10 Ways Micro Vibration Technology Enhances Precision Devices

Micro vibration technology means controlling tiny, exact vibrations in devices. It helps machines work better and more dependably. This technology is important for precision devices. It reduces extra movement, makes them steadier, and boosts how well they work. For example, anti-vibration parts in medical tools or factory machines give accurate results. They also help the machines last longer. Many industries use this technology to improve devices. It allows new features in healthcare, robots, and gadgets we use every day.

Key Takeaways

Micro vibration technology makes measurements better by cutting noise. This helps collect clearer data.

It keeps moving parts steady, like in robotic arms. This ensures smooth and accurate movements.

By reducing friction, it prevents damage to parts. This helps devices last longer.

It saves energy by stopping extra vibrations. This lowers energy use and makes devices last longer.

This technology helps build smaller and better devices. It is important for wearables and portable medical tools.

Improves Measurement Accuracy

How micro vibration technology reduces noise and interference in measurement systems

Micro vibration technology helps reduce noise and interference in systems. It controls tiny vibrations so devices can collect clear data. Noise can mess up signals, especially in vibrating environments. Advanced methods like ANA-MEMD separate weak signals from background noise. This improves signal clarity, making it easier to find useful data.

Special damping parts in devices also cut unwanted vibrations. These parts keep equipment steady, giving accurate readings even in tough conditions. With better noise control, these systems provide precise measurements for important tasks.

Uses in medical imaging and scientific tools

Micro vibration technology has changed medical imaging and science tools. In medical imaging, anti-vibration systems ensure clear results by stopping small movements. For example:

Spider systems: Test micro vibrations in medical tools for accurate imaging.

GRS equipment: Used on bridges and buildings to check vibrations and safety.

Devices like the 309 Series Hi-Def Video Micrometer show its power. This tool measures tiny movements as small as 0.0001 inches. It avoids mistakes seen in older methods and works in real-time. It gives better accuracy and performance.

In healthcare and research, this technology improves accuracy. It helps with better diagnostics and monitoring for reliable results.

Enhances Stability in Moving Components

How micro vibration technology keeps moving parts steady in robotic arms

Micro vibration technology helps keep moving parts stable. This is especially important for devices like robotic arms. It controls vibrations that might cause errors in movement. Without this control, vibrations can make parts unstable and lead to mistakes. Anti-vibration systems help keep movements smooth and improve how well devices work.

Studies show how certain factors affect stability. For example, the stability value (E) changes with the environment. Amplitude (A) and frequency (F) must stay in the right range. If not, too much vibration or signal problems can happen. The table below explains these effects:

Parameter | Effect on Stability |

|---|---|

E (stability value) | Low in stable places; high in unstable places |

A (amplitude) | Too small: no effect; too big: too much vibration |

F (frequency) | Too low: noisy; too high: vibration stops |

O and V (distances) | Too far: weak signal; too close: direct connection |

Muscle movement | Changes E without touching; should be avoided |

Global posture change | Changes E without contact; should be reduced |

By knowing these factors, you can make systems better at controlling vibrations. This helps moving parts stay steady.

Examples from factories and automation

In factories and automation, micro vibration technology makes machines more stable. Uncontrolled vibrations can cause problems like tool shaking or poor surface quality. They can also damage tools or make them wear out faster. Vibration control fixes these issues and boosts productivity.

Cutting tools with vibration control work better on different machines and materials.

Systems like Seco Tools' Steadyline® reduce vibration even with long tools.

These systems are great for making big parts where stability is very important.

Using anti-vibration systems makes machines run smoother. This leads to better results in factories and automation work.

Reduces Wear and Tear

How micro vibration technology lowers friction and helps parts last longer

Micro vibration technology helps reduce friction in precision devices. Less friction means less damage to parts over time. Special damping systems absorb extra vibrations that can harm equipment. This makes machines work smoothly and last longer. For example, studying vibrations during fast cutting shows how tools wear out. Tracking these vibrations helps predict damage and improve durability.

Study Title | Key Findings | Methodology |

|---|---|---|

Cutting tool monitoring system for high-speed turning using vibration data | 135 tests used sensors to measure vibrations and strain. | |

Research on tool life and vibration in cutting processes | Tool life depends on vibration levels during machining. | Studied tool behavior under different cutting conditions. |

Monitoring tool wear using vibration signal analysis | Vibration signals show changes in tool wear and surface quality. | Tested CNC lathe tools at different times to measure wear. |

Lower friction improves how devices work and cuts repair costs. This makes it a smart choice for industries using precise machines.

Uses in aerospace and car-making industries

In aerospace and car-making, this technology improves safety and efficiency. It solves problems caused by wear and tear. Vibration isolation systems are used in wind tunnels and engine tests. These systems make testing safer and more accurate. They also help assembly lines run better and produce higher-quality products.

In aerospace, ultrasonic vibration cutting (UVC) helps cut tough materials. It ensures precise cuts for parts that need to be very safe.

In car factories, damping systems reduce noise and shaking during assembly. This leads to safer and better-made cars.

By reducing wear and tear, this technology keeps parts safe and lasting longer. It is very useful for industries that depend on advanced machines.

Optimizes Energy Efficiency

How micro vibration technology saves energy in precision devices

Micro vibration technology helps devices use less energy. It stops extra vibrations that waste power. Vibrations make parts work harder, using more energy. Adding damping systems reduces these vibrations and saves energy.

Damping is key to controlling vibrations. It absorbs and spreads out energy from unwanted movements. This keeps devices running smoothly without wasting power. For example, in fast machines, damping systems steady moving parts. This saves energy and makes the device work better.

Using less energy also lowers costs. Devices that save energy need less fixing and make less heat. This helps them last longer. Micro vibration technology makes devices efficient and affordable.

Examples in gadgets and smart devices

Micro vibration technology improves energy use in gadgets. Phones use anti-vibration systems to save battery life. These systems stop energy waste from extra movements. This helps phones last longer on one charge. Gaming consoles also use damping to steady parts. This keeps them working well while using less power.

Smart devices like thermostats and cameras also benefit. They need precise sensors to work right. Damping systems help them stay accurate while saving energy. For example, smart meters use vibration control for exact readings. This saves power and makes them eco-friendly.

Micro vibration technology boosts energy efficiency in many devices. It helps the planet and makes devices last longer and work better.

Enables Miniaturization

How micro vibration technology helps make smaller, better devices

Micro vibration technology is important for making smaller, better devices. It controls tiny vibrations, letting engineers design small parts that still work well. A big step forward is the CMOS-MEMS platform. This combines tiny machines (MEMS) with special circuits (CMOS). Together, they create small sensors and tools.

New CMOS-MEMS methods now allow circuits to fit into tiny devices. This makes them work better while staying small. Scientists have shown how CMOS-MEMS helps build and test devices quickly. It proves that devices can be smaller but still very precise.

Uses in wearable gadgets and portable medical tools

Wearable gadgets like fitness trackers and smartwatches use this technology. Tiny sensors, made with CMOS-MEMS, track health data accurately. These sensors keep devices light and comfy to wear. Anti-vibration systems make the sensors steady, even when you move.

Portable medical tools also use this technology. Small glucose monitors and ECG machines give accurate results. They are easy to carry and use, helping more people get care. Micro vibration technology keeps these tools working well, even in tough conditions.

By helping devices get smaller, micro vibration technology changes how they are made. It creates smarter, smaller tools that improve daily life and healthcare.

Enhances Sensory Feedback

How micro vibration technology improves haptic feedback in devices like smartphones and gaming controllers

Micro vibration technology helps improve the way devices feel. It controls small vibrations to make feedback more realistic. For example, in phones, it makes touchscreens feel like real buttons. Gaming controllers use it to copy real-life sensations, like a car's rumble or a weapon's kickback.

Studies show haptic feedback helps people do tasks better. It makes them faster and more accurate, especially in tricky jobs like robotic surgery. Beginners learn quicker with haptic feedback during training. In medical tools, it lowers pressure to avoid hurting tissues. This shows how important micro vibration technology is for creating better feedback systems.

Provide examples from the tech and entertainment industries

Tech and entertainment use micro vibration technology to make things more fun. In gaming, it makes virtual worlds feel real. Game consoles now have advanced vibrations to copy real-life feelings. Haptic gloves and suits let you feel textures and movements in AR and VR.

Phones also use this technology for better feedback. It makes typing, scrolling, and gaming smoother and more enjoyable. As haptic feedback improves, new ideas will come. These include better training tools and cooler gaming systems.

Improves Material Processing

How micro vibration technology helps in cutting, drilling, and material tasks

Micro vibration technology makes cutting and drilling more precise. It controls vibrations to keep tools steady and reduce mistakes. For example, vibration-assisted machining (VAM) adds tiny vibrations to tools or materials. This lowers cutting forces, giving smoother cuts and better accuracy.

Studies show this technology improves material removal rates (MRR) and precision. Pandey et al. found that vibration-assisted EAM (Electrochemical Additive Manufacturing) worked well on aluminum and boron carbide MMC. It increased MRR and made processes more efficient. In another study, micro milling of hardened steel showed larger vibrations (13.56 m/s²) improved cutting precision. These results prove controlled vibrations help in material processing.

Uses in factories and 3D printing

In factories, micro vibration technology makes tools and machines work better. Anti-vibration systems keep tools steady, reducing wear and improving finishes. This is useful in industries like aerospace and car-making, where precision is key. Vibration-assisted turning and milling help create detailed designs with fewer flaws.

In 3D printing, this technology ensures each layer is accurate. Vibrations during printing can cause errors or misaligned parts. Micro vibration control keeps printers stable, making high-quality and precise prints. This is crucial for complex prototypes or medical implants that need exact details.

Micro vibration technology improves precision and saves time in material tasks. Whether cutting, drilling, or printing, it ensures accurate and reliable results.

Increases Reliability in Harsh Environments

How micro vibration technology ensures device performance in extreme conditions

Micro vibration technology helps devices work well in tough places. Extreme heat, strong shaking, or heavy impacts can harm devices. This technology controls vibrations and cuts noise to keep devices steady.

Anti-vibration systems are very helpful in these cases. They soak up extra vibrations and stop damage to delicate parts. For example, in places with constant stress, these systems protect devices from breaking. This makes sure equipment works even in hard conditions.

Reducing noise is another big advantage. Too much noise can mess up signals and cause mistakes. Micro vibration technology lowers this noise, helping devices work smoothly and give steady results.

Examples from space exploration and military equipment

Space and military tools use micro vibration technology a lot. In space, satellites and spacecraft face strong shaking during launch. Anti-vibration systems guard fragile tools like cameras and sensors. This helps them take clear pictures and data, even in space's vacuum.

Military tools also gain from this technology. Vehicles, drones, and radios work in rough areas or war zones. Micro vibration technology keeps their parts steady and cuts noise problems. For example, vibration-damping mounts in military vehicles make targeting systems more accurate and protect electronics.

By making devices reliable in tough spots, micro vibration technology helps in space and defense. It keeps tools working, accurate, and strong, no matter the challenges.

Helps Advanced Diagnostics

How micro vibration technology makes healthcare and engineering tools better

Micro vibration technology helps improve tools used for diagnostics. It makes devices more accurate and reliable by controlling tiny vibrations. This is very important for tools that need precise measurements, like ultrasound machines or systems that check buildings.

In healthcare, this technology has changed how we see inside the body. New methods like photoacoustic imaging show clear pictures of organs and tissues. These tools also help study chemical activities in the body. For example, acoustic tweezers can sort tiny particles based on their size or shape. This helps find tumor cells or other important particles for tests like liquid biopsies.

In engineering, vibration control improves tools that check the health of structures. These tools find early signs of damage in bridges, buildings, and other big structures. By cutting noise and extra movement, micro vibration technology helps these tools give clear and useful data.

Examples like ultrasound machines and building monitoring systems

Ultrasound machines show how this technology helps diagnostics. They use sound waves to make detailed pictures of organs inside the body. Anti-vibration systems keep the machines steady, so the images are clear and accurate. This helps doctors find problems more easily.

Building monitoring systems also use this technology. These systems have sensors that watch vibrations in bridges or tall buildings. By studying these vibrations, engineers can spot problems early. Fixing issues sooner makes structures safer and saves money on repairs.

With micro vibration technology, diagnostic tools in healthcare and engineering work better. They give more accurate results, helping people and keeping structures safe.

Supports Anti-Vibration Measures

How micro vibration technology helps reduce unwanted vibrations in devices

Micro vibration technology is key to stopping unwanted vibrations. These vibrations can harm how sensitive devices work. Systems like Newport SmartTable use special damping methods to keep devices steady. Unlike older methods, these systems adjust to changing vibrations for better results.

Tools like microscopes and microfabrication machines use pads and springs to stay stable. These parts soak up vibrations, keeping devices accurate. For instance, two-photon polymerization (TPP) needs extreme stability to make tiny 3D designs. Good anti-vibration systems ensure this process stays exact and dependable.

Vibration isolators also help by separating devices from outside movements. This reduces interference and makes tools work better. Whether using delicate sensors or fast tools, anti-vibration systems give steady and reliable results.

Examples in micro pumps and vibration-assisted machining

Micro pumps work better with anti-vibration systems. These small pumps are used in medical tools, chemical labs, and fuel systems. Vibrations can mess up their flow or make them less efficient. Pads and springs stop this, keeping the pumps steady and working well. This also makes them last longer.

In vibration-assisted machining, small vibrations improve cutting and drilling. These vibrations lower cutting forces and make smoother surfaces. Pads keep tools steady, stopping damage during work. Industries like aerospace and car-making use this for detailed, high-quality parts.

By helping with anti-vibration systems, micro vibration technology makes pumps and tools more precise and reliable. It boosts performance and efficiency in many fields.

Micro vibration technology has changed how precision devices work in amazing ways. It makes devices more accurate, stable, and energy-saving. It also helps parts last longer and supports making smaller tools. This technology improves how devices feel and keeps them working in tough places. It is also useful for better testing and making materials. Anti-vibration systems are now key to keeping devices steady and strong.

Industries like space, cars, and healthcare use this technology a lot. For example, vibration-assisted welding makes stronger and better welds. This changes how welding is usually done. By learning more about it, you can find new ideas for your work.

FAQ

What is micro vibration technology?

Micro vibration technology manages very small vibrations in devices. It helps tools work better, stay steady, and use energy wisely. This technology is used in healthcare, space, and factories to make devices more reliable.

How does micro vibration technology improve device accuracy?

It stops noise and controls vibrations to keep data clear. This helps devices give exact results. For instance, medical imaging machines use it to create sharper pictures, helping doctors find problems faster.

Can micro vibration technology save energy?

Yes, it can! It reduces extra vibrations that waste energy. Devices like phones and smart meters use it to save power and last longer.

Where is micro vibration technology used?

It is found in healthcare, space, and electronics. It improves tools like medical machines, satellites, game controllers, and fitness gadgets, making them work better and last longer.

Why is micro vibration technology important for miniaturization?

It helps make smaller, better devices by controlling tiny vibrations. This is key for creating small gadgets like smartwatches and portable medical tools that still work really well.

See Also

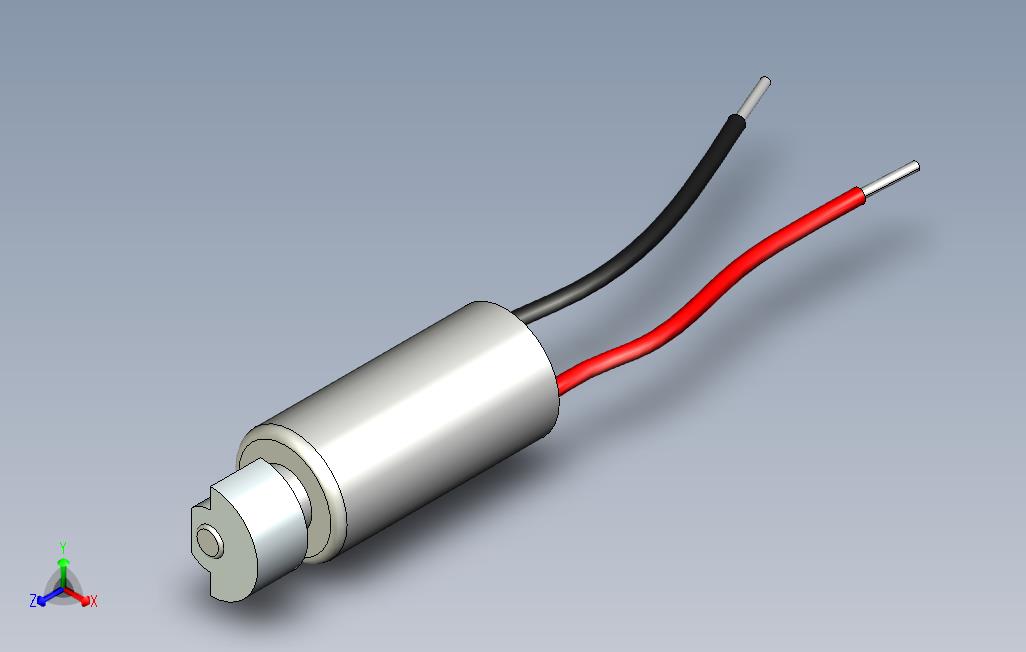

10 Key Uses of Vibrating Motors in Today's Technology

Top 5 Mini Vibration Motors for Wearable Devices

7 Major Industrial Uses of Vibration Motors for Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry