How to choose the right battery powered motor for your project

Choosing a motor for your project can seem hard, but picking the right battery powered motor really helps. If you match the motor’s specs to what you need, you get better performance, longer battery life, and fewer problems later.

The right motor means it matches power, torque, and duty cycle. This gives smoother performance and helps the battery last longer.

Studies show that small changes in motor temperature or efficiency can change how much energy your project uses and how well it works.

Think about what your project needs, what is possible, and how all the parts work together. Your project will work better if you do!

Key Takeaways

Pick a motor that matches your project’s power, torque, and size. This helps your project work better and makes the battery last longer.

Make sure your motor’s voltage and current needs fit the battery. This stops damage and helps your project run smoothly.

Think about where your project will be used and how it moves. This helps you choose the best motor type and battery for your needs.

Check amp hours and current draw to plan battery life. Use good chargers to keep batteries safe and make them last longer.

Do not make mistakes like choosing motors that are too big or too small. Do not ignore battery limits or forget to match voltage. This keeps your project safe and working well.

Project Needs

Project Type

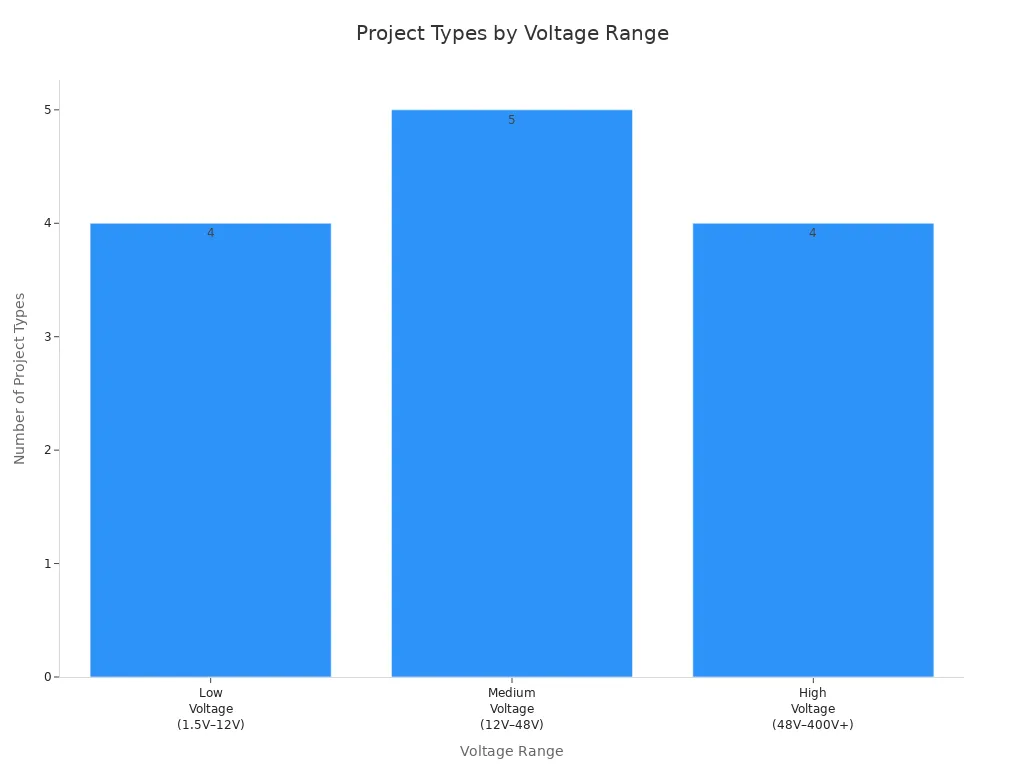

Before you choose a battery powered motor, you should know your project type. Are you making a small robot, a remote control car, or something bigger like an electric bike? Each project needs a different amount of power and performance. For example, electric vehicles need motors with high starting torque and can carry heavy things. Small toys or hobby gadgets use low-voltage motors. These motors are better for simple movement, not high performance. Look at the table below to see which projects use certain motor types and voltage ranges:

Voltage Range | Common Project Types | Typical Motor Types | Examples |

|---|---|---|---|

Low (1.5V–12V) | Toys, hobby electronics, small robots | Micro DC motors, small gear motors | RC cars, fans, small robots |

Medium (12V–48V) | Power tools, e-bikes, drones | Larger DC motors, BLDC motors | Drones, e-bikes, drills |

High (48V–400V+) | Electric vehicles, industrial robots | High-power BLDC, PMSM, stepper motors | Electric cars, forklifts |

Required Movement

Think about how your project will move. Does it need to roll forward and backward, turn, or climb? Most mobile robots and RC vehicles use motors on wheels for movement. Some projects need to change speed, while others need to steer or back up from things. You might want your project to fix its path or avoid things in the way. All these moves need the right motor and enough battery power to work well.

Forward and backward movement

Steering with a servo motor

Speed control for better results

Obstacle avoidance using sensors

Power Goals

Now, decide your power and performance goals. Ask yourself: How fast should your project move? How much weight does it need to hold? Do you want the battery to last a long time or go really fast? Electric vehicles need motors that give strong power at low speeds and keep working at high speeds. Smaller projects may just need steady, simple movement. Make a list of your project’s load, where it will be used, and any space limits. This helps you pick a motor that fits your power needs and gives the best results.

Tip: Always think about where your project will be used. Hot, cold, or dusty places can change how much power and performance you get.

Motor Specs

Voltage & Current

When you pick a battery powered motor, you need to know the right voltage and current. These two things decide how much power your motor can give and how well it works with your battery.

The voltage tells you how fast your motor can spin. Higher voltage means more speed, but only if your battery can handle it.

The current shows how much energy your motor pulls from the battery. If your project needs more torque or has to move heavy things, the current will go up.

Your battery must match the voltage and current needs of your motor, both when it is fully charged and when it is almost empty. If the battery cannot keep up, your motor will slow down or stop.

Think about the type of battery you use. Lithium-Ion batteries give you high energy and last longer, but they need special circuits to stay safe. Other batteries, like NiCd or Lead Acid, have their own pros and cons.

The controller you use must also match your motor’s power and voltage. If you use the wrong controller, your motor might not work right.

Tip: Always check your battery’s discharge rating. If your battery cannot give enough current, your motor will not reach full power.

Torque & Speed

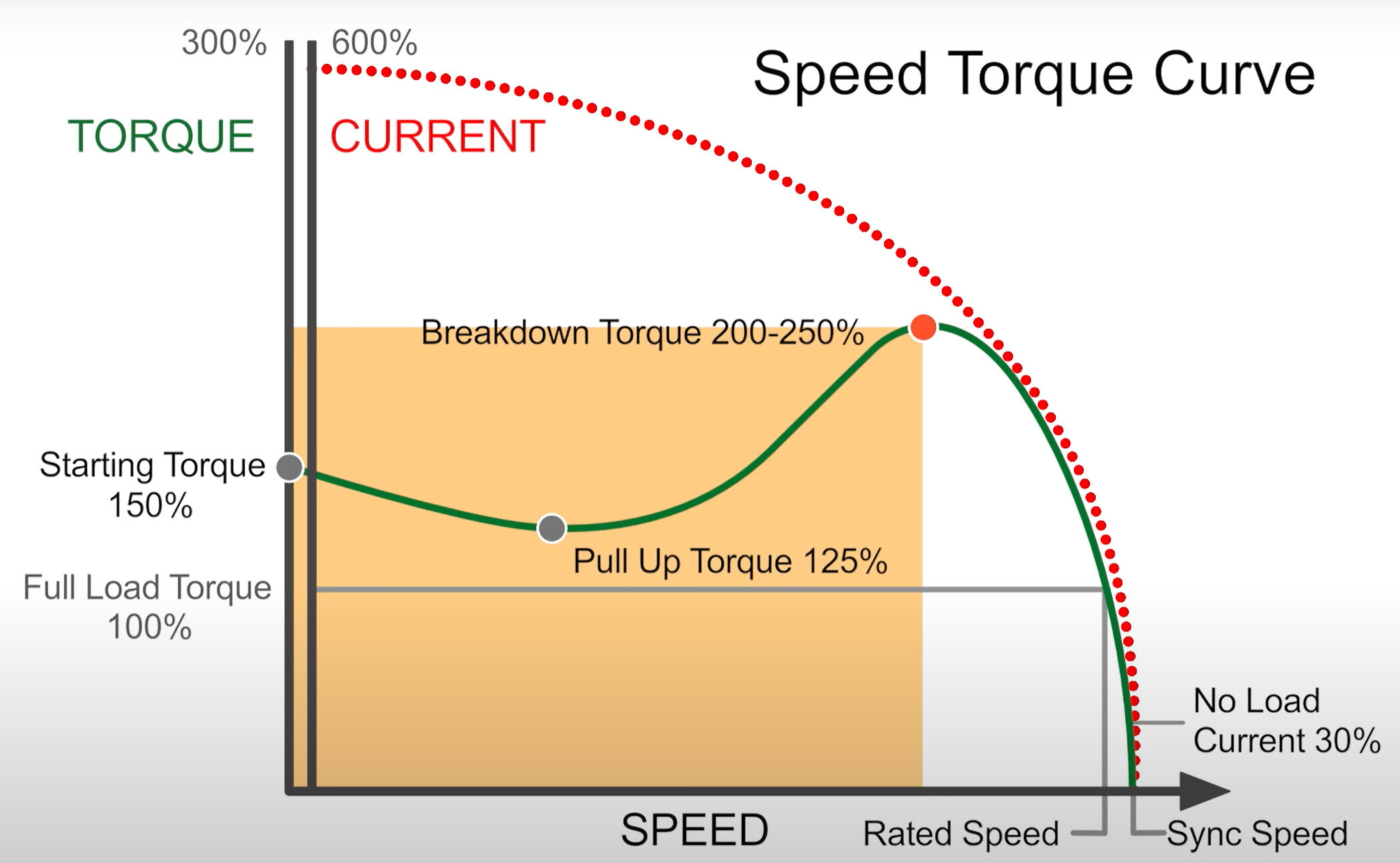

Torque and speed are the heart of any motor. Torque is the force that makes things turn. Speed is how fast the motor spins. You need to balance both to get the best results for your project.

First, figure out how much torque your project needs. If you want to move something heavy or climb a hill, you need more torque.

Next, decide how fast you want your project to go. Speed depends on both the motor and the voltage you give it.

Use this formula to find the torque:

Torque (Nm) = (Current (A) × Voltage (V) × Efficiency × 60) / (RPM × 2π)Always check the motor’s efficiency. If you do not know it, use a safe guess, like 10% for small motors.

Look at the torque-speed curve from the motor’s datasheet. This curve shows how torque changes as speed goes up or down.

Add a safety margin. Most people pick a motor that is about 1.5 times stronger than what they think they need. This helps if your project faces extra load or friction.

Note: If you use a motor that is too small, it will overheat and wear out fast. If you use one that is too big, you waste energy and space.

Size & Weight

The size and weight of your motor matter a lot, especially for portable projects. If your project needs to be light, like a wearable device or a small robot, pick a small and light motor.

Small motors are easier to fit into tight spaces. They also make your project lighter and easier to carry.

Lighter motors use less energy, so your battery lasts longer. This is very important for things like smartwatches or fitness trackers.

Always check the space in your project before you buy a motor. Some electric motors are bigger than they look in pictures, and they might not fit.

If you use a motor that is too big, you might have to change your whole design. If it is too small, it might not give enough power.

Motor Size | Typical Use Cases | Example Device |

|---|---|---|

Very Small | Wearables, tiny robots | Fitness tracker, watch |

Medium | RC cars, drones, tools | Drone, power drill |

Large | E-bikes, electric vehicles | Electric scooter, car |

Callout: Always match your motor’s size and weight to your project’s needs. If you do not, you might face problems with fitting, overheating, or wasted energy.

If you match your battery powered motor’s specs to your project’s load and space, you get better performance and fewer problems. Many projects fail because the motor does not fit or cannot give enough power. Take time to check all the details before you choose.

Battery Life

Looking at Battery Life

When you build a project with a battery powered motor, you want to know how long it will run before you need to recharge. Looking at battery life helps you plan for longer use and fewer surprises. You can figure out battery life with a few simple steps:

Find the amp hour (Ah) rating on your battery. This tells you how much energy your battery can store.

Check how much current your motor uses while running. You can find this in the motor’s datasheet or by measuring it.

Divide the battery’s amp hour rating by the motor’s current draw. This gives you an estimate of how many hours your project will run.

For example, if you have a 100 Ah battery and your motor uses 20 amps, your battery life is about 5 hours (100 Ah / 20 A = 5 hours).

Remember, the current draw can change if your project works harder, like going uphill or carrying more weight.

Weather and temperature can also affect how much power your batteries give. Cold days can make batteries weaker.

To get the most out of your battery, use variable speed motors, avoid draining the battery all the way, and store your batteries with care when you are not using them.

Tip: Always check if your battery can handle the current your motor needs, not just for a few seconds but for the whole time you want your project to run.

Battery Type & Capacity

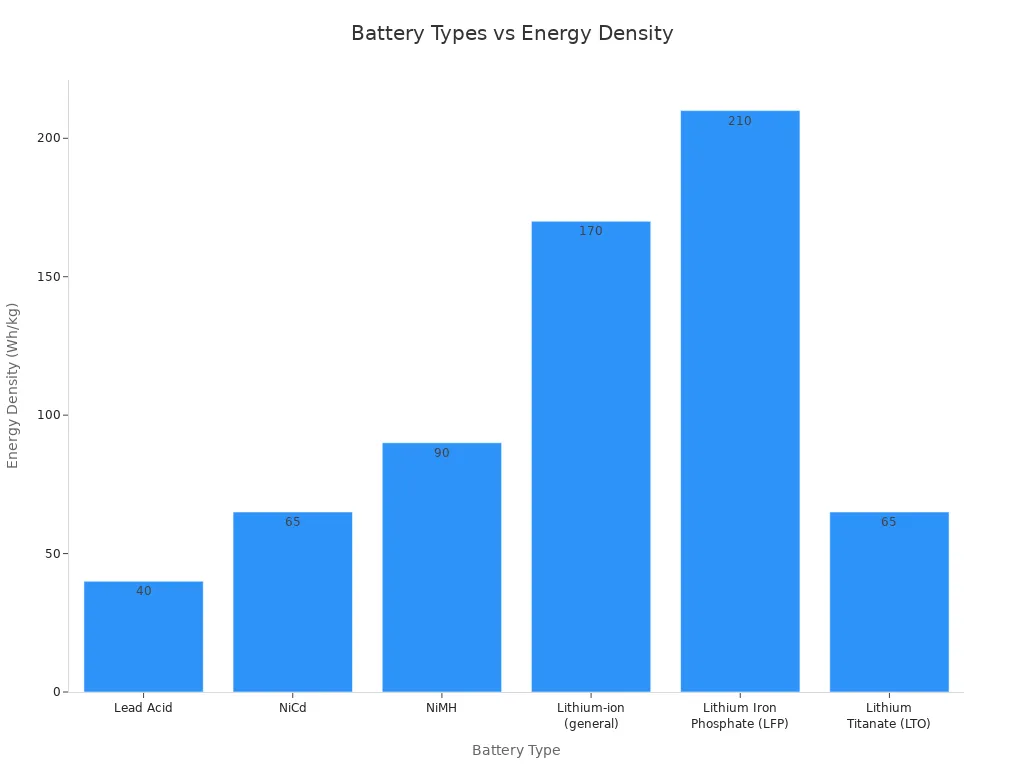

You have many choices when you pick the right battery for your project. The type of battery you choose changes how long your project runs, how heavy it is, and how much it costs. Most people use lithium batteries because they last longer, weigh less, and hold more energy than other types. Lithium ion batteries are the most popular for battery powered motors. They give you high energy density, so your project can run longer without getting heavy.

Let’s look at some common battery types and how they compare:

Battery Type | Energy Density (Wh/kg) | Cycle Life (80% DoD) | Cost Consideration | Notes |

|---|---|---|---|---|

Lead Acid | 30-50 | 200-300 | Low | Heavy, short lifespan |

NiCd | 45-80 | ~1000 | Moderate | Higher self-discharge |

NiMH | 60-120 | 300-500 | Moderate | Better than Lead Acid |

Lithium-ion | 150-190 | 500-2000 | Higher | Best for most projects |

Lithium Iron Phosphate (LFP) | up to 210 | >4000 | Cost-effective | Very safe, long life |

Lithium Titanate (LTO) | 50-80 | 3000-7000 | High | Super long life, expensive |

Lithium ion batteries make up about 92% of the market for battery powered motors. They give you the best mix of long battery life, high energy, and safety.

Lithium polymer batteries are also popular. They are light and can fit into slim packs, which is great for drones and RC cars.

Lead acid batteries are cheap but heavy and do not last as long.

NiMH and NiCd batteries are better than lead acid but still not as good as lithium batteries for most projects.

When you pick the right battery, think about how much power capacity you need. If you want your project to run longer, choose a battery with a higher amp hour rating. Always use a high-quality charger to keep your batteries healthy. If you use a rechargeable battery pack, make sure it matches your project’s needs.

Callout: Never use a cheap charger. A high-quality charger keeps your lithium batteries safe and helps them last longer.

Voltage Match

Matching the voltage of your battery to your motor is very important. If you use the wrong voltage, your project might not work, or you could damage your motor and battery pack. Here’s what you need to know:

If you connect batteries with different voltages in parallel, you can cause uneven charging and discharging. This can make some batteries overcharge and fail early.

Batteries that do not match in voltage or age can wear out faster and lower your project’s performance.

Using the wrong voltage can cause safety problems like overheating, leaks, or even fires.

Always pick the right battery that matches your motor’s voltage. Use batteries from the same brand or ones that are certified to work together.

Add fuses and circuit breakers to your battery pack for extra safety. Check your wiring and monitor your batteries often.

Note: If you use a lithium ion battery with a motor that needs a different voltage, you risk damaging both the battery and the motor. Always double-check the voltage before you connect anything.

Continuous Current Draw (CCD) and Safety Margins

You need to know how much current your motor uses all the time, not just at startup. This is called continuous current draw (CCD). Here’s how you can make sure your batteries can handle it:

Find the average current your motor uses during normal operation.

If you use more than one motor, add up the current for all of them.

Add a safety margin of at least 25% to your total. This helps your battery last longer and keeps your project safe.

Pick a battery with enough capacity to handle this current. For example, if your motors use 5.28 amps, choose a battery that can give at least 6.6 amps.

Make sure your battery can also handle short bursts of high current, like when your motor starts or gets stuck.

Balance your battery cells before you connect them in parallel. This keeps your battery pack safe and working well.

Tip: Always plan for the highest current your project might need. If you use a lithium polymer battery, check the C-rate to make sure it can handle the load.

If you follow these steps, you will get the best battery life and keep your project running safely. Picking the right battery, matching voltage, and planning for current draw will help you avoid problems and enjoy your project longer.

Motor & Battery Match

Power Calculation

It is important to match your motor and battery. This helps your project work well and last longer. Here is how you can check if your battery and motor are a good fit:

First, find out how much energy your battery has. Multiply the amp-hour rating by the battery’s voltage. This gives you watt-hours.

Next, think about how long you want your motor to run. Divide the watt-hours by the average power your motor uses. Use the real power your motor needs, not just the highest number.

Think about what your project will carry or do. If it carries more weight or goes up hills, it will use more power.

Batteries lose some power as they get used. The voltage drops, so your motor might slow down at the end.

Look at how your battery cells are connected. Series connections make the voltage higher. Parallel connections give more current.

Make sure your battery’s voltage is right for your motor. If the voltage is too high or too low, your motor might not work well or could get damaged.

Use real numbers from your project if you can. This helps you know how long your battery will last.

Tip: Always check if your battery and motor work well together before you build. This saves you time and money!

Safe Operation

You want your project to be safe and last a long time. Make sure your motor, battery, and driver all work together. Check that your motor controller can handle the battery’s voltage and current. If your motor gets stuck, it can use a lot more current. This is called stall current. Your battery and controller must handle these short bursts.

Some batteries use passive balancing. This is cheaper but wastes extra energy as heat. Other batteries use active balancing. This moves energy between cells and helps your battery last longer. For the best results, pick a battery with active balancing and a smart battery management system. These systems can even use machine learning to tell when your battery needs care. This keeps your motor running well.

Note: For big projects, active balancing and smart battery management help your battery last longer. For simple projects, passive balancing is okay.

If you follow these steps, your motor and battery will work well together. You will get more power, better fit, and a project that lasts longer.

Common Mistakes

Picking a battery powered motor can be confusing. It is easy to make mistakes that hurt how your project works or how safe it is. Here are some common problems and ways to avoid them.

Over/Under-sizing

Some people choose a motor that is too big or too small. If your motor is too strong, you spend more money and use more energy. You also have to carry extra weight that you do not need. Bigger motors need bigger batteries, which cost more and make your project heavy. If your motor is too weak, your project may not work well or could break down. Small motors wear out fast and drain the battery quickly. Try to find a motor that fits your project just right. This saves energy and money and helps your project work better.

Tip: If your motor is efficient, you can use smaller batteries. This saves weight and money.

Ignoring Battery Limits

You should never forget your battery’s limits. If you use too much voltage or current, you can damage your battery. Charging or draining lithium batteries too much can make them lose power or even catch fire. Some batteries can get short circuits inside, which is very dangerous. Always use a battery management system to keep your battery and motor safe. If you do not follow the rules, your battery will not last long and could be unsafe.

Charging too much can cause fires or explosions.

Draining too much hurts battery cells and makes them die sooner.

Short circuits inside batteries are unsafe.

Always use the right voltage and current for your battery and motor.

Environment Factors

Think about where you will use your project. Batteries and motors do not like very hot or cold places. If it is too hot, lithium batteries can wear out faster. Cold weather makes batteries weak and motors slow. Different lithium batteries handle heat and cold in different ways. Think about the weather and how you will use your project. Good cooling helps your battery and motor last longer.

Temperature changes can make batteries and motors work worse.

How often you use your motor changes how fast batteries wear out.

Always check if your battery and motor can handle your weather.

Callout: Use checklists and product tools to help you pick the right motor and battery. These tools help you match power, speed, and torque, check for weather needs, and make sure everything works together.

If you avoid these mistakes, your project will work better and last longer. You can also save money by using rechargeable batteries instead of alkalines, especially if you use your project a lot.

Selection Checklist

Ready to pick the right battery powered motor for your project? Use this checklist to make sure you cover all the important steps. This way, you can avoid common mistakes and get the best results.

Define your project’s needs. Write down what your project does, how much weight it moves, and how fast you want it to go. Think about where you will use your motor and if you need it to work in hot, cold, or dusty places.

Choose the right motor type. Decide if you need a brushed DC motor or a brushless DC motor. Each type works best for different projects. Brushless motors last longer and need less care, but brushed motors are simple and cost less.

Check voltage and current. Make sure your battery matches the voltage and current your motor needs. If you use the wrong voltage, your motor might not work or could get damaged.

Look at torque and speed. Find out how much torque your motor must give and how fast it should spin. Use the torque-speed curve from the datasheet to help you decide.

Pick the right size and weight. Your motor should fit in your project and not make it too heavy. A small motor saves space and energy, but it still needs to be strong enough.

Select efficient MOSFETs. Good MOSFETs help your motor run smoothly and waste less energy. They also keep your motor cool under different loads.

Use proper gate drivers. Gate drivers help control the MOSFETs and protect your motor from too much voltage or current.

Add protection features. Use thermal, over voltage, over current, and ESD protection to keep your motor and battery safe.

Include extra protection parts. Diodes, eFuses, and SmartFETs can stop damage if something goes wrong with your motor or battery.

Pick the right regulators. Good regulators help manage power and keep your motor running steady.

🛠️ Tip: Double-check every part before you build. A careful checklist helps your motor work better and last longer.

Choosing the right battery powered motor gets easier when you follow a few simple steps:

Pick your project type and check voltage and torque needs.

Select the best transistor and gate driver for your motor.

Match your battery voltage and capacity to your motor’s needs.

Add the right controller and protection parts.

When you match motor specs with battery lifetime, your project runs longer and stays reliable.

Good planning helps you avoid common mistakes and keeps your system safe.

Use the checklist before you build. You can create a project that works great and lasts!

FAQ

What happens if I use a battery with the wrong voltage?

If you use the wrong voltage, your motor might not run or could get damaged. Always check the motor’s voltage rating before you connect a battery.

How do I know if my motor is powerful enough?

Make a list of what your project needs to move or lift. Check the motor’s torque and speed. If you want extra safety, pick a motor that is about 1.5 times stronger than your minimum need.

Can I use any battery type for my motor project?

No, not every battery works for every motor. Some batteries give more power or last longer. Lithium-ion batteries work best for most projects. Always match the battery type to your motor’s needs.

Why does my battery run out faster than expected?

Your battery might run out fast if your motor uses more current than you planned. Heavy loads, high speeds, or cold weather can also drain batteries quickly. Try using a bigger battery or a more efficient motor.

Do I need a special charger for lithium batteries?

Yes! Lithium batteries need special chargers to stay safe and last longer. Using the wrong charger can damage the battery or cause safety problems. Always use a charger made for your battery type. 🔋

See Also

Choosing The Best Vibrating Motor For Your Project Needs

Selecting Battery Operated Electric Motors For Peak Performance

How To Pick The Ideal 3 Volt DC Motor For Projects

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry