Why Linear Vibration Motors Deliver Superior Haptic Feedback

Linear vibration motors change how you feel haptic feedback. They give clear and lifelike touch sensations. These motors make steady vibrations because of their special frequency. They respond quickly, with rise times under 50ms and fall times under 80ms. INEED Motors' 2024 LRA electrical motor features ultra-wide frequency 30Hz-500Hz, ultra-strong vibration, ultra-quiet, ultra-comfortable performance. With fewer parts, they last longer and use less energy. This makes them a great choice for powerful devices.

Key Takeaways

Linear vibration motors create clear and realistic touch feelings. They improve how devices like phones and smartwatches feel to use.

These motors work fast, reaching full vibration in 50 milliseconds. This makes them great for gaming and virtual reality.

Their small size and low power use help them fit in modern devices and save battery.

Linear vibration motors last longer and work better than older motors, even in tough conditions.

INEED's LRA2024A-1088F model shows advanced tech with strong vibrations and durability for many uses.

How Linear Vibration Motors Work

The mechanism behind linear vibration motors

Linear vibration motors work in a simple and smart way. They have a moving weight attached to a spring. When electricity powers a coil, it creates a magnetic field. This field moves a magnet, making the spring push the weight up and down. This motion creates vibrations. These motors speed up faster than older ones. They reach full vibration in 50 milliseconds. Older motors, like ERM motors, need 100 to 200 milliseconds. Their brushless design avoids wear and lasts longer. They can work five times longer than regular motors.

How resonance enhances precision and efficiency

Resonance is key to how these motors work well. They vibrate best at their resonant frequency. This frequency uses less energy and gives stronger vibrations. Resonance helps the motors give clear and steady feedback. This makes them great for haptic systems that need lifelike sensations. Adjusting the frequency and strength makes them even more useful. They can fit many different uses with this flexibility.

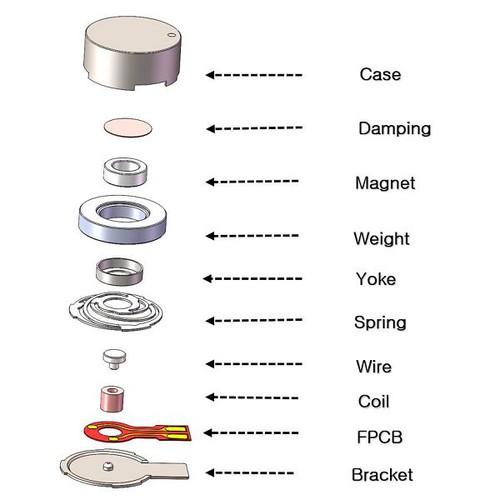

Key components of INEED's Linear Vibration Motors

INEED's motors have special parts that make them unique. Each motor has a voice coil, spring, and moving weight. The coil makes the magnetic field, and the spring keeps the weight moving smoothly. Together, they create vibrations along the z-axis for steady feedback. These motors need an external driver IC to control vibrations. This setup saves energy and lasts longer. It’s perfect for gadgets like phones and smartwatches.

Key Advantages of Linear Vibration Motors in Haptic Feedback

Precision and accuracy in delivering tactile sensations

Linear vibration motors give very accurate touch feedback. Their design makes vibrations clear and lifelike. This accuracy is important for systems where small mistakes can ruin the experience. These motors always make steady vibrations, whether in phones or wearables. You can change their frequency and strength to fit different needs. This control lets you feel realistic feedback in games or medical tools.

Faster response times for real-time feedback

Quick response is key for real-time actions. Linear vibration motors work fast with advanced parts. They reach full vibration in just 50 milliseconds. This gives instant feedback, which is great for gaming and VR. Older motors take longer and can feel slow. These motors react quickly, keeping you focused and involved. Their fast start and stop times are perfect for quick changes.

Consistency and reliability in performance

Linear vibration motors work steadily every time. They give reliable feedback in all conditions. Tests show they perform well even under tough loads. Their strong design reduces wear and lasts longer. You can count on them for steady vibrations in watches or medical tools. They pass hard tests for long use and tough environments. This makes them a top choice for devices needing long-term dependability.

Energy efficiency and compact design for modern devices

Today's devices need parts that save power and fit small spaces. Linear vibration motors are great at both. They use less energy, making them perfect for gadgets like phones and smartwatches. These motors work at a special frequency to avoid wasting power. This helps devices last longer on one charge, making them more useful.

Their small size is another big advantage. These motors are tiny but still work well. For example, INEED's smallest LRA motor is only 6mm wide and 2.5mm thick. Even though they are small, they give clear and steady vibrations. This means you can feel feedback without hurting device performance.

These motors are ideal for haptic systems because they save power and are compact. Whether in a VR controller or smartwatch, they respond quickly and feel real. They save energy while working better than older motors, which often can't keep up with modern needs.

Using linear vibration motors makes devices work better and saves energy. Their smart design and efficient use of space make them perfect for today's technology.

Comparison with Other Vibration Motor Types

Linear vibration motors vs. eccentric rotating mass (ERM) motors

Linear vibration motors work differently than ERM motors. ERM motors use a spinning weight to make vibrations. This design can be slower and less accurate. Linear vibration motors use a coil and spring to vibrate. They create faster and more precise feedback along the z-axis.

The strength and speed of vibrations also differ. Brushed ERM motors can vibrate from 0.25G to 150G. Linear vibration motors stay between 0.75G and 2.5G for better control. This makes them great for wearables and gaming devices needing realistic feedback.

Motor Type | Vibration Speed Range | |

|---|---|---|

Brushed ERM | 0.25G ~ 150G | 30Hz ~ 500Hz |

BLDC ERM | 1G ~ 30G | 200Hz ~ 208Hz |

LRA | 0.75G ~ 2.5G | 150Hz ~ 205Hz |

Linear vibration motors vs. piezoelectric actuators

Piezoelectric actuators use special materials to make vibrations. They work well at high frequencies but need more power. Linear vibration motors use less energy and are easier to add to devices. They work at low voltages, which is better for gadgets like phones and watches.

Piezoelectric actuators can break easily because of their ceramic parts. Linear vibration motors are stronger and last longer. They give steady performance even with heavy use.

Why INEED's Linear Vibration Motors are preferred for advanced applications

INEED's motors are small, efficient, and very accurate. They fit modern devices like VR controllers and smartwatches. The LRA2024A-1088F model vibrates strongly and works across many frequencies. It lasts up to 1 million cycles, making it reliable for tough tasks.

Choosing INEED's motors means using advanced technology. These motors improve haptic feedback in wearables, medical tools, and gaming systems. They are durable and perform well for creating top-notch products.

Real-World Uses of Linear Vibration Motors

Making smartphones and wearables better for users

Linear vibration motors improve how smartphones and wearables feel. They give clear and steady vibrations for alerts and messages. For example, when your phone buzzes, it feels smooth and natural. This makes using the device more enjoyable. These small motors fit easily into phones and smartwatches without losing power.

They also save energy, which is a big plus. Using less power helps batteries last longer. This is very helpful for wearables that need to work all day. By adding these motors, companies can make devices that are easy to use and last longer.

Realistic feedback in gaming and VR systems

Gaming controllers and VR systems use these motors for lifelike feedback. They make games and virtual worlds feel real by matching vibrations to actions. For example, if you touch a hard object in a game, the motor vibrates harder. This makes the experience more exciting and believable.

Here’s a table showing how these motors help in gaming:

Feature/Metric | What It Does |

|---|---|

Vibration Intensity | Changes based on how hard or soft an object feels. |

Frequency Range | Works between 130–230 Hz for different feedback types. |

Control Logic | Adjusts vibration strength to match object changes. |

Multi-finger Control | Lets you feel actions with multiple fingers in VR. |

These features make gaming and VR more fun. You can feel every move as if it’s happening for real.

Helping medical tools and assistive devices

Linear vibration motors are improving medical and assistive devices. In medical tools, they help doctors feel tiny vibrations during surgeries. This helps them work more carefully and avoid mistakes.

For assistive devices, like those for blind people, these motors give touch feedback. They help users understand important information through vibrations. These motors are strong and save energy, so they work well even in tough conditions. This makes them reliable for helping people and saving lives.

Automotive touch interfaces and smart controls

Car touchscreens and smart controls need accurate feedback to work well. Linear vibration motors help by giving clear and quick touch sensations. When you use a car's screen or control panel, these motors make sure you feel instant and real feedback. This makes using the controls easy and enjoyable.

Linear vibration motors are better than old rotary motors in many ways. The table below shows their benefits:

Feature | Linear Vibration Motors | Rotary Motors |

|---|---|---|

Touch Feedback Accuracy | High | Low |

Energy Use | Low | High |

Noise | Quiet | Loud |

Performance Efficiency | High | Moderate |

Vibration Control Detail | Fine | Basic |

Reaction Speed | Fast | Moderate |

Vibration Strength Range | Wide | Limited |

Feedback Detail | Clear | Rough |

These motors are quiet and give detailed control, perfect for cars. Drivers can focus on driving while easily using touch controls. Their mix of accuracy and efficiency makes them great for modern vehicles.

INEED's LRA Electrical Motor LRA2024A-1088F in action

INEED's LRA2024A-1088F motor works amazingly in real-life uses. It boosts haptic systems with strong and steady vibrations, making tasks feel smooth and natural. Its long life and dependability make it a smart choice for feedback systems.

This motor does more than improve user experience. It helps industries like cars and phones work better. Taking care of it keeps its performance strong over time. Its durability saves money for businesses needing lasting solutions.

The LRA2024A-1088F also syncs vibrations with sound for exciting gaming and VR. Its wide frequency range and low energy use make it flexible and efficient. Whether in car controls or wearables, this motor offers top-notch accuracy and dependability.

Linear vibration motors are very precise and respond quickly. They are important for today’s devices. These motors give steady and real touch feedback, improving how people use gadgets. From phones to gaming gear to medical tools, they work dependably. INEED's smart designs, like the LRA2024A-1088F motor, make haptic feedback even better. As technology grows, these motors will keep improving devices. They help create the best touch experiences for users.

FAQ

Why are linear vibration motors better than ERM motors?

Linear vibration motors react faster and give clearer feedback. They use a coil and spring instead of spinning parts. This makes vibrations smoother and uses less energy. They also last longer, giving more realistic feedback in devices.

How do linear vibration motors save power?

These motors work at a special frequency to use less energy. They need low voltage, which is great for battery-powered gadgets. By saving power, they help phones and wearables last longer on a single charge.

Can linear vibration motors handle heavy use?

Yes, they are built to last. With fewer parts, they wear out less. For example, INEED’s LRA2024A-1088F motor can work for 1 million cycles. This makes them reliable for tough and frequent use.

Do linear vibration motors fit in small devices?

Yes! These motors are tiny and light. INEED’s models can be as small as 6mm wide. Even though they’re small, they give strong and clear vibrations. They fit easily into slim gadgets like smartwatches and VR controllers.

Why do linear vibration motors need a driver IC?

The driver IC creates the signal that makes the motor vibrate. It helps control how strong and fast the vibrations are. This lets you adjust feedback for different uses, making devices feel better to use.

See Also

Understanding Vibration Motors in Haptic Feedback Technology

LRA Vibration Motors: Key Elements in Today's Haptic Systems

The 2024LRA Impact on Haptic Feedback and User Engagement

Exploring the Vibration Mechanism of 3V DC Motors

Evaluating Linear Resonant Actuator Options for Product Design

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry