Motor Brushes Diagram Explained: Critical Components for ERM Vibration Motor Performance and Maintenance

Motor brushes are crucial for ERM vibration motors to function effectively. These small components transmit electricity to the motor's moving parts, ensuring smooth and efficient operation.

Understanding the motor brushes diagram is essential for proper maintenance. For instance:

Spring pressure influences the longevity and performance of the brushes.

Utilizing various brush types can lead to quicker wear on motors and increased costs.

By comprehending the motor brushes diagram, you can prevent issues and maintain optimal performance.

Key Takeaways

Motor brushes help send electricity to the rotor, making motors work.

Checking and replacing old brushes often keeps the motor running well.

Using good brush materials, like carbon or graphite, helps the motor last longer.

Knowing the motor brushes diagram shows important parts for easy fixes.

Watching vibration levels can find problems early and keep the motor strong.

Understanding Motor Brushes in Vibration Motors

What Are Motor Brushes?

Motor brushes are tiny but important parts in motors, like vibration motors. They are usually made from carbon or graphite. These materials are good at carrying electricity and help things move smoothly. Brushes connect the still parts to the moving parts of the motor. This lets electricity flow easily.

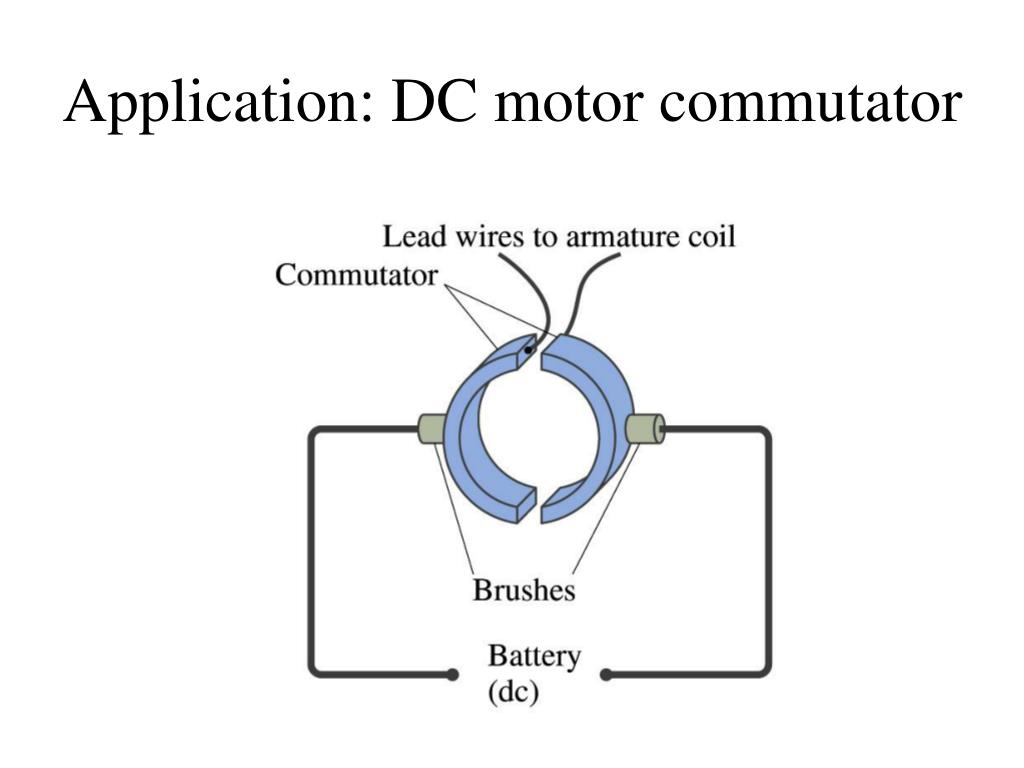

Think of motor brushes as a bridge. They carry electricity from the power source to the motor's rotor. This electricity makes the rotor spin, which is needed for vibration. Brushes touch the commutator, a spinning part of the motor, by sliding. This sliding keeps the energy flowing, even when the motor spins fast.

Key features of motor brushes are:

Carbon Brush: Moves electricity from the power to the rotor.

Sliding Contact: Keeps electricity flowing by sliding on the commutator.

Material: Usually graphite, which conducts electricity and helps things move smoothly.

Feature | Brushed DC Motor | Vibration Motors (General) |

|---|---|---|

Control Method | Changing voltage changes speed and direction | Depends on design |

Noise Generation | Noise from brush and commutator touching | Varies |

Maintenance | Needs regular care because brushes wear out | Varies |

Brush Material | Often graphite, which conducts and lubricates | Varies |

How Motor Brushes Work in ERM Vibration Motors

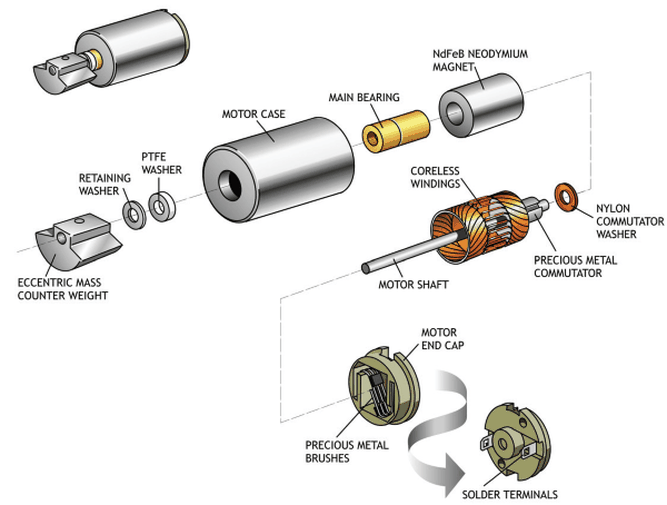

In ERM (Eccentric Rotating Mass) vibration motors, brushes help change electricity into vibrations. These motors have a weight that is not balanced on the rotor. When the rotor spins, this weight makes vibrations you can feel.

Brushes touch the commutator to keep electricity going to the rotor. This is very important for the motor to work. The commutator, usually made of copper, works with brushes to switch the electricity's direction as the rotor spins. This switching keeps the rotor spinning evenly, which is needed for steady vibrations.

Component | Description | Key Points |

|---|---|---|

Brushes | Small carbon or graphite pieces that touch the commutator to send electricity to the rotor. | - Material: Carbon brushes last long and conduct well. |

Wear and Tear: Change them often for best performance.

Contact Quality: Good contact helps energy move better. | | Commutator | A round rotor part that works with brushes to change electricity's direction. | - Construction: Made of copper with insulation to last long.

Maintenance: Clean it for good performance.

Role in Performance: A clean commutator helps smooth running and saves energy.

The sliding contact between brushes and the commutator has springs to keep pressure steady. This design keeps brushes in place even when the motor shakes. But, this contact wears them out, so regular care is needed.

Why Motor Brushes Are Essential for Vibration Performance

Motor brushes affect how well vibration motors work. Picking the right brush material helps energy move well and reduces wear, especially in tough places. Carbon brushes are strong and keep good contact with the commutator.

Good contact between brushes and the commutator is key to reducing wear and stopping sparks. Bad contact can cause uneven vibrations, less motor power, and even motor breakdown. Regular care, like cleaning the commutator and changing worn brushes, stops these problems.

You can make your vibration motor work better by doing these:

Brush Material: Pick strong carbon brushes for better electricity flow and long life.

Maintenance: Check and change brushes often to stop motor problems.

Contact Quality: Make sure brushes and commutator touch well for smooth running.

By knowing about motor brushes, you can keep vibrations steady and make your motor last longer. This is really important for things like wearable gadgets or factory machines where steady vibrations matter.

Motor Brushes Diagram: Parts and Their Jobs

Important Parts in a Motor Brushes Diagram

A motor brushes diagram shows the key parts that help a motor work well. Knowing these parts helps you fix and take care of your motor. The diagram usually includes these:

Brushes: Tiny parts that send electricity to the motor's rotor.

Commutator: A spinning piece that works with brushes to guide electricity.

Brush Holder: Holds brushes steady and keeps them touching the commutator.

Springs: Push brushes to stay in contact with the commutator.

Armature: A spinning coil that moves by working with the magnetic field.

Each part is important for smooth running and steady vibrations. Checking these parts often can stop problems and make the motor last longer.

Brush Material and How It Affects Performance

The type of material used for brushes changes how the motor works and lasts. Different materials are good for different jobs. Here’s a look at common brush materials:

Brush Material | Features |

|---|---|

Carbon-Copper Brushes | Better at carrying electricity, great for fast motors and changing loads. |

Graphite Brushes | Less friction, smoother running, less wear, good for hot places. |

Metal Alloy Brushes | Stronger and made for special uses with specific electricity needs. |

For vibration motors, graphite brushes are often the best choice. They run smoothly and wear out slower, making them great for things like wearables or factory machines needing steady vibrations.

How the Commutator and Brush Holder Help Vibration Motors

The commutator and brush holder are very important for vibration motors. The commutator, a split ring, keeps electricity flowing in one direction. This makes a full circuit with the brushes and keeps the rotor spinning to create vibrations.

The brush holder keeps brushes in place and ensures they touch the commutator properly. Springs in the holder press the brushes down, so electricity flows without stopping. Together, these parts help the motor run well and give steady vibrations.

Part | Job |

|---|---|

Carbon Brushes | Important but wear out easily; can be replaced quickly. |

Commutator | A split ring that keeps electricity flowing in one direction, completing the circuit with brushes. |

Armature Loop | Turns into an electromagnet when powered, spinning by reacting with stator magnets. |

Current Flow | The commutator switches current direction, changing the magnetic field to keep the rotor moving. |

Taking care of these parts helps your motor work smoothly and keeps vibrations steady.

How Motor Brushes Affect Vibration Motor Performance

How Brushes Help Electricity Flow in Motors

Motor brushes are key for electricity to move in motors. They connect the still parts of the motor to the spinning rotor. Without this link, the motor can't make vibrations for its tasks.

The brush material changes how well the motor works. Carbon brushes are great at carrying electricity and lower friction. This helps energy move smoothly and wastes less power. When brushes touch the commutator well, the motor runs efficiently with steady vibrations.

To keep the motor working well, check the brushes often. Worn brushes can block electricity flow, causing weak performance and uneven vibrations. Replace them quickly to keep the motor strong and lasting longer.

Wear and Tear: How It Changes Vibrations

Motor brushes wear out over time because they rub on the commutator. This wear can weaken the motor's vibrations or make it stop working sometimes.

Where the motor is used also affects brush wear. Dust, heat, and moisture can make brushes wear out faster. For example, motors in factories that run a lot need brush changes more often.

Check the brushes often to avoid problems. Look for uneven wear or too much sparking, which can mean trouble. Cleaning the commutator and keeping the springs tight can help brushes last longer and keep vibrations steady.

Keeping Vibrations Steady

Steady vibrations are important for motors to work well. To do this, take care of the brushes and watch for problems. Knowing normal vibration levels helps you spot issues early and fix them fast.

Watching vibrations has many benefits:

It helps you know what normal vibrations feel like.

It lets you fix problems quickly when something feels off.

Using sensors to predict when maintenance is needed is also smart. This way, you can fix things before they break, saving time and keeping the motor running smoothly.

Keeping records of maintenance and checking data can help even more. These records show how the motor behaves, so you can decide when to repair or replace parts.

By taking care of the motor and watching it closely, you can make sure it works well. Whether it's for a gadget you wear or a factory machine, steady vibrations are always important.

Troubleshooting and Maintaining Motor Brushes in Vibration Motors

Finding Common Problems with Motor Brushes

Motor brushes can have problems that hurt motor performance. Spotting these early can save time and money. Here’s a simple list of common issues and their causes:

Problem | Reason | Fix |

|---|---|---|

Brushes might be dirty, worn out, or not fitting right. | Clean or replace the brushes as needed. | |

7). Brushes sparking | Brushes may not have enough pressure or are set poorly. | Adjust the brush pressure and position. |

Check the brushes often to catch these problems early. Watch for things like too much sparking, uneven wear, or trouble starting the motor. These signs usually mean the brushes or their setup need fixing.

How to Replace or Fix Motor Brushes

Changing or fixing motor brushes is easy if you follow steps. Here’s what to do:

Turn off the motor: Make sure the motor is off and unplugged for safety.

Find the brushes: Open the motor case to see the brushes. Use the manual for help.

Check the brushes: Look for wear, cracks, or uneven spots. Replace worn brushes.

Take out old brushes: Gently remove damaged brushes from the holder.

Put in new brushes: Place new brushes in the holder. Make sure they fit well and touch the commutator.

Test the motor: Close the motor and test it to ensure it works smoothly.

Always use brushes that match your motor’s needs. This helps the motor work better and protects the commutator.

Keeping Vibration Motors in Good Shape

Taking care of your motor helps it last longer. Regular maintenance improves how it works and stops sudden breakdowns. Follow these tips:

Check the motor every six months or more in tough conditions.

Add oil to the bearings to reduce heat and friction.

Use vibration tools to find problems early by watching vibration patterns.

By doing these things, your motor will work well for a long time. A cared-for motor gives steady vibrations, whether for gadgets or machines.

INEED's Expertise in Vibration Motor Solutions

INEED's Reliable Vibration Motors and Custom Options

INEED makes many types of vibration motors for different uses. These include motors like eccentric rotating mass (ERM), linear resonant actuators (LRA), and brushless DC motors. Each motor is built to work well, last long, and be precise. INEED's motors perform reliably, even in tough conditions.

You can customize INEED motors to fit your needs. Choose settings like frequency, amplitude, voltage, and current. Frequency controls how fast the motor vibrates, while amplitude controls how strong the vibrations feel. Voltage and current settings help the motor work efficiently with many devices.

Metric | What It Means | Why It Matters |

|---|---|---|

Frequency shows speed; amplitude shows vibration strength. | Helps pick motors with the right feedback for your device. | |

Voltage and Current | Shows how much power the motor uses. | Ensures the motor works well with your device. |

Longevity and Durability | Tells how long the motor will last. | Durable motors work better in tough conditions. |

Noise Levels | Measures how loud the motor is. | Quiet motors are better for sensitive devices. |

INEED’s custom options ensure your motor fits your device perfectly.

How INEED Improves Motor Brush Performance

INEED uses strong materials like carbon and graphite for motor brushes. These materials help electricity flow smoothly and reduce wear. This keeps the brushes and commutator working well for steady vibrations.

INEED tests every motor carefully. They check brush alignment, pressure, and durability. These tests make sure the motor lasts longer and works better. INEED motors give steady vibrations, even with heavy use.

INEED also helps you take care of your motors. They offer advice on replacing brushes and keeping motors in good shape. This support helps your motor stay strong and work well.

Why Pick INEED for Your Vibration Motor Needs

Choosing INEED means getting reliable and innovative motors. With over 10 years of experience, INEED makes high-quality motors. They follow strict standards like ISO 9001 and meet REACH and RoHS rules.

INEED offers custom motors for many uses, like wearables, medical tools, or factory machines. Their motors use less power, last longer, and work efficiently.

INEED also cares about customers. They provide free samples, deliver on time, and offer great support. By choosing INEED, you get a partner who helps improve your product and keeps users happy.

Motor brushes are important for ERM vibration motors to work well. They help move energy, which affects how the motor vibrates and lasts. Knowing how they work can help you avoid problems and keep the motor running smoothly.

Taking care of the motor is key for it to work its best. Checking vibrations often can help find problems early, like:

Broken parts or misaligned pieces that might cause damage.

Loose parts that can lower how well the motor works.

Problems needing quick fixes to keep machines safe and working well.

INEED is a trusted company for vibration motor solutions. They focus on making strong, custom motors that work reliably for your needs.

FAQ

What do motor brushes do in a vibration motor?

Motor brushes send electricity to the motor's moving parts. This makes the rotor spin, creating vibrations for the motor to work. Without brushes, the motor won't run properly.

How often should motor brushes be replaced?

Replace motor brushes when they are worn down or uneven. Check them every six months or more often if the motor works in tough conditions. This keeps the motor working well.

Why do motor brushes wear out?

Motor brushes wear out because they rub against the commutator. Friction, heat, dust, and moisture make them wear faster. Regular care helps reduce wear and keeps the motor running smoothly.

Can you use any type of brush for a vibration motor?

No, the brush type must fit the motor's needs. Graphite brushes are best for most motors because they last long and work smoothly. Using the wrong brush can cause problems.

How can you keep a vibration motor working well?

To keep the motor working well, clean and check it often. Replace worn brushes, make sure they touch the commutator correctly, and watch vibration levels. These steps help the motor last longer and work better.

See Also

Exploring Motor Diagrams: Key Components and Their Uses

Decoding Motor Diagrams: Vital Parts and Their Roles

Battery-Powered Motors: Varieties, Uses, and Efficiency Tips

3V Motor Overview: Uses, Specs, and Choosing the Right One

Ultimate Guide to Vibration Motors: Varieties, Uses, and Selection

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry