How to Optimize LRA Motors for Vibrating Object Designs

Improving LRA motors is important for making vibrating objects work well. Adjusting these motors helps them perform better and use less energy. It also makes the vibrations smoother, which feels better for users. Whether for gadgets or medical tools, better motors give steady results. They use less power but stay accurate, perfect for today’s needs. By improving motors, you can make products that last longer and work better.

Key Takeaways

Improving LRA motors makes them work better and use less energy. This creates smoother vibrations and longer-lasting devices.

Set the LRA motor's frequency to the best level. This gives stronger vibrations and saves energy.

Watch the voltage closely to keep vibrations steady. Changes in voltage can make the motor weaker.

Use small designs and light materials to make devices easier to carry and stop extra vibrations.

Use energy-saving methods like PWM and sleep modes. These help batteries last longer in portable devices.

Understanding LRA Motors

What Are LRA Motors?

LRA motors, short for Linear Resonant Actuators, make vibrations. They are different from regular motors. They use a spring and weight system to create steady vibrations. These motors are small and save energy. This makes them great for things like phones, watches, and medical tools.

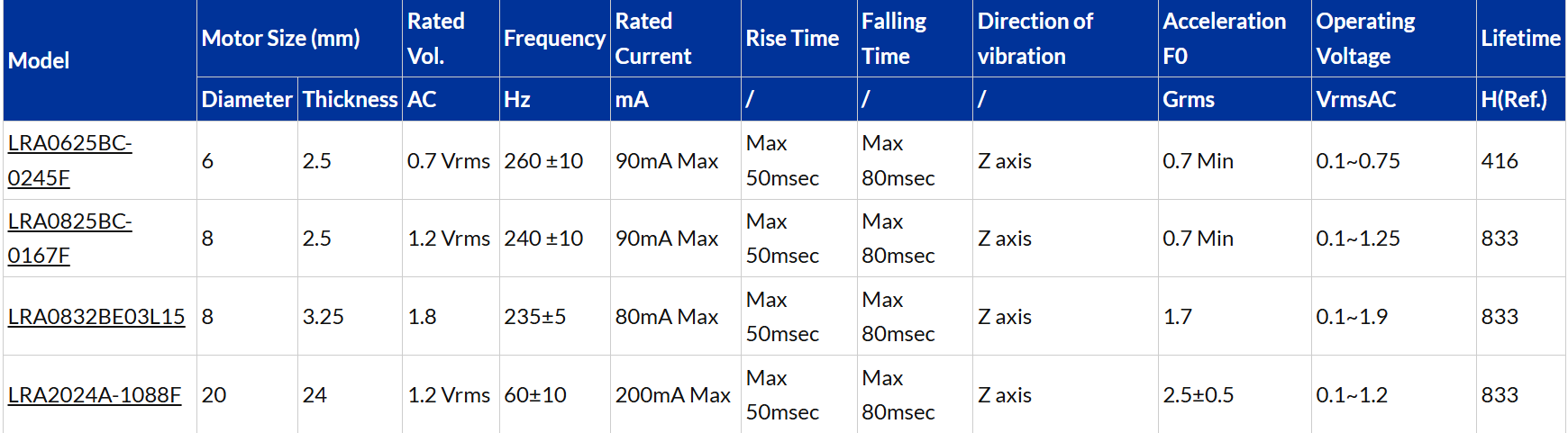

Here are some important details about LRA motors:

These details show how accurate and dependable LRA motors are. This is very important for making vibrating objects.

How Do LRA Motors Work?

LRA motors work in a simple way. They have a magnetic weight connected to a spring. When an AC signal is sent, the weight moves back and forth. This happens at the motor's special frequency. The movement makes strong and steady vibrations.

LRA motors are better than other vibration types. For example:

Feature | ERM | LRA | PIEZO |

|---|---|---|---|

Voltage | 1 - 10 VDC | 2.5 - 10 VAC | 50 - 200 Vpp |

~ 3 | ~ 1 - 5 | ~ 1 - 3 | |

Power Consumption | Good | Best | Better |

Audible Noise | Very Noisy | Moderately Noisy | Silent |

Response Time | 100 - 200ms | 50ms Max | < 1ms |

This chart shows why LRA motors are a good choice. They are fast, quiet, and use less power.

Advantages of LRA Motors for Vibrating Objects

LRA motors have many benefits for vibrating designs:

Compact Design: Small size fits into tight spaces.

Energy Efficiency: Uses little power, great for battery devices.

Precision and Accuracy: Gives steady vibrations for better user experience.

Quiet Operation: Makes less noise, good for quiet places.

Durability: Strong and works well in tough conditions.

These features make LRA motors a smart and efficient option. They help devices respond faster and use less energy. This is perfect for high-performance needs.

Key Factors for Optimizing LRA Motors

Frequency Tuning for Precision

Adjusting the frequency of an LRA motor is important. It helps the motor make strong vibrations while using less energy. Each motor has a special frequency where it works best. If the frequency is off, the motor won't work as well.

To adjust the frequency, first find the motor's best frequency. You can use special tools or software to do this. After finding it, make sure the motor's signal matches this frequency. Even a small difference can make the motor weaker and waste energy.

For devices like phones or game controllers, keeping the right frequency is key. It makes the motor work better and gives users a smoother experience.

Voltage Control for Stability

Controlling voltage is very important for LRA motors. The voltage affects how strong and steady the vibrations are. If the voltage changes too much, the motor might not work right.

There are rules for keeping voltage steady:

Voltage Control Rules | Source |

|---|---|

Keep voltage within 5% - 15% of normal when starting. | |

Motors should handle up to 10% voltage change, per NEMA rules. | Eng-Tips |

IEEE Standard 141 explains voltage drop rules for motor starting. | Eng-Tips |

To keep voltage steady, use a power supply that stays within these limits. Adding circuits to check voltage can also help fix problems quickly. This keeps the motor working well and lasting longer.

Acceleration and Response Time Optimization

Improving acceleration and response time is important for fast feedback. Response time is how quickly the motor starts and stops. Acceleration is how strong the vibrations get during use.

To make response time faster, reduce the motor's start and stop times. You can do this by adjusting the motor's signal and using its best frequency. Fast response times are needed for things like gaming or medical tools.

For better acceleration, check the motor's weight and spring system. A balanced system helps the motor vibrate strongly without delays. Testing and fixing issues can keep the motor working its best.

By focusing on these areas, you can make motors that work better and last longer. This improves how your device performs overall.

Design Considerations for Vibrating Objects

Compact Designs and Size Constraints

Making vibrating objects small is very important. Parts must fit into tight spaces without losing performance. Smaller designs save space and make devices easier to carry, like wearables or handheld gadgets.

Small designs also work better by cutting down extra vibrations. Research shows that adjusting sizes improves speed and reduces shaking. This makes devices faster, stronger, and more dependable.

To make designs compact:

Pick smaller LRA motors that still vibrate well.

Arrange parts smartly to use space wisely.

Use light materials to keep the device small and easy to carry.

These steps help create designs that work well and fit into small spaces.

Tip: Test your small designs to check if they stay steady and vibrate properly in real-world use.

Power Efficiency and Energy Management

Saving power is key for vibrating objects, especially battery-powered ones. Using energy wisely makes batteries last longer and keeps performance steady. LRA motors already use little power, but you can improve them more.

Choose a motor that matches your device's power needs. Big motors waste energy, and small ones might not vibrate enough. You can also save energy by:

Using PWM: Adjusts motor power to match vibration strength.

Adding sleep modes: Turns off the motor when not needed.

Picking good power supplies: Keeps voltage steady and avoids wasting energy.

For example, wearables with smart energy use last longer without needing frequent charging.

Note: Check power use during testing to find ways to save more energy.

Material Compatibility and Durability

The materials in your vibrating object affect how long it lasts and works. Vibrations can wear out parts over time. Picking strong materials keeps your device reliable even with constant use.

Use materials that handle vibrations well. For example:

Soft polymers: Reduce stress and absorb vibrations.

Strong metals: Stay tough in rough conditions.

Heat-resistant materials: Protect against damage from long motor use.

Make sure materials don’t mess up the motor’s work. For instance, magnetic parts near the motor can cause problems.

Choosing the right materials helps your device last longer and work better.

Tip: Test materials to see how they hold up in real-world situations.

Overcoming Challenges in LRA Motor Optimization

Reducing Noise and Improving Vibration Quality

Noise and vibration quality are very important for devices. Too much noise can bother users. Bad vibrations make feedback less accurate. Fix these problems by improving signals and system design.

Scientists have used touch and sound methods to help robots. Touch methods can be affected by extra vibrations and signal issues. This lowers accuracy and makes them less useful. Sound methods use microphones, but they don’t work well for soft items. Background noise also makes signals unclear. Both methods need a lot of processing, creating complex systems. Studies show that contact control can make robots work better. In this study, we used a sensor with an impact method. This method reduces noise by using point contact. It helps AI focus on key signals by cutting out distractions.

To make vibrations better, run the motor at its best frequency. This stops extra shaking and improves feedback. Grouping vibration-damping signals also makes data easier to process. This boosts system performance.

Preventing Overheating and Extending Lifespan

Overheating can harm motors and make them wear out faster. Stop this by controlling power and keeping the motor cool. Use materials like aluminum or heat-resistant plastics to manage heat.

Check the motor’s temperature while it runs. If it gets too hot, lower its workload or change its frequency. Adding heat sensors can catch problems early. Regular check-ups keep the motor working well.

Enhancing Efficiency in High-Performance Applications

High-performance tasks need strong motors that save energy. To do this, improve vibration strength and energy use. Use pulse-width modulation (PWM) to control power.

Pick motors made for tough jobs. These motors give steady feedback and handle heavy tasks. Test them in real situations to see if they work well.

By solving these problems, you can make devices that work better and give great feedback.

Applications of Optimized LRA Motors

Haptic Feedback in Consumer Electronics

Improved LRA motors are key for better haptic feedback. They use less energy than older ERM motors. This makes them great for phones and gaming controllers. These motors respond quickly, giving instant and accurate vibrations. This is important for real-time interactions.

For example, new LRAs with super-fast response times are now common. They make user experiences better by mimicking real-life touches. You can feel things like button clicks or rough surfaces. Apple's Taptic Engine is a famous example. It gives precise vibrations that match what users expect. Adding optimized LRA motors makes devices feel natural and fun to use.

Automotive Alerts and Controls

In cars, improved LRA motors make driving safer and more comfortable. They send soft vibrations to warn about dangers, like drifting lanes or crashes. Unlike sounds or lights, vibrations keep your eyes on the road.

For instance, the 2024LRA motor helps drivers stay alert. It vibrates to guide turns or warn of risks. This reduces the need for visual signals, keeping drivers focused. Using LRA motors in cars helps make driving safer and easier.

Therapeutic Vibrations in Healthcare Devices

Healthcare tools benefit a lot from better LRA motors. These motors give precise vibrations for pain relief and muscle therapy. Their small size and low power use make them perfect for wearable devices.

For example, LRA motors can target specific body parts to ease pain. They are quiet, so you can use them anywhere without bothering others. By using these motors, healthcare devices become more helpful and easy to use.

Making LRA motors better is key for reliable vibrating devices. It boosts how they work, saves power, and makes users happier. By adjusting things like frequency, voltage, and response time, you can get steady and accurate vibrations.

When building vibrating devices, think about size, energy use, and strong materials. The table below shows important design needs for better results:

Design Need | What It Means |

|---|---|

DR1: Scalability | Works with many motors, including ERM and LRA types. |

DR2: Precise Control | Lets you adjust vibration strength and speed exactly. |

DR3: Easy to Use | Simple controls that work with current vibration tools. |

Use these tips to make cool and powerful devices. With smart planning, you can get the best out of LRA motors in your designs.

FAQ

Why are LRA motors great for haptic feedback?

LRA motors make accurate vibrations for better haptic feedback. They react fast and save energy, perfect for phones and game controllers. These motors give clear and lifelike touch experiences.

How can you adjust LRA motors for best results?

Change the frequency to match the motor's best point. This makes vibrations strong and saves energy. Use tools or apps to find the right frequency and set the motor to it.

Can LRA motors run for a long time without overheating?

Yes, they can if heat is managed well. Use materials that resist heat and check the motor's temperature while it works. Adding coolers or heat sensors helps them last longer.

Are LRA motors good for wearable gadgets?

Yes, they are. Their small size and low power use are perfect for wearables. They give accurate vibrations and save battery, making them easy to use.

How do LRA motors make cars safer?

LRA motors help by giving touch alerts. Vibrations warn drivers about dangers like lane drifting or crashes. This keeps their eyes on the road and reduces the need for sounds or lights.

See Also

Enhancing LRA Vibration Motors For Optimal Resonance Performance

Key Role of LRA Vibration Motors in Haptic Feedback Technology

Designing Small Vibrating Motors For Limited Space Solutions

Choosing The Perfect Vibrating Motor For Your Specific Needs

Best Practices For Frequency Optimization In Compact Motor Designs

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry