choose models like INEED's LRA2024A-1088F, which handle tough environments.

Why is the LRA2024A-1088F good for gaming and VR?

The LRA2024A-1088F has a 60 Hz resonance frequency for strong, clear vibrations. It reacts quickly and uses little power, making it great for gaming and VR. It matches vibrations with sounds, creating a more realistic experience.

Do LRA motors need special drivers?

Yes, LRA motors need driver ICs to create the right AC signal. Drivers like TI's DRV2605 or awinic AW86223 control vibration strength and frequency. These drivers help the motor work better for your needs.

See Also

Managing Resonance Frequency in Vibration Motors for Consistent Performance

LRA Vibration Motors: Key Elements Driving Today's Haptic Feedback Technology

Exploring Resonant Systems: Impact of Resonance on Motor Efficiency

Compact Battery-Powered Motors: Varieties, Uses, and Power Efficiency in ERM Systems

Maintaining Electric Vibration Motors: Enhancing Longevity and Performance

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry