How to match a battery to your motor for any project

Choosing the right battery motor combination can make your project work smoothly and safely. You need to match the battery to your motor’s needs for the best results. INEED offers years of experience with micro motors and custom solutions for many industries. Before you start, collect all your project goals and motor specifications so you can make the best decision.

Key Takeaways

Identify your project needs first. Understand the application type to choose the right motor and battery combination.

Always match the battery voltage to your motor's rated voltage. Using the wrong voltage can damage your motor or reduce its performance.

Calculate the required battery capacity based on your project's power consumption. This ensures your project runs for the desired duration without interruptions.

Consider safety margins when selecting batteries. Avoid using the full charge or discharge range to extend battery life and prevent failures.

Regularly monitor your battery and motor setup. Use protection systems to detect issues early and maintain reliable performance.

Project Needs

Application Type

You should always start by identifying your project needs. Every project has a unique purpose, and the type of application will shape your choices. For example, if your project involves consumer electronics, you may use DC motors in handheld devices, gear motors in electronic products, or vibration motors in smart gadgets.

DC motors in handheld devices

Gear motors in various electronic products

Vibration motors in consumer electronics

Your project needs will determine the kind of motor and battery you select. Different application types require you to match motor performance and power consumption with the right battery. You must also consider efficiency and battery discharge characteristics. The discharge current of your battery can limit the maximum output torque of your motor, so you need a properly sized battery for your project.

Battery Voltage: Choose an appropriate battery voltage to match the rated voltage of the motor. If the battery voltage is too low, the motor may not perform optimally, and if it's too high, it could lead to damage.

Power and Movement

Your project needs will also depend on how much power and movement your application requires. For robotics projects, you must look at torque, speed, and precision. DC motors convert electrical energy into rotational motion, which is essential for driving wheels or moving robotic arms. You need to estimate the required torque based on the payload and friction in your project.

DC motors provide high starting torque, which helps start movement.

They offer a wide range of speed capabilities for accurate control.

You can easily control them with embedded systems.

When you select a DC motor, consider torque, RPM, and load capacity to match your project needs. Pairing motors with the right drivers ensures safe operation and the best performance for your project.

Usage Duration

You must also think about how long your project needs to run on a single charge. To determine the expected battery life, calculate or measure the average power consumption of your project. This step is crucial for battery longevity. For example, if your project needs to last a year and uses an average of 57uA, you might choose a 500mAh battery. This calculation shows how usage duration directly affects your battery choice.

Understanding your project needs helps you select the right battery and motor combination. You should always consider safety features and the best electrochemical technologies for your project. The process of requirements engineering helps you identify all the functions and limits that influence your battery choice.

Motor Specs

Voltage and Current

You need to check the voltage and current requirements of your motor before choosing a battery. Every motor has a rated voltage and current. These numbers tell you how much electrical energy the motor needs to run safely and efficiently. If you use the wrong voltage and current, you risk damaging your motor or reducing its performance.

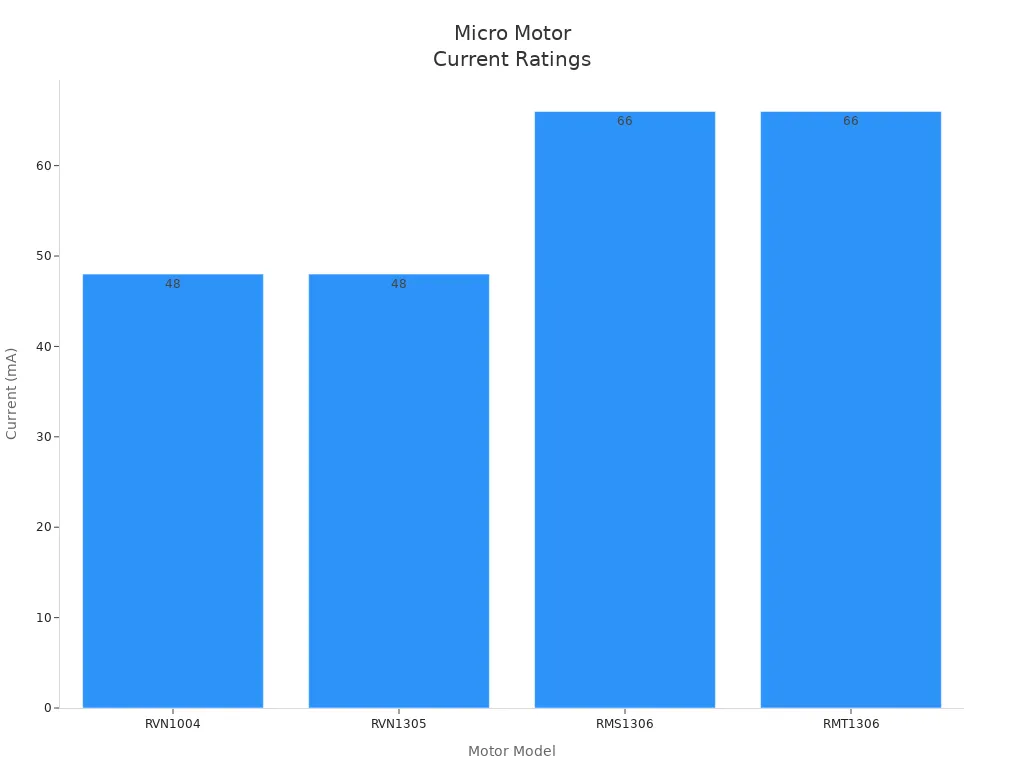

Here is a table showing typical voltage and current ranges for micro motors used in consumer electronics:

Model | Voltage Range (V) | Current (mA) |

|---|---|---|

RVN1004 | 2.8~3.3 | 48 |

RVN1305 | 2.8~3.3 | 48 |

RMS1306 | 4.5~5.5 | 66 |

RMT1306 | 4.5~5.5 | 66 |

You can see that most micro motors need a specific voltage and current to work well. Always match the battery voltage and current rating to your motor specs. If you use a battery with lower voltage and current, your motor may not start or run smoothly. If you use a battery with higher voltage and current, you could overheat or damage the motor.

Tip: Always check the datasheet for your motor to find the correct voltage and current values.

Torque and Speed

Torque and speed are two important specs that affect battery choice. Torque measures how much force your motor can produce. Speed tells you how fast the motor spins. If you need high torque, your motor will use more energy and drain the battery faster. If you want high speed, you need a battery that can keep up with the motor’s demands.

When you match motor specs to your project, think about how much torque and speed you need. For example, if you build a robot that must lift heavy objects, you need a motor with high torque. If your robot needs to move quickly, you need a motor with high speed. Both specs influence how much voltage and current your battery must supply.

Oversizing your motor can waste energy and shorten battery life. Always choose a motor that fits your project needs to optimize battery usage.

Robot DC Motors

Robot dc motors have special battery requirements compared to other motor types. You must consider voltage and current ratings, discharge rate, and weight. These factors affect how your robot performs and how long it can run.

Specification | DC Motors | Other Motor Types |

|---|---|---|

Voltage Rating | Required for operation | Varies based on type |

Current/Capacity Rating | Essential for performance | Different requirements |

Discharge Rate | Important for sustained use | May differ |

Weight | Affects overall robot design | Varies by motor type |

When you select robot dc motors, always check the voltage and current specs. Make sure your battery can deliver enough power for the motor to run smoothly. INEED offers a wide range of robot dc motors for different applications. You can find motors with the right voltage and current for your robot project. Matching these specs helps you avoid overload and ensures reliable operation.

Pick the Right Battery

Battery Motor Match

Choosing the right battery motor combination is the most important step for your project’s success. You need to match the battery to your motor’s voltage, current, and power needs. If you do not, your battery powered motor may not work as expected or could even get damaged. Start by checking your motor’s rated voltage and current. Make sure your battery matches these values.

Factor | Description |

|---|---|

Voltage Matching | Ensures the battery voltage aligns with the motor's requirements to prevent damage and ensure performance. |

Continuous Current Draw | The battery must handle the average current used by the motor during operation, including a safety margin. |

Efficiency | Higher efficiency motors reduce power requirements, allowing for smaller, cost-effective batteries. |

Battery Capacity | Determines the operational runtime between recharges, based on the amount of charge the battery can hold. |

Motor Output Torque | Must be considered as it is directly proportional to the current supplied by the battery. |

You should always check the average current your battery powered motor uses. If you use more than one motor, add up the current for all of them. Add a safety margin of at least 25% to your total current draw. Then, select the right battery that can provide this current. This method helps you avoid overload and keeps your battery life longer.

Tip: Always use batteries from the same brand or certified compatible ones. This helps prevent issues with voltage and current draw.

How to Pick the Right Battery

You need to look at several factors when you select the right battery for your battery powered motor. The most important ones are battery chemistry, voltage, capacity, and current ratings. Each factor affects how well your battery motor setup works.

Battery Chemistry

There are different types of batteries, such as lipo, nimh, and NiCad. Each type has its own strengths.

Battery Type | Interchangeability with Other Types | Voltage Differences | Notes on Compatibility with Motors |

|---|---|---|---|

NiMH | Can replace NiCad | Lower than Li-ion | Suitable for many motors requiring moderate power |

Li-ion (Lipo) | Usually cannot replace NiMH | Higher than NiMH | Often used in high-performance motors due to energy density |

NiCad | Can be replaced by NiMH | Lower than Li-ion | Less common in modern applications due to lower efficiency |

Lipo batteries have high energy density and work well for high-performance battery powered motor projects.

Nimh batteries are good for moderate power needs and are common in consumer electronics.

NiCad batteries are less common now but can be replaced by nimh in many cases.

Note: Always use the correct charger for your battery chemistry. Using the wrong charger can damage your battery and shorten battery life.

Voltage and Capacity

You must match the battery voltage to your motor’s rated voltage. If the voltage is too high, you risk overheating your battery powered motor. If it is too low, your motor may not start or run smoothly. Battery capacity, measured in amp-hours (Ah), tells you how long your battery powered motor can run before you need to recharge.

Calculate the number of batteries in series by dividing the required supply voltage by the nominal battery voltage.

To find the required battery capacity, multiply the current draw by the number of hours you want your battery powered motor to run.

For example, if your battery powered motor draws 100 mA and you want it to run for 10 hours, you need a battery with at least 1,000 mAh (1 Ah) capacity.

Tip: Add a safety margin to your battery capacity to account for unexpected power draw or longer use.

Current Ratings

Check the maximum current your battery can supply. Your battery powered motor may need more current during startup or heavy loads. Make sure your battery can handle these peaks without dropping voltage or overheating.

Select the Right Battery for INEED Motors

INEED offers custom micro motors for many industries. You need to select the right battery for each application. Let’s look at the LRA vibration motor for wearable smart devices as an example.

The LRA vibration motor in smartwatches needs a battery that meets strict power and battery life requirements. Here are the typical specs:

Specification | Value |

|---|---|

Rated voltage | 1.2 VRMS to 2.5 VRMS |

Operating voltage | 0.1 VRMS to 2.5 VRMS |

Rated current | 60 mA to 170 mA |

Typical rated current | 5 mA to 145 mA |

You need to use a battery that can supply the right voltage and current for the LRA vibration motor. Lipo batteries are a popular choice for wearable devices because they offer high energy density and long battery life. Nimh batteries can also work for moderate power needs, but lipo batteries are lighter and last longer.

When you select the right battery for INEED motors, follow these steps:

Check the motor’s rated voltage and current.

Choose a battery with matching voltage and enough capacity for your desired battery life.

Make sure the battery can handle the peak current draw of your battery powered motor.

For wearable devices, pick lipo batteries for the best balance of size, weight, and battery life.

Consider the physical size and terminal type of the battery to fit your device.

For harsh environments, use gel cell or AGM batteries for better durability.

Note: Always check the date of manufacture to ensure your battery is fresh. Old batteries lose capacity and can affect battery life.

You can calculate your battery power requirements using this formula:

Runtime (hours) = (Battery Capacity (Ah) × Battery Voltage (V) × Efficiency) / Load Power (W)

This formula helps you estimate how long your battery powered motor will run before you need to recharge. Always add a safety margin to your calculations for real-world use.

By following these steps, you can select the right battery for any INEED battery powered motor. This ensures your project meets its power needs and delivers reliable performance.

Safety and Reliability

Safety Margins

You need to build safety margins into your battery and motor system. This step helps you avoid unexpected failures and keeps your project running smoothly. When you select a battery, you should not use its full charge or discharge range. For example, electric vehicle batteries work best when you charge them up to 80% and discharge them down to 30%. This buffer protects the battery from capacity loss and extends its life.

Always choose a battery cycler that can handle the highest and lowest voltage and current levels.

Pick a controller with a current rating higher than your motor’s continuous needs. This choice helps you manage power surges and keeps your system safe.

You should plan for battery aging. Over time, the battery loses capacity. A safety margin gives you extra power when you need it most.

Protection and Monitoring

Protection and monitoring systems keep your battery and motor setup reliable. These systems watch for problems and act before damage happens. You can use controllers and protection components to monitor voltage, current, and temperature. If the system detects abnormal readings, it activates safety measures.

Aspect | Contribution to Safety |

|---|---|

Voltage Monitoring | Prevents operation below safe battery levels by checking each cell. |

Current Protection | Stops overcurrent by opening switches in the battery pack. |

Temperature Regulation | Controls heat to prevent battery and motor damage. |

Communication | Shares real-time data for better power management and safety. |

Monitoring systems can detect failures by tracking battery string currents. If a cell fails, you can replace it and extend the battery’s service life. These systems also lower costs by reducing manual checks. Accurate monitoring improves power performance by managing charge and discharge levels. Over-voltage and under-voltage detection keeps each cell within safe limits, boosting reliability.

Environmental Factors

Environmental factors affect battery and motor reliability. You must protect your system from moisture, dust, and extreme temperatures. INEED uses strict quality control and reliability testing to ensure motors work in tough conditions. Tests include visual inspection, resistance checks, insulation tests, and load tests. These steps help you spot problems like cracks, rust, or overheating before they cause failures.

You should choose a battery that matches your environment. For outdoor projects, pick batteries with strong cases and good insulation. For wearable devices, select batteries that resist moisture and temperature swings. Always check your battery and motor regularly to keep your power system safe.

Tip: Regular testing and monitoring help you catch issues early and keep your battery powered motor running at peak performance.

Common Mistakes

Overload Issues

You might face overload issues if you do not match your battery and motor correctly. Overload can damage both the battery and the motor. It often happens when you push the motor beyond its rated limits or use the wrong battery. Here is a table showing the most frequent overload problems and their causes:

Type of Overload | Common Causes |

|---|---|

Mechanical Overload | - Higher torque output than rated for heavier loads (e.g., crushing machines) |

Electrical Overload | - Overvoltage, undervoltage, or fluctuating voltage at the motor controller or power source |

If you ignore these issues, you risk overheating, reduced efficiency, or even permanent failure. Always check your load and make sure your battery can handle the demands of your motor.

Ignoring Ratings

Many people ignore the voltage and current ratings on their batteries and motors. This mistake can lead to poor performance or damage. You should always read the datasheets and labels. If you use a battery with too high a voltage, you can burn out your motor. If the current is too low, your motor may not start or could stall under load.

Tip: Always add a safety margin to your calculations. Choose a battery and motor that can handle more than your project’s maximum expected load.

Ignoring ratings can also shorten the lifespan of your components. You will save time and money by double-checking all ratings before you connect your system.

Safety Features

You need to use proper safety features to protect your project. Simple steps can prevent accidents and damage:

Remove batteries when disassembling devices.

Turn off power from the circuit breaker for maintenance projects.

Use appropriate tools to discharge large capacitors safely.

Wear protective gear such as rubber-soled shoes and eye protection.

A Battery Management System (BMS) helps keep your battery safe. The BMS monitors voltage, current, and temperature. It prevents overcurrent and undervoltage, which can damage your battery. The BMS can also include thermal management and fire protection, making your project much safer.

Use fuses to protect against overloads from short circuits.

Implement a High-Voltage Interlock system (HVIL) to monitor connections and disconnect power if needed.

Regularly check and maintain circuit protection devices.

Note: Good safety habits and the right protection systems keep your battery and motor running smoothly and safely.

You can match a battery to your motor by following these steps:

Choose a battery with enough discharge current for peak motor demand.

Select capacity based on how long you need your project to run.

Pair your motor with a compatible controller.

Use this checklist for quick reference:

Specification | Description |

|---|---|

Voltage (V) | Must match motor and controller |

Capacity (Ah) | Higher Ah means longer runtime |

Discharge Rate (C) | Crucial for high-performance applications |

Double-check all specs and safety features before you start. INEED offers custom solutions, expert guidance, and support for unique battery-motor projects.

Service Type | Description |

|---|---|

Customization Options | Tailored gear motors, output shafts, gear ratios |

Guidance on Motor Selection | Expert advice for choosing the right motor |

Design and Integration Support | Help with fitting motors into your device |

Tip: Careful planning and expert support help you achieve reliable results for any project.

FAQ

How do you know if your battery matches your motor?

Check the motor’s rated voltage and current. Choose a battery with the same voltage and enough current capacity. Review the datasheet for both parts. Add a safety margin to prevent overload.

What happens if you use a battery with too high voltage?

You risk overheating or damaging your motor. The motor may run faster than designed, which can shorten its lifespan. Always match the battery voltage to the motor’s rating.

Can you use any battery type with INEED micro motors?

No. You must select a battery type that matches the motor’s voltage and current needs. INEED recommends checking compatibility for each project. Use the correct charger for your battery chemistry.

How do you calculate battery life for your project?

Use this formula:

Battery Life (hours) = Battery Capacity (mAh) ÷ Motor Current (mA)

Estimate how long your motor will run before recharge. Add extra capacity for safety.

See Also

Optimizing Performance: Selecting Battery Powered Electric Motor Configurations

Choosing the Ideal Vibrating Motor for Your Specific Project

Understanding Electric Motor Batteries: Choosing, Performance, and Uses

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry