What Defines a Small Motor in Modern Engineering?

A small motor in modern engineering typically has 100 watts or less and is compact in size. Organizations such as NEMA and IEC establish Motor Size Classifications using specific guidelines to determine motor sizes. The table below outlines some common criteria:

Criterion | Specification / Range |

|---|---|

Horsepower (hp) | 0.25 to 3 hp |

Motor Topologies | Capacitor-Start Induction Run, Polyphase |

Pole Configurations | 2, 4, or 6 poles |

Motor size depends on these factors and its intended application. Engineers and designers must understand how size impacts efficiency and control while adhering to established Motor Size Classifications. Selecting the appropriate motor size ensures optimal performance, compliance with energy standards, and proper integration within the system. Control features such as variable speed and built-in control systems also influence the motor’s size classification.

Key Takeaways

Small motors often have 100 watts or less power. They are small and can fit in tight spaces. - Engineers use rules like NEMA and IEC to sort motors. They look at power, size, and control features. - Stepper and servo motors are popular small motors. They give exact control for robots and medical tools. - Picking the right motor size and control system helps things work better. It also makes them last longer and use less energy. - Small motors are very important in today’s technology. They help make portable devices, automation, and save energy.

Motor Size Classifications

Output Power Standards

Engineers use output power to sort motors by size. Most small motors have 100 watts or less. Some sources say the limit is 75 watts. Micro motors usually have 3 watts or less. Groups like the Department of Energy (DOE) and rules like 10 CFR 431.446(a) give clear rules for these groups. The DOE sorts small electric motors by phase count, motor topology, and pole setup. The table below shows how these rules group small motors:

Motor Classification Aspect | Details |

|---|---|

Output Power Range (hp) | 0.25 to 3 |

Motor Topologies | CSIR, CSCR, Polyphase |

Pole Configurations | 2, 4, 6 poles |

Representative Units | Polyphase 4-pole 1.00 hp; Single-phase CSCR 4-pole 0.75 hp |

These rules help engineers pick the right motor for each job. They also set how efficient motors should be and help design control systems. Many servo motors fit in these power ranges. Servo motors need careful control, so engineers must match power to the system’s needs.

Physical Dimensions

Physical size is important for sorting motor sizes. Groups like NEMA and IEC use frame size rules to group motors. These rules tell the length, width, and how to mount each motor. Small motors have small frames, so they fit in tight spots. Servo motors often use smaller frames for better control in small spaces.

Frame size changes how engineers build control systems. Smaller motors can use lighter control parts. This makes the whole system weigh less. Servo motors need this because they must move fast and be exact. The size of the motor also changes cooling and care. Smaller motors often need less cooling, so they work well in small devices.

Note: Engineers must check both power and size when picking a motor. A motor with the right power but wrong size may not fit the job.

Application Context

How the motor will be used decides its final size group. Engineers look at what the motor will do, what control it needs, and what it must perform. For example, servo motors are used in robots, automation, and CNC machines. These motors need careful control, so their size and power must fit the job.

Some jobs need motors with special control, like changing speed or knowing position. Servo motors are good for these jobs because they control very well. Simple fans or pumps may use small motors with basic control. The job also changes what motor type and frame size to use.

Motor size groups help engineers pick the best motor for each task. They look at power, size, and control needs. Servo motors are often used when control is very important. By knowing these groups, engineers can build systems that work well and last.

Types of Motors

Small Motors

Small motors are important in many devices. They usually have 100 watts or less output power. Engineers use them in electronics, medical tools, and automation. Many small motors use brushless dc motors for better efficiency and longer life. Some small motors have a gearbox to give more torque at low speeds. This helps in robotics and cars.

Small motors need careful control. Motor controllers help with speed and torque. Stepper motors and servo motors are common in this group. Stepper motors move in small steps, so they work well in printers and 3D machines. Servo motors give accurate control, which is needed in robots and automation. Engineers use stepper motor control and servo control for best results.

Note: Small motors often use low voltages like 12V DC. This fits portable and battery-powered devices.

Aspect | Small Motors Characteristics |

|---|---|

Power | Up to 100 watts |

Motor Types | Stepper motors, servo motors, brushed dc motors, brushless dc motors |

Control | Motor controllers, speed control, servo control, stepper motor control |

Applications | Robotics, medical devices, consumer electronics |

Micro Motors

Micro motors are even smaller than small motors. They often use 1 to 60 volts of power. Micro motors are light and small. Engineers use them in cars, medical tools, and handheld devices. Micro motors can be brushed dc motors or brushless dc motors. Brushless dc motors are chosen for their good efficiency and long life.

Micro motors need advanced control. Motor controllers help with speed and torque. Stepper motors and servo motors are also used in micro motors. Stepper motors give exact movement. Servo motors give strong control. Stepper motor control and servo control are needed for accuracy.

Attribute | Micro Motors Description |

|---|---|

Size and Weight | Small and lightweight |

Motor Types | Brushed dc motors, brushless dc motors, stepper motors, servo motors |

Control | Motor controllers, speed control, servo control, stepper motor control |

Applications | Automotive, medical equipment, handheld tools, computer peripherals |

Other Motor Types

There are other types of motors too. These include AC motors, DC motors, fractional horsepower motors, and integral horsepower motors. Each type is used for different jobs. AC motors are strong and need little care. DC motors give good speed control and high starting torque. Fractional horsepower motors are used in low-power devices. Integral horsepower motors are used in big machines.

Stepper motors and servo motors are special types. Stepper motors use stepper motor control for exact moves. Servo motors use servo control for accurate positions. Brushed dc motors are easy to use and cost less. Brushless dc motors last longer and need less care.

Types of motors include:

Stepper motors for printers and CNC machines

Servo motors for robots and automation

Brushed dc motors for simple devices

Brushless dc motors for high efficiency

AC motors for big machines

Motor controllers help run all these motors. Speed control, servo control, and stepper motor control are important for good performance. Engineers pick the right motor and control for each job.

Small Block Engine vs. Big Block Engine

Physical Size Differences

A small block engine is built to be compact. It has smaller bores and shorter strokes. This means it has less displacement. Most small block engines have under 400 cubic inches of displacement. Because of this, they are lighter. They fit well in cars that need quick moves and good control. For example, the first Chevy small block engine started at 265 cubic inches. It later grew to 454 cubic inches. Even as it got bigger, it stayed light and could rev fast.

A big block engine is much larger. It uses bigger bores and longer strokes. This gives it more than 400 cubic inches of displacement. The bigger size makes it heavier. This extra weight can change how a car moves and speeds up. The big block engine was first made in 1958. It was built for tough jobs. Its large size gives it more power and torque. But it also adds more weight to the car.

Feature | Small Block Engine | Big Block Engine |

|---|---|---|

Physical Size | Smaller, more compact | Larger, physically bigger |

Bore and Stroke | Smaller bores and shorter strokes | Larger bores and longer strokes |

Displacement | Less displacement | Greater displacement |

Weight | Lighter, benefits handling and acceleration | Heavier, can negatively affect handling |

Valve and Port Size | Smaller valves and ports | Bigger valves and ports |

Power Output Comparison

A small block engine makes less power than a big block engine. Small block engines are light and respond quickly. This helps with control in sports cars and fast cars. A big block engine gives much more power and torque. This is because it is bigger and has more displacement.

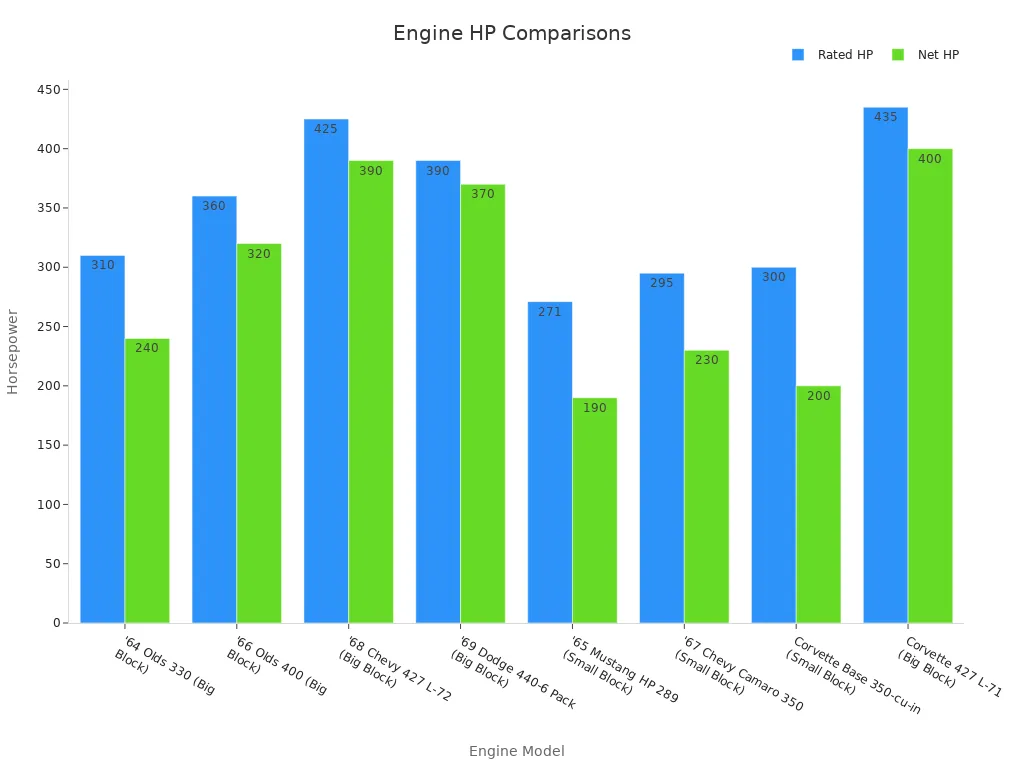

The table below shows the horsepower for each engine:

Engine Type & Model | Rated HP | Estimated Net HP |

|---|---|---|

'64 Olds 330 (Big Block) | 310 | 240 |

'66 Olds 400 (Big Block) | 360 | 320 |

'68 Chevy 427 L-72 (Big Block) | 425 | 390 |

'69 Dodge 440-6 Pack (Big Block) | 390 | 370 |

'65 Mustang HP 289 (Small Block) | 271 | 190 |

'67 Chevy Camaro 350 (Small Block) | 295 | 230 |

Corvette Base 350-cu-in (Small Block) | 300 | 200 |

Corvette 427 L-71 (Big Block) | 435 | 400 |

Some new small block engines, like the 346 CID LS1, can make over 500 horsepower. This is as much or more than many old big block engines. This shows that good control and new tech help small block engines keep up with bigger engines.

Typical Applications

A small block engine is used in hot rods, muscle cars, and drag racing cars. Its light weight and small size help cars speed up fast and turn well. Many high-performance engines use the small block design for these reasons.

A big block engine is found in muscle cars, big cars, and trucks. Its high torque and power are good for pulling heavy things or going very fast. The big block engine is best when a lot of strength and control are needed.

Note: Engineers use small block and big block engine ideas to sort motors by size, displacement, and control needs. This helps them pick the right engine for each job, just like with electric motors.

Why Motor Size Matters

Advantages of Small Motors

Small motors have many good points in engineering. Their small size lets engineers put them in tight spots. This is great for portable devices and robots. Small motors can be very efficient, from 40% up to 85%. They also have expansion ratios between 1.5 and 8. Engineers can make these motors work better and fit many uses. Semi-empirical models help guess how well they will work, with less than 5% error. Studies show that small induction motors with better materials give more torque, better efficiency, and steady work. These motors are used in electric cars, where size and control matter a lot. Stepper and servo motors help with exact moves and position control. Motor control systems, like speed control and servo control, help engineers get the results they want. The table below shows important performance facts:

Parameter | Range/Details |

|---|---|

Internal Efficiency | 40% to 85% |

Expansion Ratio | 1.5 to 8 |

Cycle Thermal Efficiency | 2% to 9% |

Model Accuracy | <5% error |

Tip: Engineers pick small motors because they are easy to use and work well in jobs that need stepper or servo control.

Limitations

Small motors also have some problems. Reports from space projects, like NASA’s X-57, show engineers have trouble with heat and fitting parts together. Small motors must deal with electromagnetic compatibility and not fail at one point. Making light motor control systems can be hard. Engineers may need to change parts after seeing how they work. Stepper and servo motors might need special motor control to stay accurate. Speed control and servo control can make things harder. These problems can hurt reliability and mean engineers must design carefully.

Common Uses

Small motors are used in many areas of engineering. Factories use stepper and servo motors for robots and exact control. Electronics use small motors in small devices. Home tools and appliances use small motors to save money and work better. Space projects use small motors in electric planes and flying tools. Medical devices need stepper and servo motors for accuracy. HVAC systems use small motors for speed control. The table below shows where small motors are used:

Sector / Application | Common Uses |

|---|---|

Industrial Automation | Robotics, stepper and servo motors |

Consumer Electronics | Compact devices |

Appliances & Power Tools | Household tools, speed control |

Aerospace | Electric aircraft, servo motors |

Healthcare | Medical devices, stepper motors |

HVAC | Speed control systems |

Note: Stepper and servo motors, with advanced motor control and speed control, help in many different jobs.

A small motor has unique features. Engineers look at output power, size, and application to define a motor. They use standards to group each motor. A motor with the right control works best in many jobs. Servo motors need strong control for exact moves. A motor in robotics uses servo control. A motor in medical tools uses servo control for safety. Each motor needs the right control. Servo motors help with control in small spaces. A motor with good control lasts longer. Servo control gives better results. A motor with servo control fits many uses.

FAQ

What defines a small motor in engineering?

A small motor gives 100 watts or less power. It is small and easy to fit in tight places. Engineers use it when they need careful control.

What are common uses for small motors?

Small motors are used in robots and medical tools. They also work in home appliances, toys, fans, and computers. Engineers pick them for jobs that need to be exact and save energy.

What is the difference between a small motor and a micro motor?

A micro motor is smaller than a small motor. It gives 3 watts or less power. Micro motors fit in tiny things like hearing aids and small robots.

What standards help classify small motors?

Groups like NEMA and IEC make rules for motor size and frame. These rules help engineers choose the right motor for each job. They also make sure motors are safe and work well.

What makes small motors important in modern technology?

Small motors help engineers build lighter and better machines. They make portable devices possible and help with automation. Their small size and control help new technology grow.

See Also

Eight Creative Uses For Mini Motor Parts In Electronics

A Comprehensive Overview Of Mini Motors And Their Uses

The Role Of Mini Motors In Advancing Portable Technology

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry