How to Select the Most Powerful Vibration Motor for Your Application

Selecting the best vibration motor for your project is crucial, especially when considering the most-powerful-vibration-motors available. You need to match the force and technical details to your specific needs. Using a simple guide to compare your options can help you understand key factors like voltage, power, size, and durability. The table below highlights important points to consider when choosing the most-powerful-vibration-motors for any application. Use these tips as a quick reference when making your selection.

Specification Aspect | Considerations |

|---|---|

Voltage | Match the motor voltage to your power source to prevent damage and ensure optimal performance. |

Power | Balance power consumption with vibration strength to get the best results. |

Size | Ensure the motor fits your device; small motors suit compact devices, while larger ones fit bigger machines. |

Noise | Choose a quiet motor for applications like medical or beauty tools. |

Durability | Consider the environment and maintenance to extend the motor’s lifespan. |

Key Takeaways

First, know what your project needs. Decide the force, frequency, and size you need for the vibration motor. Match the motor’s voltage and size to your device. Make sure it fits and works safely with your power source. Look at different motor types like electric, explosion-proof, ERM, and LRA. Find the one that gives good power, control, and saves energy. Always read datasheets carefully. Test motors in real situations to avoid problems and make sure they work well. Use a checklist to help you choose. Ask manufacturers for help if you need it. Pick a motor that lasts, works well, and follows safety rules.

Define Application Needs

Before picking a vibrating motor, you should know what your project needs. This helps you choose the right motor for your job and get good results. First, think about how much force, frequency, and amplitude your project needs.

Force, Frequency, Amplitude

Force, frequency, and amplitude are important for how vibrating motors work. You need to figure out how strong the vibration should be. Medical devices might need gentle and exact vibration for therapy or health checks. Industrial tools often need stronger vibration for tough jobs.

The frequency and amplitude change how much force the motor gives. If you use higher frequency and amplitude, the motor makes more force.

Different jobs need different vibration settings. For example:

Cars use vibration for safety and comfort.

Phones and game controllers need small motors for feedback.

Big tools need large motors for strong shaking.

Parameter | Effect on Application |

|---|---|

High Frequency & Amplitude | More force, better for heavy-duty tasks |

Low Frequency & Amplitude | Gentle vibration, better for sensitive devices |

Resonance | Can cause too much vibration and damage materials |

Damping & Mass | Help control vibration and prevent failure |

To use vibrating motors well, you must know how these things affect your project. Always check the technical details to make sure the motor is right for you.

Size, Voltage, Environment

Next, think about the size, voltage, and where you will use the motor. The motor should fit your device and work with your power source. If your device is small, pick a small motor. For bigger machines, use a larger motor with more power.

The voltage must match your power supply or the motor could break.

The technical details will show you the right voltage and size.

Where you use the motor can change how long it lasts. Keep the motor in places between 0°C and 40°C. Stay away from wet, dusty, or chemical-filled areas. Use covers and insulation to keep the motor safe.

Doing regular checks and adding oil to bearings helps the motor last longer.

You can find vibrating motors in cars, medical tools, factories, and electronics. Each place has its own needs. Always look at what your project needs and check the technical details before you decide.

Compare Most-Powerful-Vibration-Motors

When you want the most-powerful-vibration-motors, you should use a simple vibration motor comparison guide. Not every motor is good for every job. Some vibrating motors give more force. Others are better at saving energy or giving you more control. This guide helps you see which most-powerful-vibration-motors are best for your needs.

Motor Type | Power Rating | Force Output | Industrial Use & Features |

|---|---|---|---|

Electric Vibration Motors | Up to 3.5 kW | 3,040 N to 52,590 N | Most common and powerful; adjustable eccentric blocks generate high centrifugal force; widely used in conveyors, feeders, screens, and heavy industries. |

Explosion-proof Electric Motors | 500W to 750W | Around 5 kN | Suitable for hazardous environments; IP55 protection; adjustable excitation force; used in explosive industrial settings. |

Brushless DC Vibration Motors | N/A | High vibration force | Advanced control, durability, and efficiency; used in industrial, medical, and consumer electronics applications. |

Electric vibration motors are the strongest and most used. They work well in big machines like conveyors and screens. Explosion-proof motors are safe for dangerous places. Brushless DC motors last longer and let you control vibration better.

ERM Vibrating Motors

ERM vibrating motors shake things by spinning an off-center weight. These motors are used when you need strong shaking. The most-powerful-vibration-motors in this group can move heavy things. ERM motors can work at many speeds, but how much they shake depends on speed. They are cheaper and have a simple build. ERM vibrating motors use more power and take longer to start than other types. If you need a vibration motor comparison guide for tough jobs, ERM motors are often the top choice.

LRA Vibrating Motors

LRA vibration motor technology gives you smooth and exact shaking. These motors use a magnet that moves back and forth. They start fast, use less power, and let you control how much they shake. LRA vibration motor types are best for things like phones and smartwatches. The vibration motor comparison guide shows LRA motors save energy and stop shaking quickly. But they do not shake as hard as ERM vibrating motors. If you want the most-powerful-vibration-motors for small or gentle jobs, LRA vibration motor types are a good choice.

Tip: For the strongest shaking in factories, pick big electric vibration motors or explosion-proof ones. Use LRA vibration motor types for small gadgets that need gentle and exact shaking.

Key Factors to Select the Right Vibrating Motor

When you pick a vibrating motor, you must check some important things. These key points help you find the best motor for your needs. Each one changes how well the motor works and how long it lasts. They also affect how much you get for your money. Let’s talk about each one.

Force Output & Frequency

Force output and frequency show how strong and fast the vibration is. Heavy-duty jobs need high force. Small devices need gentle shaking. Force tells you how hard the motor shakes. Frequency means how many times it shakes each second. High frequency gives smooth vibration. This is good for phones and smartwatches. Low frequency with strong force is best for big machines.

If the force is too low, your device may not work right. Too much force can break parts or wear them out. Always look at the force and frequency in the specs. This helps you get the right feel and makes sure the motor fits your job.

Tip: For the best feel, match force and frequency to your device. Use high frequency for smooth effects in electronics. Use low frequency and more force for big tools.

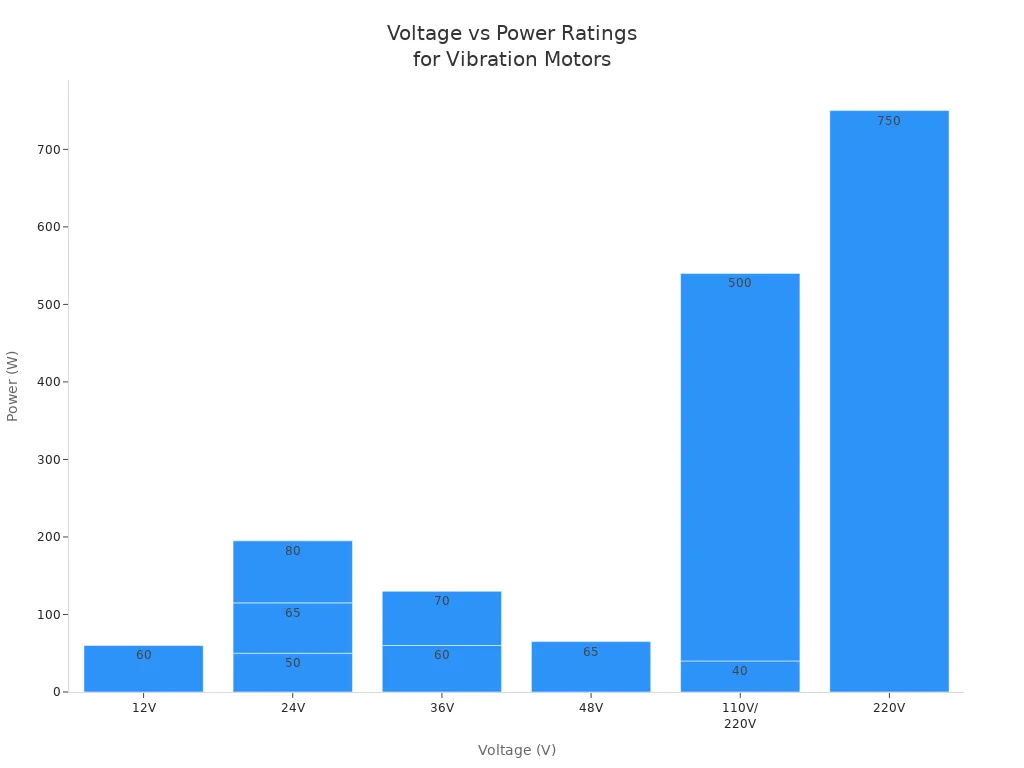

Voltage & Power

Voltage and power ratings show if the motor fits your power supply. Most industrial motors use 110V, 220V, or 240V AC. Some use 12V, 24V, or 48V DC. Power can be small (10W or less) for light jobs or over 750W for big machines. Pick a motor that matches these numbers to your setup.

Voltage (V) | Power (W) | Motor Type/Notes |

|---|---|---|

110, 220 | 40 | Single phase AC vibration motor |

110, 220 | 500 | Explosion proof vibration motor |

12 | 60 | DC brushless vibration motor |

24 | 50, 65, 80 | DC brushless vibration motors with controller |

36 | 60, 70 | DC brushless vibration motors |

48 | 65 | DC brushless vibration motor |

220 | 750 | Explosion proof 3 phase vibration motor |

If you use the wrong voltage, the motor might not start or could break. Always check the specs before you choose a motor. This keeps your system safe and working well.

Size & Mounting

The motor must fit in your device. If it is too big, it will not fit. If it is too small, it may not shake enough. Mounting is important too. You must match the mounting type to your equipment. Good mounting keeps the motor steady and stops extra wear.

Check the space in your device before you pick a motor.

Use the right mounting to stop strain and keep the motor safe.

For tough jobs, use bigger motors with strong mounts.

For small gadgets, use compact motors like an lra vibration motor.

The right size and mounting give you the best feel and keep your device safe.

Durability & Maintenance

Durability and reliability help your motor last longer. Pick a motor that can handle dust, heat, and water. Some motors have covers or cooling systems. Maintenance is important too. You need to check bearings, add oil, and clean the motor often.

Oil moving parts to stop friction and overheating.

Watch the temperature to spot problems early.

Use tools to find loose parts or worn bearings.

Keep electrical parts tight and clean.

Make sure the motor is straight and on a solid base.

Regular care helps your motors last longer and work better. This is very important for high-power motors and for lra vibration motor types in feedback systems.

Efficiency & Noise

Efficient motors use less power and save money. Brushless motors, like an lra vibration motor, use less energy and make less heat. This means lower costs and better work. Efficient motors also give better feedback and fewer mistakes in machines.

Noise matters too. Some motors are loud, which is bad for medical or beauty tools. Quiet motors are better for these jobs. Always check the noise level in the specs before you pick a motor.

Note: Making motors just 2% more efficient can save lots of money each year. Good care and vibration control help keep motors quiet and efficient.

Compliance & Compatibility

You must make sure your motor meets safety and quality rules. For cars, ISO 16750-3 and IEC 60068 test how well the motor handles vibration. For medical tools, look for FDA 510(k), IEC 60601, and ISO 14971. These rules keep people safe and make sure the motor works in your device.

Check if the motor works with your system.

Make sure it passes all needed tests for your field.

Use the right oil to stop leaks and damage.

For lra vibration motor types in feedback, check for EMC and EMI tests.

Meeting these rules helps you avoid problems and keeps your device safe and working well.

Remember: When you pick a vibrating motor, use this checklist. Look at force, frequency, voltage, power, size, mounting, durability, efficiency, noise, compliance, and compatibility. This helps you get the best feel, long life, and the right fit for your needs.

How to Select a Vibration Motor

Picking the right vibration motor is not just about size or power. You need to follow steps to make sure it fits your project. This helps the motor work well in your device. Here’s how you can choose a vibration motor with confidence.

Datasheet Evaluation

First, read the datasheet for each motor you look at. The datasheet tells you how the motor works and what it can do. When you pick a vibration motor, check these main things:

Type of Sensor: Choose the sensor that matches your system, like an accelerometer, velocity sensor, or displacement transducer.

Sensor Features: See if the motor uses piezoelectric or MEMS technology for better accuracy.

Wireless Capabilities: Check if the motor can connect to Industry 4.0 systems for easier data use.

Installation and Calibration: Follow the maker’s steps for mounting and calibration.

Baseline Values: Set normal vibration values and limits to find problems early.

Condition Guidelines: Use the datasheet to help you understand acceleration and velocity data for maintenance.

You should also look at these important details:

Sensitivity: Make sure it matches the vibration level you expect.

Frequency Range: Check if it covers what your project needs.

Amplitude Range: The motor must handle the vibration size without problems.

Temperature Range: The motor should work in your environment without losing accuracy.

Environmental Conditions: Think about humidity, chemicals, and safety certifications.

Power Requirements: Make sure your power supply matches the motor’s needs.

Size and Weight: The motor must fit your device.

Connector and Cable Needs: Check if the cables and connectors work with your setup.

Tip: Always compare datasheet numbers with what you need in real life. A motor might look good on paper, but if it cannot handle your environment or power, it will not work well.

The datasheet shows how the motor will work in your project. For example, high-frequency vibration data helps you spot problems early and keep your equipment running well.

Prototyping & Testing

After you check the datasheet, build a prototype and test the motor in real life. Prototyping lets you see how the motor works in your device. This step helps you avoid surprises and makes sure you pick a vibration motor that will last.

When you test, you should:

Use machines called shakers to copy real vibration.

Hold the device with clamps or special holders.

Control the vibration frequency and amplitude to match your needs.

Record measurements like frequency and amplitude.

Collect data to find problems like resonance or fatigue.

Prototyping also helps you check if the motor can handle heat, humidity, and electrical loads. You can find weak spots early and fix your design before making many devices. Testing rules you set now will help you keep quality high later.

Note: Some people skip testing and have problems later. Always test the motor in your real device to avoid big failures.

You may face some problems during testing:

Noise from the environment can hide important signals.

Using the wrong sensor or settings can give you bad data.

Loose cables can cause data loss.

Small devices need special test setups.

Testing can take time and money, but it saves you from bigger problems later.

Try to use good cables, pick the right sensors, and secure everything well. If you can, use simulation tools to help with testing.

Manufacturer Consultation

If you need a special motor or a high-power one, talk to the manufacturer. Many companies have over 20 years of experience making motors for tough jobs like mining, chemical plants, and construction. When you talk to experts, you get:

Custom solutions for your exact needs.

Many types and sizes of motors.

High-quality motors with good balance for smooth work.

Strong designs that last longer and need less care.

Advanced cooling and energy-saving features.

Flexible options for voltage and mounting.

Motors that work in tough places, like high heat or dust.

High horsepower options for hard jobs.

Callout: Manufacturer support helps you pick a vibration motor that fits your project perfectly. You can ask for special features or get advice on the best motor for your needs.

When you talk to the manufacturer, you should:

Explain your project needs clearly.

Ask about certifications and safety rules.

Check if the motor will work with your control system.

Ask for help with installation and calibration.

If you want to use advanced control systems, make sure the motor supports the right communication protocols, like Profinet or Modbus. Test the motor with your system before using it fully to catch problems early. Integrated motion systems can make setup easier and reduce wiring.

Common Mistakes to Avoid

When you pick a vibration motor, watch out for these mistakes:

Not listing all your project needs before choosing.

Forgetting to check key specs like torque, speed, and voltage.

Skipping motor selection guides and not comparing types.

Not testing the motor in real conditions.

Ignoring safety and compliance rules.

Overlooking cost, availability, and support.

Use a Step-by-Step Checklist

A checklist helps you remember every step in the process. Here’s a simple table you can use:

Checklist Category | Key Checks Included |

|---|---|

General Condition | Look for damage, check mounting, cooling, and lubrication systems |

Electrical Setup | Confirm voltage/current ratings, check power cables/connections, test insulation |

Motor Performance | Watch temperature and speed, listen for odd sounds, check load and current |

Safety Devices | Test overload protection, check fuses/circuit breakers, make sure control circuits work |

This checklist makes sure you do not miss anything important when you pick a vibration motor.

Remember: When you follow these steps—reviewing datasheets, testing prototypes, and talking to manufacturers—you make the best motor choice for your project. This process helps you avoid mistakes and makes sure your motor works safely and well.

You can pick the right vibration motor by using easy steps. Start by thinking about what your project needs. Then, look at different motor types and compare them. Make a checklist to help you remember important things. Test the motor and check if it works well. This way, you can find problems early and stop your device from breaking. It also helps your project cost less and saves time. Using these steps makes your project safer and helps you trust your results. If you are not sure, ask an expert for advice.

Following clear steps helps you fix problems before they happen and keeps your machines working well.

FAQ

What is the difference between ERM and LRA vibration motors?

ERM motors use a spinning weight to create vibration. LRA motors use a moving magnet for smoother, faster vibration. You get stronger force from ERM motors. LRA motors give you more control and use less power.

How do I know what size vibration motor I need?

Check the space in your device. Measure the area where you want to place the motor. Pick a motor that fits and gives enough force for your job. Always read the datasheet for size details.

Can I use any vibration motor outdoors?

You need a motor with weather protection for outdoor use. Look for motors with waterproof or dustproof ratings like IP65 or higher. These motors last longer outside and work better in rain or dust.

Why does my vibration motor get hot?

Motors get hot if you use the wrong voltage or overload them. Poor airflow or blocked vents can also cause heat. Always follow the maker’s instructions and check for dirt or damage.

What maintenance does a vibration motor need?

You should:

Check for loose parts.

Clean dust and dirt.

Oil moving parts if needed.

Inspect wires and connections. Regular care helps your motor last longer and work safely.

See Also

Choosing The Perfect Vibrating Motor For Your Needs

Five Easy Steps To Pick The Best Mini Vibrator

Comprehensive Guide To Vibration Motors: Uses And Types

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry