LRA Motors vs Other Vibration Motors: Key Differences

When choosing a vibration motor, knowing the differences is important. LRA motors are special because they are precise and save energy. Unlike other motors like piezoelectric or ERM motors, LRA motors work best at 170 to 180 Hz. This specific range makes them steady but slower than piezo motors, which are faster. For devices needing controlled vibrations, like wearable gadgets, LRA motors give good reliability and performance together.

Key Takeaways

LRA motors save energy and are accurate. They work well in wearables and medical tools needing long battery life.

ERM motors make stronger vibrations. They are great for gaming controllers and phones.

Piezoelectric motors are the fastest and most accurate. They are good for advanced tools but are hard and expensive to use.

Brush-type motors cost the least but don’t last long. They are less efficient and best for simple gadgets.

Pick a motor based on your project’s needs, like power use, size, and vibration strength.

Overview of Vibration Motor Types

Learning about vibration motors helps you pick the right one. Each motor type has special features for different uses. Let’s look at three common types: eccentric rotating mass motors, linear resonant actuators, and piezoelectric vibration motors.

Eccentric Rotating Mass (ERM) Motors

ERM motors are very popular vibration motors. They work by spinning an uneven weight at high speeds. These motors are used in things like phones and game controllers for simple vibrations.

There are two main ERM types: brushed and brushless (BLDC). Brushed ERM motors are small, with sizes from 3.2mm to 45mm, but they wear out faster, lasting 100 to 600 hours. Brushless ERM motors last over 1,000 hours and perform more steadily. Both types work in a wide frequency range, from 30 Hz to 500 Hz. They can be attached using glue or mounted on circuit boards.

Linear Resonant Actuators (LRA)

LRAs are more precise and use less energy. Unlike ERM motors, LRAs have a spring-mounted weight that moves back and forth. They work best at specific frequencies, usually between 150 Hz and 205 Hz. This makes them faster and more controlled, perfect for wearables and medical tools.

LRAs are small, about 8mm to 10mm wide, and last over 1,000 hours. They also use less power than ERM motors, making them great for battery-powered devices. Their steady performance is ideal for tasks needing accurate vibrations.

Piezoelectric Vibration Motors

Piezoelectric motors work differently. They use materials that change shape when electricity is applied, creating vibrations. These motors are super fast and efficient, with response times in milliseconds.

You’ll see piezoelectric motors in advanced tools like high-tech touchscreens and special industrial machines. They are very precise and quick but harder to set up and cost more.

Tip: If you need very fast vibrations and low power use, piezoelectric motors are a great option.

Brush-Type Vibration Motors

Brush-type vibration motors are simple and very common. These motors use brushes to pass electricity to moving parts, creating vibrations. They are often found in pagers, old mobile phones, and small toys.

How They Work

These motors have a small, uneven weight on their rotor. When the rotor spins, the weight causes vibrations. Brushes inside the motor touch a commutator, letting electricity flow to power it. This simple design makes them cheap and easy to make.

Key Features of Brush-Type Motors

Small Size: These motors are tiny, usually 3mm to 10mm wide.

Affordable: Their basic design keeps costs low.

Easy to Find: They are used in many gadgets and DIY projects.

Note: The brushes wear out over time, which shortens their lifespan.

Advantages

Simple to add to basic circuits.

Good for low-budget projects.

Come in different sizes for various devices.

Limitations

Don’t last as long as brushless motors.

Lose energy because of friction between brushes and the commutator.

Not precise enough for advanced uses.

Brush-type motors are great for simple and cheap vibration needs. But for more precise or long-lasting uses, consider LRAs or piezoelectric motors instead.

Vibration Motor Comparison: Key Differences

Performance and Efficiency

When comparing vibration motors, think about how well they work and how much energy they use. Linear Resonant Actuators (LRAs) are very precise and save energy. They work at a set frequency, wasting less energy and giving steady vibrations. This makes them great for devices like wearables and medical tools that need long battery life.

Eccentric Rotating Mass (ERM) motors use more power. They spin an uneven weight, which causes friction and heat. But they create stronger vibrations, making them good for gaming controllers and smartphones.

Piezoelectric motors are the fastest. They can vibrate in milliseconds, which is super quick. They use less power for short bursts but might not be as efficient for long use.

Brush-type motors waste the most energy. They use brushes to move electricity, which causes friction. These motors are best for simple, cheap devices where saving energy isn’t important.

Tip: Choose LRAs for precise, energy-saving vibrations. Pick ERMs for stronger vibrations.

Applications and Use Cases

Each motor type works best for certain jobs. LRAs are used in wearables, medical tools, and haptic systems. Their gentle, controlled vibrations are perfect for these uses.

ERM motors are found in many gadgets like phones, game controllers, and fitness trackers. They’re great for strong vibrations in alerts or immersive experiences.

Piezoelectric motors are used in advanced tools like high-tech touchscreens and industrial machines. Their speed and accuracy make them ideal for quick, precise tasks.

Brush-type motors are common in simple devices like toys, pagers, and old phones. They’re cheap and easy to use, making them great for low-cost projects.

Note: Think about your project’s needs before picking a motor. For example, LRAs are great for wearables.

Cost and Complexity

The price and difficulty of using these motors vary. Brush-type motors are the cheapest. They’re simple to make and easy to add to basic circuits. But they don’t last long and may cost more over time.

ERM motors are mid-priced and fairly easy to use. Brushed ERMs are cheaper but wear out quickly. Brushless ERMs cost more but last longer.

LRAs are pricier than ERMs. Their special design and need for exact circuits make them cost more. But their reliability and energy savings often make up for the higher price.

Piezoelectric motors are the most expensive and hardest to use. Their advanced design and special materials raise the cost. Setting them up also takes skill, which adds to expenses.

Reminder: Don’t just look at the price. Think about how well the motor works and how long it lasts. Spending more on an LRA or piezoelectric motor now could save money later.

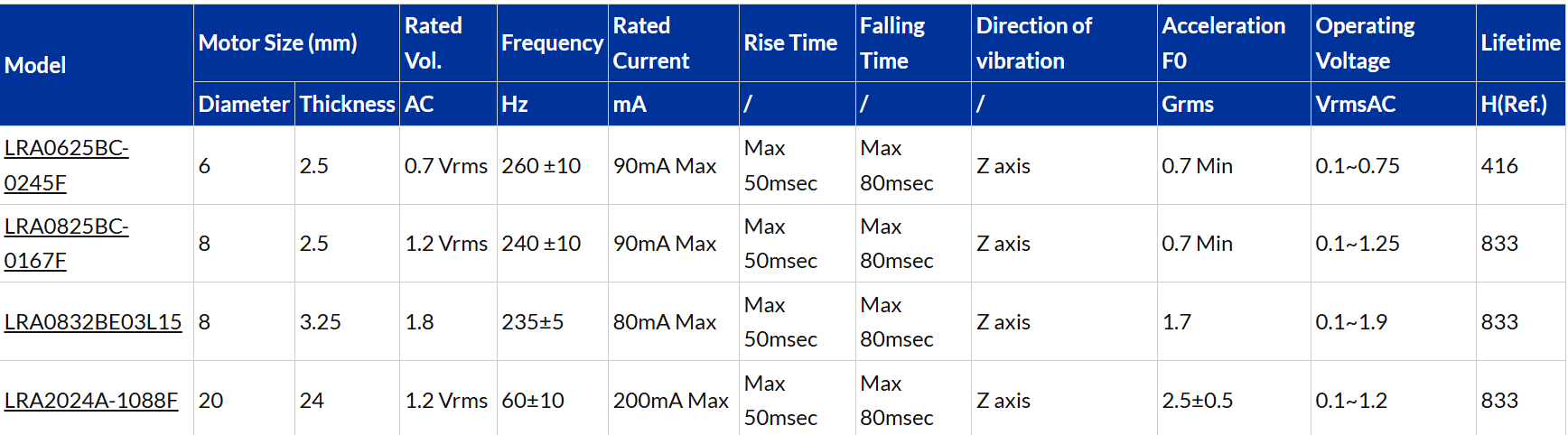

Detailed Comparison of LRA Motors vs Other Types

Rise and Fall Times

When looking at how fast motors start and stop, LRAs are the quickest. They react fast to signals, making them great for tasks needing exact control. "Rise time" means how quickly a motor starts vibrating after getting a signal. "Fall time" is how fast it stops vibrating.

LRAs are better at both because they work at a set frequency. This makes their performance steady and easy to predict. For example, in wearable devices, LRAs give sharp and clear feedback, improving user experience. ERM motors are slower because they rely on spinning weights. Piezoelectric motors are faster than ERMs, but they need tricky setups to match LRA precision.

Tip: If your project needs fast and controlled vibrations, pick LRAs. Their steady rise and fall times are perfect for haptic uses.

Power Consumption

How much power a motor uses is very important, especially for battery devices. LRAs are very efficient because they vibrate at their natural frequency. This saves energy, making them great for fitness trackers and medical tools that need long battery life.

ERM motors use more power. Their spinning parts create heat and waste energy. Piezoelectric motors are good for short vibrations but not for long use. Brush-type motors waste the most energy because of friction from their brushes. They are not good for devices needing to save power.

Reminder: For saving energy, LRAs are the best choice. They use less power, so devices last longer without recharging.

Reliability and Durability

How long a motor lasts and how reliable it is matters a lot. LRAs can last over 1,000 hours, making them very durable. They have fewer moving parts, so they don’t wear out easily. This makes them great for medical tools where steady performance is key.

ERM motors, especially brushed ones, wear out faster because their brushes get damaged. Brushless ERMs last longer but are still less reliable than LRAs. Piezoelectric motors are strong but need careful handling because their materials are delicate. Brush-type motors are cheap but wear out quickly and aren’t good for long-term use.

Note: If you need a motor that lasts long and works well, choose LRAs. They are tough and handle heavy use without breaking often.

Driver Needs and Setup

Knowing how to set up vibration motors is important. Each motor type has specific needs to work well. Understanding these helps you pick the right motor for your project.

Driver Needs for Motor Types

Linear Resonant Actuators (LRAs)

LRAs need special drivers to work properly. These drivers send AC signals at the motor's best frequency. Without the right driver, the motor might not vibrate or could waste energy.Tip: Use LRA-specific drivers for better control and energy savings.

Eccentric Rotating Mass (ERM) Motors

ERM motors are easier to use. They run on DC signals and work with simple circuits. Brushed ERMs may need extra parts to last longer.Piezoelectric Motors

Piezoelectric motors need advanced drivers that create high-frequency AC signals. These drivers must match the motor’s needs for accurate vibrations. Setting them up can be tricky.Brush-Type Motors

Brush-type motors are the simplest to use. They run on basic DC signals and need little setup. But they are less efficient and wear out faster.

Things to Think About When Setting Up

When adding a vibration motor to your project, keep these in mind:

Power Supply Match

Make sure the motor’s voltage fits your power source. LRAs use low voltage, so they’re good for battery devices.Circuit Design

Build a circuit that matches the motor’s driver needs. LRAs need AC signal drivers. ERMs and brush-type motors work with simpler circuits.Size Limits

Pick a motor that fits your device’s size. LRAs are small and great for tight spaces. ERMs may need more room because of their spinning parts.Purpose of Use

Think about what the motor will do. LRAs are best for precise feedback. ERMs are better for strong vibrations.

Reminder: Setting up the motor correctly helps it work well and last longer.

By learning about driver needs and setup, you can choose the right motor. This ensures better performance, saves energy, and lowers costs.

Pros and Cons of LRA Motors

Advantages of LRA Motors

Linear Resonant Actuators (LRAs) have many benefits for different uses. Here are their main advantages:

Energy Efficiency: LRAs use less power than other motors. This makes them great for wearables and medical devices needing long battery life.

Precision and Control: They work at a set frequency, giving steady and accurate vibrations. This improves user experience in haptic systems.

Compact Size: LRAs are tiny and light, fitting well in small gadgets like smartwatches or fitness trackers.

Durability: With fewer parts moving, LRAs last longer. They often work for over 1,000 hours, making them reliable for tough tasks.

Low Noise: LRAs are quieter than ERM motors. This makes them good for places needing quiet operation.

Tip: Choose LRAs if you want a motor that is efficient, precise, and long-lasting.

Disadvantages of LRA Motors

Even though LRAs have many strengths, they also have some downsides. Knowing these can help you decide if they suit your needs:

Higher Cost: LRAs cost more than ERM or brush-type motors. Their special design and need for exact drivers make them pricier.

Complex Driver Requirements: They need specific AC signal drivers to work right. Setting these up can be hard, especially for beginners.

Limited Frequency Range: LRAs work best in a narrow range, usually 150 Hz to 205 Hz. This makes them less flexible than other motors.

Lower Vibration Strength: LRAs are precise but may not give strong vibrations. This can be a problem for things like gaming controllers.

Note: Think about your budget, technical skills, and vibration needs before picking an LRA motor.

Knowing how vibration motors differ helps you pick the right one. LRA motors are precise, save energy, and last a long time. ERM motors make stronger vibrations, while piezoelectric motors are fast and accurate. Brush-type motors are cheap but wear out quickly.

Tip: Use an LRA motor for steady and reliable vibrations in wearables or medical tools. Pick an ERM motor for stronger vibrations. Choose piezoelectric motors for quick and precise tasks. Think about your budget and device needs to decide wisely.

FAQ

What is a BLDC motor, and how is it different?

A BLDC motor means brush-less direct current motor. It uses electronics instead of brushes to work. This makes it quieter, lasts longer, and uses less energy than brushed motors. It’s great for jobs needing strong and precise performance.

Why are LRAs good for wearable devices?

LRAs make steady and controlled vibrations. They are small, save power, and don’t make much noise. This makes them perfect for wearables like smartwatches and fitness trackers. They give a better experience without using up the battery fast.

Can BLDC motors replace LRAs in haptic systems?

BLDC motors can sometimes replace LRAs. But LRAs are better for exact vibrations and saving power. BLDC motors work well for stronger vibrations and tough jobs, like gaming controllers.

How do you pick between an LRA and a BLDC motor?

Think about what your device needs. Pick an LRA for small gadgets needing accurate and energy-saving vibrations. Choose a BLDC motor for stronger vibrations and longer-lasting use in harder tasks.

Are BLDC motors more costly than other motors?

BLDC motors cost more at first because of their design. But they last longer and save energy, which lowers costs over time. This makes them a smart choice for many uses.

See Also

LRA Vibration Motors: Key Elements Behind Haptic Feedback Technology

Understanding The Main Differences Between Vibro And Standard Motors

Tips For Enhancing LRA Motors In Vibrating Object Designs

Maximizing Efficiency By Optimizing Resonance Frequency In LRA Motors

Vibration And Frequency: Key Insights For Improved Motor Specifications

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry