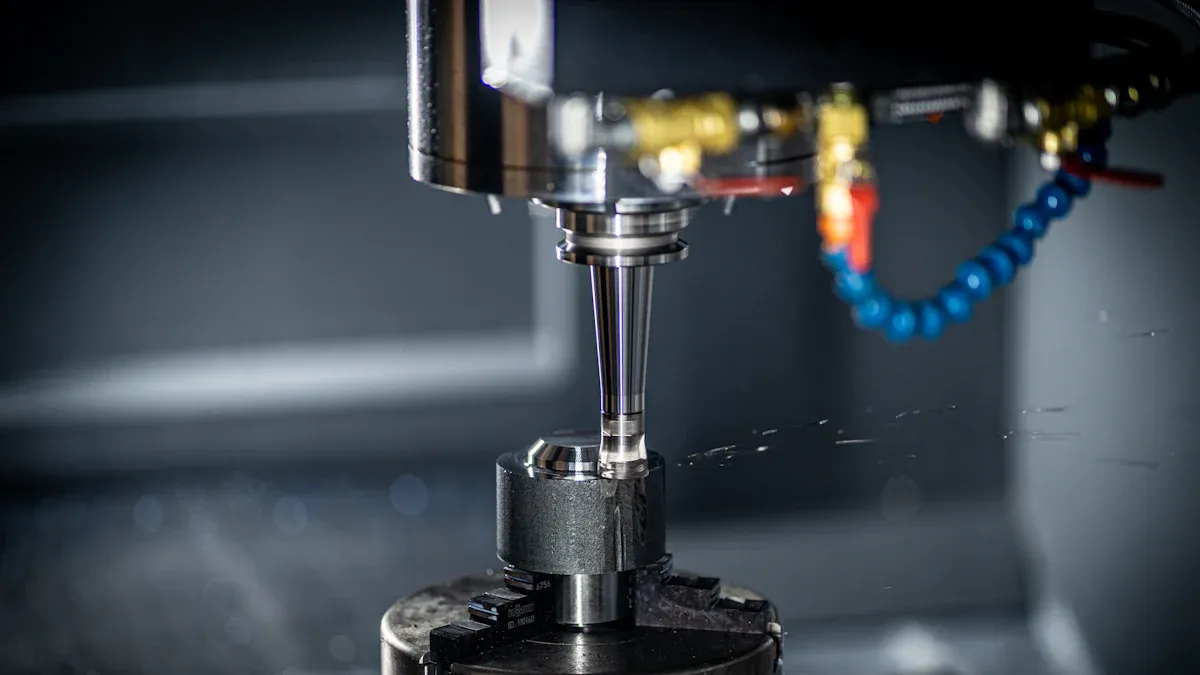

Micro DC Motors: How These Ultra-Compact Power Solutions Work in Precision Applications

Micro DC motors are small but strong tools that turn electricity into movement. Their tiny size makes them perfect for places with little space and where accuracy matters a lot. These motors are used in things like robotic arms, medical tools, and airplane parts.

More industries are using micro DC motors because they are so useful. For example:

In 2022, these motors made up about 61% of the market.

Healthcare tools with these motors are expected to grow by 7.1% each year because of better mini designs.

These motors are also important in cars, gadgets, and factory machines. They are great because they save energy and work well while staying small, making them key to today’s technology.

Key Takeaways

Micro DC motors are tiny but strong, perfect for small spaces like robots and medical tools.

These motors save energy, with brushless types using 90% of power for movement, lowering costs.

They offer precise control, helping with exact movements in tasks like surgery and machines.

Picking the right motor means checking torque, speed, size, and conditions for best results.

Micro DC motors are flexible and good for the planet, used in many modern industries.

How Micro DC Motors Work

Core Components

Micro DC motors have key parts that help them work. These parts change electricity into movement. The main parts are:

Rotor: This spinning part is light and helps save energy.

Stator: The still part holds magnets that create a magnetic field.

Commutator: It changes the current's direction to keep the motor spinning.

Brushes: These pass electricity to the rotor in brushed motors.

Bearings: They hold the rotor and make spinning smoother.

Engineers check things like speed, torque, and resistance to test motors. They also use torque-speed graphs to see how the motor performs.

Principles of Operation

Micro DC motors work using magnets and electricity. When electricity flows, it makes a magnetic field in the rotor. This field pushes against the stator's field, making the rotor turn.

Key ideas include:

Principle | Description |

|---|---|

Electromagnetic Principles | Electricity and magnets work together to create movement. |

Electromagnetic Induction | Changing magnets create electric force in the motor's coil. |

Torque Generation | Movement happens when magnets and electricity push each other. |

Commutation | Current switches direction to keep the rotor spinning. |

Brushless motors use electronics instead of brushes, lasting longer and spinning faster. Engineers use math to predict how motors will act in different situations.

Types of Micro Motors

Micro motors come in different kinds for different jobs:

Brushed DC Motors: These are simple and cheap but need upkeep for brushes.

Brushless DC Motors: These use electronics, not brushes, for better speed and life.

Permanent Magnet DC Motors: These use magnets to save energy and work in small spaces.

Catalytic Motors: These use chemical reactions to move and have special features.

Electrostatic Motors: These use electric forces but aren't strong and have friction issues.

Each type has strengths and weaknesses, studied by engineers. For example:

Micro Motor Type | How It Moves | Features |

|---|---|---|

Catalytic Motors | Uses chemical reactions like breaking down hydrogen peroxide | Great for self-moving and has extra features like magnetism |

Electrostatic Motors | Uses electric forces between parts | Limited use because of weak power and friction problems |

Brushless motors are popular because they are fast and efficient. They are often used in robots and medical tools.

Key Features and Advantages of Micro DC Motors

Compact Design

Micro DC motors are perfect for small spaces. Their tiny size and light weight make them great for tight designs. These motors often work with gearboxes to increase power and lower speed. This helps them work well in small devices.

Important details like size, voltage, and power affect how they work. For example:

Coreless motors are lighter and move faster with less effort.

Brushless motors last longer and work better in small spaces.

These features make micro DC motors useful in drones, medical tools, and robots. They fit into small devices without losing their ability to work well.

Precision and Control

Micro DC motors are made to be very accurate. This makes them great for jobs that need exact movements. Brushless DC (BLDC) motors with gears can control speed and power precisely. This helps them perform smoothly in important tasks like robotics and medical tools.

In medical devices like surgical robots and dental drills, brushless motors are reliable and precise. Their design reduces wear, which keeps them working well during delicate tasks. Also, they don’t overheat, making them dependable for high-precision jobs.

Whether for robotic arms or surgery tools, these motors give the control and accuracy needed to succeed.

Energy Efficiency

Micro DC motors are also very energy-efficient. Brushless motors can turn 85 to 90% of electricity into movement. This means they waste very little energy.

Brushed motors are less efficient, converting only 75 to 80% of energy. Brushless motors save more energy and last longer. This makes them a smart and eco-friendly choice for things like factory machines and portable medical tools.

Using energy-saving micro DC motors lowers costs and keeps performance high.

Applications of Micro Motors in Precision Industries

Robotics and Automation

Micro motors are important for robots, helping them move precisely. These motors are small and light, so they fit in tight spaces. They also make robots more efficient and take up less room in factories.

These motors save energy while still working well. They are quiet, which is helpful in places where noise matters. They also allow robots to move the same way every time, ensuring accuracy.

Benefit | Description |

|---|---|

Compact | Small size means they need less space. |

Lightweight | Light design improves robot efficiency. |

Cost-effective | They are affordable for robot projects. |

Minimal power consumption | Use less energy but still perform well. |

Reduced electromagnetic interference | Work with less interference, making them reliable. |

Quiet operation | Operate quietly, good for noise-sensitive areas. |

Precise, repeatable control | Allow robots to move accurately every time. |

Good low-speed torque | Provide strong force at slow speeds. |

These features make micro motors perfect for robots in factories and services.

Aerospace and Defense

Micro motors are great for aerospace and defense because they are small but powerful. They can handle high speeds, like 10,000 RPM or more, and work in tough conditions. Their strong build meets strict standards like DO-160G and MIL-STD-810.

These motors reduce friction and iron losses, making them last longer. Designs like coreless and slotless motors remove cogging torque, so they run smoothly. Brushless DC motors are best for precise and reliable control.

Parameter | Description |

|---|---|

Torque Density | Small motors give strong force, up to 3-5 times more briefly. |

Friction Losses | Special materials lower friction for better performance. |

Iron Losses | Coreless motors avoid iron losses; iron-core motors reduce them with smart designs. |

Maximum Speed | Can run at 10,000 RPM or more; some designs reach 40,000 RPM. |

Cogging Torque | Coreless and slotless motors avoid this problem. |

Motor Life | Brushed motors wear out faster; brushless motors last longer. |

Inertia | Brushless motors are great for low-inertia tasks. |

Robustness | Brushless motors are tough and work in harsh conditions. |

Compliance | Meet strict aerospace rules like DO-160G and MIL-STD-810. |

These qualities make them ideal for satellites, drones, and guided weapons.

Medical Devices

Micro motors are key in medical tools where accuracy is crucial. They are used in surgical robots, pumps, and drills for precise movements. Their small size fits into tiny devices without losing performance.

Brushless DC motors are especially useful because they last long and don’t wear out quickly. They are quiet, which is important in hospitals. They also save energy while working reliably.

These motors run smoothly, which is needed for delicate tasks. For example, surgical robots use them to perform detailed operations, helping patients recover better. Pumps use them to deliver medicine accurately, keeping patients safe.

Whether for advanced surgery tools or portable devices, micro motors provide the precision and reliability needed in healthcare.

How to Pick the Best Micro DC Motor

Choosing the right micro DC motor needs careful thought. You should consider torque, speed, size, weight, and the environment. This helps the motor work well and last longer.

Torque and Speed Basics

Torque and speed are very important when picking a motor. Torque is the force that makes the motor turn. Speed is how fast it spins. When torque goes up, speed goes down, and the opposite is true. This balance is key for precision tasks.

For example:

If you need high torque to lift heavy things, speed will be lower.

If you need fast spinning, like in medical drills, torque will be less.

Mechanical power comes from torque and speed together. While the balance isn’t always perfect, knowing this helps you get the performance you need.

Tip: Check torque-speed graphs from motor makers. These graphs show how the motor works with different loads. They help you pick the right motor for your job.

Size and Weight Limits

Micro DC motors are used in small spaces or lightweight designs. Picking the right size and weight is important for fitting into your device. A motor too big won’t fit, and one too small might not work well.

Think about these points:

Compactness: Pick a motor that fits your device without losing function.

Weight: Lightweight motors are better for portable tools like drones or robots.

Power-to-Weight Ratio: Choose a motor that gives strong torque for its weight. This is key for small but powerful devices.

Note: Picking the right size saves money. A motor too big costs more, and one too small may fail.

Environmental Needs

Where the motor works affects how well it performs and lasts. Things like heat, moisture, and dust can harm the motor. Picking a motor made for these conditions keeps it running well.

Key points to check:

Temperature Range: Make sure the motor works in your temperature needs. Motors for aerospace or defense must handle extreme heat or cold.

IP Rating: Look at the motor’s IP rating for dust and water protection. Higher ratings mean better safety.

Standards Compliance: Pick motors that meet safety and environmental rules. For example:

Motors in risky areas should follow ATEX safety rules.

Medical motors must meet strict safety standards.

Criteria | What It Means |

|---|---|

Safety Standards | Motors should follow rules like IEC 60034 or UL certifications to stay safe during use. |

Efficiency Rules | Motors should meet energy-saving rules like DOE benchmarks to use less power. |

Environmental Safety | Motors in risky places must follow ATEX or NFPA rules to avoid danger. |

Quality Checks | Motors should meet ISO 9001 standards to ensure they are made well. |

Special Application Rules | Motors for specific uses, like medical tools, must meet extra safety and reliability rules. |

By thinking about these factors, you can pick a motor that works well, stays safe, and lasts in tough conditions.

Micro DC motors are crucial for tasks needing precision. Their small size, energy-saving features, and accurate control make them useful in many fields. They are often found in robots, drones, and medical tools, where being reliable and precise is very important.

Main Benefits

Feature | Explanation |

|---|---|

Energy-Saving | These motors use less power, helping to save energy. |

Small and Light | Their tiny size and light weight fit tight spaces easily. |

Better Motion Control | They work with controllers to move accurately in different tasks. |

These motors also help protect the environment. Frameless brushless DC motors are both high-performing and eco-friendly. This makes them a great choice for industries that care about saving energy.

Tip: Whether you're building robots, machines, or electric cars, micro DC motors are flexible and powerful. They meet modern needs by staying efficient and precise in every use.

FAQ

What makes micro DC motors special?

Micro DC motors are tiny and lightweight compared to regular motors. They fit in small devices and offer accurate control. Their energy-saving design and ability to work in tight spaces make them perfect for robots and medical tools.

How do you take care of a micro DC motor?

Keep the motor clean and dust-free. For brushed motors, check the brushes for wear. Avoid overheating by staying within the recommended voltage and temperature. Regular checks help the motor last longer and work better.

Can micro DC motors survive tough conditions?

Yes, some micro DC motors are built for harsh environments. Choose motors with high IP ratings to resist dust and water. Aerospace motors meet strict rules for extreme heat, cold, and vibrations.

How long do micro DC motors last?

Brushless motors last longer than brushed ones because they have fewer parts. The lifespan depends on how they’re used, cared for, and the conditions they face. Good maintenance can make them last much longer.

How do you pick the right micro DC motor?

First, figure out the torque and speed you need. Think about the size and weight limits of your device. Check if the motor can handle the environment, like heat or moisture. Use torque-speed charts to find the best motor for your job.

See Also

The Value of Mini Brushless Motors in Precision Tasks

Choosing Ideal Mini DC Motors for Industrial Uses

Ten Creative Uses for Mini Motorized Parts in Electronics

Best Ten Uses of 3V DC Motors in Electronics

Guidelines for Selecting Planetary Gear Motors for Screwdrivers

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry