Motor Control Systems: DC Power Components, Circuits, and Integration Techniques

Motor control systems help you manage electric motors for tasks like moving robots or running HVAC fans. You use these systems to control speed, direction, and torque, making machines work better and save energy. Many industries—from automotive to healthcare—rely on these solutions for precision and efficiency.

Market Segment | Key Insights |

|---|---|

End-User Industries | Automotive (especially EVs), Industrial Automation, Aerospace & Defense, Healthcare, Consumer Electronics |

Energy Savings | Motor control systems contribute to 20%-50% energy reduction in applications like HVAC |

Technology Trends | IoT, AI, predictive maintenance, variable frequency drives (VFDs) |

You can boost performance with real-time feedback, advanced control strategies, and energy-saving features. Learning how to select and connect the right components, circuits, and integration methods helps you build reliable systems for any project.

Key Takeaways

Choose the right DC motor type by matching speed, torque, and efficiency to your project needs for better performance and energy savings.

Use motor drivers and controllers with PWM and feedback sensors to achieve precise speed, direction, and torque control.

Protect your motor system with fuses, thermal switches, and current sensors to prevent damage and ensure safe operation.

Design motor control circuits like H-bridge drives carefully, applying advanced PWM techniques to reduce noise and improve efficiency.

Plan wiring and use EMI mitigation methods such as shielding and filtering to keep your motor control system reliable and noise-free.

Motor Control Systems Overview

DC Motor Basics

You start with understanding how a dc motor works. A dc motor uses direct current to create motion. When you apply voltage to the terminals, the motor spins. You can change the direction by switching the polarity. Key specifications help you pick the right dc motor for your project:

Speed (measured in RPM) tells you how fast the motor turns.

Torque shows the turning force. You need more torque for heavier loads.

Current and voltage ratings help you match the motor to your power supply.

Efficiency tells you how much energy the motor uses to do work.

Performance curves show how speed, torque, and efficiency change as you load the motor. You get the best performance when you run the dc motor near its peak efficiency point. If you push the motor above 60% of its stall torque, you risk overheating and damage.

Key Components

You build motor control systems using several main parts. Each part plays a role in controlling the dc motor:

Controller: This part sends commands to the motor.

Sensor: It measures speed, position, or current.

Actuator: The dc motor itself acts as the actuator, turning electrical energy into motion.

When you select components, consider these factors:

Motion profile control for precise movement

Environmental conditions like dust or moisture

Maintenance needs and expected lifespan

Noise levels and energy efficiency

Space and integration with other parts

Total cost over time

Tip: Use online tools to compare dc motor specs and find the best fit for your application.

System Functions

You use dc motor control to manage speed, direction, and torque. Modern systems use advanced controllers that improve performance. For example, adaptive controllers can reduce errors and respond quickly to changes in load. Some systems use artificial intelligence to optimize how the dc motor runs, making it more efficient and reliable. These functions help you get steady speed, quick response, and safe operation, even when conditions change.

DC Motor Power Components

When you build a reliable dc motor control system, you need to choose the right dc power components. Each part affects how your motor, drive, and circuit work together. You can boost performance, safety, and efficiency by understanding the main types of dc motors, drivers, protection devices, and feedback sensors.

DC Motor Types

You have several dc motor types to choose from. Each type has unique features that affect your project’s performance, torque, and control. Here is a table to help you compare the most common dc motor types:

DC Motor Type | Key Features & Performance Stats | Typical Efficiency | Starting Torque | Speed Regulation | Maintenance | Control Capability |

|---|---|---|---|---|---|---|

Brushed DC Motor | Simple, low cost, easy to control, brush wear limits life | Superior | Superior | High (variable) | Moderate | Basic, possible servo |

Brushless DC Motor (BLDC) | High efficiency, long life, needs electronic driver, low maintenance | 85% - 90% | High | Excellent | Low | High, servo possible |

Permanent Magnet DC Motor | Compact, uses rare earth magnets, good efficiency | Moderate to High | High | Good | Low | Moderate |

Shunt-Wound DC Motor | Stable speed, field and armature in parallel | Moderate | Moderate | Excellent | Moderate | Moderate |

Series-Wound DC Motor | Very high starting torque, speed varies with load | Moderate | Very High | Poor | Moderate | Low |

Compound DC Motor | Mix of series and shunt, improved torque and speed regulation | Moderate | High | Good | Moderate | Moderate |

Servo DC Motor | Built-in feedback, precise positioning, high torque-to-inertia ratio | N/A | High | Excellent | Moderate | Very High |

You should match the dc motor type to your application. For example, brushed dc motors work well for simple, low-cost projects. Brushless dc motors give you high efficiency and long life, which is great for demanding drives. Permanent magnet dc motors save space and energy. Compound and shunt-wound motors help when you need stable speed or extra torque.

Note: Asia-Pacific leads global brushless dc motor consumption, with over 42% of the market. Industrial automation and electric vehicles use these motors the most. North America and Europe also show strong adoption in automotive, HVAC, and industrial drives.

Motor Drivers and Controllers

You need a motor driver to connect your dc motor to your control circuit. The driver acts as a bridge between your dc power source and the motor. It lets you adjust speed, direction, and torque. You can use different types of drivers, such as H-bridge circuits, MOSFET drivers, or integrated driver ICs.

A motor controller sends signals to the driver. It decides how the motor should move based on your commands or feedback from sensors. Some controllers use simple logic, while others use microcontrollers or DSPs for advanced control.

Testing shows that popular drivers like SPARK and Victor SP perform almost the same in real-world robot drives. Both give you linear response and low voltage drop under load. You can use hardware-in-the-loop simulation to test your controller’s performance before you build the actual circuit. This method helps you find problems early and improve your drive’s reliability.

Segment/Region | Market Share / CAGR / Value | Year / Period |

|---|---|---|

Consumer Electronics Segment | 29.3% market share | 2022 |

Asia Pacific Region | 41.8% market share, CAGR 7.8% | 2022, forecast period |

North America | CAGR 6.5% | forecast period |

DC Motor Control Devices Market | Valued at USD 1.67 billion, CAGR over 7% | 2023, 2024-2032 |

PWM Controllers Segment | Expected to reach over USD 1 billion | by 2032 |

You should pick a driver that matches your dc motor’s voltage and current ratings. Make sure your controller can handle the type of feedback and control you need. For high-performance drives, use a controller with advanced features like PWM speed control or closed loop system support.

Protection Devices

You must protect your dc motor, driver, and circuit from faults. Protection devices keep your system safe from overcurrent, overvoltage, and overheating. Common protection devices include:

Fuses: Break the circuit if current gets too high.

Circuit breakers: Resettable protection for repeated faults.

Thermal switches: Cut power if the motor gets too hot.

TVS diodes: Protect against voltage spikes.

Current sensors: Detect overloads and shut down the driver.

You should always size your protection devices for your dc motor’s maximum current and voltage. Place them close to the driver and power source for best results. Good protection keeps your drives running longer and prevents costly damage.

Tip: Use a combination of fuses and thermal switches for extra safety in high-power dc drives.

Feedback Sensors

Feedback sensors give your controller real-time data about the motor’s speed, position, and current. This information lets you build a closed loop system for precise dc motor control. Common feedback sensors include:

Hall-effect sensors: Measure speed and direction.

Encoders: Track position and rotation.

Shunt resistors: Monitor current flow.

Temperature sensors: Watch for overheating.

Motor feedback is critical for reliable operation. If a sensor fails, your controller may lose control of the load voltage and the drive can become unstable. Simulation results show that sensor faults cause the system to lose regulation, but control returns when feedback resumes. You can improve reliability by using high-resolution ADCs and low-noise amplifiers in your feedback circuit. Some systems use compensation tables to correct repeatable sensor errors, making your motor feedback more accurate.

Different sensors introduce different phase lag. Incremental encoders have low lag, while resolvers can add more delay. You can use special algorithms to reduce phase lag and improve your drive’s performance.

Note: Always test your feedback sensors during commissioning. Accurate motor feedback helps you achieve stable speed, precise torque, and safe operation in all dc drives.

Motor Control Circuit Design

Designing a reliable motor control circuit helps you achieve precise speed, direction, and torque in your dc motor drive. You need to understand how each circuit works, its benefits, and how to connect it for the best performance. Let’s look at the main types of circuits you will use in motor control systems.

H-Bridge Motor Drive

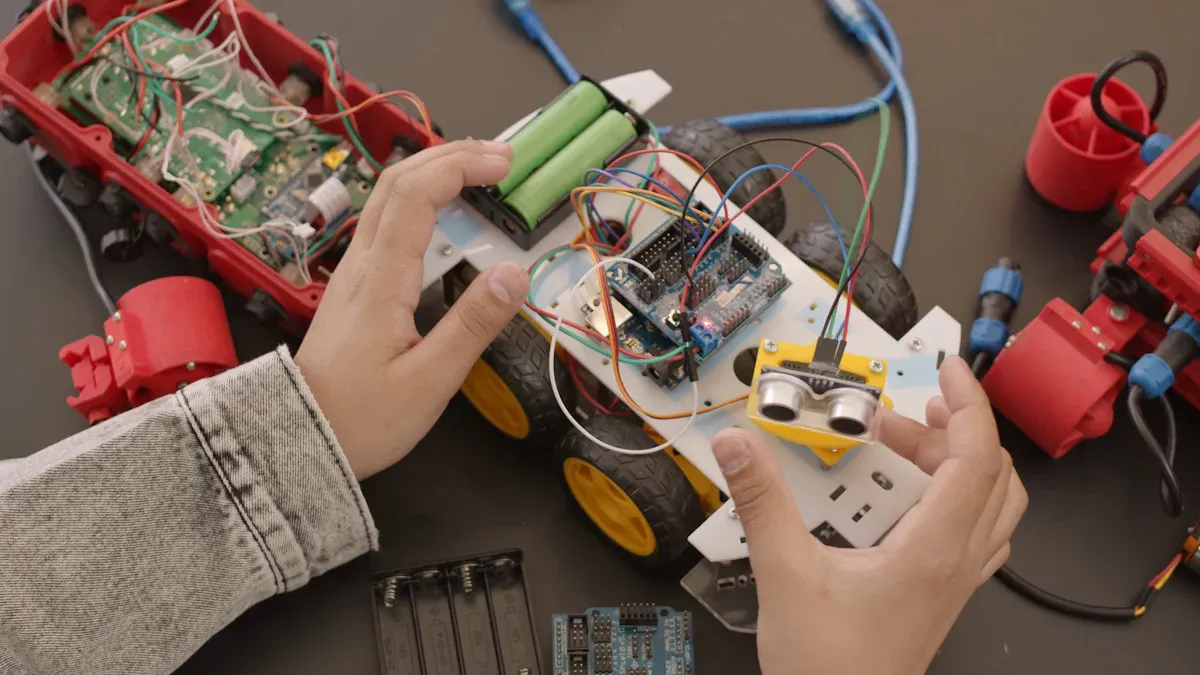

An h-bridge circuit lets you control the direction and speed of a dc motor. You use four switches (often MOSFETs or transistors) arranged in an “H” shape. By turning these switches on and off in different patterns, you can make the motor spin forward, reverse, or stop. This circuit is the foundation of many dc motor drive circuits.

How to Build and Use an H-Bridge Motor Drive:

Connect the four switches in an H pattern around your dc motor.

Use a microcontroller or logic circuit to control the switches.

Apply PWM signals to adjust speed.

Add protection devices like diodes to handle voltage spikes.

Example: You want to control a small robot’s wheels. You use an h-bridge motor drive for each wheel. By changing the switch pattern, you make the robot move forward, backward, or turn.

Performance Metric | Observed Values / Notes |

|---|---|

Stator Voltage THD | 2.22% (at 5 kHz switching frequency) |

Stator Current THD | 1.30% |

Inverter Output Voltage THD | 16.35% under full-load rated torque |

Torque Ripple | Reduced with advanced PWM |

Switching Losses | Lower with optimized PWM, improving efficiency |

Voltage Stress on Switches | Decreases with more h-bridge levels, better reliability |

Thermal Dissipation | Needs good heatsinking; total power dissipation can reach 1450 W |

Gate Driver Requirements | Needs isolation, EMI control, and fast protection for robust operation |

Tip: Use advanced PWM techniques with your h-bridge motor drive to reduce torque ripple and improve efficiency.

Pros:

Simple design for bidirectional control

Works with most dc motors

Supports speed control with PWM

Cons:

Needs careful switch timing to avoid short circuits

Can generate electrical noise (EMI)

Requires good thermal management for high-power motors

You can combine multiple h-bridge circuits for multi-motor systems. Always check your switch ratings to match your dc motor’s voltage and current.

PWM and Speed Control

PWM (Pulse Width Modulation) is a key technique for speed control in dc motor drive circuits. You send a series of on-off pulses to the motor. By changing the width of these pulses, you control how much power the motor receives. This lets you adjust speed smoothly and efficiently.

How to Use PWM for Speed Control:

Connect a PWM-capable controller to your h-bridge or driver circuit.

Set the PWM frequency (often 5 kHz or higher for smooth operation).

Adjust the duty cycle (the “on” time) to set the motor speed.

Use feedback from sensors to fine-tune speed regulation.

Performance Metric | PID Controller | Fuzzy Logic Controller (FLC) |

|---|---|---|

Rise Time | Slower | Faster |

Settling Time | ~0.1 s | ~0.05 s |

Overshoot | Present | None |

Steady-State Error | 0.6 to 1 rpm | None |

Torque Ripple | Noticeable | Significantly reduced |

Dynamic Response | Less smooth | Smoother, faster |

You get better speed control and less torque ripple when you use advanced controllers like fuzzy logic with PWM. These controllers adapt the PWM duty cycle in real time, giving you precise speed even when the load changes. Hardware tests show that fuzzy logic controllers help your dc motor reach target speed faster and with less overshoot than basic PID controllers.

Note: PWM not only improves speed regulation but also reduces mechanical stress and extends motor life.

Pros:

High efficiency for dc motor control

Smooth speed adjustment

Works well with feedback sensors

Cons:

Can cause electrical noise if not filtered

Needs careful tuning for best performance

You should always use PWM with your h-bridge motor drive for the best speed control. Combine it with feedback for closed-loop operation.

Current Sensing

Current sensing is vital in every motor control circuit. It helps you monitor the amount of current flowing through your dc motor. Accurate current sensing protects your circuit, improves performance, and enables advanced features like torque control.

How to Implement Current Sensing:

Choose a sensor type: shunt resistor, Hall-effect sensor, or current transformer.

Place the sensor in series with your motor or driver circuit.

Connect the sensor output to your controller’s analog input.

Use the data for protection, feedback, and performance monitoring.

Technology Type | Typical Accuracy Range |

|---|---|

Hall-effect sensor | 0.9% to 2% |

Shunt resistor | 0.1% to 2% |

Current transformer | 0.1% to 1% |

Rogowski coil | 0.2% to 5% |

Modern amplifiers, like the MAX40056, achieve up to 0.3% full-scale accuracy and reject PWM noise. True RMS transducers give you accurate readings even with distorted waveforms from PWM or nonlinear loads. High-speed response and good common-mode rejection are important for precise current sensing in dc motor drive circuits.

Tip: Use true RMS sensors for the most accurate current measurement in PWM-driven dc motors.

Pros:

Protects your motor and circuit from overloads

Enables precise torque and speed control

Supports advanced diagnostics

Cons:

Adds cost and complexity

Needs careful placement to avoid noise

You should always include current sensing in your motor control circuit. It helps you build safer and more reliable dc motor drive circuits.

Controlled Rectifiers

Controlled rectifiers convert ac power to dc power for your motor drive circuits. You can use them to adjust the output voltage and current, giving you flexible control over your dc motor.

How to Use Controlled Rectifiers:

Choose between semi-converter (half-controlled) or full-converter (fully controlled) designs.

Connect the rectifier to your ac supply and dc motor drive circuit.

Use control signals (like PWM) to adjust the output.

Add filters to smooth the dc output for stable motor operation.

Three-phase controlled rectifiers offer high efficiency by matching dc output power to ac input power.

Semi-converters are simple and cost-effective but need extra filtering due to discontinuous output.

Full converters allow bidirectional power flow and better control but are more complex and produce more harmonics.

Advanced PWM and soft-switching methods reduce switching losses and improve efficiency.

Load conditions affect efficiency; low loads can cause idle losses.

Filtering is essential to reduce output ripple and ensure stable dc power for your motor.

Current-fed PWM control uses a resonant circuit to manage input voltage and switching. This method improves efficiency, reduces electromagnetic interference, and extends the lifespan of switching devices. However, it requires careful tuning and can be costly.

Note: Always match your rectifier type and control strategy to your application’s power and performance needs.

Pros:

Flexible voltage and current control

Supports high-power dc motor drives

Enables efficient energy conversion

Cons:

Can be complex and expensive

Needs good filtering to reduce ripple

Sensitive to load changes

You should select the right controlled rectifier based on your dc motor’s power requirements and your desired level of control. Integrate it with your motor control circuit for efficient and reliable operation.

Integration Techniques

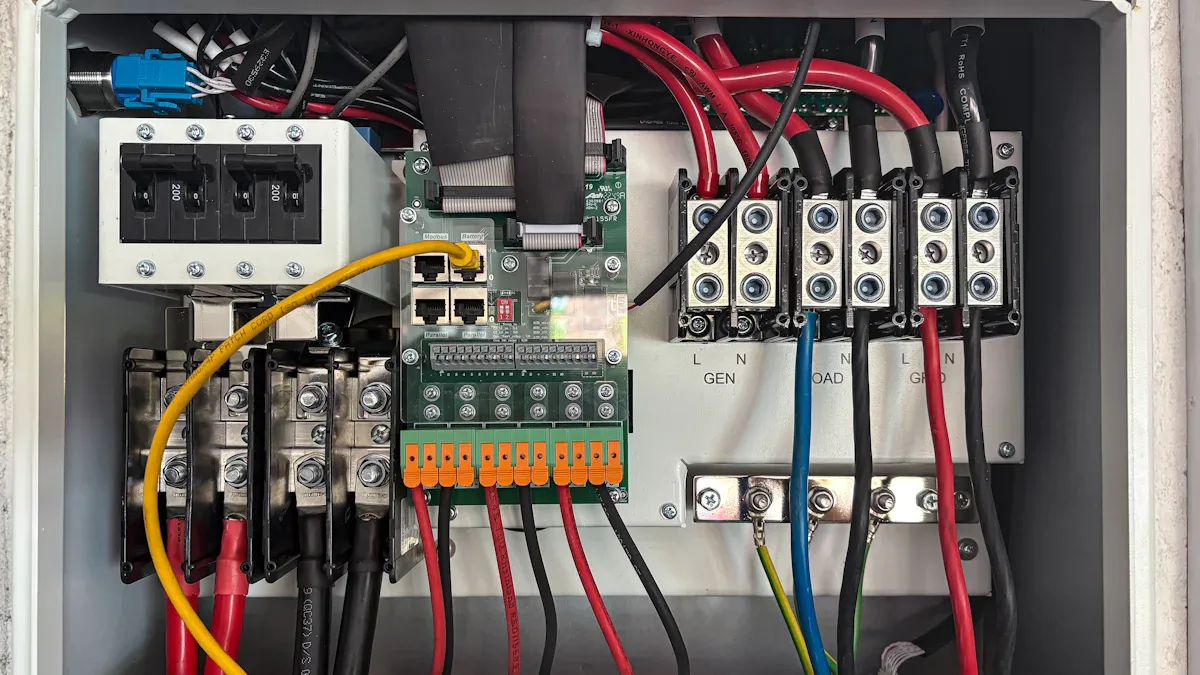

System Wiring

You need to plan your system wiring before you connect any dc motor or power component. Start by drawing a wiring diagram. Label each wire and connection point. Use wires with the right gauge for your dc power and current needs. Shorter wires reduce voltage drop and improve control accuracy. Keep signal wires away from high-power lines to avoid noise. Use color codes for easy troubleshooting. Secure all connections with proper terminals or soldering. Loose wires can cause control failures or even fires.

Tip: Bundle wires neatly and use cable ties. This keeps your dc motor system organized and safe.

EMI Mitigation

Electromagnetic interference (EMI) can disrupt your dc motor control circuits. You can use several proven methods to reduce EMI:

Shielding: Place your dc motor and control circuits in conductive enclosures.

Filtering: Add capacitors or ferrite beads to power and signal lines.

Grounding and Bonding: Connect all metal parts to a low-impedance ground.

Optimized Commutation: Use advanced control algorithms or improve brush design.

Cable Management: Use shielded cables and route them away from noisy power lines.

Studies show that these techniques lower EMI in the critical 150 kHz to 30 MHz range. You can use time-domain and frequency-domain analysis to check your EMI levels. Good EMI control helps your variable frequency drive (vfd) and dc motor run smoothly.

Feedback Integration

You improve your dc motor system by adding feedback sensors. Place sensors to measure speed, position, or current. Connect them to your control board. Use high-resolution sensors for better accuracy. Fast sensors give you quicker response and more precise control. Visual and auditory feedback can boost motor accuracy and learning. If you lose feedback, your dc motor may not perform well. Always test your feedback system before running your vfd or dc drive.

Note: Feedback sensors help you correct errors quickly and keep your dc motor running at the right speed and torque.

Safety Compliance

You must follow safety rules when you build a dc motor control system. Use fuses and circuit breakers to protect against overloads. Add thermal switches to shut down the motor if it gets too hot. Label all high-voltage areas. Cover moving parts to prevent injury. Check that your vfd and variable frequency drive meet local electrical codes. Test your safety devices before starting the system.

Common Pitfalls and Best Practices:

Do not skip wiring checks. Loose wires cause most failures.

Always use EMI filters with your vfd and dc power circuits.

Test feedback sensors for accuracy before full operation.

Never bypass safety devices to save time.

By following these steps, you create a reliable and safe dc motor control system.

DC Motor Drive Circuits: Selection and Implementation

Component Selection

You need to choose each part of your motor control circuit with care. Start by matching the motor type to your project. Decide if you need a brushed or brushless dc motor. Look at the speed, starting torque, and if you need to reverse direction. Pick a controller that can create PWM and direction signals. Make sure your motor driver IC can handle the power your dc motor needs. Always check that your power supply matches the voltage and current for your drives. Add sensors for speed, position, current, and temperature. These help you build closed-loop control for better speed and torque. Use protection devices to keep your dc drives safe from faults. Include passive parts for noise filtering and surge protection.

Component | Criteria / Performance Data |

|---|---|

Controller | Generates PWM and direction signals; logic-level control for speed and direction |

Motor Driver IC | Power handling capability (MOSFETs or IGBTs in H-bridge); amplifies control signals to drive motor coils |

Motor | Type (brushed or brushless DC); starting torque; ability to reverse direction; maintenance needs (brushes) |

Power Supply | Voltage and current matching motor and driver requirements |

Sensors | Speed, position, current, temperature sensors for feedback enabling closed-loop control |

Protection | Overcurrent, overtemperature, fault detection features to ensure reliability |

Passive Components | Noise filtering, signal shaping, surge protection |

Tip: Use variable frequency drives (vfd) for dynamic speed and torque control in advanced dc drives.

Design Checklist

You can follow this checklist to build reliable dc motor drive circuits:

Select the right dc motor for your speed and torque needs.

Choose a controller that supports PWM for speed control.

Match your motor driver to the motor’s voltage and current.

Add sensors for real-time feedback on speed, position, and current.

Use a power supply that meets all load requirements.

Install protection devices for overcurrent and overheating.

Plan your wiring to reduce noise and voltage drop.

Test your motor control circuit before full operation.

Always check your vfd and dc drives for proper grounding and EMI filtering.

Real-World Example

You can see the value of smart design in real projects. One study used an adaptive control strategy with an ARMA model to re-tune PID controller gains for dc motor drive circuits. This method improved the system’s ability to handle changes in load and motor wear. The drives showed smoother speed response and faster settling times. Another case used the Male Gazelle Optimization algorithm to set PID parameters for speed control. The result was better speed regulation and stable operation under different conditions. These examples show that you can boost performance and reliability by using advanced control in your dc motor drive circuits.

You can build reliable DC motor control systems by following proven steps. Choose each component carefully, design robust circuits, and integrate feedback and protection. Regular maintenance and proper installation keep your system safe and efficient. Use this checklist to guide your next project:

Aspect | Details / Specifications |

|---|---|

Protection Settings | Set time delays, use zone-selective interlocking |

Performance Parameters | Keep voltage stable, monitor temperature and vibration |

System Monitoring | Use vibration analysis and thermal imaging |

Installation Clearances | Allow space for access and ventilation |

Environmental Specs | Check temperature, humidity, and enclosure type |

Grounding Layout | Connect all grounds properly |

Maintenance Schedule | Inspect monthly, test quarterly, maintain yearly |

Remember, careful planning and regular checks help you achieve high performance and safety in every DC motor project.

FAQ

How do you choose the right DC motor for your project?

You should look at speed, torque, voltage, and current ratings. Check the size and weight of your load. Match the motor’s features to your application. Use manufacturer datasheets for guidance.

What is the main purpose of an H-bridge in motor control?

An H-bridge lets you control the direction and speed of a DC motor. You can make the motor spin forward or backward. You also use it for smooth speed changes with PWM signals.

Why do you need feedback sensors in a DC motor system?

Feedback sensors help you measure speed, position, or current. You use this data to adjust motor performance. This keeps your system accurate and safe. Closed-loop control depends on good feedback.

How can you reduce electrical noise in your motor control circuits?

You can use shielded cables and add filters like capacitors or ferrite beads. Keep power and signal wires apart. Good grounding also helps. These steps lower noise and improve system reliability.

What safety devices should you include in your DC motor control system?

You should use fuses, circuit breakers, and thermal switches. These devices protect against overloads and overheating. Always test safety devices before running your system. Proper safety keeps your equipment and users safe.

See Also

Eight Creative Uses of Small Motorized Parts in Electronics

Best Ten Uses for 3V DC Motors in Electronics

How to Select Battery Powered Motors for Peak Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry