The Ultimate Guide to Measuring Vibration

Measuring vibration is important to see how machines work. It helps find problems, stop breakdowns, and make things work better. This is needed in factories and gadgets where accuracy is key.

For example, tests like the Mann–Whitney U test show that speed, weight, and which hand or foot is used can change vibration levels. These studies show why measuring vibration correctly is important for safety and better performance in many places.

By learning how to measure vibration, you can make machines run better, avoid dangers, and improve how people use them.

Key Takeaways

Checking vibration finds machine problems early. This stops breakdowns and boosts performance.

Knowing vibration types—free, forced, and damped—helps fix machine issues.

Using key measures—movement, speed, and acceleration—makes vibration checks more accurate.

Smart tools like IoT and wireless tech improve vibration tracking. They give live data and help predict repairs.

Regular vibration tests make work safer, cut downtime, and save money on fixes for many industries.

Understanding Vibration and Its Sources

What is vibration?

Vibration means an object moves back and forth repeatedly. This movement can happen naturally or from outside forces. Engineers study vibration to see how systems react in different situations. For example, they check how machines handle friction or heavy loads. The "Fundamentals of Vibrations" chapter explains how math models vibrations and connects them to system behavior. Knowing this helps create safer and better-working devices.

Common sources of vibration in industrial and consumer devices

Vibration comes from many places, depending on the machine or device. In factories, spinning parts like rotors or tires vibrate if unbalanced. Worn-out bearings and gears also cause vibrations. Electric motors may shake when parts inside break. In gadgets, vibration motors are added on purpose, like in phones or game controllers. These examples show how checking vibrations early improves performance and reliability.

Rotating equipment: Unbalanced rotors or tires make specific vibration patterns.

Bearings and gears: Different vibration sounds warn of possible failures.

Electric motors: Vibrations show hidden problems missed by electrical checks.

Types of vibration: Free, forced, and damped

There are three main kinds of vibration based on what causes them:

Free vibration: Happens when something moves on its own after being pushed. For example, pulling a swing and letting it go makes free vibration.

Forced vibration: Happens when a constant outside force shakes something. A washing machine or a car on a rough road are examples.

Damped vibration: Happens when friction slows down the shaking over time. A car's suspension system is an example because it smooths out bumps.

Knowing these types helps fix vibration problems in machines or everyday items.

Key Parameters and Units in Vibration Measurement

Knowing the main parts of vibration measurement is important. It helps you understand how machines act in different situations. The key parts—displacement, velocity, and acceleration—show how strong and harmful vibrations are. Let’s break them down.

Displacement: What it means and why it matters

Displacement is how far something moves from its starting spot. It shows the total movement caused by vibration, usually in micrometers (µm) or millimeters (mm). Displacement is most useful for slow vibrations, which make bigger movements.

Think of displacement as how much a vibrating object "travels." For example, in spinning machines, too much displacement might mean parts are not lined up right. Watching displacement can help find problems before machines break.

Tip: Displacement is used in big industries like building and nuclear power. Large vibrations can weaken structures.

Velocity: What it means and why it matters

Velocity is how fast something vibrates. It mixes how far it moves with how long it takes. This is important for medium-speed vibrations. Engineers measure velocity in millimeters per second (mm/s) or inches per second (in/s).

Why care about velocity? It shows how much energy the vibration has. Faster vibrations can damage parts over time. For example, in machines, checking velocity helps see how forces affect parts like gears and bearings.

Here are some rules that show why velocity matters:

Standard | What it does |

|---|---|

Explains how to measure machine vibrations. | |

IEC 60068-2-6 | Tests if products can handle shaking. |

GM3172 | Sets rules for testing electric parts in tough conditions. |

Acceleration: What it means and why it matters

Acceleration is how quickly a vibrating object speeds up. It is measured in gravitational force (g) or meters per second squared (m/s²). Acceleration is best for fast vibrations, which often cause the most harm.

In vibration checks, acceleration finds problems like cracks or weak spots. For example, in airplanes, watching acceleration makes sure parts can handle tough flying conditions. In gadgets, acceleration improves how devices feel when they vibrate.

Did you know? Pseudo velocity links better with stress than acceleration or displacement. This helps engineers guess how materials will react to vibrations.

By learning about these three parts, you can better understand how systems work. Each part tells a different story, and together, they explain vibration behavior.

How these parameters work together in vibration analysis

Knowing how displacement, velocity, and acceleration connect is important. These three parts are linked and help explain how machines vibrate.

Displacement and Velocity

Displacement shows how far something moves, while velocity shows how fast it moves. If displacement gets bigger, velocity also increases, but only if the vibration speed stays the same. For example, slow machines can have big displacement but low velocity. Fast machines can have small displacement but high velocity.Velocity and Acceleration

Velocity and acceleration are connected. Acceleration shows how quickly velocity changes. When a machine vibrates fast, acceleration gets higher. This makes acceleration useful for spotting quick vibrations that might harm parts. Think of driving: the faster you press the gas, the quicker your speed grows.Displacement and Acceleration

Displacement and acceleration work opposite to each other when vibration speed changes. At slow speeds, displacement matters more because the object moves farther but slower. At fast speeds, acceleration matters more because the object moves quickly over short distances. This helps you choose the right measurement based on vibration speed.

Tip: Use displacement for slow vibrations, velocity for medium ones, and acceleration for fast ones. This method gives better results.

The Role of Frequency

Frequency connects these three parts. It controls how displacement, velocity, and acceleration interact. If frequency doubles, velocity doubles, but acceleration becomes four times bigger. This shows why fast vibrations can cause more damage.

Parameter | Best for Finding | Example Uses |

|---|---|---|

Displacement | Slow vibrations | Big machines, building checks |

Velocity | Medium vibrations | Motors, spinning parts |

Acceleration | Fast vibrations | Bearings, airplane parts |

By learning how these parts connect, you can study vibrations better. Each part tells you something different, but together, they explain how machines handle vibrations.

Tools and Technologies to Measure Vibration

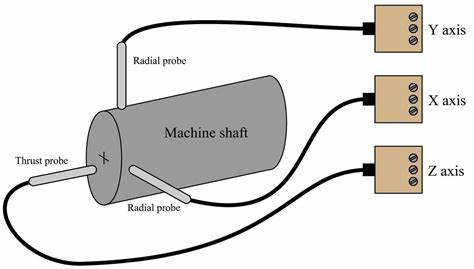

Vibration sensors: Accelerometers, velocity sensors, and displacement sensors

Vibration sensors help us understand how machines work. They find and measure vibrations, giving important data. There are three main types of sensors: accelerometers, velocity sensors, and displacement sensors.

Accelerometers: These sensors check how fast something speeds up. They are great for finding high-frequency vibrations. Industries like airplanes and cars use them to watch fast-moving parts. For example, they can spot cracks in airplane parts.

Velocity sensors: These sensors measure how fast something vibrates. They are best for medium-frequency vibrations. You’ll often see them used in motors and spinning machines. They help make sure machines run smoothly by checking energy levels.

Displacement sensors: These sensors track how far something moves when it vibrates. They work well for low-frequency vibrations. Big structures like bridges or buildings use them. Watching displacement helps stop damage over time.

Each sensor type has a special job in measuring vibration. Picking the right one helps you find problems early and fix them.

Tip: Always check and adjust your sensors to keep them working well.

Vibration meters and handheld devices for measuring vibration

Vibration meters are small tools that make measuring vibrations easy. They are simple to use and don’t need a lot of setup. Maintenance workers and field teams use them often.

These meters measure things like displacement, velocity, and acceleration. Results show up on a screen right away. Some advanced meters can save data for later. For example, you can use one to check if a motor is working well or if a machine is unbalanced.

Handheld devices are light and easy to carry. They are great for regular checks. They help find problems early, so machines don’t break suddenly. With these tools, you can keep equipment running better for longer.

Did you know? New vibration meters can send data wirelessly to computers or the cloud for more study.

Advanced vibration analyzers and software solutions

Advanced vibration analyzers give detailed information about vibrations. They collect data from sensors and show things like vibration patterns and frequency. These tools are great for fixing big machine problems.

Here are some features of advanced analyzers:

Data collectors: These gather vibration data from many spots. They help find patterns and changes over time.

Online monitoring systems: These watch machines all the time. They send alerts if something goes wrong, so you can fix it fast.

Integration with Industry 4.0: Some tools work with smart systems like IoT. This helps machines stay in good shape and work better.

Using these analyzers saves time, plans repairs better, and keeps machines working longer. For example, online systems can find problems early, so you can fix them before they get worse.

Feature | Benefit |

|---|---|

Real-time data collection | See how machines are working right away |

IoT integration | Share data easily with platforms like Microsoft Azure |

Long battery life | Works for up to 10 years with little upkeep |

These tools are very helpful for industries needing accuracy and speed. Whether you’re checking a factory or testing a product, advanced analyzers and software give you the details you need to succeed.

Emerging technologies: IoT and wireless monitoring for vibration measurement

IoT (Internet of Things) and wireless tech have changed vibration measurement. These tools let you check machines from far away. They give live updates and useful information. Using IoT sensors and wireless systems helps save time, avoid breakdowns, and make better choices.

How IoT enhances vibration measurement

IoT links sensors to a network. This lets them send data to the cloud or local systems. You can see this data on your phone, tablet, or computer. IoT also studies the data to find patterns and warn about problems.

Here’s how IoT makes vibration checks better:

Real-time monitoring: Sensors watch vibrations all the time and send updates fast. You can fix issues before they cause damage.

Predictive maintenance: IoT uses data to guess when a machine might break. This helps you plan repairs early.

Data storage and analysis: IoT saves vibration data over time. You can study it to spot trends and improve machines.

Remote access: IoT lets you check machines from anywhere, even far away.

Tip: Use IoT sensors with smart software for detailed reports and better results.

Benefits of wireless monitoring

Wireless monitoring removes the need for cables between sensors and devices. This makes setting up and using systems easier. Wireless tools are great for hard-to-reach or risky places.

Here are the main benefits of wireless monitoring:

Easy installation: No cables mean faster and cheaper setup.

Flexibility: Place sensors where wires won’t work.

Safety: Check dangerous areas without being there yourself.

Scalability: Add more sensors easily for bigger setups.

Applications of IoT and wireless vibration monitoring

IoT and wireless tools are used in many fields. They help check equipment, boost safety, and increase efficiency. Here are some examples:

Industry | Application |

|---|---|

Manufacturing | Watching motors, pumps, and belts to stop delays. |

Healthcare | Making sure medical tools work safely. |

Automotive | Checking engine vibrations for better performance. |

Energy | Watching turbines and generators in power plants. |

Consumer Electronics | Improving user experience with vibrating gadgets like phones. |

Why you should adopt these technologies

IoT and wireless tools make vibration measurement smarter and faster. They save time by automating checks and studying data. They also give better accuracy for smarter decisions. Using these tools helps you stay ahead in today’s fast-moving world.

Did you know? INEED’s vibration motors work well with IoT systems. They offer strong performance for advanced uses. Learn more at INEED Motors.

INEED's Role in Vibration Measurement Solutions

How INEED's Vibration Motor improves measurement accuracy

INEED's vibration motors help make vibration measurements more accurate. These motors create steady and exact vibrations, which are great for tasks needing high precision. Tests have proven their strong performance. For example:

Set A's AUC values were over 0.997, showing top accuracy.

Vibration features scored a perfect 1.000, proving their importance.

Time-series features scored 0.995, showing the motors' reliability.

These results show how INEED's motors improve vibration analysis. They provide dependable data for many industries.

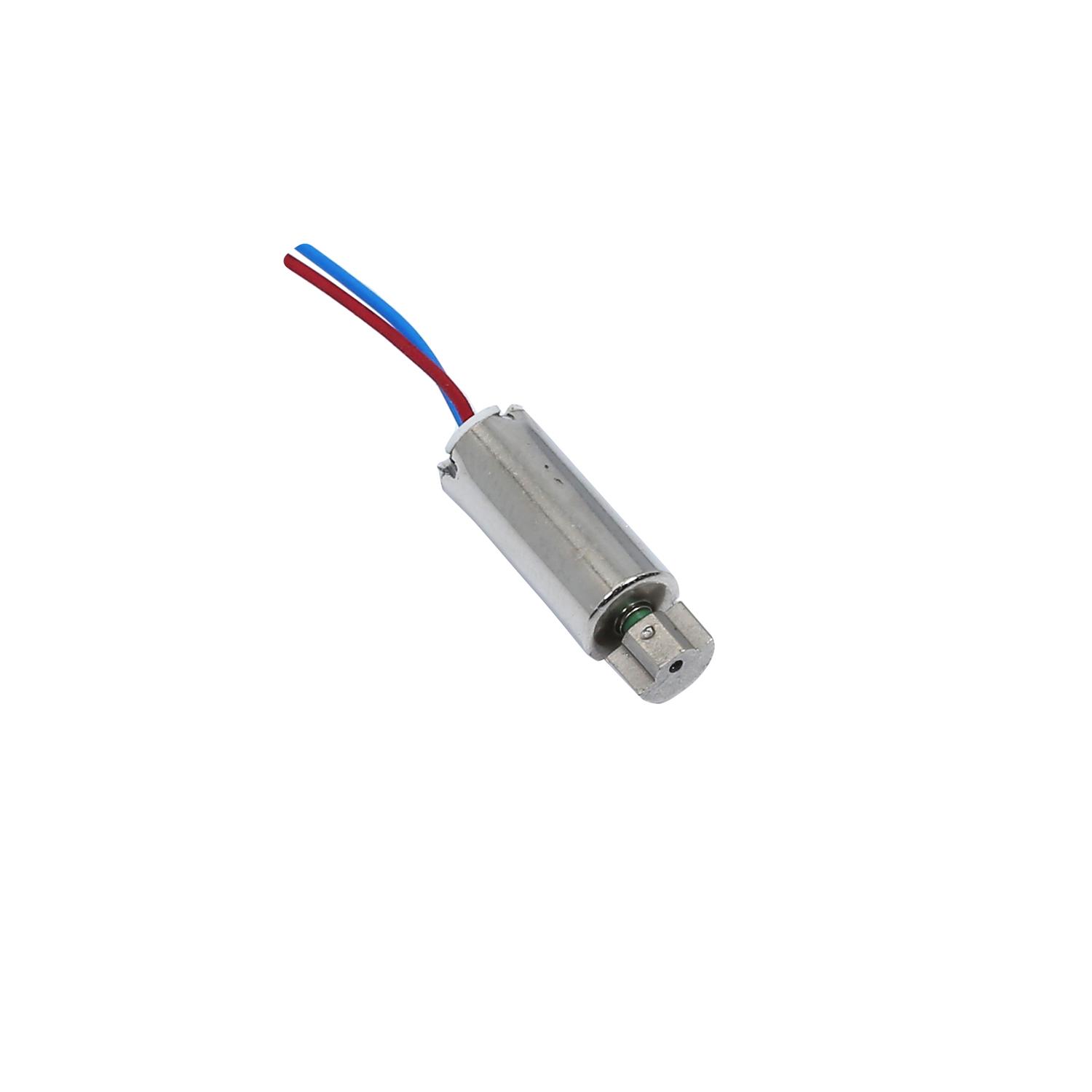

Uses of SMD Vibration Motors in small devices

INEED's SMD vibration motors are used in many small gadgets. These motors attach to surfaces, making them great for wearables and smartphones. Their small size saves space, and they last a long time.

Manufacturers like these motors because they handle high heat during soldering. This makes them good for large-scale production. For example, fitness trackers use them for alerts, and smartphones use them for haptic feedback. SMD motors make devices better by giving precise vibrations.

Tip: SMD motors come in reels for faster assembly, saving time and money.

Encapsulated Vibration Motors for tough conditions

For harsh environments, INEED's encapsulated motors are a reliable choice. These motors resist water and dust, making them ideal for medical tools, outdoor devices, and industrial machines.

They are built with strong capsules and sealed with epoxy resin for protection. For instance, they are used in facial massagers for muscle relief and vending machines for better feedback.

INEED ensures high quality with ISO 9001:2015 certification and strict testing. These motors work well even in the toughest conditions.

Coreless Vibration Motors for small and efficient devices

Coreless vibration motors are small and work very efficiently. These motors, also called "pager motors," were first used in pagers. Now, they are found in many modern gadgets. Their light weight and quick action make them popular with makers.

What Makes Coreless Vibration Motors Special

Coreless motors are different because of their smart design. They don’t have a metal core in the rotor. This makes them lighter and easier to spin. The design saves energy and makes them run smoothly. These motors are great for small spaces where good performance is needed.

Main features include:

Small Size: Sizes range from 4mm to 10mm, fitting tiny gadgets.

Energy Saving: The coreless design uses less power.

Fast Action: They respond quickly, improving user experience.

Custom Options: You can adjust wire length, mounting, and vibration style.

Tip: Add coreless motors to fitness trackers or game controllers for better feedback.

Where Coreless Vibration Motors Are Used

These motors are used in many areas. In phones, they give soft vibrations for alerts. Gaming devices use them for lifelike feedback. Wearables depend on them for workout alerts. Beauty tools use their gentle vibrations for better care.

Use | Function |

|---|---|

Smartphones | Alerts and haptic feedback |

Gaming Controllers | Realistic game vibrations |

Wearables | Workout alerts and tracking |

Beauty Devices | Better skincare routines |

Coreless vibration motors are small, efficient, and flexible. Adding them to your products can make them work better and feel nicer to use. Check out INEED’s custom options to improve your designs.

Practical Uses of Vibration Measurement

Stopping Problems Early with Preventive Maintenance

Preventive maintenance uses vibration checks to keep machines working well. Watching vibrations helps spot early signs of wear or misalignment. This stops sudden breakdowns and lowers repair costs. For example, sensors can find loose bearings or unbalanced parts before big damage happens.

Many industries use vibration monitoring successfully. Here’s how it helps in different areas:

Industry | Example Use |

|---|---|

Pulp and Paper | Special vibration tools handle tough factory conditions. |

Regular checks stop pump failures and downtime. | |

Cooling Tower | Strong sensors warn of problems in gas facilities early. |

Pharmaceutical Plant | Finds issues in air systems to keep clean rooms safe. |

Manufacturing Facility | Wireless tools find loose parts in air systems. |

Using vibration checks keeps machines safe and running smoothly.

Smarter Repairs with Predictive Maintenance in Smart Factories

Predictive maintenance uses vibration data to plan repairs early. In smart factories, IoT sensors watch machines live. These sensors collect data and warn when a machine might fail. This helps fix problems before they happen, improving machine performance.

For example, vibration checks find cracks or imbalances early. These issues could cause costly downtime. IoT lets you see live data and get alerts on your devices. Predictive maintenance is a key part of modern smart factories.

Benefits of predictive maintenance include:

Spotting problems early.

Watching machines live for better safety.

Saving money by avoiding big repairs.

Using predictive maintenance keeps machines working longer and better.

Making Electronics Better with Vibration Motors

Vibration motors make electronics more fun and easy to use. They give feedback you can feel, making devices more engaging. For example, phones vibrate for alerts, and game controllers use vibrations for realistic effects.

Noise, vibration, and harshness (NVH) tests ensure motors work quietly and smoothly. This improves comfort and user happiness. Products with less noise often get better reviews and loyalty.

Benefits of vibration motors in electronics include:

Better feedback for easier use.

Quieter devices for more comfort.

Higher quality and happier users.

Adding vibration motors makes devices stand out in the crowded electronics market.

Examples of industries benefiting from vibration analysis (e.g., manufacturing, healthcare, automotive)

Vibration analysis helps many industries work better and safer. It finds problems early, avoids expensive repairs, and improves performance. Here are some industries where it makes a big difference:

Manufacturing

Factories depend on machines to make products quickly. Vibration analysis finds issues like bent shafts, old bearings, or unbalanced parts. These problems can slow down work or stop it completely. Sensors check machine health so repairs can happen before breakdowns. For example, on assembly lines, vibration checks keep motors and belts running smoothly to avoid delays.

Tip: Checking vibrations often saves money and makes machines last longer.

Healthcare

Medical tools need to work perfectly to give correct results. Vibration analysis keeps devices like MRI machines, ventilators, and surgical tools working safely. Too much vibration can cause errors or harm patients. By measuring vibrations, you can keep these tools accurate and reliable.

Device | How Vibration Analysis Helps |

|---|---|

MRI Machines | Keeps images clear and machines safe |

Surgical Robots | Makes surgeries more precise |

Ventilators | Stops parts from breaking |

Automotive

In cars, vibration analysis improves how they run and feel. It checks engines, gears, and suspensions for problems. Too much vibration can cause wear, noise, or poor performance. For example, during car production, vibration checks make sure vehicles meet quality standards. In repairs, it finds issues like wobbly tires or broken engine mounts.

Did you know? Car designers use vibration analysis to make quieter, smoother rides.

Using vibration analysis makes machines safer, cheaper to fix, and more reliable. Whether in factories, hospitals, or cars, it helps improve how things work and last longer.

Benefits of Measuring Vibration

Better equipment performance and reliability

Checking vibration keeps your machines working well. Watching vibration levels helps find problems early. Fixing them fast stops bigger issues later. This keeps machines healthy and working their best.

Vibration checks find dangers, making workplaces safer.

Predictive maintenance lowers downtime by up to 30%, improving work.

Vibration tools give early warnings, making machines last longer.

Regular vibration checks show how machines behave. This helps improve performance and avoid sudden breakdowns.

Tip: Use vibration tools to see patterns over time. This helps plan better maintenance and use resources wisely.

Less downtime and lower repair costs

Unplanned stops can cost a lot of money. Vibration checks help avoid this by spotting problems early. Predictive maintenance can guess failures with up to 92% accuracy. Fixing issues early stops them from getting worse.

Early problem checks mean better planning and fewer stops.

Fixing things on time makes machines last longer, saving money.

Predictive maintenance cuts unplanned stops by 30-50%, saving costs.

Using vibration systems makes work smoother and reduces delays. This saves money and keeps machines in great shape.

Did you know? Companies using vibration systems save big on repairs and downtime.

Safer and more efficient operations

Measuring vibration helps make workplaces safer and more productive. Finding vibration problems early stops accidents and keeps machines running smoothly.

Watching vibration shows weak spots in machines, stopping breakdowns.

Reliable machines create safer places for workers.

Better efficiency means more work done with less waste.

Vibration checks give control over machine performance. This keeps workers safe and ensures smooth operations.

Tip: Regular vibration checks keep machines and workers in top shape, ensuring safety and efficiency.

Better product design and user experience with INEED's vibration motors

INEED's vibration motors improve how products work and feel. They give steady and reliable vibrations, making devices easier and more enjoyable to use. From wearables to smartphones and tools, these motors ensure great performance and happy users.

To see their value, engineers check key vibration metrics. These metrics show how well a motor works in different situations:

Parameter | What it shows |

|---|---|

Peak | The strongest vibration during a specific time. |

RMS | The average vibration strength over time. |

Crest Factor | Compares the strongest shake to the average strength. |

These measurements help create products that are powerful, efficient, and comfortable. For example, a high crest factor is great for phone alerts. RMS values are better for steady devices like fitness trackers.

INEED's motors use smart technology to work even better. Real-time systems make them 40% smoother. Special fault-fixing methods, inspired by nature, make them faster and steadier. Genetic algorithms shrink motor size by 9.14%, making them more efficient and compact. These features make INEED's motors perfect for modern gadgets.

By using these motors, you can design standout products. INEED offers custom options to match your needs. Whether for gaming controllers or medical tools, these motors ensure a smooth and satisfying experience.

Tip: Choose INEED's motors for better control and top performance. Their advanced designs make devices more reliable and enjoyable to use.

Measuring vibration is key to making industries safer and better. It finds equipment problems early, helps manage tools, and cuts downtime. Industries like mining and oil use vibration checks to keep machines working well. Remote sensors and cloud systems make fixing issues quicker and cheaper.

INEED's vibration motors improve this by working accurately and reliably. Their smart designs give correct results, even in tough conditions. Check out INEED's custom options to fit your needs and boost your products' performance.

FAQ

What tool works best for checking vibration in small gadgets?

Use accelerometers for small gadgets. They measure fast vibrations well. These tiny sensors are perfect for devices like smartwatches and phones.

Tip: Combine accelerometers with INEED's vibration motors for accurate results.

How often should machines have their vibration checked?

Check vibrations often, based on how much the machine is used. For important machines, weekly or monthly checks are best. Regular checks help find problems early and save on repairs.

Can vibration motors be made to fit special needs?

Yes, vibration motors can be adjusted for your needs. You can change their size, strength, frequency, and how they are attached. INEED provides custom options for many industries.

Why does vibration analysis matter for safety?

Vibration analysis finds weak parts in machines. It stops accidents by catching problems early. Safer machines mean fewer risks and better work efficiency.

How does IoT make vibration checks better?

IoT links sensors to networks for live updates. You can check data from anywhere and get alerts quickly. This helps fix problems faster and reduces downtime.

Did you know? INEED's vibration motors work great with IoT systems for smarter checks.

See Also

Top Instruments for Measuring Vibration Effectively Today

Understanding Vibration Motors: Varieties, Uses, and How to Choose

Vibration Motors in Today’s Industries: Key Applications Explored

The Functionality of Vibration Motors in Haptic Feedback Systems

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry