Discover How 3V DC Motors Create Vibrations

You might wonder how small gadgets like phones vibrate to alert you. A 3V DC motor makes this happen by turning electricity into movement. This movement, with an uneven weight, creates vibrations. These vibrations are important in modern gadgets, giving feedback and improving how we use them.

INEED’s vibration motors are known for being strong and reliable. Made with smart technology, these motors work well in many uses. Whether in healthcare, robots, or electronics, INEED gives you solutions you can trust.

Key Takeaways

3V DC motors change electricity into motion, making vibrations with uneven weights. This helps improve how devices like phones and wearables work.

You can adjust the motor's weights to change vibration strength and speed. This lets you set the motor to work best for different uses.

INEED vibration motors are small, work well, and last long. Their tiny size makes them great for medical tools, gadgets, and factory machines.

These motors use less energy and cost less to run. They are eco-friendly because they save power but still work strongly.

INEED makes motors you can customize for your projects. You can change things like vibration power and wiring to make them work perfectly.

Working Principle of Vibration Motors

How 3V DC Motors Work

A 3V DC motor changes electricity into motion. When powered, electricity moves through coils, making a magnetic field. This field pushes against magnets inside, spinning the rotor. The spinning rotor creates torque, which turns the motor's shaft.

Engineers check motor performance by studying key factors like speed and torque. For example:

Parameter | Unit | Description |

|---|---|---|

Speed | rpm | Shows how torque and speed are connected. |

Force | G | How much vibration force under the fixed Jia. |

Torque | gf-cm | Measures the load on the motor shaft. |

Current | A | Tracks how current changes with torque from no load to full lock. |

Lifetime | H | Show the service lifetime according to the test model. |

How Eccentric Weights Create Vibrations

Vibration motors use uneven weights to make vibrations. These weights are fixed to the motor's shaft and are off-balance. When the motor spins, the uneven weight causes centrifugal force. This force creates the vibrations you feel in gadgets like phones.

Adjustable weights let you change the vibration strength. Matching the weight force to the motor's power ensures smooth running and less noise. This balance is key for strong vibrations without losing performance.

Adjusting Vibration Strength and Speed

You can change vibration strength and speed by controlling the motor's spin. Using an inverter helps manage how fast or slow the motor moves. Two main factors—amplitude (strength) and frequency (speed)—affect how the motor works.

Changing the frequency alters how the motor reacts. Slower changes give smoother vibrations, while faster changes create quicker peaks but less strength. By adjusting these settings, you can make the motor work best for different tasks.

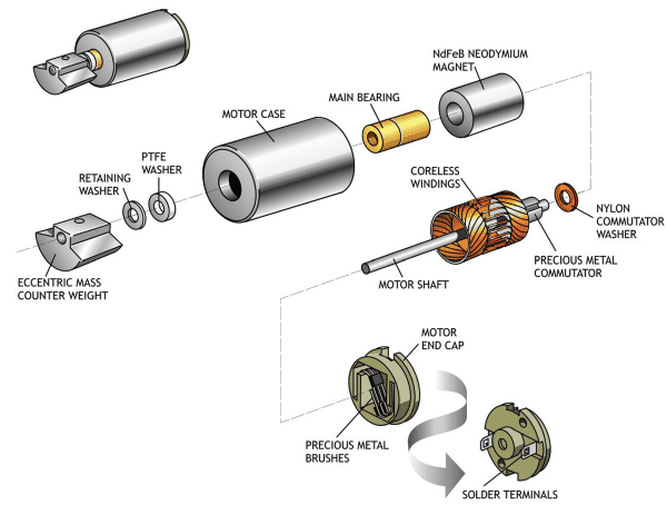

Key Parts of 3V DC Vibration Motors

Rotor and Stator Design

The rotor and stator are key parts of a vibration motor. The rotor spins when electricity powers the motor. The stator stays still and creates the magnetic field that moves the rotor. The materials used for these parts affect how well the motor works. Special magnetic alloys make the motor stronger and waste less energy, improving performance.

Engineers check the design of these parts using several methods:

Accurate data collection reduces mistakes during testing.

Efficiency mapping helps improve motor design and production.

Managing heat keeps the motor working longer and better.

The final design must give high power and torque while staying efficient. Good heat control also helps the motor last longer.

Eccentric Weight Mechanism

The eccentric weight mechanism makes vibration motors special. These weights are uneven and attached to the rotor shaft. When the rotor spins, the uneven weights create force, causing vibrations. This is what gives feedback in devices like phones and smartwatches.

Changing the weights lets you control how strong the vibrations are. Engineers can adjust the angle of the weights to change the vibration pattern. Adding or removing weights changes the force, making the motor useful for different jobs.

Power Supply and Wiring

The power supply and wiring keep the motor running smoothly. A 3V DC motor needs steady electricity to turn energy into motion. Proper wiring connects the motor to its power source for reliable performance.

The wiring design affects how well the motor works and vibrates. Good wires lower energy loss, and capacitors help keep voltage steady. For example, a capacitor in a motor might have 3V and 600F, ensuring it works well.

Wiring can also be customized to fit different needs. Longer wires or special connectors can make the motor more flexible for various uses.

Applications of 3V DC Motors in Vibration Devices

Consumer Electronics and Wearables

Vibration motors are important in gadgets and wearable devices. They create vibrations that improve how users interact with devices. For example, your phone vibrates when you get a message. This happens because of a small vibrating motor inside. Fitness trackers and smartwatches also use these motors for alerts and better usability.

Smaller and smarter devices need compact and efficient motors. A 3V DC motor is perfect because it is small and works well. It creates enough force for vibrations without using much power. This makes it great for devices where saving battery is important.

Companies now add these motors to advanced gadgets to match user needs. Because of this, vibration motors are key to making cool and easy-to-use products.

Medical and Healthcare Devices

In healthcare, vibration motors help improve care and device use. They are found in massagers, health monitors, and diagnostic tools. These motors make vibrations that boost blood flow or give therapy. They can also alert users about health issues.

For instance, a heart monitor might vibrate to warn about heart problems. The motor's precise vibrations ensure accurate alerts, which is vital in healthcare. Their small size lets them fit into tiny medical devices without losing performance.

The dependability of 3V DC motors makes them a top choice for doctors and device makers. They play a big role in improving patient care and health tools.

Industrial and Robotics Applications

In factories, vibration motors help with tasks like sorting and moving items. They create vibrations that make material handling easier. For example, conveyor belts use these motors to move materials smoothly.

Robots also use vibration motors for precise tasks and feedback. These motors help robots handle delicate items or do detailed work. The motor's force allows robots to perform tricky operations.

3V DC motors are tough and work well in hard industrial conditions. They provide steady performance, meeting the needs of these demanding jobs.

Advantages of INEED Vibration Motors for Applications

Small and Lightweight Design

INEED vibration motors are small and light, perfect for tight spaces. Their tiny size fits easily into wearables, medical tools, and machines. For example, one motor is only 8 mm wide and 2 mm thick. Despite its size, it works very well.

Model | motor size (mm) | Vol. | RPM | Current | Starting | Starting Vol. | Operating Vol. | |

Dia | H | V DC | RPM | mA | mA | V DC | V DC | |

C0820BE03L27 | 8.0 | 2.0 | 3.0 | 9000 Min | 80.0 Max | 190.0 Max | 2.3 Max | 2.5-3.3 |

These small motors are still powerful. They run fast and efficiently, giving strong vibrations. Their light weight also makes devices easier to carry and use.

Customizable for Your Needs

Different projects need different features, and INEED understands this. You can adjust these motors to match your needs. Change vibration strength, speed, or wiring to fit your device.

This makes the motors useful for many jobs. They can give gentle feedback in gadgets or strong vibrations in machines. INEED’s focus on customization ensures the motor fits your project perfectly. This improves how it works and makes users happier.

Why Pick INEED for Vibration Motor Solutions

Skilled in Tiny Motor Technology

INEED knows a lot about small motor technology. Their team uses smart methods to make better vibration motors. For example, they found a bearing problem in a motor using vibration data. Timothy A. Morrison, an expert in vibration analysis, helped fix it. After repairs, the motor's vibrations became much weaker. This shows how good INEED is at solving motor issues. Their skills ensure you get motors that work well and last long.

Strong and Trustworthy Products

INEED makes motors that are tough and dependable. They test each motor carefully to meet high standards. The 3V DC motor gives steady vibrations and saves energy. These motors are great for wearables and medical tools needing accurate feedback. You can count on them to improve your devices without breaking easily.

Custom Options for Many Uses

Different industries need different motor features. INEED lets you change motor settings to fit your needs. You can adjust vibration strength, speed, or wiring for your device. Whether for gadgets, health tools, or factory machines, INEED has solutions for you. Their flexible designs make the motors work well in many situations. This makes them a smart choice for all kinds of jobs.

Vibration motors change electricity into movement, making vibrations with uneven weights. Important parts like the rotor, stator, and power supply work together. These motors are efficient, with performance rates between 70% and 90%. This makes them dependable for many uses.

3V DC motors are used in many areas. They power gadgets like wearables, medical devices, and factory machines. Their accuracy and flexibility make them important in today's technology.

INEED provides top-quality vibration motors you can customize. Their focus on new ideas ensures you get motors you can trust.

FAQ

1. Why are 3V DC motors good for vibration devices?

A 3V DC motor is small, efficient, and dependable. It changes electricity into motion, making vibrations with an uneven weight. Its tiny size and low energy use make it great for wearables, medical tools, and machines.

2. Can vibration motors be changed for special uses?

Yes, vibration motors can be adjusted to fit your needs. You can change the strength, speed, wiring, or connectors. This makes sure the motor works well in your device, like a smartwatch, medical tool, or machine.

3. How do uneven weights make vibrations?

Uneven weights are off-center pieces on the motor’s shaft. When the motor spins, these weights create a pulling force. This force makes vibrations, like the ones you feel in phones or fitness trackers.

4. Are INEED vibration motors good at saving energy?

Yes, INEED vibration motors save a lot of energy. They turn electricity into vibrations with very little waste. This helps lower power use, saving money and being better for the planet.

5. Why pick INEED for vibration motor solutions?

INEED makes top-quality motors with over 10 years of experience. Their motors are strong, save energy, and can be customized for many uses. You can trust INEED to improve how your device works.

See Also

Understanding 3V Motors: Key Applications And Specifications Guide

Vibration Motors: Key Applications Across Various Modern Industries

LRA Vibration Motors: Crucial For Today's Haptic Feedback Technology

Brushed Versus Brushless: A Comparison Of 3 Volt Motors

Top Vibration Measuring Instruments: A Comprehensive Selection Guide

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry