Why Permanent Magnets Are Key to Modern Electric Motors

Permanent magnets, especially the magnet for motor applications, play a crucial role in modern electric motors. These magnets enhance motor performance and reduce energy consumption. They also contribute to making motors more compact and reliable. A magnet for motor use generates strong magnetic fields without requiring additional power. Rare-earth magnets such as Nd-Fe-B and Sm-Co provide increased torque and power, enabling engineers to design lighter motors with fewer components. The table below illustrates how these magnets benefit a motor:

Magnet Type | Benefit | Effect on Motor |

|---|---|---|

Nd-Fe-B, Sm-Co | Strong magnetic properties | Higher efficiency |

Soft Magnetic | Reduces energy losses | Lower heat generation |

Key Takeaways

Permanent magnets help electric motors work better. They make strong magnetic fields without needing extra power. This saves energy and makes less heat.

These motors are smaller and lighter. Rare-earth magnets give a lot of power in a small size. This makes them good for things like smartphones and electric cars.

Permanent magnet motors are dependable and quiet. They give steady torque and last longer. They also need less fixing.

Using rare-earth materials in magnets can be costly. It can also hurt the environment. New designs and recycling try to fix these problems.

Permanent magnet motors run many important things. They are in electric vehicles, home appliances, wind turbines, and medical devices. They help save energy and protect the planet.

Permanent Magnet Motors

How They Work

Permanent magnet motors use a magnet for motor operation. This creates a strong and steady magnetic field. The rotor has magnets made from ndfeb or samarium cobalt. These magnets do not need extra power to work. When electric current goes through the stator coils, it makes another magnetic field. The two fields push and pull on each other. This makes the rotor spin. The spinning changes electrical energy into motion.

Many permanent magnets in these motors use rare earth materials like ndfeb. These materials make the magnet for motor applications strong but small.

The design does not need extra windings or outside power for the magnetic field. This makes permanent magnet motors simpler and more efficient than other types.

Permanent magnet synchronous motors keep the rotor spinning at the same speed as the stator’s magnetic field. This helps the motor give steady torque and smooth movement.

Tip: Using a magnet for motor design lets engineers build motors that are smaller, lighter, and stronger.

Magnet for Micro Vibration Motor

A magnet for motor use is also important in micro vibration motors. These tiny motors are found in things like smartphones and wearables. The permanent magnet motors in these devices use small but strong magnets, often made from ndfeb, to make the needed magnetic field. The small size of the magnet for motor applications lets the motor fit in tight spaces. It still gives enough force for vibration.

Comparison Table: Permanent Magnet Motors vs. Induction Motors

Feature | Permanent Magnet Synchronous Motor (PMSM) | AC Induction Motor (ACIM) |

|---|---|---|

Rotor Driving Principle | Rotor has permanent magnets; rotor spins with stator's magnetic field | Rotor current made by electromagnetic induction; rotor spins at a different speed |

Rotor Speed | Spins with stator magnetic field | Always a little slower than stator magnetic field |

Requirement for Drive | Needs a variable frequency drive (VFD) for speed control | Can work without VFD but often uses one for better efficiency |

Efficiency and Size | More efficient and smaller | Usually less efficient and bigger |

Cost and Complexity | Costs more and needs a drive | Costs less and can work without a drive |

Permanent magnet motors are known for being efficient, small, and giving steady performance. Using a magnet for motor design, especially with new materials, helps make better electric motors.

Benefits

Efficiency

Permanent magnet motors work very well in many places. These motors use a magnet for motor design to make a strong magnetic field. They do not need extra energy for this. This helps machines and appliances use less electricity. Studies show these motors use 22-42% less energy than old AC motors in homes. People who use these motors at home can save about 30% on solar energy system costs. Factories and businesses also save energy with these motors. This makes them better for the environment.

Permanent magnet motors do not get as hot as other motors. Their special design lowers core losses and eddy current losses. This means less energy is wasted. Good heat control keeps the motor cool, even when used a lot. The motors run quietly and move smoothly. This makes them work better and makes less noise. High power density lets these motors give more power in a small size. The motors keep steady torque at different speeds. This helps machines work well and last longer.

Note: Permanent magnet motors help save energy and money at home and at work. They are very efficient and quiet, so they are a good choice for new technology.

Compact Size

Permanent magnet motors are small because of their strong magnet for motor design. Engineers use rare-earth materials to make small but strong magnets. This lets the motor fit in tight spaces and still be powerful. These motors have high power density. This means they give more power for their size than other motors.

Many things like smartphones and electric cars need small, light motors. Permanent magnet motors are good for this. They give steady torque and high torque in a small size. The motors also let you control them very well. This is important for things that need to move just right. Their small size makes them great for portable and space-saving products.

Feature | Permanent Magnet Motor | Induction Motor |

|---|---|---|

Size | Smaller | Larger |

Power Density | High | Lower |

Torque Consistency | Constant | Variable |

Reliability

Permanent magnet motors are very reliable in many ways. They have fewer moving parts, so they break less often. Their design gives steady torque and high torque, even at low speeds. This helps machines and appliances work well for a long time. The motors also run quietly, so there is less noise and shaking.

Permanent magnet motors work well even in tough places. They keep full torque and good control, even if the voltage is low or the power is not steady. This makes them good for places with weak power. The motors last a long time because they do not get too hot and need less fixing. Their high efficiency and high power density help them work well in many jobs.

Tip: Permanent magnet motors give steady torque and good control. This makes them great for important things like medical devices and renewable energy systems.

Challenges

Materials

Permanent magnet motors need rare-earth materials like ndfeb, dysprosium, and terbium. These materials help make strong magnets for motor designs. The price of ndfeb and other rare-earth elements changes a lot. Prices can go up or down quickly. This makes it hard for companies to plan ahead. Manufacturers use different ways to handle these costs:

They use rare earth saving technologies to use less dysprosium and terbium.

They sign long-term supply deals to keep prices steady.

They make products better by using high-performance magnets or new system designs.

Rare-Earth Material | Price Trend (2021-2024) | Impact on Motor Cost |

|---|---|---|

Neodymium | Fluctuating | Cost pressure |

Dysprosium | Fluctuating | Cost pressure |

Terbium | Fluctuating | Cost pressure |

Ndfeb magnets are very strong, but making them needs a steady supply of rare-earth elements. Government rules also change how companies get these materials. Some countries limit where ndfeb and samarium cobalt magnets can be made. New laws will soon make companies show where their magnets come from. These rules make the supply chain harder and can raise costs.

Better magnet designs help fix some problems. Engineers add rare-earth elements to ndfeb to make magnets stronger and better with heat. They use special processing to use less heavy rare earths. New materials like nitrogen-iron compounds and hybrid designs give strong performance without only using rare earths.

Sustainability

Mining and processing rare-earth materials for ndfeb magnets causes many environmental problems. Open-pit mining destroys animal homes and can turn land into desert. Big machines remove soil and plants, which hurts animals. Water pollution happens when acid and heavy metals get into rivers and lakes. Processing uses strong chemicals that can poison farms and drinking water. Radioactive waste builds up and can make people sick.

Note: Making ndfeb magnets helps green technology, but mining can hurt the environment.

Air pollution from dust and toxic fumes can make people sick. Soil loses nutrients and can wash away more easily. Processing uses a lot of energy, often from coal, which adds to greenhouse gases. Water use is also very high, which can stress local water supplies.

Recycling ndfeb magnets from old motors is hard. Not enough motors get sent to recycling centers. Motors have different amounts of rare earths, so sorting is tough. Taking motors apart by hand costs too much. Machines have trouble because magnets are strong and motors are small. Many motors do not have clear labels about their magnet types, which makes recycling even harder.

New materials help lower these problems. Some new motors use electromagnets or switched reluctance motors, which do not need ndfeb. Scientists have made hybrid magnets with cobalt and nano-carbon molecules. These magnets work well and may work at room temperature soon. These advances could mean less rare-earth mining and make electric motors better for the planet.

Applications

Permanent magnet motors are used in many new technologies. These motors are found in electric cars, factories, home energy systems, and medical tools. They work well, are small, and run quietly. Engineers like them because they are the best choice for many jobs.

Electric Vehicles

Electric cars use permanent magnet motors for strong power and good efficiency. Studies show that in 2021, 84% of electric cars had these motors. In early 2022, this number went up to 86%. Car companies pick these motors because they give more power, better performance, and less noise. Drivers feel smooth starts and quiet rides. The motors help cars go farther before needing to charge.

Industry

Factories use permanent magnet motors for many jobs. These motors run pumps, fans, belts, and robots. Workers trust them because they keep a steady speed and do not break often. The motors save energy and help machines work longer. Many factories pick them because they are quiet and last a long time. Permanent magnet motors also help save money by using less electricity.

Home & Energy

Permanent magnet motors are important in clean energy systems. Wind turbines use these motors to make electricity from wind. The motors work up to 20% better than old ones. Some wind turbines use neodymium magnets and do not need gearboxes. This means less fixing and more trust. Offshore wind farms use samarium-cobalt magnets because they can handle heat and water. Home machines like washers and air conditioners use these motors to save energy and run quietly.

Permanent magnet motors help homes and energy systems use less power and be more earth-friendly.

Medical

Medical tools need motors that are small, safe, and quiet. Permanent magnet motors are perfect for this. They use strong magnets like Neodymium Iron Boron to save space and give lots of power. Doctors and patients like how the motors work smoothly and quietly. These motors work in hot or cold places and do not need oil, so they are safer and cleaner. Hospitals use them in breathing machines, pumps, and scanners for better care and safety.

Application Area | Key Benefit | Example Use |

|---|---|---|

Electric Vehicles | High efficiency, low noise | EV drive motors |

Industry | Reliable, energy saving | Factory automation |

Home & Energy | Sustainable, efficient | Wind turbines, appliances |

Medical | Compact, quiet, safe | Medical pumps, scanners |

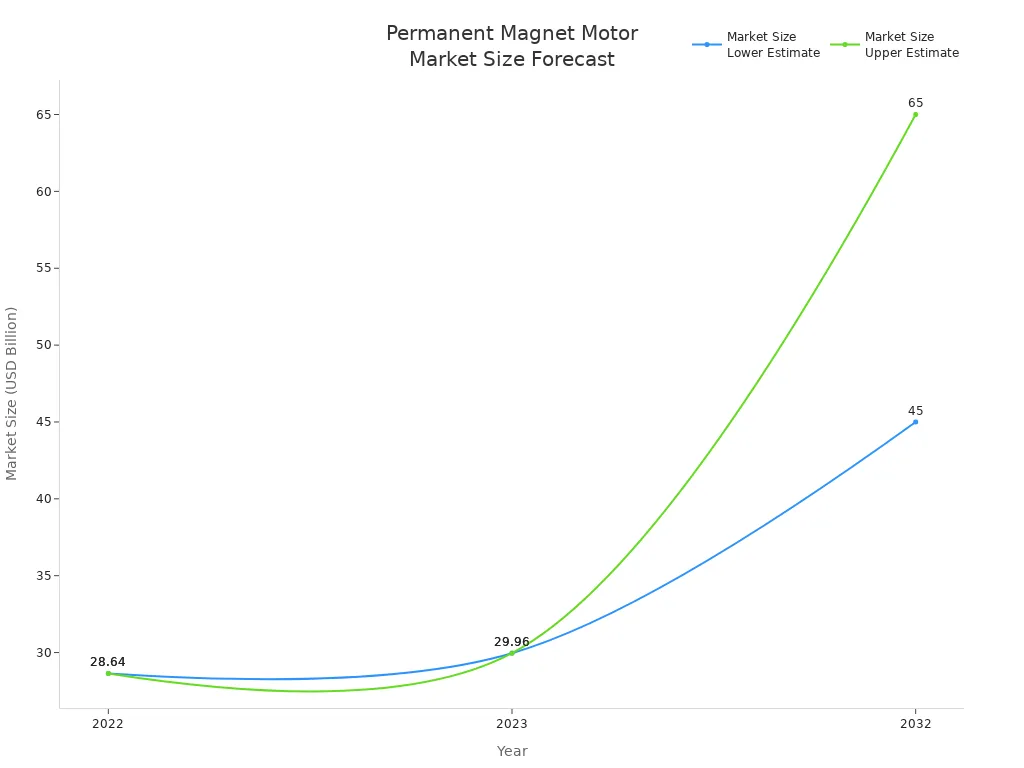

Permanent magnets are changing electric motors in big ways. They help cars, factories, and wind turbines use less power. These motors also help machines work better and faster. Many companies use them to make products cleaner. The market for permanent magnet motors could reach $65 billion by 2032. This is because electric vehicles and automation are growing fast.

New ideas like rare-earth-free magnets and better recycling will help even more. These changes will make motors more important for a green future. People everywhere can expect smarter machines that save energy and help the planet.

FAQ

What makes permanent magnet motors more efficient than other types?

Permanent magnet motors use strong magnets like ndfeb. These magnets make a magnetic field. The design helps save energy and work better. The motors do not need extra power for the field. They make less heat and work well.

Why do electric vehicles use permanent magnet motors?

Electric vehicles need high torque and power density. Permanent magnet motors give steady torque and run quietly. The rotor with magnets helps control the motor exactly. These motors boost power in ev motors. They also let cars drive farther.

How do permanent magnet motors help save energy at home?

Permanent magnet motors work well in home appliances. They use a magnet for motor design to cut energy use. Devices like air conditioners and washers save energy and run quietly. The motors last longer and need less fixing.

Are permanent magnet motors reliable for medical devices?

Medical devices need to be small and quiet. Permanent magnet synchronous motors work better and give steady torque. The rotor with magnets helps control the motor exactly. These motors have high power density. They work well in sensitive places.

What challenges come with using rare-earth magnets in motors?

Rare-earth magnets like ndfeb cost more and need careful sourcing. Mining can hurt the environment. Engineers try new materials and designs to lower costs. Recycling old magnets helps cut waste. Companies look for ways to keep motors efficient and working well.

See Also

Why Investing In Mini Brushless Motors Enhances Precision Tasks

The Role Of Mini Motors In Advancing Portable Technology

Ten Key Uses For 3V DC Motors In Today’s Electronics

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry