How to Identify and Reduce Motor Mount Vibration

Motor mount vibration happens when engine mounts can't stop vibrations. These vibrations come from the engine. This problem can hurt engine performance and make rides less comfortable. Over time, engine mounts get stiffer because they age and wear out. Stiff mounts can't block vibrations well, which can damage the car's parts and structure.

If you ignore motor mount vibration, it can get worse. Stronger vibrations can break important parts, make the car noisier, and shorten its life. Fixing this problem early keeps the engine running smoothly and protects your car from big damage later.

Key Takeaways

Motor mount vibration can hurt your car's ride and function. Fixing it early avoids bigger problems and saves money.

Check engine mounts often for cracks, leaks, or damage. This easy task helps your car last longer.

If you feel strong shaking or hear odd sounds, check the engine mounts right away. Finding problems early stops expensive fixes.

Pick engine mounts that match your car's needs. Rubber mounts work well for daily use, while polyurethane mounts are better for fast cars.

Vibration dampeners and isolators help lower engine shaking. Installing them correctly makes them work better.

Understanding Motor Mount Vibration

What is motor mount vibration?

Motor mount vibration happens when engine mounts stop working well. These mounts hold the engine steady and block vibrations. When they wear out or break, you might feel shaking while driving. This can make rides bumpy and hurt your car's performance.

Experts use tools to check motor mount vibration. Here's a simple guide:

Measurement Type | Description |

|---|---|

Total Vibration | Measures the highest and lowest vibration levels. |

Displacement | Shows movement on a screen in real-time. |

Velocity | Found from displacement and helps check machine health. |

Acceleration | A common way to measure vibration, can change to other units. |

Tracking TIR | Tracks vibration changes over time, showing peak values. |

Measurement Units | Includes peak, average, RMS, and measures in time or frequency. |

Causes of motor mount vibration

Motor mount vibration can happen for many reasons. One main cause is old engine mounts. As they age, they can't cushion the engine well. Bad installation or cheap mounts can also cause problems. If the engine is not balanced, it can shake too much for the mounts to handle.

Weather and chemicals can also weaken mounts. Very hot or cold weather, or oil spills, can damage them. Regular check-ups can find these problems early and stop bigger issues.

Why motor mount vibration matters

Ignoring motor mount vibration can cause big problems. Too much shaking makes rides rough and damages car parts. Over time, parts can wear out faster or even break. A study showed cars with vibrations had more accidents than those without. This shows why fixing motor mount vibration is important for safety.

Fixing the problem early saves money and keeps your car lasting longer. It also helps your engine run better and makes rides quieter.

How to Identify Motor Mount Vibration

Symptoms of motor mount vibration

Spotting motor mount vibration early can save money. Look for these signs:

Symptoms | Description |

|---|---|

Feel for Vibrations | Strong shaking in the steering wheel, seat, or floor. |

Clunking or Banging | Happens when starting or speeding up the car. |

Grinding or Scraping | Occurs when turning the steering wheel. |

Humming or Buzzing | Noticeable when the car is not moving. |

Excessive Engine Movement | Engine shifts a lot during braking or speeding up. |

Increased Noise and Vibration | Louder sounds and more shaking while driving. |

Misalignment Issues | Can harm other parts of the car. |

You might feel shaking in the car or steering wheel. In bad cases, the engine may move when you speed up or shift gears. Strange noises like clunks or thumps when starting the car or shifting gears are warning signs. If you notice these, check your engine mounts soon.

Diagnostic methods for detecting vibration

Finding motor mount vibration needs both looking and testing. First, check the engine mounts for cracks or damage. Look for oil leaks, as they can weaken mounts. If the engine moves too much when braking or speeding up, it’s a problem.

Testing tools give better results. A three-axis sensor measures vibration levels more accurately. Studies show modern tools remove extra noise better. For example, at 80 Hz, new tools had only a 0.5% error, while old ones had 7.3%. This shows why using good tools is important for finding motor mount problems.

Common tools for assessing engine mounts

To check engine mounts, you need the right tools. Here are some common ones:

Tool Type | Description |

|---|---|

Oscilloscope | Shows engine problems by checking cylinder vacuum events. |

Engine Analyzer | Runs tests like compression and vacuum tests to check engine health. |

Pressure Transducer | Measures how cylinders work and how systems affect mounts. |

An oscilloscope finds engine issues by studying cylinder vacuum. An engine analyzer runs tests to check how well the engine works. A pressure transducer checks cylinder performance and how systems impact mounts. These tools help find the exact cause of motor mount vibration.

Practical Steps to Minimize Engine Vibration

Regular maintenance to reduce vibration

Taking care of your engine mounts helps reduce vibration. Check them often for cracks, tears, or oil stains. These problems mean the mounts can't stop vibrations well. Cleaning the mounts and nearby areas keeps dirt from causing damage.

Watch how your engine runs. If it shakes or makes strange noises, fix it quickly. Ignoring these signs can wear out the mounts and harm other parts. Regular oil changes and keeping fluids at the right levels also protect the mounts from damage.

Tip: Write down when you check or fix your car. This helps you catch problems early before they get worse.

Replacing worn or damaged engine mounts

If mounts are old or broken, replacing them works best. First, find out what type of mounts your car uses. Rubber mounts are soft and absorb vibrations well. Polyurethane mounts last longer but are stiffer. Pick mounts that fit your car's needs.

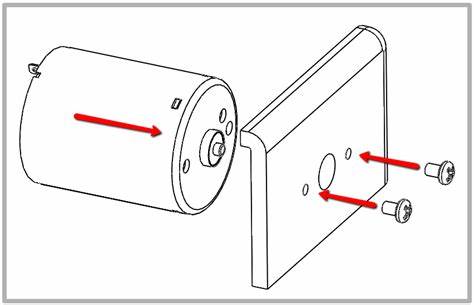

Be careful when changing mounts. Use a jack to hold the engine while removing the old ones. Put the new mounts in place and tighten the bolts properly. Misaligned mounts can cause more shaking.

If you're not sure how to do this, ask a mechanic. Installing mounts the right way is important for keeping your car running smoothly.

Note: Changing bad mounts quickly stops vibrations and protects other car parts from wearing out.

How to choose the best engine mounts for your vehicle

Picking the right mounts is key to reducing vibration. Start by checking your car's make and model. Not all mounts fit every car. Rubber mounts work well for daily driving. Polyurethane mounts are better for tough conditions or high-performance cars.

Newer mounts are becoming popular, especially for electric and hybrid cars. In 2023, North America led this market, worth $34.25 billion, and it may grow to $45.0 billion by 2032. Some mounts now use advanced systems to block vibrations better.

When choosing mounts, think about material, strength, and if they fit your car. Spending more on good mounts now can save money later by lasting longer.

Pro Tip: Check your car's manual or ask a mechanic to pick the best mounts for your car.

Using vibration dampeners and isolators

Vibration dampeners and isolators help reduce shaking from bad engine mounts. These tools absorb and block the energy from engine movement. This makes your ride smoother and protects your car from damage. Learning how to use them can improve your car's comfort and performance.

What are vibration dampeners and isolators?

Vibration dampeners lower shaking by soaking up energy. They are made of materials like rubber or polyurethane, which soften engine movement. Isolators, however, separate the engine from the car's body. This stops vibrations from spreading to other parts of the car.

Both tools work together to protect your car. Dampeners reduce the strength of vibrations, while isolators stop them from traveling through the car.

How to use vibration dampeners and isolators effectively

Pick the right type for your car

First, figure out what your car needs. Some cars need strong dampeners, while others use lighter ones. Check your car's manual or ask a mechanic for advice. Rubber dampeners are good for daily driving, while polyurethane ones suit high-performance cars.Install them properly

Correct installation is very important. Place dampeners near engine mounts to reduce vibrations at the source. Put isolators between the engine and car frame to block vibrations. Use a torque wrench to tighten bolts securely.Check and maintain often

Over time, these tools can wear out. Inspect them during regular car check-ups. Look for cracks or damage. Replace them if they are worn out or broken.Use with good engine mounts

Dampeners and isolators work best with strong engine mounts. Together, they reduce and block vibrations, giving your car better protection.

Benefits of using vibration dampeners and isolators

These tools offer many benefits. They make rides quieter and more comfortable by reducing shaking. They also help engine mounts last longer by lowering stress and wear. Plus, they improve your car's performance, making it safer and more fun to drive.

Pro Tip: If you're unsure about installing or fixing these tools, ask a mechanic. Proper installation helps them work better and last longer.

Preventing Engine Vibration and Harshness in the Future

Best practices for ongoing maintenance

Regular care helps stop engine vibration and harshness. Check engine mounts often for cracks, tears, or oil stains. Clean the mounts and nearby areas to avoid dirt buildup. Dirt can weaken mounts over time. Listen for strange noises or watch for shaking. These are early signs of problems.

Stay organized with a maintenance schedule. Follow steps from troubleshooting guides to fix issues early. Service bulletins share safety tips to keep your car reliable. Maintenance plans suggest tasks to boost engine performance and reduce downtime. Non-destructive tests find hidden damage, keeping your car smooth and efficient.

Tip: Write down all maintenance work. This helps track repairs and spot repeated problems.

Monitoring early signs of motor mount wear

Finding motor mount wear early stops bigger problems later. Look for cracks, leaks, or other visible damage. Watch for unusual engine movement when braking or speeding up. Vibrations in the steering wheel or floor are also warning signs.

Technology makes checking easier. Smart systems track real-time data to spot wear early. Condition monitoring records engine data, helping plan repairs before issues grow. This cuts surprise breakdowns and extends mount life. Using this data, you can fix problems early and keep your car running well.

Pro Tip: Use smart sensors to check engine mounts. They give helpful details about wear and tear.

The role of professional inspections in prevention

Professional checks are key to reducing engine vibration and harshness. Mechanics use special tools to find hidden problems. Regular inspections improve your car's performance and avoid expensive repairs.

Studies show the value of professional care. Companies with regular checks have fewer breakdowns and defects. Unplanned downtime costs big companies billions yearly. Preventive care lowers these losses and keeps cars running better. Required inspections also help meet emission rules and improve efficiency.

Professional checks catch engine issues early, reducing failures during emissions tests. Cars with good maintenance perform better and last longer. By getting expert help, you protect your car and make it more comfortable.

Note: Get professional inspections yearly to keep your engine in top shape.

Fixing motor mount vibration quickly makes rides smoother and saves money. Taking care of your car early helps it last longer, break down less, and stay on the road more.

Improvement Type | Description |

|---|---|

Vehicle Lifespan | Regular care helps your car last longer. |

Failure Rates | Servicing often lowers the chance of breakdowns. |

Hazard Rate | Well-kept cars are safer than neglected ones. |

Operational Downtimes | Maintenance programs keep cars running with fewer delays. |

Acting fast saves money, improves safety, and uses less fuel. Don’t wait for small issues to grow—ask a mechanic to check your car today.

Tip: Regular check-ups stop big problems and make driving safer and more comfortable.

FAQ

What happens if you ignore motor mount vibration?

Ignoring motor mount vibration can cause serious problems. Vibrations put pressure on engine parts, making them wear out faster. Over time, this can lead to expensive repairs, a shorter car life, and safety dangers. Fixing the issue early avoids these troubles and keeps rides smooth.

Tip: Check engine mounts during regular maintenance to find problems early.

How often should you check motor mounts?

Check motor mounts every 12,000 to 15,000 miles or during routine servicing. Regular checks help spot cracks, leaks, or wear before they get worse. If you drive in tough conditions, inspect them more often to keep your car running well.

Can you drive with a damaged motor mount?

Driving with a damaged motor mount is unsafe. It causes more vibrations, which can damage the engine and other parts. Over time, this can make driving dangerous. Replace damaged mounts quickly to avoid bigger problems and keep your car safe.

How do you know if a motor mount needs replacement?

Watch for these signs:

The engine moves too much when braking or speeding up.

You hear clunking or banging sounds.

The mounts have visible cracks or oil leaks.

If you see these signs, replace the mounts right away to stop further damage.

Are aftermarket motor mounts reliable?

Aftermarket motor mounts can work well if you pick good brands. Look for mounts made from strong materials like polyurethane or reinforced rubber. Make sure they fit your car model. If unsure, ask a mechanic for advice.

Pro Tip: Spending more on high-quality aftermarket mounts can boost performance and last longer.

See Also

Effective Strategies for Diagnosing Motor Vibration Issues

Maintaining Electric Vibration Motors for Optimal Performance

Techniques for Accurate Vibration Measurement

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry