Exploring the Applications of Vibration Motors in Modern Industries

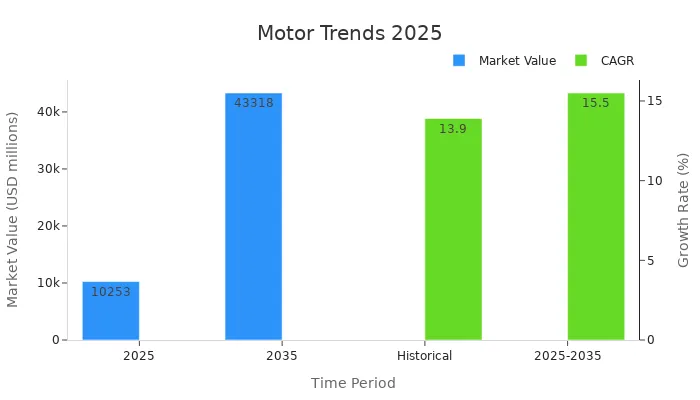

Vibration motors are revolutionizing industries by improving efficiency, safety, and user experience. These compact devices power innovations across sectors, from consumer electronics to medical devices. Their impact is evident in the numbers: the global market for vibration motors was valued at USD 4,851 million in 2020 and is projected to reach USD 10,253 million by 2025. This growth reflects a rising demand for precise motion control and automation.

Consumer electronics lead the way, using vibration motors for haptic feedback in smartphones and gaming controllers.

The medical field benefits from these motors in wearable devices, enhancing user engagement and feedback.

As industries evolve, understanding how to make a vibrator motor function effectively becomes crucial for driving innovation.

Key Takeaways

Vibration motors make devices like phones and watches more fun. They give touch feedback, making use feel real and exciting.

In cars, vibration motors keep drivers safe. They warn about dangers by touch, helping drivers act fast.

Vibration motors help machines work better. They make moving materials easier and fix problems before they get worse.

In healthcare, vibration motors are important for tools and wearables. They help doctors work carefully and improve patient care.

The demand for vibration motors is growing fast. By 2035, the market may reach USD 43,318 million because of new technology and more uses.

Consumer Electronics

Vibration motors have become a cornerstone in consumer electronics, driving innovation and improving user interaction. Their applications span from enhancing user experience to making smart home devices more accessible.

Enhancing User Experience

Haptic feedback in smartphones and wearables

Haptic feedback has transformed how you interact with devices. By simulating physical sensations, it creates a more immersive experience. For instance, when you press a virtual button on your smartphone, the vibration motor mimics the tactile feel of a real button. Devices like Apple’s Taptic Engine and Lenovo’s ThinkPad laptops showcase how this technology enhances usability. In wearable technology, haptic feedback plays a crucial role in delivering discreet alerts and improving engagement. The demand for such immersive experiences continues to grow, especially in gaming and mobile applications.

Silent alerts for calls and notifications

Vibration motors also enable silent alerts, ensuring you never miss an important call or notification. This feature is particularly useful in environments where sound alerts are disruptive or impractical. Whether you're in a meeting or a quiet library, the subtle vibration keeps you connected without drawing attention.

Smart Home Applications

Tactile feedback in smart devices

Smart home devices increasingly rely on vibration motors to provide tactile feedback. When you adjust a smart thermostat or interact with a touch-sensitive control panel, the vibration confirms your input. This feedback not only improves usability but also adds a layer of interactivity that traditional interfaces lack.

Accessibility improvements for users with disabilities

Vibration motors play a vital role in making technology more inclusive. For users with hearing impairments, tactile alerts serve as an alternative to auditory notifications. Similarly, haptic feedback can guide visually impaired users through touch-based interfaces, enhancing their ability to interact with smart devices independently.

The adoption of vibration motors in consumer electronics is growing rapidly. By 2025, the market size is projected to reach USD 10,253 million, with a compound annual growth rate of 15.5%. This growth underscores their importance in modern applications.

Automotive Industry

Vibration motors play a pivotal role in modern automotive applications, enhancing safety, performance, and comfort. Their integration into vehicles has transformed how drivers interact with their cars, making them more efficient and user-friendly.

Safety and Performance

Vibration alerts for driver assistance systems

Driver assistance systems rely heavily on vibration motors to improve safety. These systems use tactile feedback to alert you about potential hazards, such as lane departures or obstacles. For example, a vibrating steering wheel can warn you when the car drifts out of its lane, helping you react quickly. According to industry data, haptic systems in driver assistance features achieve a 99.76% obstacle detection rate and significantly improve reaction times compared to visual alerts. This makes vibration motors indispensable in reducing risks on the road.

Feedback in touch-based controls

Touch-based controls in modern vehicles also benefit from vibration motors. When you interact with a touchscreen or touch-sensitive button, the motor provides tactile feedback to confirm your input. This feedback ensures you can operate controls without taking your eyes off the road, enhancing both safety and usability. As infotainment systems become more advanced, the demand for vibration motors in these applications continues to grow.

Comfort and Customization

Seat vibration for enhanced comfort

Vibration motors contribute to comfort by offering features like seat massage and lumbar support. These functions use targeted vibrations to reduce fatigue during long drives, making your journey more enjoyable. The growing preference for comfort features among customers has driven the integration of vibration motors into seat adjustment systems.

Adaptive steering wheel feedback

Steering wheels equipped with vibration motors provide adaptive feedback based on driving conditions. For instance, the wheel may vibrate to signal icy roads or other hazards, helping you adjust your driving style. This customization enhances your driving experience and ensures better control over the vehicle. The rise of driverless vehicles has further increased the demand for such haptic feedback systems.

Market Trends and Drivers:

Increased adoption of Electric Vehicles (EVs) enhances demand for vibration motors.

Advanced Driver Assistance Systems (ADAS) require tactile feedback for safety features.

Miniaturization of vibration motors improves space efficiency in modern cars.

Integration with IoT and connected systems enhances user experience.

The automotive industry continues to innovate with vibration motors, making vehicles safer, more comfortable, and more efficient. These applications highlight the versatility and importance of vibration motors in shaping the future of transportation.

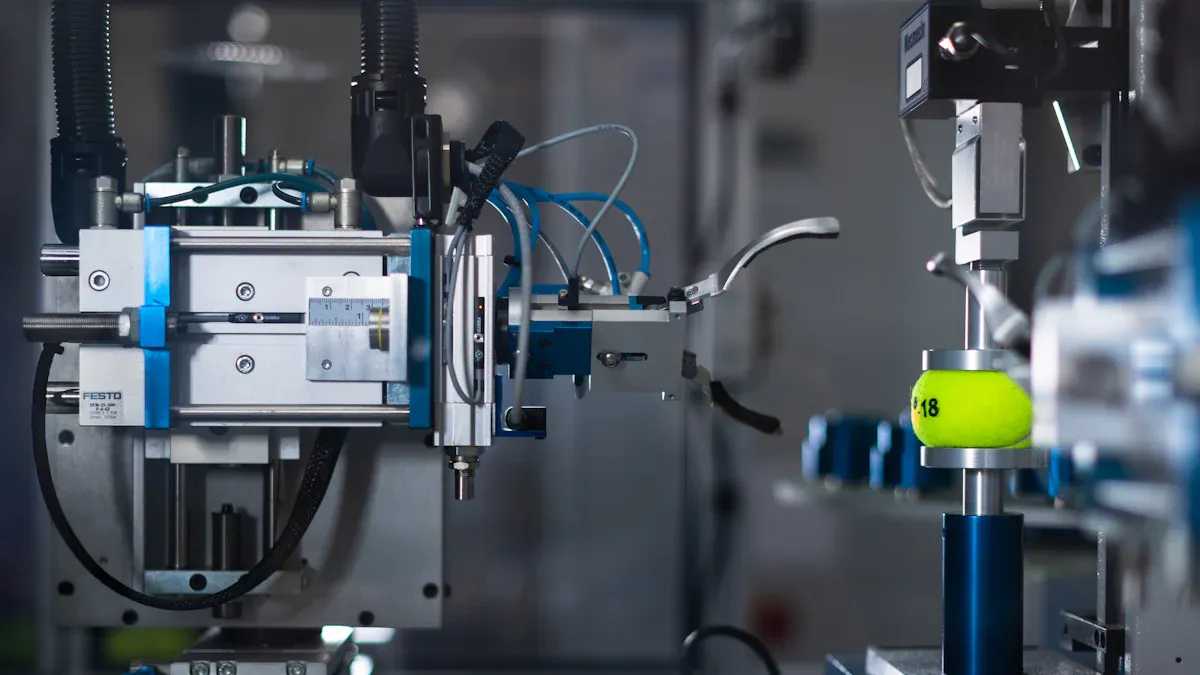

Industrial Machinery

Vibration motors have revolutionized industrial applications by enhancing operational efficiency and enabling smarter maintenance practices. Their role in material handling and equipment monitoring has made them indispensable in modern manufacturing.

Efficiency in Operations

Vibratory conveyors for material handling

Vibratory conveyors powered by vibration motors streamline material handling processes. These systems ensure consistent material flow, reducing blockages and improving productivity. For example:

Vibratory feeders distribute materials evenly, which is critical for manufacturing and packaging.

Vibrating screens separate particles by size, ensuring product quality in industries like mining and construction.

In food processing, vibratory motors drive sorting machines that separate products based on quality.

Statistical analysis of vibratory conveying systems highlights the importance of optimizing parameters like stiffness and sliding friction. This optimization improves conveying behavior, confirming the effectiveness of vibratory conveyors in industrial applications.

Sorting systems in manufacturing

Sorting systems equipped with vibratory motors enhance accuracy and speed in manufacturing. These systems efficiently move and sort bulk materials, increasing operational efficiency. By integrating vibration motors, manufacturers achieve better productivity and reduce manual intervention.

Tip: Vibratory motors not only improve material handling but also ensure product consistency, which is vital for maintaining quality standards.

Maintenance and Monitoring

Vibration analysis for predictive maintenance

Predictive maintenance relies on vibration analysis to monitor equipment health. Vibration sensors detect issues like improper motor calibration or excessive vibration, allowing you to address problems before they escalate. This approach minimizes unexpected downtime and extends equipment lifespan.

Evidence Description | Impact on Equipment Downtime |

|---|---|

Early failure detection allows for immediate corrective action. | Reduces unexpected equipment failures and downtime. |

Condition-Based Maintenance (CBM) optimizes maintenance schedules. | Minimizes unnecessary maintenance and disruptions. |

Quick action enables proactive maintenance. | Prevents major issues that could lead to equipment failure. |

Alerts for equipment malfunctions

Industrial vibrators play a crucial role in condition monitoring by providing real-time alerts for equipment malfunctions. These alerts help you identify and resolve issues quickly, ensuring operational stability. Proactive maintenance strategies derived from vibration analysis improve reliability and safety, making vibration motors essential in industrial applications.

Note: Predictive maintenance supported by vibration motors not only reduces downtime but also enhances the overall efficiency of industrial operations.

Medical Devices

Vibration motors have become essential in modern medical devices, driving advancements in precision and accessibility. Their applications enhance patient care, improve outcomes, and make healthcare more inclusive.

Precision in Healthcare

Vibration motors in wearable health monitors

Wearable health monitors rely on vibration motors to provide real-time feedback. These devices track vital signs like heart rate and blood pressure, alerting you to any irregularities. For example, a fitness tracker might vibrate to notify you of an elevated heart rate during exercise. This immediate feedback helps you take timely action, improving health management. The growing demand for wearable medical devices highlights the importance of vibration motors in ensuring accuracy and reliability.

Feedback in surgical tools

Surgical tools equipped with vibration motors offer tactile feedback to surgeons, enhancing precision during procedures. This feedback allows you to feel subtle changes in tissue resistance, improving control and reducing errors. Robotic-assisted surgeries also benefit from this technology, as vibration motors simulate the sense of touch for the operator. By 2025, the market for vibration motors in medical devices is projected to reach USD 10,253 million, with a compound annual growth rate (CAGR) of 15.5%.

Accessibility and Therapy

Tactile feedback in prosthetics

Prosthetic devices use vibration motors to provide tactile feedback, helping users regain a sense of touch. This feedback improves the ability to perform daily tasks, such as gripping objects or navigating environments. Studies show that circular proportional arrangements in tactile feedback systems achieve up to 91.67% accuracy in user responses. This demonstrates the effectiveness of vibration motors in enhancing prosthetic functionality.

Vibration therapy for rehabilitation

Rehabilitation therapy often incorporates vibration motors to stimulate muscles and improve recovery. Devices like vibration plates use targeted vibrations to enhance blood flow, reduce pain, and strengthen muscles. This therapy is particularly beneficial for patients recovering from injuries or surgeries. The integration of vibration motors in rehabilitation applications ensures more effective and efficient treatment outcomes.

Metric | Value |

|---|---|

Projected Market Value by 2025 | USD 10,253 million |

Projected Market Value by 2035 | USD 43,318 million |

CAGR (2025-2035) | 15.5% |

Historical CAGR | 13.9% |

Tip: When choosing medical devices with vibration motors, consider their precision and feedback capabilities to ensure optimal performance.

The role of vibration motors in medical devices continues to expand, offering innovative applications that improve healthcare delivery and patient outcomes.

Emerging Technologies

Vibration motors are at the forefront of emerging technologies, driving innovation in virtual reality (VR), augmented reality (AR), and robotics. These applications are reshaping industries by enhancing precision, realism, and interactivity.

Virtual and Augmented Reality

Haptic feedback for immersive experiences

Haptic feedback is revolutionizing VR and AR by creating a more immersive experience. Vibration motors simulate touch sensations, allowing you to feel textures, impacts, or even resistance in virtual environments. For example, when you use gaming controllers in VR, the motors replicate the sensation of firing a weapon or hitting an object. This tactile interaction bridges the gap between the digital and physical worlds, making your experience more engaging. The growing demand for haptic feedback in gaming controllers and wearable devices highlights its importance in these applications.

Enhancing realism in simulations

Simulations in VR and AR rely on vibration motors to enhance realism. Whether you're training for surgery or piloting an aircraft, these motors provide tactile cues that mimic real-world conditions. This feedback improves your ability to react and adapt, making simulations more effective. Innovations in electric vibration motors are further enhancing their performance, ensuring precise and consistent feedback. By 2025, advancements in this technology will expand its applications across industries, from education to professional training.

Robotics and Automation

Precision in robotic grippers

Robotic grippers equipped with vibration motors achieve remarkable precision. These motors enable robots to handle delicate objects without causing damage. For instance, in manufacturing, robotic arms use vibration motors to adjust their grip based on the object's texture and weight. This precision reduces errors and improves efficiency. The adoption of electric vibration motors in robotics is growing, driven by their ability to deliver consistent performance in demanding environments.

Feedback systems in autonomous machines

Autonomous machines use vibration motors for real-time feedback, enhancing their ability to navigate and interact with their surroundings. For example, drones equipped with these motors can detect obstacles and adjust their path accordingly. In industrial automation, vibration motors play a crucial role in monitoring equipment and providing alerts for malfunctions. This capability ensures smoother operations and reduces downtime. The market for vibration motors in robotics and automation is expected to grow significantly, fueled by advancements in technology and the increasing demand for precision.

Key Insights:

The vibration motors market is expanding into sectors like healthcare, automotive, and industrial automation.

Technological advancements are improving their performance, efficiency, and sustainability.

Sector | Key Drivers |

|---|---|

Consumer Electronics | Increasing demand for haptic feedback in smartphones, tablets, and gaming devices. |

Automotive | Rising demand for haptic feedback systems in navigation, driver assistance, and infotainment. |

Industrial Automation | Growing adoption of vibration motors in machinery notifications and precise control applications. |

Healthcare | Expanding applications in medical devices. |

Wearable Devices | Popularity of haptic technology for enhanced user experience. |

The role of vibration motors in emerging technologies continues to grow, shaping the future of VR, AR, and robotics. Their applications are broadening, offering innovative solutions that improve efficiency, precision, and user experience.

Vibration motors have become essential in modern industries, transforming how you interact with technology and machinery. Their diverse applications, from enhancing user experience in consumer electronics to improving safety in automotive systems, highlight their versatility. Industries like healthcare and manufacturing also benefit from their precision and efficiency.

The global vibration motors market is projected to grow significantly, driven by rapid industrialization, urbanization, and advancements in motor technology.

Increasing demand for tactile feedback in smart devices and the shift toward electric vehicles further fuel this growth.

By 2035, the market value is expected to reach USD 43,318 million, reflecting their expanding role in automation and motion control.

As technology evolves, vibration motors will continue to shape the future of innovation, offering solutions that improve efficiency, safety, and user experience across industries.

FAQ

What is a vibration motor, and how does it work?

A vibration motor is a small device that generates vibrations through an unbalanced mass attached to its motor shaft. When the motor rotates, the imbalance creates vibrations. These vibrations are used in various applications, such as haptic feedback in devices or material handling in industries.

Where are vibration motors commonly used?

You can find vibration motors in consumer electronics, automotive systems, industrial machinery, medical devices, and robotics. They enhance user experience, improve safety, and increase efficiency in these fields. For example, smartphones use them for haptic feedback, while industrial machines rely on them for material sorting.

How do vibration motors improve safety in vehicles?

Vibration motors provide tactile feedback in driver assistance systems. For instance, they send alert notifications through a vibrating steering wheel when the car drifts out of its lane. This helps you react quickly to potential hazards, improving road safety.

Can vibration motors be used for medical purposes?

Yes, vibration motors are essential in medical devices. They provide feedback in surgical tools, enhance prosthetic functionality, and support rehabilitation therapy. For example, wearable health monitors use them to alert you about irregular vital signs, ensuring timely action.

What factors should you consider when choosing a vibration motor?

You should consider size, power consumption, vibration strength, and application requirements. For example, a smartphone needs a compact motor with precise feedback, while industrial machinery requires a more robust motor for heavy-duty tasks.

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry