Motor Diagrams: Understanding Components, Types, and Applications in ERM Vibration Motors

ERM vibration motors are important in modern technology. These motors make vibrations by spinning an uneven weight. This creates touch feedback in devices like phones and smartwatches. Their small size makes them perfect for jobs needing accurate vibrations.

Motor diagrams help explain how these motors work. They show parts, connections, and how they operate clearly. By looking at these diagrams, you can learn to improve performance and fix problems easily.

Key Takeaways

ERM vibration motors make devices buzz by spinning a lopsided weight. They are important in gadgets like phones and smartwatches.

Knowing motor parts, like the rotor and stator, helps you pick the right motor. Balance power and vibration strength for your needs.

ERM motors come in types like brushed and brushless. Each type lasts differently and vibrates differently, so choose based on your project.

Installing and taking care of motors properly makes them work better and last longer. Attach them tightly and check for damage often.

Motor diagrams make it easier to see how ERM motors work. They help you fix problems and improve how the motor runs.

Components of ERM Vibration Motors

Rotor and Eccentric Mass

The rotor is a key part of the motor. It spins when powered, creating vibrations in devices like phones and watches. An uneven weight, called the eccentric mass, is attached to the rotor. This uneven weight causes the motor to vibrate as it spins.

The rotor's design affects how the motor works. A bigger weight or faster spin makes stronger vibrations. But, this also uses more power. Below are some important rotor details:

Measurement/Characteristic | Details |

|---|---|

Power Consumption | Uses more power for higher speeds and stronger vibrations. |

Speed Control | Voltage changes motor speed, affecting vibration strength and frequency. |

Rise Time to 90% Target Speed | Takes about 50 to 100 milliseconds. |

Fall Time to Stop | Stops in about 50 to 100 milliseconds. |

Suitability for Haptic Effects | Not great for quick effects like in gaming due to delay. |

Knowing these details helps pick the right motor. You can balance strong vibrations with energy use.

Stator and Magnetic Field

The stator is the still part of the motor. It makes a magnetic field that moves the rotor. A stronger magnetic field means more power and stronger vibrations.

Here are things that affect the stator's power:

More winding turns increase torque.

Bigger stators make more torque.

Stronger magnetic fields give more torque. For example, a 1.2T field gives 20% more torque than a 1T field.

Longer stators and higher currents also add torque.

A motor with a 100mm stator makes twice the torque of a 50mm one.

These points show how the stator's design changes the motor's power and vibrations. Improving the stator can make the motor work better for your needs.

Electrical Characteristics: Resistance, Inductance, and Electromotive Force

The motor's electrical parts are important for how it works. Resistance, inductance, and electromotive force (EMF) decide how well it turns electricity into vibrations.

Resistance: Controls the current in the motor. Lower resistance means stronger vibrations but uses more power.

Inductance: Affects how fast the motor reacts to voltage changes. Lower inductance means quicker response, good for fast vibrations.

Electromotive Force (EMF): The voltage made by the motor as it spins. It affects speed and efficiency.

Understanding these helps adjust the motor's performance. Lowering resistance and inductance makes it respond faster. Managing EMF keeps it running smoothly.

Bearings and Housing

Bearings and housing are key parts of a motor. Bearings help the rotor spin easily by reducing friction. Housing protects the motor from dust, water, and damage.

Bearings: Helping the Motor Run Smoothly

Bearings are important for the motor to work well. They hold the rotor and let it spin with little resistance. Without bearings, the rotor would wear out quickly. Here are some facts about bearings:

Types of Bearings: Motors use ball or sleeve bearings. Ball bearings last longer and handle high speeds. Sleeve bearings are quieter and cheaper.

Lubrication: Adding oil or grease reduces friction and makes bearings last longer.

Maintenance: Checking bearings often helps find problems early and avoids motor failure.

Housing: Protecting the Motor from Harm

The housing is the motor's outer cover. It keeps the motor safe and working properly. Here’s what to know about housing:

Material: Most housings are made of strong metal or plastic to handle tough conditions.

Design: Good housing design helps cool the motor and stops it from overheating.

Sealing: Tight seals keep out dust and water, which can harm the motor.

Tip: Pick motors with strong bearings and housing. This makes them last longer and need less fixing.

Brushes and Commutator (for brushed motors)

In brushed motors, brushes and the commutator send electricity to the rotor. These parts are needed for the motor to work but need care to stay in good shape.

Brushes: Sending Power to the Rotor

Brushes are small pieces made of carbon or graphite. They touch the commutator to pass electricity to the rotor. Here’s what to know:

Material: Carbon brushes are common because they last long and carry electricity well.

Wear and Tear: Brushes wear out over time. Replacing them keeps the motor working well.

Contact Quality: Good contact between brushes and the commutator helps transfer energy better.

Commutator: Keeping the Rotor Spinning

The commutator is a round part on the rotor. It works with brushes to change the current’s direction, so the rotor keeps spinning. Key points include:

Construction: Made of copper pieces with insulation, it is built to last.

Maintenance: Dirt or damage on the commutator can lower performance. Cleaning it helps it work better.

Role in Performance: A clean commutator keeps the motor running smoothly and saves energy.

Note: If your motor sparks or makes strange sounds, check the brushes and commutator. These problems may mean they are worn out or dirty.

Types of ERM Vibration Motors

Knowing the types of vibration motors helps you pick the right one. ERM vibration motors come in different styles, each with special uses. Let’s look at the main types.

Brushed ERM Motors

Brushed ERM motors are very common. They use brushes and a commutator to send power to the rotor. The rotor spins the uneven weight, making vibrations. These motors are simple and cheap, great for saving money.

But, brushed motors don’t last long because the brushes wear out. They usually work for 100 to 600 hours. Even so, they can make vibrations from 0.25G to 150G. They run at speeds between 30Hz and 500Hz. This makes them good for toys, gadgets, and low-cost electronics.

Here’s how brushed ERM motors compare to others:

Motor Type | Lifespan (MTTF) | Vibration Strength Range | Vibration Frequency |

|---|---|---|---|

Brushed ERM | 72 – 600 hours | 0.25G ~ 150G | 30Hz ~ 500 Hz |

BLDC ERM | 1000+ hours | 0.1G ~ 30G | 200 Hz ~ 208 Hz |

LRA | 400+ hours | 0.70G ~ 2.5G | 60 Hz ~ 260 Hz |

Tip: Brushed ERM motors are a good choice for short-term, low-cost needs.

Brushless ERM Motors

Brushless ERM motors, or BLDC motors, are more advanced. They don’t use brushes or a commutator. Instead, they use electronic parts to move the rotor. This design lasts longer, over 1,000 hours.

These motors give steady vibrations, ranging from 1G to 30G. They work at a smaller frequency range, usually 200Hz to 208Hz. This makes them reliable and precise. Brushless motors are great for medical tools, wearables, and industrial machines.

Here’s a comparison of brushed and brushless ERM motors:

Feature | Brushed ERM | Brushless ERM |

|---|---|---|

Lifespan (MTTF) | 72 – 600 hours | 1000+ hours |

Vibration Strength | 0.25G ~ 150G | 0.1G ~ 30G |

Vibration Frequency | 30Hz ~ 500 Hz | 10 Hz ~ 208 Hz |

Cost vs Longevity | Cheaper | Long-lasting |

Note: Use brushless ERM motors for long-term, reliable projects.

Cylindrical vs. Coin-Shaped Vibration Motors

ERM motors come in two shapes: cylindrical and coin-shaped. Each has its own benefits.

Cylindrical Vibration Motors

Cylindrical motors, also called pager motors, are small but strong. They have a round body with an uneven weight on the rotor. These motors are flexible and create strong vibrations. They’re good for handheld devices, gaming controllers, and tools. Their shape fits well in tight spaces.

Coin-Shaped Vibration Motors

Coin-shaped motors, also called pancake motors, are flat and tiny. They’re perfect for very small spaces like wearables, fitness trackers, and medical tools. These motors use a spinning weight to vibrate. They often stick to devices with adhesive for easy setup.

Feature | Cylindrical Motors | Coin-Shaped Motors |

|---|---|---|

Shape | Round | Flat, coin-like |

Uses | Handheld devices, tools | Wearables, trackers |

Vibration Strength | Strong | Moderate |

Setup | Screws or brackets | Adhesive backing |

Tip: Pick cylindrical motors for strong vibrations and coin-shaped ones for small designs.

By learning about these motor types, you can choose the best one. Whether you need something cheap, long-lasting, or compact, there’s a motor for you.

Choosing the Right Type for Your Application

Picking the right vibration motor can seem tricky. Breaking it into steps makes it simpler. Each motor type has its own advantages. Knowing these helps you choose wisely.

1. Know What Your Project Needs

First, figure out what your project requires. Ask yourself:

Does it need strong or gentle vibrations?

How much space is there for the motor?

Will it run all the time or just briefly?

What is your budget?

For example, a coin-shaped motor is great for small devices like fitness trackers. A cylindrical motor works better for tools or controllers needing stronger vibrations.

2. Think About How Long It Will Last

The motor's lifespan is important. Brushed motors are cheaper but wear out faster. Brushless motors last over 1,000 hours and need less care. They are better for long-term use, like in medical tools or industrial machines.

Tip: Use brushed motors for short-term projects. For long-term use, pick brushless motors to save on replacements.

3. Check Vibration Strength and Frequency

Different devices need different vibration levels. Brushed motors can give both soft and strong vibrations. Brushless motors are more steady. For precise feedback, like in smartwatches, brushless motors or LRAs are best.

Motor Type | Vibration Strength | Frequency Range | Best For |

|---|---|---|---|

Brushed ERM Motors | 0.25G ~ 150G | 30Hz ~ 500Hz | Toys, gadgets, low-cost devices |

Brushless ERM Motors | 0.1G ~ 30G | 10Hz ~ 208Hz | Wearables, medical tools |

LRAs | 0.70G ~ 2.5G | 60Hz ~ 260Hz | Smartwatches, gaming controllers |

4. Make Sure It Fits the Space

The size of your device matters. Coin-shaped motors are ideal for small spaces like wearables. Cylindrical motors are better for bigger devices where space is not tight.

Note: Measure the space in your device first. This avoids fitting issues and redesign costs.

5. Balance Cost and Quality

Your budget is key. Brushed motors cost less but need replacing more often. Brushless motors and LRAs cost more but last longer. Pick one that fits your needs and budget.

6. Test and Adjust

After choosing a motor, test it in your device. Check how strong it vibrates, how loud it is, and how much power it uses. Adjust settings like voltage to get the best results.

Pro Tip: Work with trusted suppliers like INEED Electronics. They offer custom options and expert advice to help you find the right motor.

By following these steps, you can pick the best motor for your project. Whether it’s a wearable, medical tool, or industrial device, knowing your needs and the motor’s features ensures success.

Motor Diagrams and Control Techniques

Understanding Motor Diagrams for ERM Motors

Motor diagrams are helpful for learning how ERM motors work. They show the motor's parts, connections, and how it operates. By studying these diagrams, you can see how electrical energy turns into vibrations. This helps you improve performance and fix problems easily.

Here’s a table comparing key details of different ERM motors:

This table makes it easier to compare motor features and choose the best one.

Driving Methods: Voltage and PWM Control

To control an ERM motor, you can adjust its speed and vibration. There are two main ways to do this: voltage control and Pulse Width Modulation (PWM).

Voltage Control:

You can change the motor's speed by applying a steady voltage. A higher voltage makes the motor spin faster and vibrate more. This method is simple but not very precise for creating detailed vibration patterns.PWM Control:

PWM is a smarter way to control the motor. It uses quick on-and-off pulses to adjust the motor's average voltage. By changing the pulse width, you can fine-tune the motor's speed and vibration. This method works well for devices like wearables or gaming controllers that need accurate feedback.

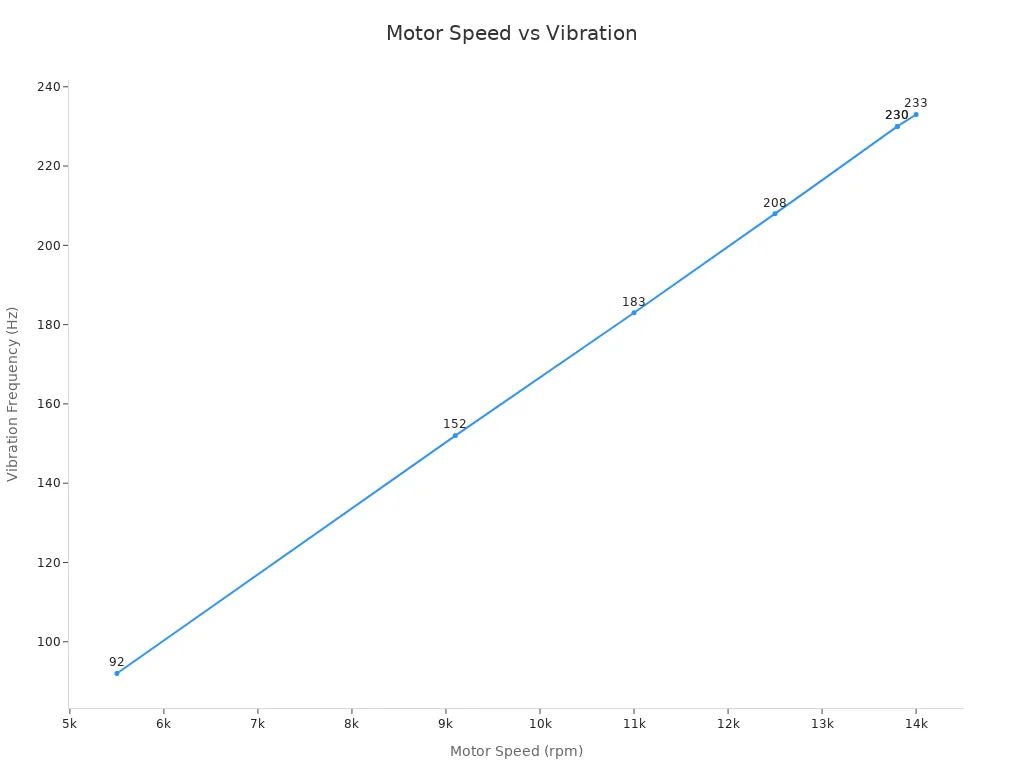

Here’s a chart showing how motor speed matches vibration frequency:

Using PWM lets you create custom vibration patterns, making devices more user-friendly.

Torque and Current Relationships

Torque and current are connected in ERM motors. Torque controls how strong the vibrations are, while current shows how much energy is used. Higher current gives stronger vibrations but uses more power.

To keep your motor working well, watch the current during use. Too much current can overheat the motor and shorten its life. Balancing torque and current keeps the motor efficient and lasting longer.

Tip: Use a motor controller to manage current and keep torque steady. This prevents overheating and improves reliability.

Speed Control and Feedback Mechanisms

Controlling how fast an ERM motor spins is important. It helps set the right vibration strength and frequency. There are different ways to adjust the motor's speed for smooth and accurate operation.

Ways to Control Speed

Voltage Adjustment

Changing the voltage is an easy way to control speed. Higher voltage makes the motor spin faster and vibrate more. Lower voltage slows it down and reduces vibrations. This method is simple but not very precise, so it’s best for basic uses.Pulse Width Modulation (PWM)

PWM is a smarter way to control speed. It turns the motor on and off quickly to adjust the average voltage. By changing how long the motor stays on, you can fine-tune its speed. This method works well for devices like smartwatches or gaming controllers that need accurate feedback.H-Bridge Circuit

An H-bridge circuit gives better control by letting you reverse or stop the motor quickly. It uses reverse voltage to slow the motor down fast. Combining this with adjustable voltage improves how the motor starts and stops. For example:A higher voltage helps the motor start faster.

Reverse voltage slows it down quickly when stopping.

Feedback Systems

Feedback systems check how the motor is working and adjust its speed as needed. Sensors measure speed or vibration strength and send data to the controller. The controller changes the voltage or PWM settings to keep performance steady. This helps the motor work well, even if conditions change.

Tip: Using an H-bridge with feedback control makes the motor more precise and energy-efficient. It also reduces wear and tear, helping the motor last longer.

By learning these methods, you can control speed and feedback in ERM motors. This improves how devices perform and makes them more user-friendly.

Applications of ERM Vibration Motors

ERM vibration motors are used in many everyday devices. They create accurate vibrations, making them useful in different industries. Let’s see how these motors improve various systems.

Haptic Feedback in Mobile Devices

Your phone vibrates because of haptic feedback. ERM vibration motors spin a weight to make this happen. This simple action makes your phone feel more interactive. Vibrations make notifications, calls, and games more engaging.

Smartphones depend on these motors for steady vibrations. They help you notice alerts, even in loud places. By changing the motor’s speed, unique vibration patterns are created. This makes phones easier and more fun to use.

Wearable Technology and Fitness Trackers

Smartwatches and fitness trackers use ERM motors for alerts. These small motors fit well in tiny spaces. They give gentle vibrations for messages, reminders, or fitness updates.

For example, when you hit your step goal, the motor vibrates to celebrate. This quiet feedback keeps you motivated without being annoying. These motors are light and don’t make devices bulky. They also save battery, which is great for wearables.

Industrial and Medical Equipment

In factories, ERM motors improve safety and work. They give vibrations as alerts in noisy places where sounds can’t be heard. Workers use these vibrations to stay aware of machines or dangers.

In medical tools, these motors add accuracy and ease of use. Devices like scanners or diagnostic tools use vibrations to guide users. For example, a motor might vibrate to confirm a scan or warn of an error. This feedback helps tools work better and more precisely.

Tip: For industrial or medical uses, pick durable and reliable motors. This ensures they work well in tough conditions.

Integration Tips for Best Results

To make vibration motors work well, you must install them properly. Good setup ensures they last longer and perform better. Follow these simple tips to get the most out of your motor.

Pick the Right Motor for Your Device

Choose a motor that fits your device's needs. Think about size, power, and vibration strength. Coin-shaped motors are great for small gadgets. Cylindrical motors are better for stronger vibrations.Secure the Motor Firmly

Attach the motor tightly to stop it from moving around. Use sticky backing for coin motors or screws for cylindrical ones. A firm setup makes vibrations stronger and reduces noise.Use a Stable Power Source

Give the motor steady power to avoid problems. Adjust vibration strength with voltage control or PWM. This helps you create custom vibrations for your device.Test in Real-Life Situations

Try the motor in your device under normal conditions. Check if vibrations are steady, noise is low, and power use is okay. Change settings if needed for better performance.Keep Up with Maintenance

Look at the motor often to spot wear and tear. Clean the outside and check the bearings to keep it working well. Replace worn brushes in brushed motors when needed.

Tip: Work with trusted suppliers like INEED Electronics. They can give expert advice and custom motor options for your project.

New Trends in Vibration Motor Uses

Vibration motors are improving, and new trends are making them even more useful. These changes are helping industries create better devices and experiences.

Smaller Motors: Tiny motors are now used in small gadgets like wearables and medical tools. This trend supports portable and efficient designs.

Better Feedback in Cars and Games: Vibration motors are making cars and games more interactive. Haptic steering wheels and gaming controllers give precise and fun feedback.

Smart Home Gadgets: Smart devices like alarms and locks now use vibration motors. These motors make devices more interactive with touch alerts.

Healthcare Tools: Vibration motors are popular in medical wearables and therapy devices. They help monitor health and improve treatments.

These trends show how important vibration motors are becoming. By keeping up with these changes, you can find new ways to use haptics in your projects.

INEED's Expertise in Vibration Motors

Coin Vibration Motor: Features and Uses

INEED's coin vibration motor is small and works well in tight spaces. Its flat, round shape fits wearables and fitness trackers perfectly. These motors run on 3V DC power and can spin up to 10,000 RPM. They are built to last and have sticky backing for easy setup.

You can change these motors to match your needs. Options include different wire lengths, connectors, and ways to attach them. This makes it easy to use them in many devices. Coin vibration motors are great for medical tools, portable gadgets, and smartphones. They give accurate vibrations, making devices more user-friendly.

Coreless Vibration Motor: Benefits and Uses

Coreless vibration motors, also called pager motors, give quick and strong vibrations. They are light and shaped like a cylinder, making them good for small devices. These motors use low power, between 1.3V and 3V DC, and respond quickly. This makes them perfect for instant feedback.

You can find these motors in gaming controllers, phones, and pagers. They last a long time and work efficiently, so they don’t need much fixing. Their lightweight design is ideal for portable gadgets. Using coreless motors improves how devices feel when touched.

Custom Solutions for Special Needs

INEED creates custom motors for different industries. Whether you need one for a wearable or a machine, INEED can design it to fit your needs. You can choose options like shaft design, gear settings, and vibration strength.

INEED ensures their motors work well for your projects. They focus on quality and deliver on time, making them a reliable partner. By choosing INEED, you get smart solutions that improve how your devices work.

Why Pick INEED for Your Vibration Motor Needs

Choosing the right motor supplier is key to success. INEED is a trusted choice, offering quality motors and custom solutions for many uses. Here’s why INEED is a great option for your motor needs.

Reliable and Trusted Performance

INEED’s motors work well in many industries. Whether for wearables, medical tools, or machines, their motors meet high standards. Customers have shared positive reviews:

David Haimes gave 5/5, calling the motor a "work horse" with no problems after three months.

Satish Kumar also rated 5/5, praising its reliability in a virtual pinball cabinet.

Asako Kimura rated 4/5, liking its speed, size, and price for her needs.

These reviews prove INEED’s motors perform well in real-life situations.

Custom Motors for Your Needs

INEED makes motors that match your exact needs. You can adjust features like vibration strength, size, and how they attach. This makes sure the motor fits perfectly into your device and works better.

Focus on Quality

INEED checks quality at every step. Their motors go through tough tests to ensure they last long and work well. From checking materials to testing lifespan, each motor is built to last. This reduces repair costs and makes devices last longer.

Expert Help and Advice

INEED’s team helps you pick the right motor and use it well. Their knowledge makes setup easier and saves you time. You can trust their advice to get the best results for your project.

Tip: Choosing INEED means getting reliable motors, custom options, and expert help to make your devices work their best.

Learning about ERM motors starts with their parts, types, and controls. Each piece, like the rotor and stator, helps make accurate vibrations. Different motor types, such as brushed, brushless, and LRA, suit various tasks. Control methods like voltage changes and PWM improve how they work. Motor diagrams make these ideas easier to understand, helping you boost performance and fix problems.

Feature | Details |

|---|---|

Motor Types | Brushed ERM, Brushless ERM (BLDC), Linear Resonant Actuators (LRA) |

Shapes | Cylindrical, Coin-shaped, Encased, or Fully Enclosed |

Brushed motors wear out faster; BLDC and LRA last longer without brushes. | |

Vibration Strength | Increases with higher voltage, creating more torque and force. |

Vibration Speed | Matches motor speed; important for specific uses, especially with LRAs. |

Attachment Methods | Includes sticky backing for coin motors or screws for others. |

Check out INEED's motors for dependable and customizable options for your devices.

FAQ

How long do ERM vibration motors last?

The lifespan varies by motor type. Brushed motors last 100–600 hours because the brushes wear out. Brushless motors and LRAs last over 1,000 hours, making them better for long-term use. Regular care can help them last longer.

How can I pick the right vibration motor?

First, think about what your device needs. Look at size, vibration strength, and how long it will last. Coin motors are great for small devices. Cylindrical motors work well for stronger vibrations. Brushless motors are best for durability. Testing helps you find the perfect match.

Can ERM vibration motors be customized?

Yes, you can change things like size, vibration strength, and how they attach. INEED offers custom options, such as different wire lengths, connectors, and mounting styles. Custom motors ensure a perfect fit for your device.

How can I control an ERM motor's vibration strength?

You can change the vibration strength by adjusting the voltage or using Pulse Width Modulation (PWM). Higher voltage makes stronger vibrations. PWM gives more precise control. Both methods let you create custom vibration patterns.

Where are ERM vibration motors used?

ERM motors are found in phones, wearables, medical tools, and factory machines. They give haptic feedback, alerts, and accuracy in many devices. Their flexibility makes them important in today’s technology.

Tip: Check out INEED's custom motors for dependable solutions made for your industry.

See Also

Understanding Motor Diagrams: Key Parts and Their Roles in ERM Vibration Systems

Compact Battery-Powered Motors: Varieties, Uses, and Energy Efficiency in ERM Vibration Systems

3V Motor Overview: Uses, Features, and Choosing the Right Option for ERM Vibration Systems

Types of Vibration Motors: Uses and Operational Mechanisms Explained

A Comprehensive Resource on Vibration Motors: Varieties, Uses, and Choosing Guidelines

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry