How to Select the Right Low Speed Motor for Your Application in 2025

Choosing the right low speed motors starts with knowing what you need. You must figure out the load, speed, and torque for your job. Many industries use these motors for tough jobs. Oil and gas, mining, and renewable energy need them for hard work.

Common Use Cases for Low Speed Motors (2025) |

|---|

Oil & Gas, Power Generation, Mining & Metal |

Industrial Machinery and Automation |

Renewable Energy (Wind, Hydro) |

You should think about motor choices early. People make mistakes like forgetting about the environment. Some people get the torque wrong. Others forget about all the machine parts.

Picking a motor that is too small or too big

Forgetting about how often it runs or feedback

You can stop these problems by knowing what you need from the start.

Key Takeaways

First, write down your load, speed, and torque needs. This helps you pick the right motor size and type. Think about where you will use the motor and how much space you have. This keeps your motor safe and helps it last longer. Pick a motor type that matches your job. Try to balance cost, how well it works, and how much care it needs. Use gearboxes if you need more torque at low speeds. Make sure to balance speed and power too. Check and take care of your motor often. This keeps it working well and stops expensive repairs.

Application Requirements

Load and Performance

First, you need to know what your machine must do. Make a list of every job the motor will handle. Think about how heavy or strong the load is. This is called the load. Loads can stay the same, change, or have sudden shocks. For example, a conveyor belt has a steady load. A press machine can have a shock load.

Tip: Write down each job for your motor. This helps you remember every detail.

To check the load, use a true-RMS clamp meter or a flexible current probe. These tools show the voltage and current the motor uses. You can use this formula:Horsepower (hp) = Voltage x Amperage x % Efficiency x Power Factor x 1.73 / 746

This formula is for three-phase motors. Use the efficiency from the motor's nameplate. If you do not know the power factor, make a good guess. Check and write down these numbers often. This keeps your motor safe and helps you pick the right one.

Manufacturers give you torque and speed charts. These charts show how much torque the motor gives at different speeds. Look at these charts to see if the motor fits your needs. If you need more torque, you may need a bigger motor frame or a different winding.

Speed and Torque

You need to know your speed and torque needs before picking a motor. Speed means how fast the motor spins, in rpm. Torque is the twisting force the motor gives. Both are needed for good work.

Most low speed motors run from 1 rpm to 150 rpm.

Some motors, like AC induction motors, give full torque at low speeds.

Servo motors are good for high torque at low speeds, but torque drops as speed goes up.

Gearboxes help motors give more torque at lower speeds.

To find the right torque, add up the inertia of all moving parts. Use this formula:T = J × A / Lead

T is torque, J is inertia, A is acceleration, and Lead is the screw lead. Do not forget frictional torque. Always compare your total torque to the motor's holding torque. Check the speed-torque chart to make sure the motor will not stall. Add a safety margin of 10-30% to your numbers.

Motor Type | Torque Range (Nm) | Voltage Range (V) | Typical Applications |

|---|---|---|---|

Inrunner Frameless Torque Motor | 0.025 to 50 | 24 to 48 (custom) | Robotics, Medical, Aerospace, Semiconductor, LCD manufacturing, Industrial Automation |

Outrunner Frameless Torque Motor | 0.01 to 6 | 12 to 48 (custom) | Same as above |

Think about how often the motor starts and stops. If your job needs lots of starts and stops, pick a motor that can handle it without getting too hot. Always check the manufacturer's specs for performance and duty cycle.

Note: Picking the right motor for your speed and torque needs helps your machine work better and last longer.

Environmental and Installation Factors

Operating Conditions

You should look at where your motor will work. Good conditions help your motor last longer. Bad conditions can make your motor break faster.

Temperature extremes can make motors wear out quickly. Hot places break down grease and insulation. Cold places can make parts crack.

Dust and chemicals can get inside the motor. They can damage bearings and cause rust. This means more repairs and a shorter life.

Moisture and humidity can cause rust and damage insulation. Motors in wet places need extra protection.

Vibration can shake parts loose and make the motor fail early.

Tip: Clean, dry, and cool rooms help your motor last longer. Use seals and filters to keep out dust and water. Try to control the temperature and humidity in your workspace.

If you hear odd sounds or see the motor getting hot, check for dirt or water inside. Use water-resistant grease and sealed bearings for more safety. Do not use high-pressure cleaning because it can push dirt deeper inside.

Space and Mounting

You need to plan for enough space and the right mounting before you put in your motor. Good setup keeps your motor safe and easy to fix.

Leave at least 3 inches around the motor for air to move. This helps stop overheating.

Put the motor on a flat, strong surface. This stops it from getting out of line and wearing out.

Use bolts that fit the motor’s size and weight. Make sure they are tight.

Check that the motor is level with a tool before you finish.

If you use a frameless motor, line up the rotor and stator carefully. Make sure the rotor spins easily and does not touch anything else. If the magnets are strong, keep them away from steel or iron to stay safe.

When you connect the motor shaft, pick the right coupling. Here is a simple guide:

Coupling Method | Common Use | Installation Tips |

|---|---|---|

Flexible Elastomeric | Most low/medium speed | Needs good alignment; no grease needed; allows some movement |

Rigid Couplings | Vertical pumps | Needs perfect alignment; use strong bolts; no grease needed |

Gear Couplings | High power/speed | Needs grease; do not overfill; check alignment |

Key Fits | Motors and pumps | Needs careful fit; heat for removal; not for frequent changes |

Spline Fits | Easy removal needed | Rigid fit; no heat needed; common in turbines |

Hydraulic Fits | Turbo-compressors | Needs special fit; no keys; uses pressure for assembly |

Note: Always check the alignment and space for your coupling. Good setup helps your motor run well and last longer.

Selecting the Right Motor

Motor Types

There are many kinds of low speed motors. Each kind is best for certain jobs. You should know how they are different before you pick one for your job.

Aspect | Brushed DC Motors | Brushless DC Motors | AC Motors |

|---|---|---|---|

Efficiency | Lower due to brush friction and wear | High efficiency, minimal energy loss | Generally efficient, especially at higher power; close to brushless DC with modern tech |

Maintenance | High (brush replacement, wear) | Low (no brushes, less wear) | Low (no brushes, occasional bearing/insulation maintenance) |

Lifespan | Shorter due to brush wear | Longer lifespan | Durable, long-lasting |

Speed Control | Good precision and control | Excellent precision and dynamic control | Requires VFD for variable speed control |

Cost (Initial) | Low cost | Higher cost due to electronic controllers | Moderate cost, cost-effective for high power |

Torque at Low Speed | High starting torque but degrades over time | Consistent torque, suitable for high performance | Strong torque, but speed control complex without VFD |

Thermal Performance | Generates heat from friction | Runs cooler due to efficiency | Handles heat well, often with cooling systems |

Typical Applications | Toys, small appliances, cost-sensitive | Industrial automation, robotics, electric vehicles | Industrial machinery, pumps, HVAC, heavy-duty applications |

Brushed DC motors are easy to use and not expensive. They are good for simple jobs if you do not mind fixing them often. You can use them in toys or small machines. Brushless DC motors cost more at first, but they last longer and need less fixing. They give better speed control and use less energy. These motors are great for robotics, automation, and electric vehicles. AC motors are strong and last a long time. You see them in big machines and pumps. If you want to change their speed, you need extra equipment like a variable frequency drive.

When you work with robotics or conveyor systems, you may use brushless DC motors, geared motors, DC motors, servo motors, and stepper motors. Each motor has something special:

DC motors are easy to control and work well for conveyor belts.

Servo motors help move things to exact spots, which is important in robotics.

Geared motors help move heavy things slowly.

Brushless DC motors move smoothly and quietly and give high torque at low speeds.

Stepper motors hold positions and move in small steps.

Tip: Write down what your job needs. This helps you pick the best motor for your work.

Gearbox Use

Sometimes, you need your motor to turn slowly but push hard. In these cases, you should use a gearbox. A gearbox connects to your motor and changes how fast it spins and how much torque it gives.

Look at this example:

Motor Configuration | Speed (rpm) | Torque (in-lbs) |

|---|---|---|

Motor alone (12v PM8014) | 934 | 4.75 |

Motor + 10:1 Gearbox | 93.4 | 40.45 |

Motor + 15:1 Gearbox | 62.3 | 59.81 |

Adding a gearbox makes the motor spin slower but gives more torque. This helps you move heavy things or keep them in place. You see gearboxes in mining, renewable energy, and construction. For example, mining machines use planetary gearboxes to crush rocks. Wind turbines use gearboxes to turn slow blades into faster spins for making electricity. Construction machines like excavators use gearboxes to dig and lift heavy things.

When you use a gearbox, you should think about efficiency. A gearbox lets your motor run at a speed that uses less energy. This can save power and money. But, if you pick a low gear ratio, you get less torque and more speed. This can make it hard to start heavy loads. High gear ratios give you more torque but slow down the output speed.

Gear Ratio Type | Effect on Torque | Effect on Speed | Efficiency Trade-offs |

|---|---|---|---|

High Gear Ratio (e.g., 100:1) | High torque output, good for heavy loads | Low output speed | Better for heavy tasks, but slower movement |

Low Gear Ratio (e.g., 5:1) | Lower torque, not good for heavy loads | Higher output speed | Faster movement, but less torque and may waste energy under heavy loads |

Note: Always balance torque and speed when you pick a gearbox. The right choice helps your low speed motors work better and last longer.

Power, Voltage, and Efficiency

Power Calculation

You need to know how much power your machine needs. First, find the torque and speed your machine uses. Use this formula to get the power:

Power (Watts) = Torque (Nm) × Angular Speed (rad/s)

This formula helps you see how much power your low speed motor needs. If you use direct drive, add the inertia from both the motor and the load. Multiply the total inertia by the acceleration and angular speed. This gives you the total power needed. Always look at the manufacturer's numbers to be sure.

Tip: Add extra power when you pick your motor. Most people use a 15% to 20% safety margin. This extra power helps if the load changes or if the voltage drops.

A safety margin helps with small differences between motors.

It helps if your process changes or if you do not know everything.

Many people choose a bigger motor to feel safe.

Voltage Match

It is important to match the voltage for your motor. If you use less voltage than needed, the motor will not give enough torque. It will also waste energy. If you use too much voltage, it can hurt the insulation and other parts. Changes in voltage can make the motor too hot and not last as long.

Always check that your power supply matches the motor’s voltage.

Use a voltage regulator to keep the voltage steady.

Do not mix voltages between controllers, batteries, and motors.

Note: If the voltage does not match, the motor can work poorly, get too hot, or break forever. Always check your voltage before you start.

Efficiency Class

Picking a high efficiency motor saves money and energy. Motors with higher efficiency classes, like IE3, IE4, or IE5, use less electricity and make less heat. For example, IE5 synchronous motors can be up to 99% efficient. These motors help lower your bills and are better for the environment.

Efficiency Class | Typical Efficiency (%) | Benefits |

|---|---|---|

IE2 | 85-88 | Meets basic standards |

IE3 | 89-94 | Lower energy use, less heat |

IE4 | 95-97 | High savings, less maintenance |

IE5 | 98-99 | Maximum savings, top performance |

If you switch to a high efficiency motor, you can use up to 10% less electricity. Over time, the money you save can pay for the motor. Always check the efficiency class before you buy a motor.

Reliability and Maintenance

Duty Cycle

You need to check the duty cycle before you choose a motor. Duty cycle tells you how long a motor can run without stopping. If you pick a motor with a high duty cycle, it can work for long hours without overheating. This is important for jobs that need the motor to run all day, like in factories or conveyor belts. Motors made for continuous duty last longer because they do not get too hot. They also keep their torque and power steady.

Motors with a low duty cycle are for short jobs. These motors need breaks to cool down. If you use them too long, they can overheat and wear out fast. Always match the duty cycle to your job. If you use a motor for more time than it can handle, it will not last as long. You may need to fix or replace it sooner.

Tip: Always check the label or manual for the duty cycle rating. This helps you avoid early breakdowns and keeps your machine running smoothly.

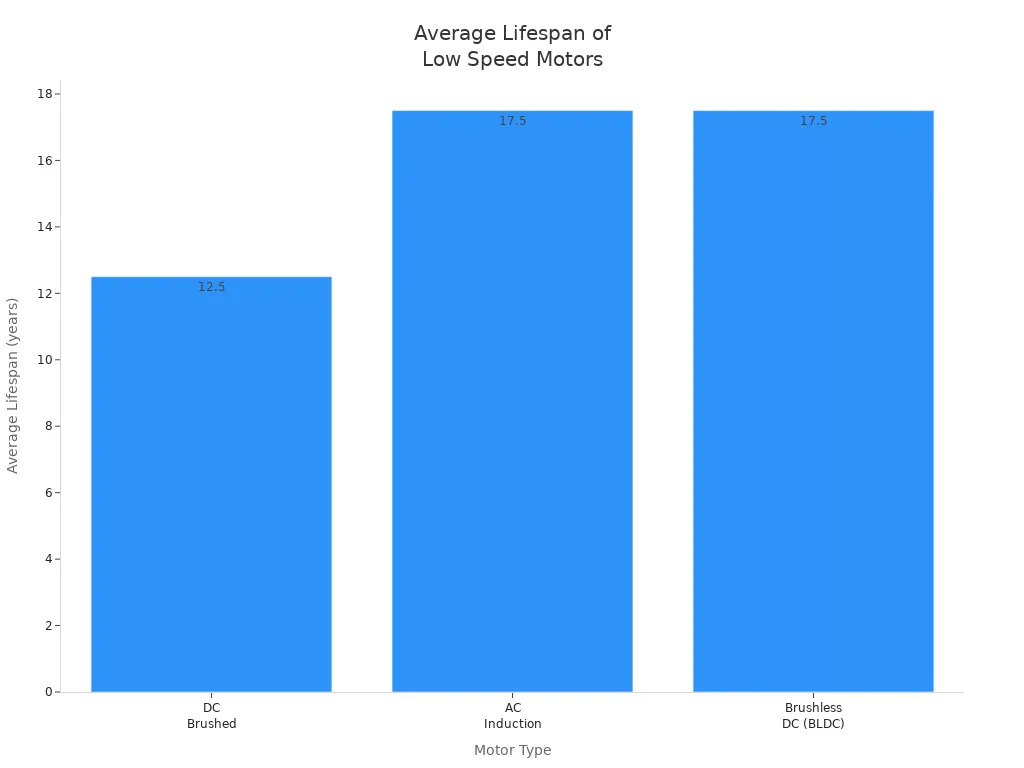

Lifespan and Service

You want your motor to last as long as possible. The type of motor you choose makes a big difference. Brushless DC motors last much longer than brushed motors. This is because they do not have brushes that wear out. Brushless motors can last two to three times longer than brushed motors. Brushed motors need new brushes every 1,000 to 3,000 hours. Brushless motors can run for over 10,000 hours, even in tough places.

AC induction motors also last a long time. They need less fixing and can work for up to 20 years. Dust and moisture can make any motor wear out faster, so keep them clean and dry.

Motor Type | Average Lifespan (years) | Maintenance Details | Environmental Impact on Lifespan | MTBF (hours) |

|---|---|---|---|---|

DC Brushed | 10-15 | Brushes replaced every 1,000-3,000 hours; replacement costs add up over time | Lifespan reduced by 20-30% in humid/dusty conditions | 20,000-30,000 |

AC Induction | 15-20 (up to 25 for high-quality) | Lower maintenance costs (~500-800 yuan/year) | Lifespan reduced by ~10% in humid/dusty conditions | Up to 100,000 |

Brushless DC (BLDC) | 15-20+ (2-3 times longer than DC brushed) | No brushes, significantly reduced maintenance | Less affected by environmental factors | Not specified |

Regular checks and cleaning help your motor last longer. Replace worn parts on time. This keeps your machines safe and saves money in the long run.

Selecting the right low speed motor starts with knowing your load, speed, and torque needs. You should follow a step-by-step process:

List your application’s requirements.

Match the motor type and size to your job.

Check ratings, space, and environment.

Review efficiency and power supply.

Plan for reliability and maintenance.

Use a checklist or talk with motor experts if you have questions. Careful selection helps your machines run better, saves energy, and reduces downtime. Gather your data and reach out to suppliers for advice. The right choice leads to long-term success.

FAQ

What is the best way to size a low speed motor for my project?

You should start by listing your load, speed, and torque needs. Use the formulas in this guide. Always add a safety margin to your calculations.

Can I use a low speed motor outdoors?

Yes, you can use a low speed motor outdoors. Make sure you choose a motor with weatherproof housing. Protect it from rain, dust, and extreme temperatures.

How often should I maintain my low speed motor?

Check your motor every few months. Clean dust and dirt. Listen for odd noises. Replace worn parts as needed. Regular care helps your motor last longer.

Do I need a gearbox for every low speed motor application?

Not every job needs a gearbox. Use a gearbox if you need more torque at very low speeds. For light loads or direct drive, you may not need one.

See Also

Choosing The Best Rotating Motor For Industrial Use

Guide To Picking The Perfect Vibrating Motor For Projects

How To Choose Mini DC Motors For Industrial Applications

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry