How to Select the Perfect Brushless Mini Motor for Your Next Project

To select the perfect brushless mini motor, you need to match its size, voltage, kV, and torque to your project’s needs. Motors work best when you understand how torque lets you move a load and how speed controls how fast the motor turns. If you pick a brushless mini motor with the wrong torque or speed, your project might run slowly or the motor might strain. Many people run into problems like choosing gearheads that cannot handle enough torque, ignoring how long the motors will run, or forgetting about dust and water in the environment.

Mismatched torque and speed often lead to poor performance.

Gearheads that cannot handle the load may fail early.

Motors that run too long without rest can overheat.

Always check if your motors fit your project’s needs and pay attention to how much power, time, and protection they require.

Key Takeaways

Make sure the motor’s torque, speed, size, and power fit your project’s needs for best results.

Pick motors that have good protection and cooling. This helps stop overheating and makes the motor last longer.

Use the right battery and electronic speed controller (ESC) for your motor’s voltage and current needs.

Follow easy steps: know what you need, figure out power, choose the motor and gearbox, then test it well.

Check all wiring, sensors, and connections when setting up. This helps stop problems and keeps things working smoothly.

Project Requirements

Application and Load

When you start a project, you need to know what the motors must do. Think about the job. Does your project need to lift, spin, or move something? For example, picking motors for rc cars means you want fast speed and quick starts. If you are picking motors for rc planes, you want lightweight motors with high speed. In a custom rc car project, you need motors that can handle both speed and heavy loads.

Balance torque and speed for your task. Heavy loads need more torque. Fast tasks need higher speed.

Check the torque and speed profiles. Make sure the motor matches your load.

Look at the environment. Dust, water, and heat can damage motors. Some motors have special protection.

Make sure the power supply matches the motor’s voltage and current needs.

Motors for robotics need high precision and feedback. When choosing motors for drones, you want lightweight, efficient motors that give stable flight and long battery life. Small rc electric motor options work well in portable devices because they save energy and reduce weight.

Size and Weight Limits

Motors come in many sizes and weights. You must fit the motor into your project. If you use a small rc electric motor, your device stays light and easy to carry. Heavy motors use more energy and make portable devices less efficient. In drones and mobile robots, lighter motors help with longer battery life and better movement.

Motor Series | Diameter Range (mm) | Motor Length Range (mm) | Power Range (W) | Nominal Torque (mNm) |

|---|---|---|---|---|

OpenECX FLAT | 22 to 42 | 14 to 21.2 | 4.5 to 150 | Up to 214 |

OpenEC | 22 to 60 | 60 to 180 | 80 to 400 | Up to 800 |

OpenEC-max | 16 to 40 | 24 to 88 | 5 to 120 | Up to 200 |

Motors for aeromodelling can weigh as little as 5 grams. Combat robotics use motors from 75 grams up to 250 pounds. Always check the size and weight so your motor fits and works well.

Power and Duty Cycle

You must know how long your motors will run and how much power they need. Duty cycle tells you if the motor runs all the time or just in short bursts. Continuous duty means the motor runs nonstop, like on a conveyor belt. Intermittent duty means the motor works in short bursts, like in power tools.

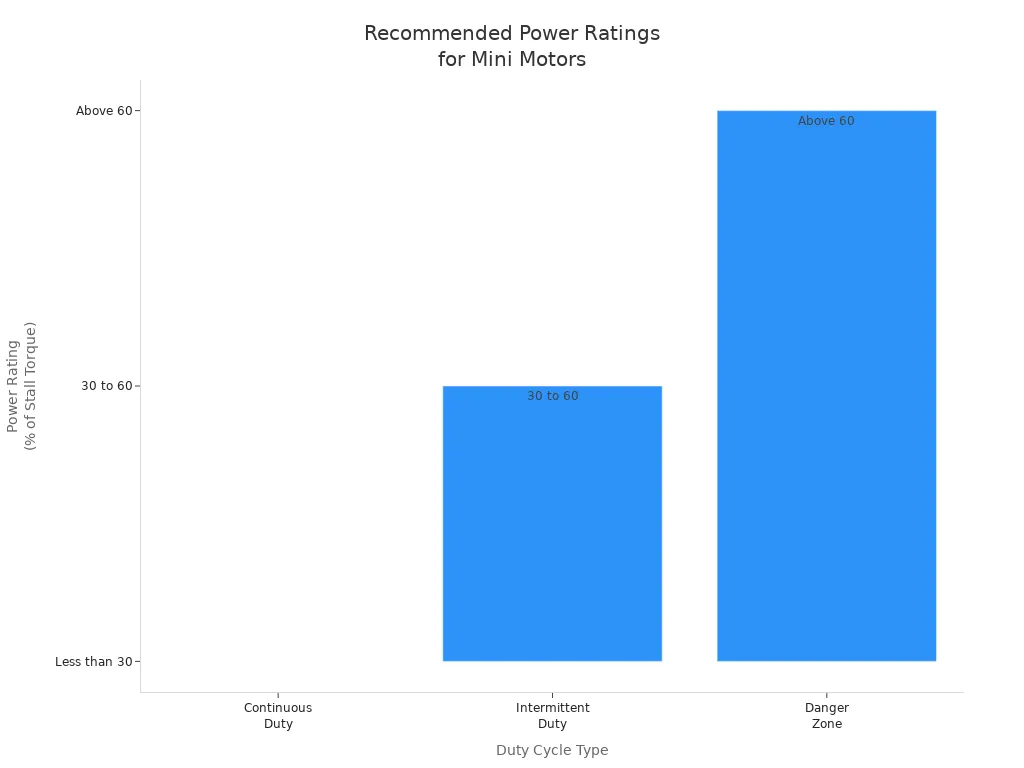

Duty Cycle Type | Recommended Power Rating (as % of Stall Torque) | Notes |

|---|---|---|

Continuous Duty | Less than 30% | Avoids overheating and supports long life. |

Intermittent Duty | Between 30% and 60% | Allows higher torque for short periods with cooling breaks. |

Danger Zone (>60%) | Above 60% | Risks overheating and damage; only for very short or single-use tasks. |

Tip: Motors last longer if you follow the duty cycle limits. Overloading motors or running them too long can cause overheating and shorten their life. Always check the power rating and give motors time to cool if needed.

Brushless Mini Motor Specs

kV, Torque, and Speed

When you look at brushless motors, you will see a kV rating. This number tells you how many times the motor spins for each volt you give it. For example, a 2000 kV brushless motor spins 2000 times per minute for every volt. If you want more speed, pick a higher kV. If you need more force to move heavy things, choose a lower kV. There is a tradeoff: higher kV means more speed but less torque, while lower kV gives you more torque but less speed. This is like using different gears on a bike. The torque depends on the current and the load you put on the motor. Brushless mini motor performance changes with these settings, so always match the kV to your project’s needs.

Voltage and Current

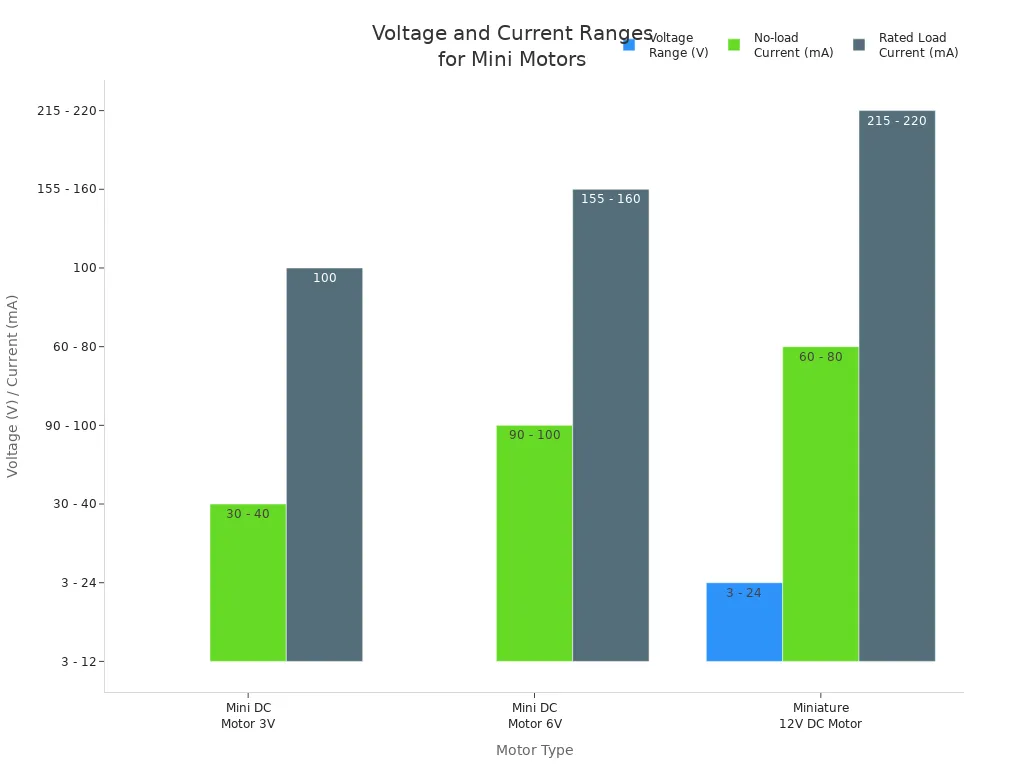

Brushless mini motors need the right voltage and current to work well. Most motors in consumer electronics use between 3V and 24V. The current can range from tens to a few hundred milliamps, depending on the size and load. If you use too much voltage or current, the motor can overheat or break. The table below shows common voltage and current values for different motor types:

Motor Type | Voltage Range (V) | No-load Current (mA) | Rated Load Current (mA) | Typical Applications |

|---|---|---|---|---|

Mini DC Motor 3V | 3 - 12 | 30 - 40 | 100 | Electric screwdriver |

Mini DC Motor 6V | 3 - 12 | 90 - 100 | 155 - 160 | Hair curler |

Miniature 12V DC Motor | 3 - 24 | 60 - 80 | 215 - 220 | Robot joints |

General Mini Motors | 1.5 - 24 | N/A | N/A | Consumer electronics (general) |

If you want your motors to handle more power, look for ones with lower internal resistance. These motors can draw more current and stay cooler, which helps them last longer. If the resistance gets too high, the motor may get hot and lose power.

Efficiency and Thermal Limits

Brushless motors are very efficient. They can turn 85-90% of the electricity into motion. You can control their speed using special circuits that turn the power on and off quickly. This keeps the motor running smoothly and saves energy. To measure efficiency, you can use a multimeter to check voltage and current, a tachometer for speed, and a tool to measure torque. Then, use this formula:

Motor Efficiency = (Torque × Speed) / (Voltage × Current)

You must also watch the temperature. Try to keep the motor below 180°F (82°C). If it gets hotter than 200°F (93°C), you risk damage. Use metal mounts or fans to help cool the motor. If you see the temperature rising too much, reduce the load or change the setup. Motors with good water and dust protection last longer in tough environments.

Tip: Always check the motor’s specs for maximum temperature and use a thermometer to monitor it during use.

Matching Brushless Motor to Project

Selection Steps

Choosing the right motor for your project means following a clear process. Start by writing down what you want your project to do. Think about how much torque and speed you need. For example, a robot arm needs strong torque to lift objects, while a drone needs high speed for flight. Next, pick the type of motor that fits your needs. Brushless motors work well for most modern projects because they last longer and run more efficiently than brushed motors.

You should calculate the power your project needs. Multiply the torque by the speed, then add extra power to cover losses from gears or friction. Pick a brushless motor that can handle this power. If your project needs a gearbox, choose one that matches your torque and speed needs. Calculate the gear ratio by dividing the motor speed by the speed you want at the output. Make sure the motor and gearbox together can deliver the torque and speed your project requires.

Here is a step-by-step list to help you:

Define your project’s torque and speed needs.

Choose the motor type that fits your application.

Calculate the output power needed (torque × speed).

Add extra power for losses in gears or friction.

Select a motor that meets or exceeds this power.

Pick a gearbox if needed, checking torque and size.

Calculate the gear ratio for your desired output speed.

Check that the motor and gearbox together meet your needs.

For projects that need high precision, like CNC machines or robotic arms, feedback options matter. Encoders give you exact position and speed data, which helps you control the motor with great accuracy. Hall sensors cost less and work well for basic position sensing. When you combine encoders with Hall sensors, you get better control and smoother motion. This setup is important if you want your brushless motor to move to exact spots or follow a set path.

You also need to decide between geared and direct-drive brushless motors. Geared motors give you more torque at low speeds, which helps with heavy loads or climbing. Direct-drive motors run more quietly and efficiently, but they do not provide as much torque at low speeds. Use geared motors for tasks that need strong, slow movement. Use direct-drive motors for smooth, fast, and quiet operation.

Feature | Geared Brushless Mini Motors | Direct-Drive Brushless Mini Motors |

|---|---|---|

Torque at Low Speeds | High, good for heavy loads | Lower, better for light loads |

Efficiency | Lower due to gear friction | Higher, less friction |

Noise and Vibration | More noise and vibration | Quieter and smoother |

Maintenance | More maintenance, gears wear out | Less maintenance, longer lifespan |

Cost | Lower initial cost | Higher initial cost |

Control and Precision | Good at low speeds | Good at high speeds |

Best Use | Robotics, heavy lifting | Drones, e-bikes, smooth drives |

Tip: Always match the motor type and feedback system to your project’s needs. This helps you get the best performance and control.

ESC and Battery Compatibility

Your brushless motor needs an electronic speed controller (ESC) and a battery that work together. The ESC acts as the brain, telling the motor how fast to spin. You must match the ESC’s voltage range to your battery. For example, if you use a 3-cell LiPo battery (11.1V), your ESC must handle at least that voltage. The ESC’s current rating should be higher than the motor’s peak current to prevent overheating.

Follow these steps to set up your ESC and battery:

Match the ESC voltage to your battery voltage.

Make sure the ESC’s current rating is higher than the motor’s maximum draw.

Look for ESC features like throttle curve and braking if you want more control.

Mount the ESC where it can stay cool.

Connect the three motor wires to the ESC. Swap any two wires to change the motor’s direction.

Connect the ESC to the battery and receiver with the right connectors.

Calibrate the ESC to your transmitter for smooth control.

Pick a battery that matches the ESC voltage and can supply enough current.

Battery chemistry also affects how your brushless motor works. LiPo batteries give high power and long run times. NiMH and NiCd batteries offer lower energy density but can be safer or cheaper. Always match the battery’s voltage and current to your motor and ESC. If you use the wrong battery, your motor may run poorly or get damaged.

Note: The battery’s capacity (mAh) decides how long your motor can run. The discharge rate (C rating) tells you how much current the battery can safely supply. Pick a battery that meets your motor’s needs for best results.

Avoiding Common Mistakes

Many people make mistakes when matching brushless motors to their projects. One common error is using the wrong voltage. If you supply too little voltage, the motor may not turn. Too much voltage can damage the motor. Another mistake is picking an ESC that cannot handle the motor’s current. This can cause the ESC to overheat or fail.

Loose or poor connections also cause problems. Always check your wiring and connectors. If you use Hall sensors, make sure they are aligned correctly. Misaligned sensors can cause the motor to stop or run poorly. Picking a motor with the wrong power rating leads to inefficiency or failure. If you ignore the relationship between winding size, torque, and speed, your motor may not perform as expected.

You can avoid these pitfalls by following a few strategies:

Define your torque, speed, and duty cycle before you start.

Consider the environment. Pick motors with protection if you expect dust, water, or heat.

Use proper cooling to prevent overheating.

Look at the total cost, not just the price. Think about maintenance, energy use, and lifespan.

Check supplier certifications for safety and reliability.

Pick the right Kv rating for your battery and speed needs.

Use datasheets, checklists, and testing to make sure your choice fits your project.

Remember: Choosing the right motor means thinking about all these factors. Take your time, check your numbers, and test your setup before final use.

Testing Brushless Motors

Setup and Testing

You need a good setup to test brushless mini motors. Start by planning your design and picking the right materials. Estimate how much power your motor will need. Use simple tools like an Arduino-based test rig for quick checks. For more advanced testing, you can use a PWM controller or a system like Tuner X with RoboRIO hardware. These tools help you control the motor and collect data.

Set up your motor on a stable test bench. Connect the motor to your controller and power supply. If your project uses Hall Effect sensors, make sure they are in place for accurate feedback. Use a multimeter to measure voltage and current. You can also use a tachometer to check speed. For detailed tests, a system like the Magtrol Micro Dyne can measure torque, speed, and even tiny changes in motor performance.

Here are some best practices for testing:

Use spring-loaded switches for safety. You can stop the motor quickly if needed.

Plot real-time data like speed and current to see how the motor behaves.

Test both no-load and load conditions to understand how the motor works in your project.

Make sure all connections are tight and secure.

Tip: Always wear safety glasses and keep loose items away from spinning parts.

Troubleshooting Issues

Sometimes, motors do not work as expected. You might see problems like overheating, strange noises, or the motor not spinning. Many issues come from wiring problems, sensor misalignment, or controller faults.

Follow these steps to troubleshoot:

Check all wiring and connectors. Make sure nothing is loose or damaged.

Rotate the motor shaft by hand. Listen for grinding or clicking sounds. These can mean bearing problems or dirt inside.

Inspect Hall sensors and encoders. Misalignment can cause poor motor performance or even stop the motor.

Use a multimeter to check voltage and current. Make sure they match the motor’s specs.

Look at the controller for error codes or warning lights. Update firmware if needed.

If you hear odd noises, check for mechanical damage or worn bearings.

If you cannot fix the problem, ask a professional for help.

Note: Proper alignment of sensors and encoders is key. Bad alignment can make the motor run poorly or not at all.

Picking the right brushless mini motor means matching its specs to your project. Use this checklist to make sure you think about everything important:

Stay within the motor’s electrical and mechanical limits for longer life.

Figure out how much torque and speed you need, then add a safety margin.

Look at the load inertia and any other mechanical loads.

Make sure the motor has enough protection and cooling for its environment.

Check that the controller and battery match the motor’s needs.

Pick the best commutation and control options for your project.

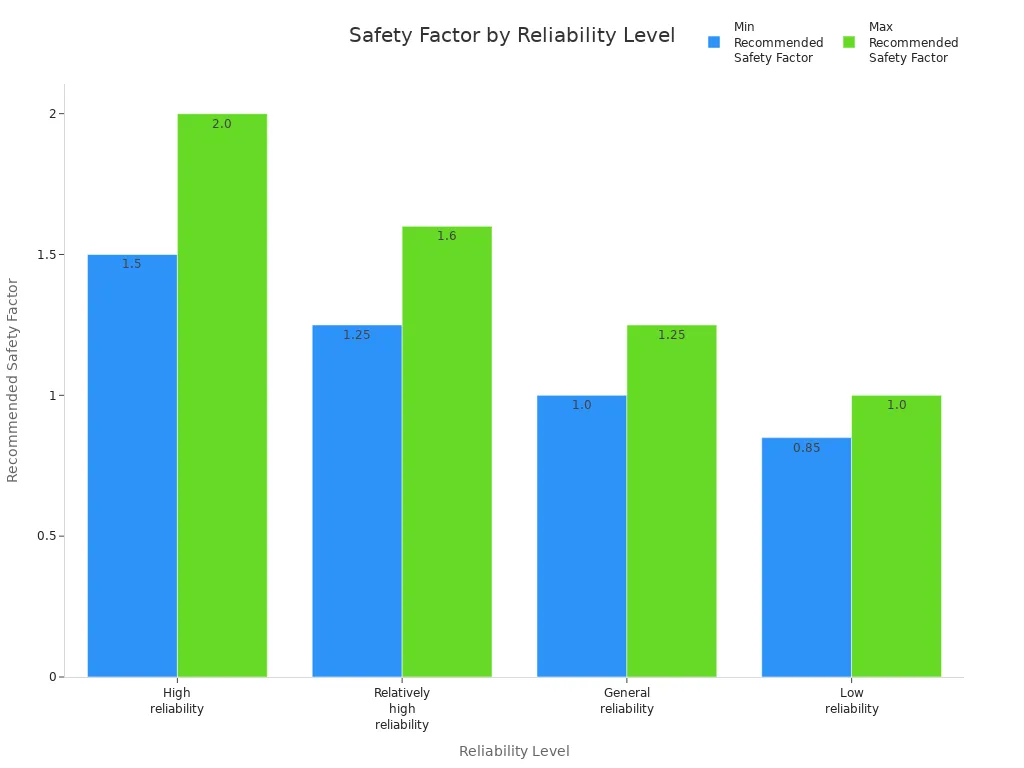

Reliability Level | Recommended Safety Factor Range |

|---|---|

High reliability | 1.50 to 2.00 |

Relatively high | 1.25 to 1.60 |

General reliability | 1.00 to 1.25 |

Low reliability | 0.85 to 1.00 |

Always check if everything works together and use a safety margin. If you are not sure, ask experts like Castle Creations or Qorvo, or visit forums like Practical Machinist to get help and learn from others.

FAQ

What does kV mean for brushless motors?

kV shows how many times the motor spins for each volt you give it. High kV means fast spinning. Low kV gives more force. Pick the kV that matches your project’s speed or torque needs.

How do you know if a motor will fit your project?

Check the motor’s size and weight. Measure your space. Compare the motor’s dimensions to your project. Use a table to match motor models with your space limits.

Motor Model | Diameter (mm) | Length (mm) |

|---|---|---|

Mini A | 22 | 14 |

Mini B | 40 | 21 |

Why does my brushless motor get hot?

Motors get hot if you use too much power or run them too long. Check the load and cooling. Use a fan or metal mount. Lower the power if the motor feels hot.

What battery should you use with your brushless motor?

Pick a battery with the right voltage and enough current. LiPo batteries work well for most projects. Check the battery’s voltage and match it to your motor and ESC.

Tip: Always check the battery’s capacity (mAh) and discharge rate (C rating).

Can you use a brushless motor in wet or dusty places?

Yes, you can use motors with water and dust protection. Look for motors with sealed cases or special ratings like IP54. These motors last longer in tough environments.

See Also

Choosing Ideal Mini DC Motors For Industrial Use Cases

Steps To Choose The Best Vibrating Motor For Projects

Why Investing In Mini Brushless Motors Benefits Precision Tasks

Comprehensive Overview Of Mini Motors: Uses And Selection Tips

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry