Maintenance Requirements of AC Motors vs DC Motors and their Lifespan Comparison

When you choose between AC motors and DC motors, you want to know which motor will last longer and need less work to keep running. AC motors usually require less maintenance and have a longer lifespan than DC motors. You can see why this matters when you look at how often you must check or repair each type.

AC motors have no brushes, carbon, or commutators, so you do not need to replace these parts often.

DC motors need inspection and brush changes every three months. DC motors are also open to the environment, which means more dirt and more maintenance.

The average lifespan for AC motors under 1 horsepower is about 12 years, with most lasting between 10 and 15 years.

Horsepower Range | Average Lifespan (years) | Lifespan Range (years) |

|---|---|---|

Less than 1 HP | Approximately 12 | 10 to 15 |

If you want a motor that will give you fewer maintenance requirements and more years of service, AC motors stand out as the stronger choice.

Key Takeaways

AC motors need less maintenance because they have no brushes or commutators, which wear out in DC motors.

DC motors require frequent brush inspections and replacements, increasing maintenance time and costs.

AC motors usually last longer, often 10 to 15 years, while DC motors last about 5 to 10 years due to wear on brushes.

Keeping motors clean, cool, and well-lubricated helps extend their lifespan regardless of type.

Choosing AC motors can save money and reduce downtime thanks to their simple design and lower upkeep needs.

AC Motors Overview

Structure and Key Features

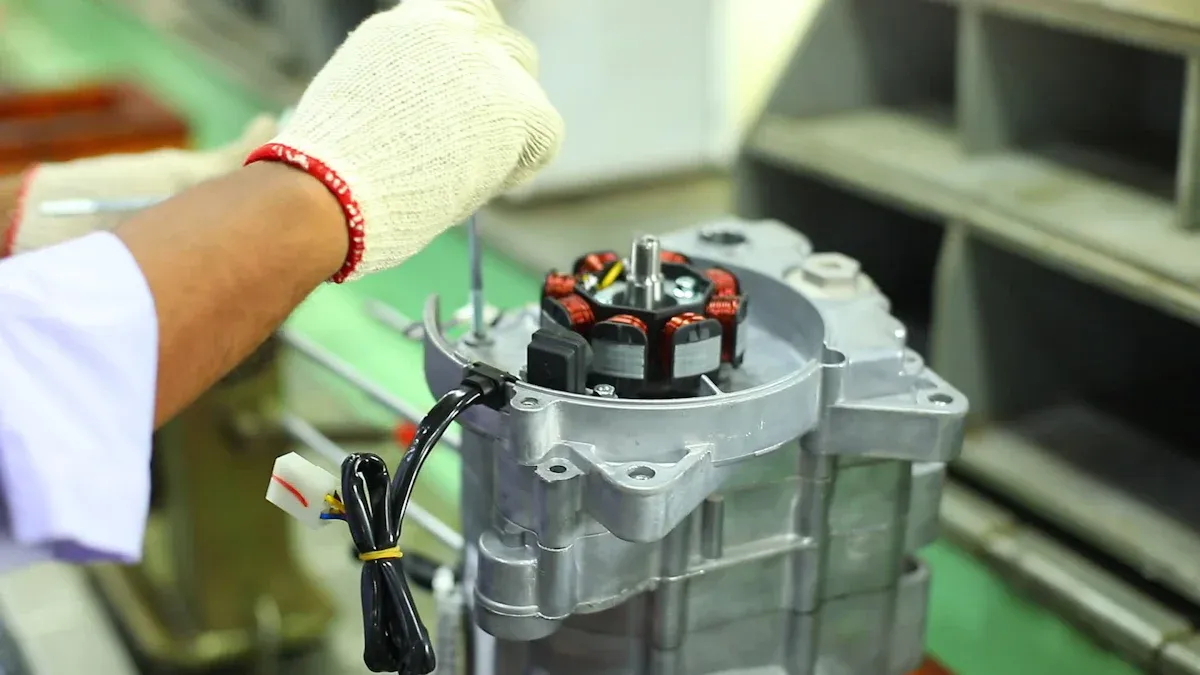

When you look at AC motors, you see a design built for reliability and long service life. You do not find brushes or commutators inside most AC motors. This simple structure means fewer moving parts that can wear out. The main parts include a stator, which stays still, and a rotor, which spins. Many AC motors use a squirrel-cage rotor. This design removes the need for parts that need frequent attention.

You also notice that AC motors use strong materials like cast iron, steel, or aluminum alloys. These materials protect the motor from dust, moisture, and chemicals. Cooling systems, such as fins or fans, keep the motor from overheating. Some motors even use liquid cooling for extra protection. High-quality magnetic materials help improve motor efficiency and reduce energy loss. Good electrical insulation keeps the motor safe from heat and extends its life.

Motor frames shield the inside from dirt and moisture.

Cooling systems prevent overheating and damage.

Strong materials add strength and resist harsh environments.

High-quality magnets and insulation boost motor efficiency and lifespan.

The lack of brushes and commutators means less friction and fewer breakdowns.

Impact on Maintenance

You benefit from lower maintenance requirements when you choose AC motors. The simple design means you do not have to replace brushes or commutators. This reduces the time and cost spent on upkeep. You also avoid problems caused by friction and wear, which are common in motors with more moving parts.

AC motors can handle high voltages and run for long periods without much wear. Improved cooling and heat-resistant materials keep the motor safe from overheating. This means you spend less time worrying about breakdowns. In many industries, AC motors show longer service life and fewer repairs. You get more value and less hassle over the years.

Tip: If you want a motor that needs less attention and lasts longer, AC motors are a smart choice. Their design keeps maintenance needs low and helps you avoid unexpected downtime.

DC Motors Overview

Structure and Key Features

When you look inside dc motors, you find a different design from ac motors. The main parts include the armature, field windings, brushes, and commutator. The brushes sit against the commutator and help transfer electricity to the spinning part of the motor. This setup allows you to control the speed and direction of the motor easily. The brushes and commutator work together to keep the motor running, but they also create friction and heat.

You will notice that dc motors use carbon brushes. These brushes press against the commutator, which is a ring made of copper segments. As the motor spins, the brushes wear down. This design makes dc motors good for applications where you need variable speed or quick starts and stops. However, the moving contact between brushes and commutator means you must pay close attention to their condition.

Note: The brush and commutator system gives you flexibility in controlling the motor, but it also brings extra parts that can wear out over time.

Maintenance Challenges

You face more maintenance tasks with dc motors because of the brushes and commutator. These parts wear out and need regular inspection. If you do not check them, you risk damage to the motor. Experts like Roly Roberge point out that choosing the right brush grade is important. The wrong brush can cause arcing, sparking, or even destroy the commutator. You must also keep the commutator clean and smooth to avoid overheating and poor contact.

You should inspect brushes and commutator every 3 to 6 months, or even monthly in tough environments.

Replace brushes when they wear down to 25% of their original length.

Clean the commutator to remove dirt and burns.

Test electrical connections to prevent arcing and motor failure.

Use wear indicators to know when to replace brushes.

Industry reports show that dc motors need more frequent maintenance than ac motors. The brushes and commutator wear out, so you spend more time and money on upkeep. If you keep good records and follow a strict maintenance schedule, you can extend the life of your dc motor by up to 40%. Still, the need for regular attention makes dc motors less attractive for jobs where you want low maintenance and long service life.

Metric | AC Motor | DC Motor |

|---|---|---|

Maintenance Needs | Lower maintenance due to fewer sub-parts | Higher maintenance due to brushes and commutators requiring frequent replacement |

Tip: If you want a motor that needs less maintenance, dc motors may not be the best choice. The brush and commutator system means you must plan for regular checks and part replacements.

Maintenance Requirements Comparison

AC Motors Maintenance Requirements

When you choose AC motors, you notice that the maintenance requirements are simple. The design of these motors removes many parts that wear out quickly. You do not need to worry about brushes or commutators. This means you spend less time checking and replacing parts. Most of your attention goes to the bearings and the cooling system.

You should check the bearings for signs of wear or lack of lubrication.

You need to keep the motor clean and free from dust.

You should monitor the temperature to prevent overheating.

You can use vibration sensors to spot problems early.

AC motors often use variable frequency drives. These drives help control speed and reduce stress on the motor. This lowers the chance of damage and cuts down on maintenance needs. You can expect fewer breakdowns and longer service life because of these features.

Tip: Regular checks on bearings and cooling systems help you avoid most common issues with AC motors.

DC Motors Maintenance Tasks

DC motors have different maintenance requirements. You must pay close attention to the brushes and commutator. These parts wear down as the motor runs. If you do not replace them in time, the motor can fail.

You need to inspect the brushes every few months.

You must replace brushes when they get too short.

You should clean the commutator to remove dirt and burns.

You need to check the springs that press the brushes against the commutator.

You must test electrical connections to prevent arcing.

DC motors do not use vibration sensors as often as AC motors. Instead, you focus on the moving parts inside the motor. The extra steps add to your workload and increase the chance of missing a problem.

Note: If you skip regular brush checks, you risk damaging the commutator and shortening the motor’s life.

Frequency and Costs

You may wonder why maintenance costs and intervals matter so much. The answer is simple: more maintenance means more time, money, and effort. AC motors need less frequent attention. You can check bearings and cooling systems every six months or once a year. DC motors require you to inspect and replace brushes every three to six months, sometimes even more often in tough environments.

Here is a side-by-side look at the main maintenance tasks for both types:

Maintenance Aspect | AC Motors | DC Motors |

|---|---|---|

Common Issues | Failed windings, shaft bearings (overheating, lack of lubrication) | Brush and commutator wear, arcing, dirt buildup |

Bearing Maintenance | Regular lubrication | Regular lubrication |

Vibration Monitoring | Use of sensors for early problem detection | Not common |

Overheating Detection | Temperature checks and data logging | Temperature checks and data logging |

Brush Maintenance | Not needed | Frequent inspection and replacement |

Electrical/Mechanical Differences | Variable frequency drives reduce stress | Starters limit high startup currents |

You also need to think about costs. Maintenance costs make up about 6% of the total cost of owning a motor. Worker costs are much higher, at 92%. DC motors may cost less to buy, but you spend more on repairs and upkeep because of the brushes. Brushless DC motors cost more at first, but they last longer and need less maintenance. AC motors give you a good balance of low maintenance needs and long service life.

Cost Component | Percentage of Total Costs |

|---|---|

Buying Costs | 2% |

Maintenance Costs | 6% |

Worker Costs | 92% |

Why do these differences matter? If you want to save money and reduce downtime, you should choose a motor with fewer maintenance requirements. AC motors help you avoid frequent repairs and keep your equipment running longer. DC motors give you more control over speed, but you must plan for more regular checks and part replacements.

💡 Choosing the right motor based on maintenance needs can save you time and money over the life of your equipment.

Lifespan Comparison

Typical Lifespan of AC Motors

When you choose AC motors, you often get a longer lifespan. Most AC motors last between 10 and 15 years, with many reaching about 12 years of service under normal use. You see this long life because AC motors have a simple design. They do not use brushes or commutators, so you avoid the main parts that wear out quickly in other motors. The strong materials and good cooling systems in AC motors help them run for many years with little trouble.

You also benefit from better motor efficiency in AC motors. This means less wasted energy and less heat, which helps the motor last longer. If you keep the bearings lubricated and the motor clean, you can expect your AC motor to serve you well for a long time.

Tip: If you want a motor that gives you more years of use and less worry about repairs, AC motors are a smart choice.

Typical Lifespan of DC Motors

DC motors usually have a shorter lifespan than AC motors. Most DC motors last about 5 to 10 years, but heavy use or tough environments can make them wear out even faster. The main reason for this shorter life is the brushes and commutator inside DC motors. These parts rub against each other every time the motor runs. Over time, this causes friction, heat, and wear.

You need to replace the brushes often, and if you do not, the commutator can get damaged. This leads to more repairs and a shorter lifespan. Studies show that heat and electrical corrosion can also hurt DC motors, especially if you use them in places with poor cooling or high humidity. If you want your DC motor to last longer, you must follow a strict maintenance schedule and keep the motor clean and cool.

Note: DC motors give you good speed control, but you pay for it with more maintenance and a shorter lifespan.

Factors Affecting Longevity

You might wonder why some motors last longer than others. Many factors can change the lifespan of both AC and DC motors. If you understand these factors, you can make your motors last longer and work better.

Environmental Factors:

Ambient temperature should stay between 0°C and 40°C. High heat can damage insulation and shorten lifespan.

Elevation matters. Motors work best at 3300 feet or lower. Higher places can cause cooling problems.

Good ventilation is key. Blocked airflow makes motors overheat.

Mechanical shock and vibration can damage bearings and shorten life.

Moisture and humidity can cause rust and break down insulation.

Dust, dirt, and water in the air can get inside motors and cause problems.

Usage Factors:

Frequent starts and stops wear out motors faster. Some motors have a limit on how many times you can start them.

Using the right size motor for your job is important. If the motor is too small, it will overheat and wear out quickly.

Heavy loads on the motor shaft can damage bearings and shorten lifespan.

Keeping bearings clean and well-lubricated helps the motor last longer.

Motors work best when the voltage and frequency match the nameplate values. Big changes can cause damage.

You also need to think about how you repair and maintain your motors. For AC motors, following best repair practices—like controlling burnout temperature and using the right winding methods—can keep motor efficiency high and help the motor last longer. For DC motors, good thermal management and protection from electrical corrosion are very important. If you use your motors in tough places, you should pick designs that protect against heat, dust, and moisture.

Factor | AC Motors Impact | DC Motors Impact |

|---|---|---|

Brush/Commutator Wear | Not present | Major cause of shorter lifespan |

Bearing Maintenance | Important for long life | Important for long life |

Cooling/Ventilation | Helps prevent overheating | Critical to avoid brush damage |

Environmental Exposure | Can cause insulation breakdown | Can cause corrosion and rust |

Usage Patterns | Fewer starts = longer lifespan | Frequent starts = faster wear |

💡 If you want your motors to last, keep them clean, cool, and well-maintained. Pick the right motor for your job and watch for signs of wear.

You should choose AC motors if you want less maintenance and a longer-lasting motor. AC motors do not use brushes or commutators, so you avoid frequent repairs. DC motors need more care because brush wear and sparking happen often, especially at high speeds. When you pick a motor, think about how much time and money you will spend on maintenance. AC motors work well for most jobs and help you save on long-term costs.

AC motors and brushless DC motors need less maintenance than brushed DC motors.

Brushed DC motors require frequent servicing due to brush and commutator wear.

Tip: Always consider the total cost of owning a motor, not just the price at the start.

FAQ

Why do AC motors last longer than DC motors?

You get a longer lifespan from an AC motor because it does not use brushes or a commutator. These parts wear out quickly in a DC motor. The simple design of an AC motor helps it run for many years with less trouble.

Why does a DC motor need more maintenance?

A DC motor uses brushes and a commutator. These parts create friction and wear down over time. You must check and replace them often. If you skip maintenance, the motor can fail much sooner than an AC motor.

Why should you choose an AC motor for low-maintenance needs?

You should pick an AC motor if you want less work. The design has fewer moving parts. You do not need to replace brushes. This means you spend less time and money keeping the motor running well.

Why does the environment affect a motor’s lifespan?

Heat, dust, and moisture can damage any motor. High temperatures break down insulation. Dust and water can get inside and cause rust or short circuits. You should keep your motor clean and cool to help it last longer.

Why do some motors cost more to maintain?

Some motors, like DC types, have parts that wear out fast. You must replace brushes and clean the commutator often. This adds to your costs. An AC motor usually needs less work, so you save money over time.

See Also

How To Maintain Electric Vibration Motors For Longer Life

Choosing The Best Mini DC Motors For Industrial Use

How To Pick The Ideal 3 Volt DC Motor For Projects

Understanding Motor Brushes Diagrams For ERM Vibration Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry